- DL manuals

- Riso

- Printer

- RN SERIES

- Technical Manual

Riso RN SERIES Technical Manual - Adjustment

6 – 10

RN (Version 1.0)

CHAPTER 6. PRESS SECTION

MOUNTING POSITION OF THE PRESSURE LEVER ASS’Y

Adjustment

1.

Mounting Position of the Pressure Lever Ass’y

Checking and adjustment procedure

(1)

Make a confidential master, and then bring the print drum to position A.

(2)

Remove the rear cover.

(3)

Remove the screws and pull forward the filter PCB unit.

(4)

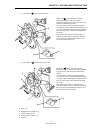

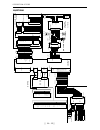

Remove the Second pressure spring, push up the Pressure lever B [A], and disengage it from the

Solenoid lever [D].

(5)

Attach the Second pressure spring and check that the gap between Pressure lever A [B] and

Pressure lever B [A] is between 1.5 mm and 2.0 mm. (See detailed figure 2.)

(6)

If the gap in step (5) is outside the specifications, remove the Second pressure spring and

loosen the two set screws on Pressure lever B [A]. Insert a 3 mm Allen wrench [C] between

Pressure lever A [B] and Pressure lever B [A] (see detailed figure 1), rotate the Pressure shaft [E]

fully counter-clockwise, and then tighten the set screws on Pressure lever B [A] with the pressure

roller pressing hard against the print drum. The Pressure lever B [A] should be pushed all the

way back against the machine, when tightening the set screws.

(7)

Check as in step (5), and if the gap is still outside the specifications, repeat step (6). If the gap is

within the specifications, push Pressure lever B [A] upwards, lock with the Solenoid lever [D], and

attach the Second pressure spring.

Symptoms

• If the gap is too small, the pressure will be too weak, and the printing density may become too light.

• If the gap is too large, there will not be sufficient space between the Pressure roller and the Clamp

plate base on the print drum, and they may touch, damaging the Clamp plate base.

A

B

C

D

E

Summary of RN SERIES

Page 1

Riso international group riso kagaku corporation (japan) riso deutschland gmbh (germany) riso, inc. (u.S.A.) riso france (france) riso europe limited (u.K.) riso iberica (spain) riso hong kong (hong kong) riso canada (canada) riso uk (u.K.) riso zhuhai (hong kong) riso thailand limited (thailand) ri...

Page 2

Inde inde inde inde index xx xx chapter 1 maintenance chapter 2 machine summary chapter 3 machine drive section chapter 4 first paper feed section chapter 5 second paper feed section chapter 6 press section chapter 7 paper ejection system chapter 8 print drum section chapter 9 master clamp section c...

Page 3: Chapter

1 – 1 rn (version 1.0) chapter 1 : maintenance contents 1. Preface ...................................................................................................................... 1-2 caution .........................................................................................................

Page 4

1 – 2 rn (version 1.0) chapter 1. Maintenance 1. Preface this manual provides technical service information for the risograph model rn series. This manual is published as a reference guide for use by riso group (riso kagaku corp./ riso,inc./riso europe ltd.) certified technical representatives exper...

Page 5: Caution

1 – 3 rn (version 1.0) chapter 1. Maintenance [handling of lithium battery] - never fail to follow the following instructions when you discard the used lithium battery. 1. Never let the battery short-circuited. If the (+) and (-) terminals contact each other or metal materials, the battery will be s...

Page 6: !! Warning !!

1 – 4 rn (version 1.0) chapter 1. Maintenance !! Warning !! Important safety precautions 1. Always disconnect electrical supply before placing hands in the machine. I. To avoid injuries: be sure to disconnect the electrical power before disassembling, assembling,or when making adjustments on the mac...

Page 7

1 – 5 rn (version 1.0) chapter 1. Maintenance work precautions 2. Work precautions inspection if you discover any defects or problems during an inspection, fix the problems or if necessary take steps such as replacing a part. Removal check the problem area. At the same time, examine the cause of the...

Page 8

1 – 6 rn (version 1.0) chapter 1. Maintenance electrical system work • after removing wire bundles, fasten them with wire bundle bands (bar lock ties) so that they will not sag. • when installing parts, be careful to avoid pinching or damaging the wire bundles. • if a fuse blows, always replace it w...

Page 9

1 – 7 rn (version 1.0) chapter 1. Maintenance installation location • do not install the machine in any of the following locations. (1) those subject to direct sunlight or any bright location such as by a window (if you must install in such a location, put a curtain or the like over the window.) (2)...

Page 10

1 – 8 rn (version 1.0) chapter 1. Maintenance 3. Exterior cover removal 1. Bring the print cylinder to position-a and remove the print cylinder from the machine. 2. Turn off the power and remove the power cord from the machine. Front cover remove mounting screws (m4x8: 2 pcs) from the hinge, and rem...

Page 11

1 – 9 rn (version 1.0) chapter 1. Maintenance exterior cover removal rear cover remove mounting screws (m3x5: 2pcs) of the connector lock of the controller and open the connector locks flat against the controller. Remove screws (m4x8: 4 pcs) and remove the rear cover. Rear cover connector lock maste...

Page 12

1 – 10 rn (version 1.0) chapter 1. Maintenance exterior cover removal stage cover remove mounting screw (m4x10: 1 pc) from each of the two hinges of the stage cover, and then as shown on the photograph, attach those screws in the secrew holes behind. Remove screw (m4x8: 1 pc) on the scanner unit cov...

Page 13

1 – 11 rn (version 1.0) chapter 1. Maintenance scanner unit cover (left) remove mounting screw (m4x8: 4 pcs) and remove the scanner unit cover (left). Scanner unit cover (left) scanner unit cover (rear) remove the stage cover. Remove mounting screw (m4x8: 4 pcs) and remove the scanner unit cover (re...

Page 14

1 – 12 rn (version 1.0) chapter 1. Maintenance scanner unit cover (front) remove mounting screw (m4x8: 3 pcs) and remove the scanner unit cover (front). Exterior cover removal scanner unit cover (front) scanner unit cover (right) remove scanner unit cover (front) and scanner unit cover (rear). Remov...

Page 15

1 – 13 rn (version 1.0) chapter 1. Maintenance exterior cover removal 4. Controller (risorinc2) and system pcb controller (risorinc2) remove the rear cover. Disconnect three connectors from the controller (1 on the top and 2 on the bottom of the controller). Remove screws (m3x6: 2 pcs), and pull the...

Page 16

1 – 14 rn (version 1.0) chapter 1. Maintenance exterior cover removal system pcb remove the rear cover. Remove screws (m3x5: 1 pc), and remove the wire harness support plate. Disconnect all the connectors from the system pcb, remove screws (m3x5: 6 pcs), and then remove the system pcb together with ...

Page 17

1 – 15 rn (version 1.0) chapter 1. Maintenance system pcb support bracket a unplug the connector of the fb junction wire harness from the junction connector, and then detach the junction connector from the system pcb support bracket a. Remove seven snap bands from the system pcb support bracket a. R...

Page 18

1 – 16 rn (version 1.0) chapter 1. Maintenance [memo].

Page 19: Chapter

2 – 1 rn (version 1.0) chapter 2 : machine summary contents 1. Specifications (metric model) .................................................................................... 1-2 2. Specifications (inch model) ...................................................................................... ...

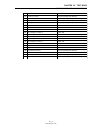

Page 20: Reference Only

2 – 2 rn (version 1.0) chapter 2. Machine summary 1. Specifications (metric model) specifications (metric model) reference only.

Page 21: Reference Only

2 – 3 rn (version 1.0) chapter 2. Machine summary specifications (metric model) reference only.

Page 22: Reference Only

2 – 4 rn (version 1.0) chapter 2. Machine summary specifications (metric model) reference only.

Page 23: Reference Only

2 – 5 rn (version 1.0) chapter 2. Machine summary specifications (metric model) reference only.

Page 24: Reference Only

2 – 6 rn (version 1.0) chapter 2. Machine summary specifications (inch model) 2. Specifications (inch model) reference only not available to u.S.A. (u.S.A. Has rn2000 designed only for letter size).

Page 25: Reference Only

2 – 7 rn (version 1.0) chapter 2. Machine summary specifications (inch model) reference only.

Page 26: Chapter

3 – 1 rn (version 1.0) chapter 3 : main drive section contents mechanism ............................................................................................................................ 3-2 1. Main drive section ...............................................................................

Page 27: Mechanism

3 – 2 rn (version 1.0) chapter 3. Main drive section – main drive section mechanism 1. Main drive section when the main motor [a] is turned on, the main pulley [b] rotates and the rotation is transmitted to the print drum pulley [d] via the main belt [c]. The main motor encoder sensor [e] detects th...

Page 28

3 – 3 rn (version 1.0) chapter 3. Main drive section main motor safety mechanism 2. Main motor safety mechanism two safety switches (flat bed set switch [a] and print drum safety switch [b]) prevent the motor from being turned on if parts are not positioned. A: flat bed set switch b: print drum safe...

Page 29

3 – 4 rn (version 1.0) chapter 3. Main drive section print drum position check mechanism 3. Print drum position check mechanism the print drum’s rotation position is detected by the main motor encoder sensor referenced to the position a detected by the position a sensor [a] on the machine and positi...

Page 30

3 – 5 rn (version 1.0) chapter 3. Main drive section [memo].

Page 31: Removal and Assembly

3 – 6 rn (version 1.0) chapter 3. Main drive section removing the main motor unit removal and assembly 1. Removing the main motor unit (1) position the print drum at position a, turn off the power, and then remove the following covers and components. • front door • front cover • rear cover • control...

Page 32

3 – 7 rn (version 1.0) chapter 3. Main drive section [precautions on reassembly] • tension the main belt by aligning the position-a alignment hole [j] on the print drum with the main- pulley position-a alignment hole [k] and then turning the idler c ass’y [e] counter-clockwise to apply tension on th...

Page 33

3 – 8 rn (version 1.0) chapter 3. Main drive section 2. Removing the flat bed set switch (1) pull out the print drum and remove the covers. • front door • front cover (2) unplug the connector [c], remove the mounting screws (m4 x 6: 2 pcs), and then remove the entire flat bed set switch cover [a]. (...

Page 34

3 – 9 rn (version 1.0) chapter 3. Main drive section removing the print drum safety switch 3. Removing the print drum safety switch (1) pull out the print drum. (2) remove the covers. • front door • front cover (3) remove the print drum safety switch cover [b]. (m4 x 6: 2 pcs) (4) unplug the connect...

Page 35: Adjustment

3 – 10 rn (version 1.0) chapter 3. Main drive section adjustment 1. Print drum position-a adjustment checking and adjustment procedure (1) pull out the print drum and return it back after removing the master attached to it. (2) open the scanner table. (3) start the test mode, and run test mode no. 5...

Page 36: Chapter

4 – 1 rn (version 1.0) chapter 4 : first paper feed section contents mechanism ............................................................................................................................ 4-2 1. Paper feed tray mechanism ..................................................................

Page 37: Mechanism

4 – 2 rn (version 1.0) chapter 4. First paper feed section paper feed tray mechanism a: paper feed tray b: adjustment dial c: paper size detection sensor d: paper width potentiometer mechanism 1. Paper feed tray mechanism 1) horizontal positioning (horizontal print positioning) of the paper feed tra...

Page 38

4 – 3 rn (version 1.0) chapter 4. First paper feed section paper feed tray elevation mechanism 2. Paper feed tray elevation mechanism the presence of paper loaded in the paper feed tray [a] is detected by the paper detection sensor [b]. When light is received at the paper detection sensor [b] (paper...

Page 39

4 – 4 rn (version 1.0) chapter 4. First paper feed section paper feed tray safety mechanism 3. Paper feed tray safety mechanism the paper feed tray lower safety switch [c] ensures safety while the paper feed tray is being raised or lowered or is stationary. If the safety switch actuator plate [b] is...

Page 40

4 – 5 rn (version 1.0) chapter 4. First paper feed section first paper feed drive mechanism 4. First paper feed drive mechanism when the printing operation commences, the main motor [a] activates to rotate the print drum via the main belt [c]. When the main motor [a] is running, the paper feed timin...

Page 41

4 – 6 rn (version 1.0) chapter 4. First paper feed section paper strip mechanism 5. Paper strip mechanism the paper loaded in the paper feed tray is fed in between the pickup roller [a] and stripper pad [b] by the rotating scraper roller. The paper is then separated by the pickup roller [a] and stri...

Page 42

4 – 7 rn (version 1.0) chapter 4. First paper feed section paper feed pressure adjust lever 6. Paper feed pressure adjust lever the paper feed pressure adjust lever [a] is located on the left-hand side of the scraper unit, and moving this to the left or right switches the scraper-roller paper-feed p...

Page 43

4 – 8 rn (version 1.0) chapter 4. First paper feed section [memo].

Page 44: Removal and Assembly

4 – 9 rn (version 1.0) chapter 4. First paper feed section removing the paper feed tray unit removal and assembly 1. Removing the paper feed tray unit (1) lower the paper feed tray [f] fully. (2) remove the rear cover. (3) unplug the connector [a] on the wire harness [b] from the paper feed tray [f]...

Page 45

4 – 10 rn (version 1.0) chapter 4. First paper feed section 2. Removing the paper width potentiometer, paper detection sensor, and paper size detection sensor (1) remove the paper feed tray unit. (2) remove the e-ring and remove the adjustment dial [a]. (3) remove the e-rings [c] and bearings from b...

Page 46

4 – 11 rn (version 1.0) chapter 4. First paper feed section removing the paper width potentiometer, paper detection sensor, and paper size detection sensor [precautions on reassembly] • with the fence opened fully, mount the spur gear [l] and the flat face of the potentiometer shaft [m] facing the p...

Page 47

4 – 12 rn (version 1.0) chapter 4. First paper feed section 3. Removing the pickup and scraper rollers removing the scraper roller (1) lower the paper feed tray fully and switch off the power. (2) remove the lock ring [e] on the scraper roller shaft [c]. (3) slide the scraper roller [d] off the scra...

Page 48

4 – 13 rn (version 1.0) chapter 4. First paper feed section removing the feed tray descent button and upper limit sensor 4. Removing the feed tray descent button and upper limit sensor (1) remove the master-removal lower cover. (mounting screws m4 x 8: 4 pcs) (2) unplug connector [a], remove the mou...

Page 49

4 – 14 rn (version 1.0) chapter 4. First paper feed section removing the paper feed clutch 5. Removing the paper feed clutch (1) remove the rear cover. (2) loosen the retaining screw [c] on the paper timing belt tension bracket [b], and reduce the tension on the paper feed timing belt [e]. (3) unplu...

Page 50

4 – 15 rn (version 1.0) chapter 4. First paper feed section removing the pickup roller shaft ass’y 6. Removing the pickup roller shaft ass’y (1) remove the covers. • rear cover • master-removal lower cover (2) remove the pickup and scraper rollers. (3) remove the upper limit sensor. (4) remove the p...

Page 51

4 – 16 rn (version 1.0) chapter 4. First paper feed section removing the elevator motor 7. Removing the elevator motor (1) lower the paper feed tray fully, switch off the power, and pull out the print drum. (2) remove the covers. • front door • front cover • master-removal lower cover (3) squeeze th...

Page 52

4 – 17 rn (version 1.0) chapter 4. First paper feed section removing the paper feed tray lower safety switch 8. Removing the paper feed tray lower safety switch (1) remove the screws (shoulder screw, m4 x 30: 2 pcs), securing the printer to the risograph stand. (2) remove the rear cover. (3) slide o...

Page 53

4 – 18 rn (version 1.0) chapter 4. First paper feed section 9. Removing the stripper unit (1) lower the paper feed tray fully. (2) place a finger on the top of the stripper unit [a] and pull it forward to remove it. [precautions on reassembly] • set the stripper pad ass’y [b] in the paper guide plat...

Page 54

4 – 19 rn (version 1.0) chapter 4. First paper feed section removing the stripper pad ass’y 10. Removing the stripper pad ass’y (1) lower the paper feed tray fully, and remove the stripper unit. (2) lift up the stripper pad ass’y [a] by hand and remove it. [precautions on reassembly] • attach the st...

Page 55: Adjustment

4 – 20 rn (version 1.0) chapter 4. First paper feed section upper limit sensor position adjustment adjustment 1. Upper limit sensor position adjustment procedure (1) remove the paper on the paper feed tray. (2) start test mode no. 453 (elevator servo) and raise the paper feed tray and bringing it to...

Page 56

4 – 21 rn (version 1.0) chapter 4. First paper feed section stripper unit adjustment 2. Stripper unit adjustment procedure (1) slide the paper feed pressure adjust lever to suit the paper type before printing. (2) if multiple feeding or non-feeding occurs, adjust the stripper-pad angle and pressure....

Page 57

4 – 22 rn (version 1.0) chapter 4. First paper feed section 3. Paper-feed clutch “on” timing adjustment check and adjustment procedure (1) test print to check that paper is fed smoothly. (2) if the first stage paper feed timing is not synchronized, adjust using test mode no. 481 (paper- feed-clutch ...

Page 58: Chapter

5 – 1 rn (version 1.0) chapter 5 : second paper feed section contents mechanism ............................................................................................................................ 5-2 1. Second paper feed mechanism ...............................................................

Page 59: Mechanism

5 – 2 rn (version 1.0) chapter 5. Second paper feed section – second paper feed mechanism mechanism 1. Second paper feed mechanism when the main motor operates during printing, the main cam [a] rotates clockwise. The main cam [a] rotation moves the timing gear [c] via the cam follower arm [b], and t...

Page 60

5 – 3 rn (version 1.0) chapter 5. Second paper feed section second paper feed mechanism drum position-a at drum position-a, the protrusion on the timing cam [b] pushes against the timing lever [c] to raise the guide roller [d]. First paper feed start when the first paper feed starts and the paper is...

Page 61

5 – 4 rn (version 1.0) chapter 5. Second paper feed section vertical print positioning mechanism 2. Vertical print positioning mechanism pressing the or print position keys on the panel activates the print positioning pulse motor [a], which rotates the print positioning adjuster cam [b] to move the ...

Page 62

5 – 5 rn (version 1.0) chapter 5. Second paper feed section vertical print positioning mechanism a: main cam b: print-positioning plate ass’y c: print-positioning cam d: print-positioning lever ass’y e: bearing when the key is pressed, the print- positioning adjuster cam [c] and print- positioning a...

Page 63: Removal and Assembly

5 – 6 rn (version 1.0) chapter 5. Second paper feed section removing the guide roller ass’y removal and assembly 1. Removing the guide roller ass’y (1) pull out the print drum and remove the following covers. • front door • front cover • rear cover (2) unplug the three connectors and remove the cont...

Page 64

5 – 7 rn (version 1.0) chapter 5. Second paper feed section removing the paper guide plate ass’y 2. Removing the paper guide plate ass’y (1) pull out the print drum and remove the following covers. • front door • front cover • rear cover • master-removal lower cover (2) remove the following componen...

Page 65

5 – 8 rn (version 1.0) chapter 5. Second paper feed section removing the paper guide plate ass’y (6) unplug the connector from the paper guide plate [a], remove the mounting screws (m4 x 8: 7 pcs), and then remove the paper guide plate [a]. [precautions on reassembly] • hook the paper guide plate [a...

Page 66

5 – 9 rn (version 1.0) chapter 5. Second paper feed section removing the paper sensor 3. Removing the paper sensor (1) pull out the print drum and remove the following covers. • front door • front cover • rear cover • master-removal lower cover (2) remove the following components. • paper feed tray ...

Page 67

5 – 10 rn (version 1.0) chapter 5. Second paper feed section removing the timing roller 4. Removing the timing roller (1) remove the following covers. • front door • front cover • rear cover • master-removal lower cover (2) remove the following components. • paper feed tray unit • stripper unit • pa...

Page 68

5 – 11 rn (version 1.0) chapter 5. Second paper feed section a: timing roller b: timing cam c: collar d: load spring e: bearing bush removing the timing roller a d c e load spring mounting direction.

Page 69

5 – 12 rn (version 1.0) chapter 5. Second paper feed section 5. Removing the print-positioning unit (1) remove the rear cover. (2) remove the controller. (3) remove the timing gear spring [a]. (4) unplug the connectors on the vertical centering sensor [b] and print-positioning pulse motor [c]. (5) r...

Page 70

5 – 13 rn (version 1.0) chapter 5. Second paper feed section removing the vertical centering sensor 6. Removing the vertical centering sensor (1) remove the rear cover. (2) unplug the connector, remove the mounting screw (3 x 6: 1 pc), and then remove the vertical centering sensor [b] together with ...

Page 71

5 – 14 rn (version 1.0) chapter 5. Second paper feed section 7. Removing the print-positioning pulse motor (1) remove the rear cover. (2) remove the following components. • controller • timing gear spring • print-positioning unit [a] (3) remove the e-ring and remove the print-positioning cam [b]. (4...

Page 72

5 – 15 rn (version 1.0) chapter 5. Second paper feed section removing the timing gear 8. Removing the timing gear (1) remove the rear cover. (2) remove the following components. • controller • guide roller spring • timing cam [a] • timing gear spring [b] • print-positioning unit [c] (3) remove the e...

Page 73: Adjustment

5 – 16 rn (version 1.0) chapter 5. Second paper feed section adjustment 1. Timing cam mounting position procedure (1) move the print drum to position a, centralize the printing position, switch off the power, and then remove the rear cover. (2) with the positioning marks aligned on the main cam and ...

Page 74: Chapter

6 – 1 rn (version 1.0) chapter 6 : press section contents mechanism ............................................................................................................................ 6-2 1. Press mechanism .......................................................................................

Page 75: Mechanism

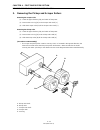

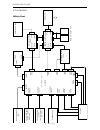

6 – 2 rn (version 1.0) chapter 6. Press section press mechanism mechanism 1. Press mechanism the main motor activates when printing begins, and the pressure solenoid [f] activates once the print drum rotates through 40°. As the clamp plate base on the print drum approaches the pressure roller, the p...

Page 76

6 – 3 rn (version 1.0) chapter 6. Press section press mechanism a: pressure cam b: pressure lever a c: pressure lever b d: pressure spring e: second pressure spring f: pressure solenoid g: solenoid lever h: pressure shaft pressure roller is raised a b c g pressure roller is lowered a b c h.

Page 77

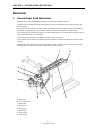

6 – 4 rn (version 1.0) chapter 6. Press section pressure control mechanism 2. Pressure control mechanism pressing the or print density keys on the panel activates the pressure control motor [a] and moves the print pressure gear ass’y [d]. The movement of the print pressure gear ass’y [d] varies the ...

Page 78: Removal and Assembly

6 – 5 rn (version 1.0) chapter 6. Press section removing the pressure roller removal and assembly 1. Removing the pressure roller (1) pull out the print drum. (2) insert a screwdriver through the opening in the front frame of the machine, and remove the retaining screw [b]. (3) slide the pressure ro...

Page 79

6 – 6 rn (version 1.0) chapter 6. Press section removing the pressure solenoid 2. Removing the pressure solenoid (1) remove the rear cover. (2) remove the mounting screws (m4x8: 3 pcs), and pull the filter pcb unit [a] forward. (3) remove the second pressure spring [b] and pressure spring [c]. (4) u...

Page 80

6 – 7 rn (version 1.0) chapter 6. Press section removing the pressure lever ass’y 3. Removing the pressure lever ass’y (1) make a confidential master, and then bring the print drum to position a. (2) open the scanner table, and remove the rear cover. (3) remove the screws and pull forward the filter...

Page 81

6 – 8 rn (version 1.0) chapter 6. Press section removing the pressure control motor and print pressure control sensor 4. Removing the pressure control motor and print pressure con- trol sensor removing the pressure control motor (1) remove the rear cover. (2) remove the e-ring and the drive transfer...

Page 82

6 – 9 rn (version 1.0) chapter 6. Press section [memo].

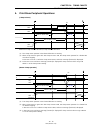

Page 83: Adjustment

6 – 10 rn (version 1.0) chapter 6. Press section mounting position of the pressure lever ass’y adjustment 1. Mounting position of the pressure lever ass’y checking and adjustment procedure (1) make a confidential master, and then bring the print drum to position a. (2) remove the rear cover. (3) rem...

Page 84

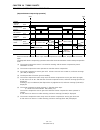

6 – 11 rn (version 1.0) chapter 6. Press section mounting position of the pressure lever ass’y a: pressure lever b b: pressure lever a c: allen wrench (3 mm) d: solenoid lever e: pressure shaft a b c detailed figure 1 a b 1. 5 –2.0 mm detailed figure 2.

Page 85

6 – 12 rn (version 1.0) chapter 6. Press section [memo].

Page 86: Chapter

7 – 1 rn (version 1.0) chapter 7 : paper ejection system contents mechanism ............................................................................................................................ 7-2 1. Paper ejection mechanism ......................................................................

Page 87: Mechanism

7 – 2 rn (version 1.0) chapter 7. Paper ejection system – paper ejection mechanism mechanism 1. Paper ejection mechanism printed paper is first detached from the print drum by the separator [b] and two separation fans [f]. It is then sent to the paper receiving tray by the transfer belts [e]. The tr...

Page 88

7 – 3 rn (version 1.0) chapter 7. Paper ejection system paper separator mechanism 2. Paper separator mechanism the separator [a] is close to the print drum when the paper is being detached from the print drum. As the print drum rotates and the clamp plate base approaches the separator [a], the separ...

Page 89

7 – 4 rn (version 1.0) chapter 7. Paper ejection system paper ejection wing mechanism 3. Paper ejection wing mechanism the left- and right-hand ejection wings on the suction unit can be set manually to the raised [b] or lowered [c] positions to suit the paper ejection requirements. Normally, the eje...

Page 90

7 – 5 rn (version 1.0) chapter 7. Paper ejection system removing the paper receiving tray removal and assembly 1. Removing the paper receiving tray (1) fold down the fences of the paper receiving tray [a], and close the paper receiving tray [a] to an angle of about 45°. (2) lifting the paper receivi...

Page 91

7 – 6 rn (version 1.0) chapter 7. Paper ejection system removing the de-electricity plate and suction unit 2. Removing the de-electricity plate and suction unit removing the de-electricity plate (1) switch off the power, remove the rear cover, and remove the following components. • paper receiving t...

Page 92

7 – 7 rn (version 1.0) chapter 7. Paper ejection system removing the de-electricity plate and suction unit [precautions on reassembly] • mount the suction unit by hooking the left- and right-hand side front edges [g] onto the brackets [h] on the machine side frames. G: suction unit front edge h: bra...

Page 93

7 – 8 rn (version 1.0) chapter 7. Paper ejection system removing the suction fan 3. Removing the suction fan (1) switch off the power, remove the rear cover, and remove the following components. • paper receiving tray • de-electricity plate • suction unit (2) turn the suction unit [a] upside down, a...

Page 94

7 – 9 rn (version 1.0) chapter 7. Paper ejection system removing the paper ejection wing 4. Removing the paper ejection wing (1) switch off the power, remove the rear cover, and remove the following components. • paper receiving tray • de-electricity plate • suction unit (2) lift up the belt driven ...

Page 95

7 – 10 rn (version 1.0) chapter 7. Paper ejection system removing the timing roller (5) remove the mounting screws (m3 x 8: 2 pcs) [f] from both the left- and right-hand ejection wings [e], and remove the ejection wings. E: ejection wings (left, right) f: mounting screws (m3 x 8: 2 pcs each) [precau...

Page 96

7 – 11 rn (version 1.0) chapter 7. Paper ejection system removing the paper ejection motor and encoder sensor 5. Removing the paper ejection motor and encoder sensor removing the paper ejection motor (1) switch off the power, remove the rear cover, and remove the following components. • paper receiv...

Page 97

7 – 12 rn (version 1.0) chapter 7. Paper ejection system removing the transfer belts 6. Removing the transfer belts (1) switch off the power, remove the rear cover, and remove the following components. • paper receiving tray • de-electricity plate • suction unit • ejection wings (2) remove the paper...

Page 98

7 – 13 rn (version 1.0) chapter 7. Paper ejection system removing the separation fan unit 7. Removing the separation fan unit (1) switch off the power and remove the rear cover. (2) unplug the separation fan unit connector [a]. (3) remove the mounting screws (m4 x 8: 2 pcs) [b] on the separation fan...

Page 99

7 – 14 rn (version 1.0) chapter 7. Paper ejection system removing the separator fan and paper receiving sensor 8. Removing the separator fan and paper receiving sensor removing the separator fan (1) switch off the power, remove the rear cover, and remove the following component. • separation fan uni...

Page 100

7 – 15 rn (version 1.0) chapter 7. Paper ejection system removing the separator 9. Removing the separator (1) pull out the print drum, switch off the power, and remove the front cover. (2) remove the separator mounting screw (m3 x 8: 1 pc) [a]. (3) remove the release arm mounting screw (m3 x 8: 1 pc...

Page 101: Adjustment

7 – 16 rn (version 1.0) chapter 7. Paper ejection system separator mounting position adjustment 1. Separator mounting position (1) using test chart no.15, create a master and make prints. Check that the paper does not jam on the drum and that there is no black line through the center of the paper ca...

Page 102: Chapter

8 – 1 rn (version 1.0) chapter 8 : print drum section contents mechanism ............................................................................................................................ 8-2 1. Master on drum (in printing) check mechanism .....................................................

Page 103: Mechanism

8 – 2 rn (version 1.0) chapter 8. Print drum section master on drum (in printing) check mechanism mechanism 1. Master on drum (in printing) check mechanism this mechanism checks whether there is a master on the print drum when printing begins. The print drum begins to rotate when the start key is pr...

Page 104

8 – 3 rn (version 1.0) chapter 8. Print drum section print drum set mechanism 2. Print drum set mechanism the print drum set sensor [a] checks whether the print drum is correctly set in the machine. A light beam from the print drum set sensor [a] is transmitted when the levers are gripped, and block...

Page 105

8 – 4 rn (version 1.0) chapter 8. Print drum section ink cartridge set switch pcb 3. Ink cartridge set switch pcb different ink cartridge set switch pcbs are used for the black ink and color ink print drums. The black ink cartridge set switch pcb [a] has five sensors, while the color ink cartridge s...

Page 106

8 – 5 rn (version 1.0) chapter 8. Print drum section squeegee roller rotation mechanism 4. Squeegee roller rotation mechanism the main motor drives the joint gear [a] via the junction gear ass’y [b], and this rotates the print drum main gear [c]. The rotation also drives the squeegee roller gear (r)...

Page 107

8 – 6 rn (version 1.0) chapter 8. Print drum section inking mechanism 5. Inking mechanism when the main motor is operating and the print drum is rotating, if the ink bead moves away from the ink sensor [d], the inking motor activates to pump in the ink from the ink cartridge. The ink pumped is fed v...

Page 108

8 – 7 rn (version 1.0) chapter 8. Print drum section removing the print drum front cover, ink cartridge guide ass’y, drum front upper cover removal and assembly 1. Removing the print drum front cover, ink cartridge guide ass’y, drum front upper cover a: print drum front cover b: ink cartridge guide ...

Page 109

8 – 8 rn (version 1.0) chapter 8. Print drum section removing the print drum front cover, ink cartridge guide ass’y, drum front upper cover removing the drum front upper cover (4) remove the ink cartridge guide ass’y. (5) remove the mounting screws (m4 x 6: 2 pcs) [e] on the drum front upper cover [...

Page 110

8 – 9 rn (version 1.0) chapter 8. Print drum section removing the ink cartridge set switch cover and ink cartridge set switch pcb 2. Removing the ink cartridge set switch cover and ink cartridge set switch pcb removing the ink cartridge set switch cover (1) remove the mounting screws (m4 x 6: 2 pcs)...

Page 111

8 – 10 rn (version 1.0) chapter 8. Print drum section removing the ink cartridge set switch pcb mounting bracket 3. Removing the ink cartridge set switch pcb mounting bracket (1) pull out the print drum, pull out the ink cartridge, and remove the following components. • rint drum front cover • ink c...

Page 112

8 – 11 rn (version 1.0) chapter 8. Print drum section removing the swing base ass’y 4. Removing the swing base ass’y (1) pull out the print drum, pull out the ink cartridge, and remove the following components. • print drum front cover • ink cartridge guide ass’y • drum front upper cover (2) remove ...

Page 113

8 – 12 rn (version 1.0) chapter 8. Print drum section removing the ink cartridge guide bottom ass’y 5. Removing the ink cartridge guide bottom ass’y (1) pull out the print drum, pull out the ink cartridge, and remove the following components. • print drum front cover • ink cartridge guide ass’y • dr...

Page 114

8 – 13 rn (version 1.0) chapter 8. Print drum section removing the ink pump unit and inking motor 6. Removing the ink pump unit and inking motor removing the ink pump unit (1) pull out the print drum, pull out the ink cartridge, and remove the following components. • print drum front cover • ink car...

Page 115

8 – 14 rn (version 1.0) chapter 8. Print drum section removing the print drum set sensor 7. Removing the print drum set sensor (1) pull out the print drum, pull out the ink cartridge, and remove the following components. • print drum front cover • ink cartridge guide ass’y • drum front upper cover •...

Page 116

8 – 15 rn (version 1.0) chapter 8. Print drum section removing the screen 8. Removing the screen [suggestion prior to starting work] • attaching the print drum stand [b] (part no. 015-26836-002) to the rear of the print drum side frame ass’y [a] makes the work easier by keeping the print drum level....

Page 117

8 – 16 rn (version 1.0) chapter 8. Print drum section removing the print drum body 9. Removing the print drum body (1) make a confidential master, pull out the print drum, and remove the following component. • screen (2) remove the mounting screws (special screws: 2 pcs) [b] and remove the clamp pla...

Page 118

8 – 17 rn (version 1.0) chapter 8. Print drum section removing the print drum body [precautions on reassembly: 1] • arrow marks are engraved on both sides of the print drum body, and “f” is engraved at the front. Likewise, arrow marks are engraved on both the right and left print drum supports. Alig...

Page 119

8 – 18 rn (version 1.0) chapter 8. Print drum section removing the ink sensor pcb 10. Removing the ink sensor pcb (1) pull out the print drum, and remove the following components. • screen • print drum body (2) unplug the connector on the ink sensor pcb [b]. (3) remove the mounting screws (m3 x 8: 2...

Page 120

8 – 19 rn (version 1.0) chapter 8. Print drum section 11. Removing the squeegee roller (1) pull out the print drum, and remove the following components. • print drum front cover • ink cartridge guide ass’y • drum front upper cover • ink cartridge set switch pcb cover • ink cartridge set switch pcb m...

Page 121

8 – 20 rn (version 1.0) chapter 8. Print drum section (7) remove the pivot screw [f] on the front of the print drum via the opening in the print drum support (f) where the print drum lock plate ass’y was removed. Likewise, remove the pivot screw [g] on the front of the print drum via the opening in ...

Page 122

8 – 21 rn (version 1.0) chapter 8. Print drum section removing the squeegee roller (7) remove the e-rings on both ends of the squeegee roller [i], remove the gears [j], remove the bearings [k], and then remove the squeegee roller [i] from the squeegee frame [l]. (the doctor roller [m] and driven sha...

Page 123

8 – 22 rn (version 1.0) chapter 8. Print drum section removing the print drum supports (r) and (f) 12. Removing the print drum supports (r) and (f) (1) pull out the print drum, remove the ink cartridge, and remove the following components. • print drum front cover • ink cartridge guide ass’y • drum ...

Page 124

8 – 23 rn (version 1.0) chapter 8. Print drum section removing the print drum supports (r) and (f) (9) pull the print drum support (r) [k] from the ink distributor. (10) pull the ink outlet nozzle [a] from the ink distributor. (11) remove the mounting screws (m4 x 8: 3 pcs) [b] on the drum front sup...

Page 125

8 – 24 rn (version 1.0) chapter 8. Print drum section removing the print drum supports (r) and (f) a: drum front support ass’y b: print drum support (f) c: tool (print drum jig) d: print drum support (r) e: drum rear frame plate [precautions on reassembly: 1] • use the tool (print drum jig) when tig...

Page 126: Adjustment

8 – 25 rn (version 1.0) chapter 8. Print drum section filter cleaning adjustment 1. Filter cleaning (1) pull out the print drum, remove the ink cartridge, and remove the following components. • ink cartridge guide ass’y • drum front upper cover • ink cartridge set switch pcb cover • ink cartridge se...

Page 127

8 – 26 rn (version 1.0) chapter 8. Print drum section squeegee gap adjustment 2. Squeegee gap adjustment (1) pull out the print drum, and remove the following components. • screen • print drum body (2) clean out the ink inside the squeegee unit. (3) using a feeler gauge, check that the gap between t...

Page 128

8 – 27 rn (version 1.0) chapter 8. Print drum section ink blocking plate position adjustment 3. Ink blocking plate position adjustment front (1) pull out the print drum, remove the ink cartridge, and remove the following components. • print drum front cover • ink cartridge guide ass’y • drum front u...

Page 129

8 – 28 rn (version 1.0) chapter 8. Print drum section squeegee pressure balance adjustment 4. Squeegee pressure balance adjustment (1) create a master with test chart no. 15 and print to check the left and right print density balance. (2) if the left and right print density is not balanced, adjust a...

Page 130

8 – 29 rn (version 1.0) chapter 8. Print drum section squeegee pressure balance adjustment [continued on next page] • using your finger, press the print drum from underneath, and adjust the gap to approx. 0.3 mm. [checking after adjustment] • run an actual print after the adjustment to check the lef...

Page 131

8 – 30 rn (version 1.0) chapter 8. Print drum section [memo].

Page 132: Chapter

9 – 1 rn (version 1.0) chapter 9 : master clamp section contents mechanism ............................................................................................................................ 9-2 1. Clamp unit home positioning mechanism ..........................................................

Page 133: Mechanism

9 – 2 rn (version 1.0) chapter 9. Master clamp section clamp unit home positioning mechanism mechanism 1. Clamp unit home positioning mechanism when the start key is pressed to create confidential or normal masters, the clamp open arm [a] and master release arm [b] are checked to ensure that they ha...

Page 134

9 – 3 rn (version 1.0) chapter 9. Master clamp section clamp plate master release mechanism 2. Clamp plate master release mechanism when the start key is pressed to create confidential or normal masters, the print drum makes one turn and checks for the presence of master on the print drum. Once the ...

Page 135

9 – 4 rn (version 1.0) chapter 9. Master clamp section clamp plate master clamp mechanism 3. Clamp plate master clamp mechanism as the used master is removed from the print drum, the print drum makes one revolution and returns to position-a, and the clamp plate master clamp operation starts. The cla...

Page 136: Removal and Assembly

9 – 5 rn (version 1.0) chapter 9. Master clamp section removing the clamp unit removal and assembly 1. Removing the clamp unit (1) remove the rear cover. (2) remove the main pcb. (3) unplug the clamp motor connector [a] and sensor connector [b]. (4) remove the mounting screws (m4 x 8: 3 pcs) [c] on ...

Page 137

9 – 6 rn (version 1.0) chapter 9. Master clamp section removing the clamp motor, clamp sensor a, clamp sensor b 2. Removing the clamp motor, clamp sensor a, clamp sensor b removing the clamp motor (1) remove the following components. • rear cover • main pcb • clamp unit (2) remove the e-ring and rem...

Page 138: Chapter

10 – 1 rn (version 1.0) chapter 10 : master removal section contents mechanism ......................................................................................................................... 10-2 1. Master removal mechanism .....................................................................

Page 139: Mechanism

10 – 2 rn (version 1.0) chapter 10. Master removal section – master removal mechanism mechanism 1. Master removal mechanism masters on the print drum are removed as follows. (1) at the start of master removal, the master sensor [a] checks whether the master to be removed on the print drum actually e...

Page 140

10 – 3 rn (version 1.0) chapter 10. Master removal section master on the drum (before master removal) check mechanism 2. Master on the drum (before master removal) check mecha- nism when creating confidential or normal masters, the print drum moves to position a, and with the print drum at the 75° p...

Page 141

10 – 4 rn (version 1.0) chapter 10. Master removal section removed master vertical transport mechanism 3. Removed master vertical transport mechanism when the clamp unit is operated to release the leading edge of the master from the clamp plate, the master removal motor [a] activates, rotating the v...

Page 142

10 – 5 rn (version 1.0) chapter 10. Master removal section disposed master compression mechanism 4. Disposed master compression mechanism 1) initializing • if the light path on the master compression sensor [b] is open when the power is switched on or when everything is reset, the master compression...

Page 143

10 – 6 rn (version 1.0) chapter 10. Master removal section disposed master compression mechanism 4) disposed-master-full detection the removed-master-full detection is performed using the following two mechanisms, and a master- full indication is displayed by either. (1) the number of masters remove...

Page 144

10 – 7 rn (version 1.0) chapter 10. Master removal section disposed master compression mechanism when the master disposal box becomes full, the master compression plate stops rotating before the removed-master-full sensor is blocked. When the light path to the master compression sensor is open and t...

Page 145

10 – 8 rn (version 1.0) chapter 10. Master removal section disposal box safety switch 5. Disposal box safety switch the master disposal box safety switch checks whether the master disposal box and master disposal gate housing are properly positioned. If the master disposal gate housing is locked and...

Page 146: Removal and Assembly

10 – 9 rn (version 1.0) chapter 10. Master removal section removing the master removal hook removal and assembly 1. Removing the master removal hook (1) pull out the print drum, switch off the power, and remove the front cover. (2) remove the spring [a] from the master removal hook bracket. (3) remo...

Page 147

10 – 10 rn (version 1.0) chapter 10. Master removal section removing the master removal unit 2. Removing the master removal unit (1) move the scanner table to the servicing position [a]. (2) remove the front and rear covers. (3) remove the upper housing cover (master removal unit cover). (m3 x 6: 2 ...

Page 148

10 – 11 rn (version 1.0) chapter 10. Master removal section removing the master removal unit (5) remove the master removal unit mounting screws (m4 x 8: 4 pcs). (6) detach the connectors on both sides, and remove the master removal unit..

Page 149

10 – 12 rn (version 1.0) chapter 10. Master removal section removing the master disposal gate housing 3. Removing the master disposal gate housing (1) remove the e-rings and bearings on both sides of the pulley shaft [b], and remove the pulley shaft. (2) remove the e-rings, bearings, and gears on bo...

Page 150

10 – 13 rn (version 1.0) chapter 10. Master removal section removing the master removal roller (bottom) 4. Removing the master removal roller (bottom) (1) loosen the screws on the tension roller [a], and remove the belt [b]. (m3 x 6: 2 pcs) (2) remove the e-rings, bearings, gears, and pulleys on bot...

Page 151

10 – 14 rn (version 1.0) chapter 10. Master removal section removing the master compression plate 5. Removing the master compression plate (1) remove the e-rings and bearings from both sides of the compression shaft [a]. (2) rotate the compression shaft to move the master compression plate [c] to th...

Page 152

10 – 15 rn (version 1.0) chapter 10. Master removal section removing the master compression plate (5) remove the shaft from the unit, with the master compression plate attached. A: compression shaft b: compression gear c: master compression plate d: piston shaft e: piston shaft link f: piston block ...

Page 153

10 – 16 rn (version 1.0) chapter 10. Master removal section removing the motors 6. Removing the motors (1) remove the master removal motor [a]. (mounting screws m4 x 6: 2 pcs) (2) remove the compression motor [b]. (mounting screws m4 x 6: 2 pcs) (3) remove the e-rings, and then remove the safety swi...

Page 154: Chapter

11 – 1 rn (version 1.0) chapter 11 : fb original scanning section contents mechanism .......................................................................................................................... 11-2 1. Scanner table setting system ..........................................................

Page 155: Mechanism

11 – 2 rn (version 1.0) chapter 11. Fb original scanning section scanner table setting system mechanism 1. Scanner table setting system the flat bed set switch [b] checks whether or not the scanner table [a] has been set correctly. This switch also acts as a safety switch, which cuts the power suppl...

Page 156

11 – 3 rn (version 1.0) chapter 11. Fb original scanning sction scanner table setting system [memo].

Page 157

11 – 4 rn (version 1.0) chapter 11. Fb original scanning section original scanning mechanism 2. Original scanning mechanism the fb read pulse motor [j] drives the front and rear wire spool pulleys [g] via the 2-stage reduction pulleys linked by the timing belts [h], [i]. The front and rear wire spoo...

Page 158

11 – 5 rn (version 1.0) chapter 11. Fb original scanning sction original scanning mechanism a: spring b: mirror carriage c: lamp carriage d: sliding pulley no. 1 e: sliding pulley no. 2 f: fixed pulley g: wire spool pulley h: scanner timing belt 1 i: scanner timing belt 2 j: flat bed read pulse moto...

Page 159

11 – 6 rn (version 1.0) chapter 11. Fb original scanning section flat bed initialization movement 3. Flat bed initialization movement initialization is performed in the following situations to bring the flat bed unit to standby mode. • when power is switched on • when everything has been reset initi...

Page 160

11 – 7 rn (version 1.0) chapter 11. Fb original scanning sction a b c flat bed initialization movement a: image scanner adf shading sensor b: flat bed read pulse motor c: lamp carriage.

Page 161

11 – 8 rn (version 1.0) chapter 11. Fb original scanning section stage glass original detection system 4. Stage glass original detection system the flat bed original detection sensor [b] checks whether an original is placed on the stage glass [a]. The flat bed original detection sensor [b] performs ...

Page 162

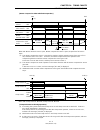

11 – 9 rn (version 1.0) chapter 11. Fb original scanning sction stage glass original detection system stage cover sensor 41 mm 8 mm 15 mm 2.6 mm 2.6 mm 20.2 mm 100 ms 100 ms 100 ms 100 ms set original to fb scanning operation 1 to fb scanning operation 1 press feed feed feed feed shading adjustment ...

Page 163

11 – 10 rn (version 1.0) chapter 11. Fb original scanning section flat bed automatic base control 5. Flat bed automatic base control this operation is performed after the shading compensation for line mode only when the original scanning density is set to “auto”. (it is not performed in photo, line/...

Page 164

11 – 11 rn (version 1.0) chapter 11. Fb original scanning sction flat bed automatic base control 41 mm 8 mm 15 mm 2.6 mm 2.6 mm 20.2 mm 100 ms 100 ms 100 ms 100 ms thermal pressure motor standby position scanning start standby position return feed start key on to fb scanning operation 1 shading comp...

Page 165

11 – 12 rn (version 1.0) chapter 11. Fb original scanning section fb original scanning mechanism 6. Fb original scanning mechanism this scanning operation describes the following situations. One is in which the abc (auto base control) is not performed. The other is when the start key is pressed with...

Page 166

11 – 13 rn (version 1.0) chapter 11. Fb original scanning sction fb original scanning mechanism * l = paper size set by the users mode. Adjustment value b = adjusted by test mode no. 181 (flat bed scanning start position adjustment) adjustment value c = adjusted by test mode no. 281 (master making s...

Page 167: Removal and Assembly

11 – 14 rn (version 1.0) chapter 11. Fb original scanning section removing the scanner unit removal and assembly 1. Removing the scanner unit (1) move the carriage to the locking position using test mode no. 154 (scanner lock action), open the scanner table [i], secure the mirror carriage using the ...

Page 168

11 – 15 rn (version 1.0) chapter 11. Fb original scanning sction a b c d e f g h i j k removing the scanner unit a: stage cover b: scanner unit cover (left) c: original receiving tray bracket d: scanner unit cover (rear) e: scanner unit cover (right) f: stage cover sensor ass’y g: stage cover bracke...

Page 169

11 – 16 rn (version 1.0) chapter 11. Fb original scanning section removing the stage glass 2. Removing the stage glass (1) switch off the power. (2) remove the scanner unit cover (left) [a] by removing four screws (m4 x 8). (if the adf unit is fitted, remove the original receiving tray bracket by re...

Page 170

11 – 17 rn (version 1.0) chapter 11. Fb original scanning sction removing the flat bed original detection sensor 3. Removing the flat bed original detection sensor (1) switch off the power. (2) remove the stage glass [a]. (refer to this section for details.) (3) unplug the connector, and remove the ...

Page 171

11 – 18 rn (version 1.0) chapter 11. Fb original scanning section removing the lamp 4. Removing the lamp (1) switch off the power. (2) remove the scanner unit cover (left) by removing four screws (m4 x 8). (if the adf unit is fitted, remove the original receiving tray bracket by removing two (m4 x 1...

Page 172

11 – 19 rn (version 1.0) chapter 11. Fb original scanning sction removing the lamp a: glass stage bracket b: lamp carriage c: cutaway d: stopper e: connectors f: lamp bracket (with screw hole) g: lamps h: lamp bracket a b c d e f g.

Page 173

11 – 20 rn (version 1.0) chapter 11. Fb original scanning section removing the lens ass’y 5. Removing the lens ass’y (1) switch off the power. (2) remove the stage glass. (refer to this section for details.) (3) remove the lens cover [a] and the three screws (m3 x 6). (4) remove the three washer scr...

Page 174

11 – 21 rn (version 1.0) chapter 11. Fb original scanning sction removing the lens ass’y a: lens cover b: lens ass’y c: half-pierce a b c loosen these screws..

Page 175: Adjustment

11 – 22 rn (version 1.0) chapter 11. Fb original scanning section flat bed read pulse motor speed adjustment adjustment 1. Flat bed read pulse motor speed adjustment before making this adjustment, first adjust the image elongation and shrinkage by adjusting the write pulse motor speed (see chapter 1...

Page 176

11 – 23 rn (version 1.0) chapter 11. Fb original scanning sction fb scan start position adjustment 2. Fb scan start position adjustment checks and procedure (1) place a scale face down on the stage glass, pressing the front edge flush against original stopper, and then close the stage cover. (2) sel...

Page 177

11 – 24 rn (version 1.0) chapter 11. Fb original scanning section fb horizontal scan position adjustment 3. Fb horizontal scan position adjustment checks and procedure (1) place b4 size papers on the paper feed tray, place test chart no. 15 on the stage glass, and make a master. (2) inspect the mast...

Page 178: Chapter

12 – 1 rn (version 1.0) chapter 12 : adf scanning section contents mechanism ......................................................................................................................... 12-2 1. Adf original set mechanism .....................................................................

Page 179: Mechanism

12 – 2 rn (version 1.0) chapter 12. Adf scanning section adf original set mechanism mechanism 1. Adf original set mechanism when the original is set along the original guide fence and pushed up against the original stopper gate [c], the adf original detection sensor [a] is activated (light path open...

Page 180

12 – 3 rn (version 1.0) chapter 12. Adf scanning section adf original set mechanism a: adf original detection sensor b: pickup roller c: original stopper gate d: original stripper roller e: original stripper pad f: adf registration sensor g: registration roller h: registration driven roller i: origi...

Page 181

12 – 4 rn (version 1.0) chapter 12. Adf scanning section adf original set mechanism (1) “a10-107” is displayed if the adf original registration sensor is not activated (light path blocked) even when the adf read pulse motor transports the original 182 mm after the feeding in process begins. Adf orig...

Page 182

12 – 5 rn (version 1.0) chapter 12. Adf scanning section adf original set mechanism [memo].

Page 183

12 – 6 rn (version 1.0) chapter 12. Adf scanning section adf original scanning mechanism (with automatic base control) 2. Adf original scanning mechanism (with automatic base con- trol) (this operation only occurs when the original scanning density is set to “auto”.) once the adf original setting op...

Page 184

12 – 7 rn (version 1.0) chapter 12. Adf scanning section adf original scanning mechanism (with automatic base control) (1) “a10-108” is displayed if the original in sensor is not activated (light path blocked) even when the adf read pulse motor transports the original 138 mm after the start key is p...

Page 185

12 – 8 rn (version 1.0) chapter 12. Adf scanning section adf original scanning mechanism note: abc stands for automatic base control. 3. Adf original scanning mechanism once the adf original setting operation is complete, pressing the start key illuminates the lamp. The flat bed read pulse motor imm...

Page 186

12 – 9 rn (version 1.0) chapter 12. Adf scanning section adf original scanning mechanism a c i k l m a: registration roller b: registration driven roller c: original read roller d: original read driven roller e: original in sensor f: reflecting plate g: shading plate h: adf stage glass i: original o...

Page 187

12 – 10 rn (version 1.0) chapter 12. Adf scanning section adf original scanning mechanism (1) “a10-108” is displayed if the original in sensor is not activated (light path blocked) even when the adf read pulse motor transports the original 138 mm after the start key is pressed. (2) “a10-109” is disp...

Page 188: Removal and Assembly

12 – 11 rn (version 1.0) chapter 12. Adf scanning section removing the original scraper ass’y removal and assembly 1. Removing the original scraper ass’y (1) switch off the power and open the adf unit. Now remove the two screws (m3 x 10), and remove the adf cover [a]. Finally, close the adf unit. (2...

Page 189

12 – 12 rn (version 1.0) chapter 12. Adf scanning section removing the original scraper ass’y a: adf cover b: original scraper ass’y c: lock ring d: bearing bush e: original stopper gate b c c d d e.

Page 190

12 – 13 rn (version 1.0) chapter 12. Adf scanning section removing the pickup roller 2. Removing the pickup roller (1) switch off the power and open the adf unit. Now remove the two screws (m3 x 10), and remove the adf cover. Finally, close the adf unit. (2) pull apart both ends of the pickup roller...

Page 191

12 – 14 rn (version 1.0) chapter 12. Adf scanning section removing the original stripper roller 3. Removing the original stripper roller (1) switch off the power and open the adf unit. Now remove the two screws (m3 x 10), and remove the adf cover. Finally, close the adf unit. (2) remove the original...

Page 192

12 – 15 rn (version 1.0) chapter 12. Adf scanning section removing the adf original detection, original in, and original out sensors 4. Removing the adf original detection, original in, and original out sensors (1) switch off the power and open the adf unit. Now remove the two screws (m3 x 10), and ...

Page 193

12 – 16 rn (version 1.0) chapter 12. Adf scanning section removing the adf original registration sensor 5. Removing the adf original registration sensor (1) switch off the power and open the adf unit. Now remove the two screws (m3 x 10), and remove the adf cover. Finally, close the adf unit. (2) rem...

Page 194

12 – 17 rn (version 1.0) chapter 12. Adf scanning section removing the adf read pulse motor 6. Removing the adf read pulse motor (1) switch off the power and open the adf unit. Now remove the two screws (m3 x 10), and remove the adf cover. Finally, close the adf unit. (2) detach connectors cn1 and c...

Page 195

12 – 18 rn (version 1.0) chapter 12. Adf scanning section removing the adf read pulse motor a: adf-pcb b: adf upper guide ass’y c: ground screw d: adf read pulse motor e: original in sensor b d d.

Page 196

12 – 19 rn (version 1.0) chapter 12. Adf scanning section removing the registration roller, original read roller, and original ejection roller (top) 7. Removing the registration roller, original read roller, and original ejection roller (top) (1) switch off the power and open the adf unit. Now remov...

Page 197

12 – 20 rn (version 1.0) chapter 12. Adf scanning section removing the registration roller, original read roller, and original ejection roller (top) a: adf upper guide ass’y b: jam release dial c: registration roller d: original read roller e: original ejection roller (top) f: idler g: idler spring ...

Page 198

12 – 21 rn (version 1.0) chapter 12. Adf scanning section front rear removing the registration roller, original read roller, and original ejection roller (top) k: washer l: thrust spring m: e-ring n: bearing bush o: clutch spring p: e-ring q: timing gear registration roller original read roller orig...

Page 199: Adjustment

12 – 22 rn (version 1.0) chapter 12. Adf scanning section adf scan start position adjustment adjustment 1. Adf scan start position adjustment checks and procedure (1) make a master with the adf unit using an original with no blank margin at the top, and print. (2) examine the prints to check that th...

Page 200

12 – 23 rn (version 1.0) chapter 12. Adf scanning section adf horizontal scan position adjustment 2. Adf horizontal scan position adjustment checks and procedure (1) place a sheet of b4 size paper on the paper feed tray, and make a master of test chart no. 15 using the adf unit. (2) examine the mast...

Page 201

12 – 24 rn (version 1.0) chapter 12. Adf scanning section adf read pulse motor speed adjustment (image elongation & shrinkage adjustment) 3. Adf read pulse motor speed adjustment (image elongation & shrinkage adjustment) before adjusting, first adjust the image elongation and shrinkage using the wri...

Page 202

12 – 25 rn (version 1.0) chapter 12. Adf scanning section original in sensor sensitivity adjustment 4. Original in sensor sensitivity adjustment procedure (1) open the adf unit, remove the two screws (m3 x 10), and then remove the adf cover. Finally, close the adf unit. (2) turn variable resistor vr...

Page 203

12 – 26 rn (version 1.0) chapter 12. Adf scanning section adf image skew adjustment a: adf mount plate b: nut c: adf slide screw figure 1 t a b c x x bottom top figure 2 5. Adf image skew adjustment checks and procedure (1) place a sheet of b4 size paper on the paper feed tray, and make a master of ...

Page 204: Chapter

13 – 1 rn (version 1.0) chapter 13 : master making section contents mechanism ......................................................................................................................... 13-2 1. Master making & master loading ................................................................

Page 205: Mechanism

13 – 2 rn (version 1.0) chapter 13. Master making section master making & master loading mechanism 1. Master making & master loading the master making & master loading mechanism is made up of the following components. 1) scanner table set detection mechanism the flat bed set switch [a] confirms that...

Page 206

13 – 3 rn (version 1.0) chapter 13. Master making section master making & master loading a: flat bed set switch b: master loading unit sensor c: master end sensor d: cutter motor e: cutter home position switch f: thermal print head g: thermal pressure motor h: tph pressure sensor i: write roller j: ...

Page 207

13 – 4 rn (version 1.0) chapter 13. Master making section scanner table set detection mechanism 2. Scanner table set detection mechanism scanner table and master loading set detection mechanism the flat bed set switch [a] confirms that the scanner table is closed. The flat bed set switch [a] is the ...

Page 208

13 – 5 rn (version 1.0) chapter 13. Master making section master cutting mechanism 3. Master cutting mechanism • the master is cut by the upper cutter of the cutter unit being moved up and down by the cutter motor [a]. • the cutter motor rotates in a constant direction, and the cutter home position ...

Page 209

13 – 6 rn (version 1.0) chapter 13. Master making section thermal print head elevation mechanism 4. Thermal print head elevation mechanism thermal print head elevation when the system is on standby or when winding the master onto the print drum after master making, the thermal print head is raised f...

Page 210

13 – 7 rn (version 1.0) chapter 13. Master making section thermal print head elevation mechanism a: thermal pressure motor b: pressure release cam c: tph pivot plate d: pressure detection disc e: tph pressure sensor f: sliding plate g: blade link b c a d f e h g j i k h: load roller no. 1 (top) i: l...

Page 211

13 – 8 rn (version 1.0) chapter 13. Master making section master positioning mechanism 5. Master positioning mechanism the master positioning operation is performed to bring the master to the master positioning sensor when opening or closing the master loading unit or during master making. For maste...

Page 212

13 – 9 rn (version 1.0) chapter 13. Master making section master making 6. Master making the sequence of operations from master making to master mounting is as described below. (1) at the start of master making, the thermal print head is lowered to clamp the master between it and the write roller. (...

Page 213

13 – 10 rn (version 1.0) chapter 13. Master making section master making (6) the print drum pauses at the 220° position, where the master is cut. (8) the master setting operation is performed. (7) after the print drum has rotated a further 15°, the master positioning sensor confirms that the master ...

Page 214: Rmoval and Assembly

13 – 11 rn (version 1.0) chapter 13. Master making section removing the write roller rmoval and assembly 1. Removing the write roller (1) switch off the power, and remove the rear cover. (2) loosen the mounting bracket screws (m4 x 8: 2 pcs) on the write pulse motor [b], and remove the belt [c]. (3)...

Page 215

13 – 12 rn (version 1.0) chapter 13. Master making section removing the load roller (bottom) 2. Removing the load roller (bottom) (1) switch off the power, and remove the rear cover. (2) loosen the screw (m4 x 8: 1 pc) on the tension assembly [b], loosen the mounting bracket screws (m4 x 8: 2 pcs) o...

Page 216

13 – 13 rn (version 1.0) chapter 13. Master making section removing the load roller (bottom) (5) remove the master roll, and remove the master cover [f]. (m4 x 6: 1 pc) (6) remove the master holders [g] on both sides. (m3 x 6: 2 pcs each) (7) remove the master set guide [h]. (m4 x 8: 2 pcs) (8) unpl...

Page 217

13 – 14 rn (version 1.0) chapter 13. Master making section removing the cutter unit 3. Removing the cutter unit (1) switch off the power, remove the rear cover, and pull out the print drum. (2) unplug the rear connector, and remove the cutter cover [a]. (m4 x 8: 2 pcs) a: cutter cover b: load guide ...

Page 218

13 – 15 rn (version 1.0) chapter 13. Master making section removing the load roller 4. Removing the load roller (1) perform steps (1) to (4) to remove the cutter unit. (2) remove the loading guide (bottom) [e]. (m4 x 8: 2 pcs) (3) loosen the screw (m4 x 8: 1 pc) on the tension assembly [a], and remo...

Page 219

13 – 16 rn (version 1.0) chapter 13. Master making section removing the thermal print head 5. Removing the thermal print head (1) lift up the master loading unit, and remove the master loading unit bottom cover [a]. (screws only need be loosened.) (2) remove the mounting screws on the tph bracket [b...

Page 220

13 – 17 rn (version 1.0) chapter 13. Master making section removing the master loading unit 6. Removing the master loading unit (1) move the scanner table unit to the servicing position [a]. (2) remove the master loading unit upper cover [d]. (m3 x 6: 4 pcs) (3) remove the wire harness and ground wi...

Page 221

13 – 18 rn (version 1.0) chapter 13. Master making section removing the thermal pressure motor 7. Removing the thermal pressure motor (1) remove the master loading unit. (2) remove the e-rings and bearings, and then remove the load roller no. 1 (top) [a]. (3) remove the de-electricity brush plate [b...

Page 222: Adjustment

13 – 19 rn (version 1.0) chapter 13. Master making section thermal power of thermal print head adjustment 1. Thermal power of thermal print head the thermal power must always be set before making masters after the thermal print head has been replaced. Procedure (1) switch off the power to the system...

Page 223

13 – 20 rn (version 1.0) chapter 13. Master making section master feeding adjustments 2. Master feeding adjustments 1) master cut position adjustment this adjustment sets the master cutting timing (print drum stop position for cutting). Checks and procedure (1) adjust if the tail end of the master m...

Page 224

13 – 21 rn (version 1.0) chapter 13. Master making section master feeding adjustments 4) write start position adjustment adjust the write start position (distance from master positioning sensor on to read/write signal on). Adjustment for a leading edge margin of 5 mm assuming that the master clamp r...

Page 225: Chapter

14 – 1 rn (version 1.0) chapter 14 : timing charts contents initialization operations ..................................................................................................... 14-2 1. Overall initialization operation ..........................................................................

Page 226: Initialization Operations

14 – 2 rn (version 1.0) chapter 14. Timing charts overall initialization operation initialization operations 1. Overall initialization operation returns the following items to their home positions when the power is switched on or when everything is reset. 2. Individual initialization operations [the...

Page 227

14 – 3 rn (version 1.0) chapter 14. Timing charts individual initialization operations [master compression plate initialization operation] (1) the master compression sensor is checked on starting, and the operation starts from start 1 if it is on, and from start 2 if it is off. At start 1, the maste...

Page 228

14 – 4 rn (version 1.0) chapter 14. Timing charts individual initialization operations [vertical printing position initialization operation] (1) the print pressure control sensor is checked on starting, and the operation starts from start 1 if it is off, and from start 2 if it is on. At start 1, the...

Page 229: Printing Operations

14 – 5 rn (version 1.0) chapter 14. Timing charts normal overall printing operation printing operations 1. Normal overall printing operation elevator print drum print start vertical printing position print pressure change print in progress ink pressure release servo operation inking, overflow detect...

Page 230

14 – 6 rn (version 1.0) chapter 14. Timing charts individual printing operations 2. Individual printing operations [print start operation] paper detection at press section position a sensor paper sensor paper receiving sensor paper detection sensor paper ejection motor overload current main motor pa...

Page 231

14 – 7 rn (version 1.0) chapter 14. Timing charts individual printing operations (1) the paper receiving sensor is checked on starting printing, and error message [a09-417] is displayed if it is on (paper jam from start). The paper sensor is checked on starting printing, and error message [a07-418] ...

Page 232

14 – 8 rn (version 1.0) chapter 14. Timing charts individual printing operations [print in progress - end operation] (4) the paper detection sensor is checked at the drum angle, a, and the paper feed clutch is activated if paper is present. Error message [c04-402] is displayed if no paper is present...

Page 233

14 – 9 rn (version 1.0) chapter 14. Timing charts individual printing operations [three-cycle no-paper pickup operation] (1) if the paper sensor does not detect the paper by the time the print drum has rotated to angle c, it determines that no paper has been picked up, and moves to the three-cycle n...

Page 234

14 – 10 rn (version 1.0) chapter 14. Timing charts elevator operations 3. Elevator operations [elevator raise operation] (1) the operation ends if the upper limit sensor is on from the start. If the upper limit sensor is off, the elevator operates until the upper limit sensor goes on. (2) error mess...

Page 235

14 – 11 rn (version 1.0) chapter 14. Timing charts elevator operations [elevator lower operation] (1) the operation ends if the lower limit sensor is on from the start. If the lower limit sensor is off, the elevator operates until the lower limit sensor goes on. (2) the elevator motor overload curre...

Page 236

14 – 12 rn (version 1.0) chapter 14. Timing charts elevator operations [elevator servo operation] (1) the operation ends if the upper limit sensor is on from the start. If the upper limit sensor is off, the elevator operates until the upper limit sensor goes on. (2) the elevator motor overload curre...

Page 237

14 – 13 rn (version 1.0) chapter 14. Timing charts print drum peripheral operations 4. Print drum peripheral operations [clamp release] (1) the clamp motor operates in the forward direction on starting. (2) when clamp sensor b goes off with clamp sensor a on, the clamp motor operates for a further 2...

Page 238

14 – 14 rn (version 1.0) chapter 14. Timing charts print drum peripheral operations [inking operation (no ink detection)] (1) inking is performed with the main motor on. (2) the ink sensor is monitored at 500 ms intervals, and if it is detected as off, the inking motor is activated until the ink sen...

Page 239

14 – 15 rn (version 1.0) chapter 14. Timing charts print drum peripheral operations (1) the print drum set sensor and print drum release switch are monitored at 100 ms intervals. (2) if the print drum release switch is detected as having been depressed twice in succession, the position a sensor is c...

Page 240

14 – 16 rn (version 1.0) chapter 14. Timing charts print adjustment operations 5. Print adjustment operations [print speed change] (1) if the print speed adjustment key is pressed, the speed does not change immediately, but rather at the next time the print drum reaches the 220° position. (2) if the...

Page 241

14 – 17 rn (version 1.0) chapter 14. Timing charts print adjustment operations [vertical print positioning operation] (1) if the print position adjustment key is pressed once (within 1 s), the position is immediately changed 0.5 mm. (2) if the print position adjustment key is pressed twice (within 1...

Page 242: Master Removal Operations

14 – 18 rn (version 1.0) chapter 14. Timing charts overall timing for normal master creation master removal operations 1. Overall timing for normal master creation image scanning master making master loading master setting thermal print head master cutting removed master vertical transport master co...

Page 243

14 – 19 rn (version 1.0) chapter 14. Timing charts individual master removal operations 2. Individual master removal operations [removed master vertical transport operation] the removed master vertical transport operation starts after the print drum clamp plate releasing operation ends. (1) the mast...

Page 244

14 – 20 rn (version 1.0) chapter 14. Timing charts individual master removal operations [disposed master compressing operation] the disposed master compressing operation starts after the removed master vertical transport operation ends. (1) the master compression sensor is checked on starting, and t...

Page 245: Master Making Operation

14 – 21 rn (version 1.0) chapter 14. Timing charts overall timing for normal master creation master making operation 1. Overall timing for normal master creation image scanning master making master loading master setting thermal print head master cutting removed master vertical transport master comp...

Page 246

14 – 22 rn (version 1.0) chapter 14. Timing charts individual master making operation 2. Individual master making operation [thermal print head compression operation] (1) the thermal pressure motor operates in the direction of compression. (2) the tph pressure sensor goes off, and the thermal pressu...

Page 247

14 – 23 rn (version 1.0) chapter 14. Timing charts individual master making operation [master positioning operation] the master positioning operation starts after master cutting is complete when setting the master loading unit and master creation. (1) the master detection sensor detects whether a ma...

Page 248

14 – 24 rn (version 1.0) chapter 14. Timing charts individual master making operation [master cutting operation] when the master making operation starts, the cutter home position switch is checked at the start of the master cutting operation. Error message [a17-209] is displayed if it is off. (1) th...

Page 249

14 – 25 rn (version 1.0) chapter 14. Timing charts individual master making operation [master making operation] the master loading and master making operation start once the thermal print head compressing is complete. (1) the master detection sensor checks for the presence of a master on starting. (...

Page 250