- DL manuals

- Riso

- Printer

- GR 3770

- Technical Manual

Riso GR 3770 Technical Manual - 1. Preface

MACHINE SUMMARY

PREFACE

GR3770

1 - 1

1. PREFACE

This manual provides Technical Service Information for the RISOGRAPH GR 3770 duplicator. You are advised to

use this together with “RA Series” “GR Series” Technical Manual as this “GR 3770” Technical Manual includes

only the items different from the other GR Series machines.

This manual is published as a reference guide for use by RISO Group (RISO Kagaku Corp./RISO, INC./RISO

EUROPE Ltd.) Certified Technical Representatives experienced in duplicator repair and service.

This manual also provides procedures for removing and installing major components. Following these proce-

dures will minimize machine malfunctions. This information and format will also increase technical representa-

tives’ awareness and experience regarding repairs necessary to insure end-user satisfacion.

If assistance is required, please contact one of the following:

[ RISO Kagaku Corp. ]

Overseas Technical Section, Overseas Technical Dept.

2-5-1, Akanehama, Narashino-shi, Chiba 275, JAPAN

TEL: (0474) 52-4111 FAX: (0474) 52-3106 TELEX: 252-2298RISO J

[ RISO EUROPE LTD. ]

1230 High Road, Whetstone, London N20 0LH, United Kingdom

TEL: (81) 446-1188 FAX: (81) 446-9547

[ RISO, INC. ]

NOTE : Before attempting to correct machine malfunctions, study the Technical Manual and make sure all

questions and/or concerns have been satisfied. If necessary, please use the Technical Hotline:

TECHNICAL HOTLINE

800-578-7476

(Emergency Technical Assistance Only!!!)

REFERENCE

ADDRESSES

FOR

A

RISO, INC.

Tech. Support Center

310 Andover Street

Danvers, MA 01923

B

RISO, INC. REPAIR DEPT.

310 Andover Street

Danvers, MA 01923

Technical Support Operations Corre-

spondence and Technical Training

Repairs and Warranty Claims

Summary of GR 3770

Page 1

Gr3770 technical manual version 1.0 august, 1997 copyright : 1997 riso kagaku corporation all rights reserved. This technical manual was prepared and written for the exclusive use of riso international group certi- fied dealers. Reproduction and/or transmittal of this material in any form or by any ...

Page 2: Contents

Gr3770 - 1 - contents 1. Machine summary 1. Preface ....................................................................................................................................................... 1-1 caution .......................................................................................

Page 3

Gr3770 - 2 - [ removal ] 1. Clamp unit .................................................................................................................................................. 5-6 2. Disassembling of clamp unit ..................................................................................

Page 4: 1. Machine Summary

Gr3770 1. Machine summary contents 1. Preface .............................................................................................................................. 1-1 caution ......................................................................................................................

Page 5: 1. Preface

Machine summary preface gr3770 1 - 1 1. Preface this manual provides technical service information for the risograph gr 3770 duplicator. You are advised to use this together with “ra series” “gr series” technical manual as this “gr 3770” technical manual includes only the items different from the ot...

Page 6: Caution

Machine summary caution gr3770 1 - 2 caution [ handling of lithium battery ] • never fail to follow the following instructions when you discard the used lithium battery. 1. Never let the battery short-circuited. If the (+) and ( − ) terminals contact each other or metal materials, the battery will b...

Page 7: !! Warning !!

Machine summary warning gr3770 1 - 3 !! Warning !! Important safety precautions 1. Always disconnect electrical supply before placing hands in the machine. 1. To avoid injuries: be sure to disconnect the electrical power before disassembling, assembling, or when making adjustments on the machine. 2....

Page 8

Machine summary notice gr3770 1 - 4 please be sure to follow the procedures as below in installation : notice 1 remove the parts in 5 places as shown in the figures below. 2 activate the test mode. 3 enter no.133 to release the electrical lock. Caution do not turn the power on with scanner unit secu...

Page 9

Machine summary features gr3770 1 - 5 2. Features of the risograph gr3770 this chapter mainly describes technical features. As for advantages concerning business operation, see the documents issued by sales dept. The gr3770 is a new type of the gr3750 for which 600dpi has been realized. Special feat...

Page 10: 3. Specifications

Machine summary specifications gr3770 1 - 6 3. Specifications gr3770 • processing • time to first copy • print speed • scanning resolution • original type • original size • paper size • original weight • paper weight • image area • paper capacity • optional adf capacity • machine weight • dimensions...

Page 11: 4. Product Compatibility

Machine summary product compatibility gr3770 1 - 7 4. Product compatibility accessory compatibility chart applicable model gr3770 gr3750 gr2750 gr2710 gr1750 gr1700 product gr3770 black drum gr color drum a3 gr drum b4/a4 gr3770 black a4 wide drum gr color drum a4 wide adf unit iii (s) adf unit iii ...

Page 12

Machine summary product compatibility gr3770 1 - 8 consumables compatibility chart applicable model gr3770 gr3750 gr2750, 2710, 1750, 1700 product risograph gr master 77w risograph gr master 76w risograph gr master 75 risograph gr ink hd (black) risograph gr ink (black) risograph gr ink (red) risogr...

Page 13: 2. Drum Section

Gr3770 2. Drum section contents [ theory of operation ] 1. Drum insertion error preventive system ..................................................................... 2-1 2. Ink bottle detecting system ......................................................................................... 2-2 3. ...

Page 14: 1. Theory of Operation

Drum section theory of operation gr3770 2 - 1 1. Theory of operation 1. Drum insertion error preventive system the drum cover (lower) differs in shape so that the gr3770 dedicated drum is not inserted into the gr3750 machine by mistake. On the other hand, gr3750 drum can be inserted into the gr3770,...

Page 15

Drum section theory of operation gr3770 2 - 2 2. Ink bottle detecting system ink bottle sws 1/2/3 as well as ink bottle sw-hd detects if an ink bottle appropriate for the drum has been set in position. * if ink bottle sw has not been pushed, “install ink cartridge” message is displayed. * if ink bot...

Page 16

Drum section theory of operation gr3770 2 - 3 3. Ink supply system as the main shaft catch rotates, the squeegee roller and the ink driving shaft are turned. There is a slight gap between the squeegee roller and the doctor roller, through which ink, applied on the squeegee roller, is supplied inside...

Page 17: 2. Removal

Drum section removal gr3770 2 - 4 2. Removal 1. Ink bottle set sw assy..

Page 18

Gr3770 3. Flat bed image scanning section contents [ theory of operation ] 1. Scanner table setting system .................................................................................... 3-1 2. Stop position of image scanner .........................................................................

Page 19: 1. Theory of Operation

Flat bed image scanning section theory of operation gr3770 3 - 1 1. Theory of operation 1. Scanner table setting system flat bed set sw detects if the scanner table has been set in position. When the scanner table is left open, the interlock switch neither for the thermal print head nor for the main...

Page 20

Flat bed image scanning section theory of operation gr3770 3 - 2 2. Stop position of image scanner positions for the image scanner to stop include the following four: • home position (image scanner home position sensor position) • original detecting position • adf shading position (adf shading senso...

Page 21

Flat bed image scanning section theory of operation gr3770 3 - 3 3. Image scanner position detecting system on supply of power or on closing of the stage cover, if the image scanner is not in the home position sensor position, image scanner position detection is performed. Image scanner home positio...

Page 22

Flat bed image scanning section theory of operation gr3770 3 - 4 timing chart of image scanner position detection (1) when the image scanner is held close to the adf read-in position: (2) when the image scanner is in the image scanner adf shading sensor position: (3) when the image scanner is held b...

Page 23

Flat bed image scanning section theory of operation gr3770 3 - 5 when the image scanner adf shading sensor or the image scanner home position sensor is not turned on within 3 seconds after the flat bed read pulse motor gets on, step (3) takes place. “wait a moment” message is displayed until the ima...

Page 24

Flat bed image scanning section theory of operation gr3770 3 - 6 4. Flat bed original set confirming system the flat bed original detection sensor serves to confirm that an original has been set on the stage glass. Stage cover image scanner home position sensor stage cover sensor flat bed original d...

Page 25

Flat bed image scanning section theory of operation gr3770 3 - 7 5. Flat bed auto scanning contrast adjustment system this is made effective only when original scanning density is set to “auto”. Further, the “auto scanning contrast adjustment function” does not operated in photo, line/photo mixed (d...

Page 26

Flat bed image scanning section theory of operation gr3770 3 - 8 6. Flat bed image scanning system the original reading area, in general, depends on size of sheet set on the paper feed tray. When bound original mode is on, realtime trimming is performed. Flat bed read pulse motor image scanner home ...

Page 27

Flat bed image scanning section theory of operation gr3770 3 - 9 sectional view of image scanner.

Page 28: 2. Removal

Flat bed image scanning section removal gr3770 3 - 10 2. Removal 1. Stage glass removal 1) turn off the power and remove the adf unit. 2) remove mounting screws ( × 2) of the glass holder (r), remove the holder. 3) shifting the stage glass rightward, lift it up for removal. Caution on mounting • shi...

Page 29

Flat bed image scanning section removal gr3770 3 - 11 2. Image scanner unit removal 1) turn off the power and remove the stage glass. 2) remove mounting screws ( × 8) of the image scanner cover, remove the cover. 3) remove mounting screws ( × 2) of the image scanner wire stand, raise the stand. 4) p...

Page 30

Flat bed image scanning section removal gr3770 3 - 12 3. Flat bed original detection sensor and image flexible wire 1) turn off the power and remove the stage glass. Flat bed original detection sensor 2) remove mounting screw of the flat bed original detection sensor, cut off the wire band and disco...

Page 31

Flat bed image scanning section removal gr3770 3 - 13 4. Flat bed read pulse motor unit removal 1) turn off the powr and remove the following parts: • adf unit • stage cover, scanner cover (rear) 2) remove the tension spring. 4) remove the support screw (step flat screw) and mounting screws ( × 2) o...

Page 32

Flat bed image scanning section removal gr3770 3 - 14 5. Original stopper and shading glass the original stopper is correctly positioned and fitted prior to shipment. Therefore, pay enough attention when you remove it. Removal 1) turn off the power and remove the following parts: • stage cover, scan...

Page 33

Flat bed image scanning section removal gr3770 3 - 15 mounting 1) confirming that both the shading glass and the shading plate are free of contamination, temporarily fasten the glass and the original stopper with fixing screws ( × 2). 2) loosen, beforehand, fixing screws ( × 2) of the glass holder (...

Page 34: 4. Master Making Section

Gr3770 4. Master making section contents [ removal ] 1. Thermal print head ..................................................................................................... 4-1 [ adjustment ] 1. Thermal power of thermal print head ....................................................................

Page 35: 1. Removal

Master making section removal gr3770 4 - 1 1. Removal 1. Thermal print head removal 1) turn on the power and open the scanner table. Then turn off the power. (the thermal print head is raised automatically.) 2) remove mounting screws ( × 2) of the master making unit cover, remove the cover. 3) remov...

Page 36

Master making section removal gr3770 4 - 2 6) remove mounting screws ( × 2) of the thermal print head, disconnect connectors (x 2) and remove the unit. - precautions in removal - • be careful not to damage the heating elements of the thermal print head. • be careful not to touch the metal pins of th...

Page 37: 2. Adjustment

Master making section adjustment gr3770 4 - 3 2. Adjustment 1. Thermal power of thermal print head procedure 1) turn off the power, and remove the front right cover. 2) connect a voltmeter between pins tp1(+) and tp2(gnd) on the power supply pcb. 3) turning on test mode no.77 (tph/ctl signal), confi...

Page 38

Master making section adjustment gr3770 4 - 4 tph voltage setting table resistance value ( Ω ) voltage (v) 1700 ∼ 1713 11.4 1714 ∼ 1743 11.5 1744 ∼ 1774 11.6 1775 ∼ 1804 11.7 1805 ∼ 1835 11.8 1836 ∼ 1866 11.9 1867 ∼ 1897 12.0 1898 ∼ 1929 12.1 1930 ∼ 1961 12.2 1962 ∼ 1993 12.3 1994 ∼ 2026 12.4 2027 ∼...

Page 39

Gr3770 5. Master clamp & loading section contents [ theory of operation ] 1. Clamp unit home positioning system ........................................................................ 5-1 2. Clamp plate master release system ......................................................................... ...

Page 40: 1. Theory of Operation

Master making section theory of operation gr3770 5 - 1 1. Theory of operation 1. Clamp unit home positioning system when the clamp unit is held lowered in power on or all reset state (when the clamp safety sw has not been pushed), perform the following clamp unit home position returning to raise the...

Page 41

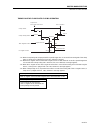

Master clamp & loading section theory of operation gr3770 5 - 2 2. Clamp plate master release system drive gear clamp safety sw clamp motor clamp cam led drm1 lit up when 180 ° angular sensor detects magnet. Key on clamp motor is turned off. Clamp motor gets on in "open" direction and clamp plate st...

Page 42

Master making section theory of operation gr3770 5 - 3 timing chart of clamp plate opening operation when a detection sensor is not on, start operation after a detection of the drum is performed. When clamp safety sw is kept pushed for a period longer than 1.5 seconds from turning on of the clamp mo...

Page 43

Master clamp & loading section theory of operation gr3770 5 - 4 3. Clamp plate master system drive gear clamp safety sw clamp cam clamp motor led drm0 lit up when 0 ° angular sensor detects magnet. Clamp motor on in "close" direction and clamp plate starts to close. Clamp motor is turned off. Clamp ...

Page 44

Master making section theory of operation gr3770 5 - 5 timing chart of clamp plate closing operation when clamp safety sw is kept pushed for a period longer than 1.5 seconds from turning on of the clamp motor, a clamp error is judged and “t14 call service” appears. When the 0 ° angular sensor and th...

Page 45: 2. Removal

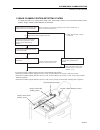

Master clamp & loading section removal gr3770 5 - 6 2. Removal 1. Clamp unit removal 1) turn off the power and remove the back cover. 2) disconnect connectors of the clamp motor and clamp safety sw. 3) remove mounting screws ( × 4) of the clamp unit, remove the unit. - precaution in assembly - • be ...

Page 46

Master clamp & loading section removal gr3770 5 - 7 2. Disassembling of clamp unit disassembly 1) remove the clamp spring. 2) detaching the c-ring ( × 1) fixing the clamp slide shaft, remove the motor unit. 3) remove mounting screws ( × 2) of compensator plate, remove the compensator plate, the meta...

Page 47

Master clamp & loading section removal gr3770 5 - 8 3. Angle sensor assy. Removal 1) pull out the drum, turn off the power and remove the back cover. 2) before taking off the angular sensor, put a mark in the sensor fitting position so that place for fitting is clearly known. 3) disconnect the angul...

Page 48: Appendix (I)

Gr3770 appendix (i) contents 1. Test mode 1. Operation procedures ......................................................................................... Apx(i)-1 2. Testing sensor and switch .................................................................................. Apx(i)-3 3. Testing mot...

Page 49: 1. Test Mode

Appendix (i) test mode gr3770 apx(i)-1 1. Test mode 1. Operation procedures (1) starting up test mode turn on the power, pressing down both and buttons on the main panel. ← ver.No. Of the system rom ← ver.No. Of the panel rom (2) how to operate input a test mode no. By using panel-keys. (for example...

Page 50

Appendix (i) test mode gr3770 apx(i)-2 (4) how to operate test mode no’s 81 to 89, 121, and 122 (memory sw’s) starting test mode, input a test mode no. And press key. (for example, when scanning start position adjustment has been selected) to change the memory switch setting, press the or > key of t...

Page 51

Appendix (i) test mode gr3770 apx(i)-3 2. Testing sensor and switch the current states of sensors and switches are indicated with buzzer sound: detection : 0.1 second interval beep no detection : 0.5 second interval beep no. Test component detection status remarks 1 paper detection sensor reflected ...

Page 52

Appendix (i) test mode gr3770 apx(i)-4 no. Test component detection status remarks 41 paper feed cassette sensor 1 magnetism is detected. 42 paper feed cassette sensor 2 magnetism is detected. 43 paper feed cassette sensor 3 magnetism is detected. 44 paper feed cassette sensor 4 magnetism is detecte...

Page 53

Appendix (i) test mode gr3770 apx(i)-5 4. Memory switch various kinds of setting concerning master making, etc. Are stored in memory switches. Use adjust> key to change setting. No. Details of memory sw 81 image scanner adf home position adjustment (this applies only to 300/400dpi type.) adjusts the...

Page 54

Appendix (i) test mode gr3770 apx(i)-6 no. Details of memory sw 85 master marking lenght (write pulse motor operation time) adjustment (except 600dpi type) adjusts the master making length by controlling the operation time of the write pulse motor. Memory sw 9 a b c d e f o change volume mm − 3.5 − ...

Page 55

Appendix (i) test mode gr3770 apx(i)-7 no. Details of memory sw 121 setting of original scanning density default (fb type) (initial setting of original scanning density on starting.) memory sw 0 1 2 3 default auto manual 3 manual 4 power off state 122 setting of sheet no. Return on switching of mast...

Page 56

Appendix (i) test mode gr3770 apx(i)-8 6. Sequential operation test no. Details of test mode 101 ink supply operation until the ink sensor gets on, the main motor and the ink motor are held on. Ink sensor on ⇒ confidential op. ⇒ press application × 30 times ⇒ stopped on a detection position. (for fb...

Page 57

Appendix (i) test mode gr3770 apx(i)-9 no. Details of test mode 111 thermal pressure motor operation when tph home position sw is on: down ⇒ tph pressure sw on ⇒ stop when tph pressure sw is on: up ⇒ tph home position sw on ⇒ stop 112 cutter motor one-cut operation 113 fb type adf original feed oper...

Page 58

Appendix (i) test mode gr3770 apx(i)-10 no. Details of test mode 137 clamp plate closing operation (this applies only to 600dpi type.) clamp plate is closed when the 180 ° angular sensor is on. 139 sorter initial communication mode (this applies only to 600dpi type.) following connecting to the sort...

Page 59: 2. Advice Displays

Appendix (i) advice displays gr3770 apx(i)-11 2. Advice displays 1. Trouble messages (t display) display details how to cancel t1 call service ⇓ to resume opera- tion press start key (while in master making.) t2 call service t3 call service ⇓ to resume opera- tion press start key. T3 call service ⇓ ...

Page 60

Appendix (i) advice displays gr3770 apx(i)-12 display details how to cancel t5 call service t6 call service t7 turn main power sw. Off then on t8 turn main power sw. Off then on t9 turn main power sw. Off then on t10 turn main power sw. Off then on t11 call service t12 t13 call service t14 call serv...

Page 61

Appendix (i) advice displays gr3770 apx(i)-13 display details how to cancel t14 call service t15 call service t15 call service t16 call service t17 call service replace battery clamp error (2) 600dpi type • in 2 seconds from turning on of the clamp motor in clamp unit home position return operation,...

Page 62

Appendix (i) advice displays gr3770 apx(i)-14 display details how to cancel t18 turn main power sw. Off then on t19 call service t20 call service t50 call service t68 call service t78 call service power off -> on press key. Press key. Electromagnetic counter set- ting signal l (connect an elec- trom...

Page 63

Appendix (i) advice displays gr3770 apx(i)-15 2. Trouble messages (others) display details how to cancel check paper feed area paper misfeed check paper feed area and press all reset key paper jam check paper feed area paper jam on drum (print cylinder) remove paper paper jam under drum pull out dru...

Page 64

Appendix (i) advice displays gr3770 apx(i)-16 display details how to cancel original jam reset original /3 original jam remove original. /2 master mis-feed remove master roll then re- install clamp error remove master roll then re- install ⇓ to return operation press start key master cut error remov...

Page 65

Appendix (i) advice displays gr3770 apx(i)-17 display details how to cancel disposal error remove drum (print cylinder) and discard master ⇓ to return operation press start key remove jammed master in disposal unit empty disposal box close sheet feeder cover and press all reset key paper jam in sort...

Page 66

Appendix (i) advice displays gr3770 apx(i)-18 3. Setting confirmation messages display details how to cancel close front cover add paper set drum in place install print cylinder wrong-size drum (print cylinder) installed wrong-type drum (print cylinder) installed install ink cartridge wrong-type ink...

Page 67

Appendix (i) advice displays gr3770 apx(i)-19 display details how to cancel insert card in key/card counter 4. Change-of-consumables messages display details how to cancel replace ink cartridge replace master roll insert card into key/card counter displayed to prevent the machine operation: • if an ...

Page 68

Gr3770 appendix (ii) description of pcb’s contents 1. Block chart .......................................................................................................... Apx(ii)-1 2. Location of pcbs ....................................................................................................

Page 69: 1. Block Chart

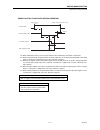

Description of pcbs drum control pcb3 gr3770 apx(ii)-1 1. Block chart system pcb2 image processing pcb (ipif) fbi pcb adf pcb power supply p c b tph sub pcb image scanner tph option pcb aiii drum control pcb3 motor control pcb mk2 lcd control pcb lcd panel unit main sw pcb sub sw pcb cn5 cn3 cn2 cn7...

Page 70: 2. Location of Pcbs

Description of pcbs block chart gr3770 apx(ii)-2 2. Location of pcbs sub sw pcb lcd panel unit lcd control pcb main sw pcb power supply pcb tph sub pcb adf pcb image processing pcb (ipif) system pcb2 motor control pcb mk2 drum pcb drum control pcb3 fbi pcb.

Page 71: 3. System Pcb2

Description of pcbs system pcb2 gr3770 apx(ii)-3 3. System pcb2 cn15 1 2 cn2 to lcd control pcb cn2 29 30 to drum control pcb2 cn1/cn2 1 cn5 to components cn7 10 to power supply pcb cn5/cn2 cn6 b2 b1 a2 a1 b30 b29 a30 a29 cn14 to option pcb cn1 22 21 to components 2 1 cn9 2 1 49 50 to components to ...

Page 72

Description of pcbs system pcb2 gr3770 apx(ii)-4 led sensor name when led is on drm0 drm1 pfd2 pdtc ten prss ink flow drma drmc p-up hmas csen mend mdtc mjam ptls wait psen rcv1 rcv2 p-in prp tume 0 angular sensor 180 angular sensor paper feed clutch sensor paper detection sensor vertical centering ...

Page 73

Description of pcbs system pcb2 gr3770 apx(ii)-5 d00 gnd1 d01 gnd1 d02 gnd1 d03 gnd1 d04 gnd1 d05 gnd1 d06 gnd1 d07 gnd1 a00 gnd1 a01 gnd1 a02 gnd1 pnl-cs/ gnd1 iord/ gnd1 iowr/gnd1 reset/ gnd1 ireq/ gnd1 pnl-en/ gnd1 wait gnd1 busy gnd1 n.C. N.C. Cn2 rd gy gy gy bl gy gy gy gy bl gy gy gy gy bl gy ...

Page 74

Description of pcbs system pcb2 gr3770 apx(ii)-6 gnd1 low when pressed gnd1 low when pressed load p/m (a pulse) load p/m (com. A pulse) load p/m (b pulse) load p/m (rev. A pulse) load p/m (com. B pulse) load p/m (rev. B pulse) +5v low when blocked gnd1 low in operation +24v gnd1 low when pressed +24...

Page 75

Description of pcbs system pcb2 gr3770 apx(ii)-7 gnd1 high in master det. +5v gnd1 low when pressed low in operation +24v n.C. Low in operation +24v low in operation +24v gnd1 +5v gnd1 low when blocked +5v gnd1 low in master det. +5v gnd1 high when pressed low in operation +24v low in operation +24v...

Page 76

Description of pcbs system pcb2 gr3770 apx(ii)-8 cn9 br rd or y w gr bl vt gy wh bk br rd or y w gr bl vt gy wh bk br rd or y w gr bl vt gy wh bk br rd or y w gr bl vt gy wh bk rd rd 50pins 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40...

Page 77

Description of pcbs system pcb2 gr3770 apx(ii)-9 gnd1 gnd1 ink sensor (high with ink) overflow sensor (high with ink) +12v +24v inking motor (low in operation) gnd1 n.C. Gnd1 det. A sensor (low when blocked) det. C sensor (low when blocked) +5v gnd1 drum size data signal 1 sw1 drum size data signal ...

Page 78

Description of pcbs image processing pcb (ipif) gr3770 apx(ii)-10 4. Image processing pcb (ipif) 6 3 b2 b1 a2 a1 1 c n 4 to fbi pcb cn5 to power supply pcb cn5 c n 2 1 2 3 9 4 0 to system pcb2 to tph 1 2 2 7 2 8 c n 6 sw1 led3 led2 led1 ic30 sw sw1(gam) : for gamma compensation adjustment light (0) ...

Page 79

Description of pcbs image processing pcb (ipif) gr3770 apx(ii)-11 adgnd advcc n.C. Paper size sensor temp.Det.Sensor n.C. Gnd1 gnd1 gnd1 gnd1 d00 d01 d02 d03 d04 d05 d06 d07 gazo-cs1 gazo-cs2 ioer/ iord/ a00 a01 a02 a03 a04 a05 ck/ lst/ yukou/ kukan n.C. I/f-rddata i/f-wrdata gnd1 gnd1 gnd1 gnd1 res...

Page 80

Description of pcbs image processing pcb (ipif) gr3770 apx(ii)-12 +24v +24v +12v lst gnd clk dgtless /yukou r/w-start /sk-sig /nega /white /black /photo /chara /dgtop /dgtdata /aux01 n.C. /start /s-cancel /auxi n.C. Gnd gnd gnd cn3 26pins 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 2...

Page 81: 5. Motor Control Pcb Mk2

Description of pcbs motor control pcb mk2 gr3770 apx(ii)-13 5. Motor control pcb mk2 to main motor cn2 15 1 to system pcb2 cn1 9 1 u1 led led1 : the actuator of elevator upper limit sensor is raised to open the light path. Cn3 10 1 cn6 1 8 cn4 2 cn5 1 8 1 relay open led1 to components to power suppl...

Page 82

Description of pcbs image processing pcb (ipif) apx(ii)-14 gr3770 +24va n.C. +24vb +24vb gnd2 gnd3 gnd3 +5v gnd1 cn1 1 2 3 4 5 6 7 8 9 9pins cn2 15pins 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 22 14 gy gy gy gy gy gy gy gy gy gy gy gy gy gy gy power supply pcb cn5 cn2 3 6 12 5 11 10 or rd rd rd rd rd rd ...

Page 83: 6. Drum Control Pcb3

Description of pcbs motor control pcb mk2 apx(ii)-15 gr3770 6. Drum control pcb3 to bottle set switch cn3 7 1 cn1 1 2 19 20 sw sw1 : drum data cn2 11 12 cn6 6 1 cn4 1 1 2 3 inking motor to drum pcb to system pcb cn15 cn7 1 2 3 4 5 6 sw1 data sw setting drum general data drum size data (ledger/a3) in...

Page 84

Description of pcbs drum control pcb3 apx(ii)-16 gr3770 gnd1 gnd1 ink sensor (high with ink) overflow sensor (high with ink) +12v inking motor (low when activated) +24v gnd1 n.C. Gnd1 det. A sensor (low when blocked) det. C sensor (low when blocked) +5v gnd1 drum size data signal 1 sw1 drum size dat...

Page 85: 7. Adf Pcb

Description of pcbs adf pcb apx(ii)-17 gr3770 7. Adf pcb to adf read pulse motor 1 6 vr vr1 : for sensitivity adjustment of original in sensor (receive) cn6 1 2 2 1 cn4 2 1 shading solenoid cn1 cn2 cn3 cn5 cn7 cn8 cn9 cn10 cn11 2 1 2 1 1 2 20 19 1 3 1 3 1 3 1 3 d6 in vr1 tp2 tp1 gnd in to original f...

Page 86

Description of pcbs adf pcb apx(ii)-18 gr3770 a pulse com. A pulse rev. B pulse rev. A pulse com. B pulse b pulse cn1 6pins 1 2 3 4 5 6 m adf read pulse motor bl bk y w rd br wh cn2 2pins 1 2 +24v low when activated s original stripper solenoid bl rd cn3 2pins 1 2 +24v low during activation m origin...

Page 87: 8. Fbi Pcb

Description of pcbs fbi pcb apx(ii)-19 gr3770 8. Fbi pcb 4 1 1 2 1 cn13 1 6 20 19 12 1 1 2 to adf pcb cn6 to components cn16 cn17 6 3 cn18 cn15 cn11 40 39 to image processing pcb cn5 open cn12 to fbi read pulse motor to image scanner to image processing pcb cn1.

Page 88

Description of pcbs fbi pcb apx(ii)-20 gr3770 gnd1 original out sensor sig. Trig original in sensor sig. Gnd1 original registration sensor sig. Lst/ original in place sig. (adf) gnd1 adf cover closed sig. Dclk adf unit connect sig. Gnd1 adf motor rst sig. Sd7 adf motor enb sig. Gnd1 adf motor clock ...

Page 89

Description of pcbs fbi pcb apx(ii)-21 gr3770 gnd2 sabas gnd2 pikm gnd1 rpmck gnd1 pmenb pmrst pmfrc adf enl safsg +5v gensen +5v sabasen +24v ginsen +24v goutsn cn13 20pins 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 br rd or y w gr bl vt gy wh bk br rd or y w gr bl vt gy wh bk adf pcb cn6 1...

Page 90: 9. Option Pcb Aiii

Description of pcbs option pcb aiii apx(ii)-22 gr3770 9. Option pcb aiii gnd1 gnd1 gnd1 gnd1 gnd1 gnd1 +5v +5v +5v +5v gnd2 gnd2 gnd2 +24v +24v +24v txd1 rxd1 rts1/ cts1/ txd2 rxd2 rts2/ cts2/ txd3 rxd3 rts3/ cts3/ i/f pcb set sig. Paper sensor sig. Paper rcv.Sen.2 sig. Master count sig. Copy count ...

Page 91

Description of pcbs option pcb aiii apx(ii)-23 gr3770 wr-data rd-data vsync lst yukou ck r-busy start-sig +5v cts txd rts rxd rpwr wr-data ret rd-data ret vsync ret lst ret yukou ret ck ret r-busy ret start-sig ret cts ret txd ret rts ret rxd ret prwr ret exe-i/f-umu gnd1 cn2 40pins 1 2 3 4 5 6 7 8 ...

Page 92: 10.Lcd Control Pcb

Description of pcbs lcd control pcb apx(ii)-24 gr3770 10.Lcd control pcb ic1 to system pcb2 cn2 cn8 3 36 vr1 tp1 tp2 gnd to sub sw pcb cn11 to lcd panel unit ic2 1 cn7 1 cn1 cn2 7 1 bz1 cn6 cn9 1 13 to power supply pcb cn5 to lcd panel unit to main sw pcb cn10

Page 93

Description of pcbs lcd control pcb apx(ii)-25 gr3770 d00 gnd1 d01 gnd1 d02 gnd1 d03 gnd1 d04 gnd1 d05 gnd1 d06 gnd1 d07 gnd1 a00 gnd1 a01 gnd1 a02 gnd1 pnl-cs/ gnd1 iord/ gnd1 iowr/ gnd1 reset/ gnd1 ireq/ gnd1 pnl-en/ gnd1 wait gnd1 busy gnd1 n.C. N.C. Cn2 40pins a1 a2 a3 a4 a5 a6 a7 a8 a9 a10 a11 ...

Page 94: 11.Power Supply Pcb 100-120V

Description of pcbs power supply pcb 100-120v apx(ii)-26 gr3770 11.Power supply pcb 100-120v f2 f7 f5 f3 f4 f6 24 23 cn5 1 2 cn2 12 6 7 1 cn4 cn6 cn3-2 cn3-1 1 2 19 20 1 3 3 1 1 2 vr101 tph vr100 f1 7 1 cn1 fuse f1 : 10a 125v f2 : 8a 125v f3 : 3.15a 125v f4 : 3.15a 125v f5 : 3.15a 125v f6 : 3.15a 12...

Page 95

Description of pcbs power supply pcb 100-120v apx(ii)-27 gr3770 cn1 7pins 1 2 3 4 5 6 7 bk wh sw bk wh primary power w-h connector gr/yw ac ac cn2 12pins 1 2 3 4 5 6 7 8 9 10 11 12 +24va (f3) +24vc (f5) +24ve (f7) gnd3 gndm +24vm (f2) +24vb (f4) +24vd (f6) gndd gnde gndm +24vm (f2) or y w or br bk r...

Page 96: 12.Power Supply Pcb 200-240V

Description of pcbs power supply pcb 200-240v apx(ii)-28 gr3770 12.Power supply pcb 200-240v f2 24 23 cn5 1 2 cn2 12 6 7 1 cn7 cn3-2 cn3-1 1 2 19 20 1 3 f1 7 1 cn1 fuse f1 : 5a 250v f2 : 6.3a 250v f3 : 3.15a 250v f4 : 3.15a 250v f5 : 3.15a 250v f6 : 3.15a 250v f7 : 3.15a 250v f40 : 3.15a 125v f80 : ...

Page 97

Description of pcbs power supply pcb 200-240v apx(ii)-29 gr3770 cn1 7pins 1 2 3 4 5 6 7 bk wh sw bk wh primary power w-h connector gr/yw ac ac cn2 12pins 1 2 3 4 5 6 7 8 9 10 11 12 +24va (f3) +24vc (f5) +24ve (f7) gnd3 gndm +24vm (f2) +24vb (f4) +24vd (f6) gndd gnde gndm +24vm (f2) or y w or br bk r...

Page 98

Description of pcbs power supply pcb apx(ii)-30 gr3770 fuse replacement caution : for continued protection against risk of fire, replace only with same type and ratings of fuse(s). Power supply model 100-120v type 200-240v type f1 f2 f3 f4 f5 f6 f7 f40 f80 f90 10a 125v 8a 125v 3.15a 125v 3.15a 125v ...

Page 99: 13.Tph Sub Pcb

Description of pcbs tph sub pcb apx(ii)-31 gr3770 13.Tph sub pcb to tph to power supply pcb cn2 cn1 cn1 20pins 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 gnd2 -remote gnd2 gnd2 gnd2 gnd2 gnd2 gnd2 gnd2 gnd2 +14v +14v +14v +14v +14v +14v +14v +14v +14v +remote br bl bl bl bl bl bl bl bl rd rd...