- DL manuals

- Riso

- Printer

- RZ Series

- Manual

Riso RZ Series Manual - Control Panels

Getting Acquainted

Control Panels

8

Control Panels

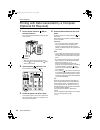

Main Control Panel

1)

Check & Error Display ()p.82)

Indicates error locations and status.

2)

indicator

3)

Print Quantity Display (Error number

display)

Shows the number of printed copies, numeric val-

ues entered for various settings, and error num-

bers.

4)

Master-Making Key

Makes the printer be ready for making masters.

5)

Progress Arrows

Indicates master-making and printing progress

status.

When making masters is ready, all the indicators

above the Master-Making Key light.

When printing is ready, all the indicators above the

Print Key light.

6)

Print Key

Makes the printer be ready for printing.

7)

Wake-Up Key

Wakes up the printer in Energy Saving mode.

8)

Auto-Process Key/Indicator ()p.43)

Perform non-stop operation from master-making

through printing.

When activated, the indicator besides the key

lights.

9)

Print Speed Adjustment Keys/Indicator

()p.50)

Select the print speed from five levels.

The indicator above the keys shows the current

speed level.

10)

Print Density Adjustment Keys/Indicator

(For RZ2XX, unavailable) ()p.47)

Select the print density from five levels.

The indicator above the keys shows the current

density level.

11)

Vertical Print Position Adjustment Keys/

Indicator ()p.48)

Adjust the print position in the vertical direction

(within

±15 mm) after making a master.

The indicator above the keys shows the offset

amount from the centre.

To clear the offset amount, press

.

12)

Key

Use when printing with an optional Linked Printer.

13)

Print Quantity Keys (0 to 9 Keys)

Use to enter the number of copies to be printed or

to enter other numeric values.

14)

C Key

Cancels entered numeric values or resets the

counter to zero.

15)

P Key/Indicator ()p.52)

Allows the printer to print and group copies as

specified (programmed printing).

When activated, the indicator above the key lights.

ORCH_GB.book Page 8 Thursday, February 19, 2004 2:08 PM

Summary of RZ Series

Page 1

1 riso shall not be responsible for any damage or expense that might result from the use of this manual. As we are constantly improving our products, the machine may differ in some respects from the illustrations used in this manual. Riso shall not be liable for any direct, incidental, or consequent...

Page 2: Contents

2 contents welcome to the riso rz series model .............................................................................. 5 getting acquainted 6 parts and components........................................................................................................ 6 control panels ............

Page 3

Contents 3 setting up for scanning originals 32 selecting the image processing mode [line, photo, duo] ................................................ 32 scanning originals written with pencils [pencil] (for rz2xx, unavailable)...................... 33 processing photos with dot screening [dot proc...

Page 4

Contents 4 replacing and disposing consumables 68 replacing the ink cartridge ............................................................................................... 68 replacing the master roll ....................................................................................................

Page 5

Welcome to the riso rz series model 5 welcome to the riso rz series model thank you for purchasing this printing machine that produces clear prints with easy key operations. Besides many useful functions as a printer, the machine provides you with various conveniences such as progressive arrow indi-...

Page 6: Getting Acquainted

Parts and components 6 getting acquainted parts and components orch_gb.Book page 6 thursday, february 19, 2004 2:08 pm.

Page 7

Getting acquainted parts and components 7 1) platen cover 2) sub control panel ()p.10) 3) platen glass ()p.79) place an original face down. 4) main display ()p.82) 5) main control panel ()p.8) 6) master disposal box ()p.73) holds discarded masters. 7) paper feed pressure adjustment lever ()p.19) adj...

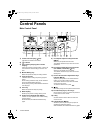

Page 8: Control Panels

Getting acquainted control panels 8 control panels main control panel 1) check & error display ()p.82) indicates error locations and status. 2) indicator 3) print quantity display (error number display) shows the number of printed copies, numeric val- ues entered for various settings, and error num-...

Page 9

Getting acquainted control panels 9 16) + key use when setting up for programmed printing or when changing the initial settings. 17) × key use when setting up for programmed printing. 18) start key starts master-making or printing process or exe- cutes specified operations. The key is lighted only w...

Page 10

Getting acquainted control panels 10 sub control panel 1) free reproduction size display (for rz2xx, unavailable) ()p.36) shows the enlargement/reduction ratio specified using the zoom function. 2) reproduction size selection key ()p.35) when selecting from among the standard repro- duction sizes, p...

Page 11

Getting acquainted control panels 11 12) interface key/indicator ()p.30) when connected with a computer (optional kit needed), switches between line connection and disconnection. When the line is in connection, the indicator above the key lights. 13) custom key/indicator ()p.59) use when changing th...

Page 12: Before Starting to Use

Safety guide - installation 12 before starting to use safety guide - installation this section describes the precautions to be observed when installing the machine. Read this section before install- ing the machine. Note: • your dealer will help you to determine a proper location for the machine at ...

Page 13

Before starting to use safety guide - installation 13 power connection a warning: • do not overload the wall socket or extension cord, nor damage the power cord by placing heavy objects on it or pulling or bending it. This can result in fire or electric shock. • do not pull the power cord but hold t...

Page 14

Before starting to use connection with a computer (option) 14 connection with a computer (option) with an optional interface board (printer control board risorinc3n) installed, you can directly send data from a connected computer to the machine as an original for printing. Because digital data itsel...

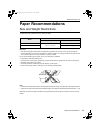

Page 15: Paper Recommendations

Before starting to use paper recommendations 15 paper recommendations size and weight restrictions the table shows the specifications of the usable print paper. Important!: • even when using paper whose sizes and weight are supported by the machine, it may not pass through the machine depending on s...

Page 16

Before starting to use paper recommendations 16 tips for better paper feeding to prevent paper jams and misfeeds, follow the directions below: • when using standard or light-weight paper, set the paper feed pressure adjustment lever to “ ”. Then set the paper ejection wing adjustment dial (for rz2xx...

Page 17: Originals

Before starting to use originals 17 originals size and weight restrictions usable originals are as follows. • originals are scanned according to the size of paper placed on the paper feed tray when masters are made; for the same width, the positions of the feed tray paper guides. When the placed pap...

Page 18

Before starting to use originals 18 maximum printing areas and margins the maximum printing areas are as follows. Important!: • no matter which size of originals is printed, the margins indicated on the figure are required for the originals. Reduce the original if necessary to fit it inside of the m...

Page 19: Preparing to Print

Before starting to use preparing to print 19 preparing to print setting up the paper feed tray 1 open the paper feed tray. 2 load paper. Place paper in the printing orientation, and slide the feed tray paper guides to fit to the sides of the paper. Then turn the right and left feed tray paper guide ...

Page 20

Before starting to use preparing to print 20 adding or replacing paper when you add paper or replace with paper of a different size at the time of printing, press the feed tray descent but- ton to lower the paper feed tray. Pressing the button gently causes the tray to be lowered to the bottom. If y...

Page 21

Before starting to use preparing to print 21 setting up the paper receiving tray 1 open the paper receiving tray. 2 position the receiving tray paper guides. Raise the guides, hold their lower parts, and then slide them according to the width of paper. Important!: • for thick paper such as drawing p...

Page 22

Before starting to use preparing to print 22 z for ordinary paper with images lopsided on page press to open the two paper arrangers on the more heavily printed side. Z for thick paper press to open the two paper arrangers (right and left) closer to the machine. 5 adjust the paper ejection wing. (fo...

Page 23

Before starting to use preparing to print 23 6 set the corrugators. (for rz3xx, unavailable) lower the corrugators to the inside of the paper guides. Note: • usually the corrugators should be lowered. When using thick paper, you need not lower the corrugators. Note: • when closing the paper receivin...

Page 24: Basic Operations

Safety guide - handling and operation 24 basic operations safety guide - handling and operation this section describes the precautions to be observed when handling the machine. Read this section before operat- ing the machine. Operation environment important!: • operate the machine under the followi...

Page 25

Basic operations safety guide - handling and operation 25 consumables important!: • for ink and master roll, it is recommended to use the products specified by riso. • store consumables such as master roll and ink properly. Do not store consumables in the following places: – locations that are subje...

Page 26: Basic Process

Basic operations basic process 26 basic process the machine presents two basic operational processes; master-making process and printing process. Z process for printing from a paper document or book a placed original is scanned by the scanner, and a generated master is rolled around the print drum. ...

Page 27: Basic Operations

Basic operations basic operations 27 basic operations printing from a paper document or book 1 set the power switch to (on) to turn the power on. The power switch is located on the lower right side of the machine. : power on : power off important!: • when the machine is in the energy saving mode, th...

Page 28

Basic operations basic operations 28 • if using the custom setting mode you select on for semi-auto, the next master-making is automatically started and then the machine will stop when the adf unit con- tains originals. ) p.59 4 make necessary settings. Make various settings including image processi...

Page 29

Basic operations basic operations 29 9 remove the printed paper. Pull and open the receiving tray paper guides, and then remove the paper. Note: • for rz2xx, lift the corrugators and pull the guides open. Tip: • depending on the operation status of the machine, different progressive arrow sections l...

Page 30

Basic operations basic operations 30 printing with data generated by a computer (optional kit required) 1 set the power switch to (on) to turn the power on. The power switch is located on the lower right side of the machine. : power on : power off important!: • when the machine is in the energy savi...

Page 31

Basic operations basic operations 31 orch_gb.Book page 31 thursday, february 19, 2004 2:08 pm.

Page 32: Setting Up For

Selecting the image processing mode [line, photo, duo] 32 setting up for scanning originals selecting the image processing mode [line, photo, duo] in order to make a quality master, select an appropriate mode depending on whether originals contain only line(text) or photo or both of them. Press the ...

Page 33

Setting up for scanning originals scanning originals written with pencils [pencil] (for rz2xx, unavailable) 33 scanning originals written with pencils [pencil] (for rz2xx, unavailable) this function allows clearer printing from such originals containing faint contents as those written with pencils. ...

Page 34: [Dot Process]

Setting up for scanning originals processing photos with dot screening [dot process] (for rz2xx, unavailable) 34 processing photos with dot screening [dot process] (for rz2xx, unavailable) this function processes photo originals with dot screening, resulting in clearer printing. You can select the d...

Page 35: [Enlargement/reduction]

Setting up for scanning originals enlarging and reducing originals [enlargement/reduction] 35 enlarging and reducing originals [enlargement/reduction] you can enlarge or reduce originals when printing. Specify the enlargement/reduction ratio by selecting the standard ratios; or specify it in increme...

Page 36

Setting up for scanning originals enlarging and reducing originals [enlargement/reduction] 36 enlarging and reducing with the zoom function [zoom] (for rz2xx, unavailable) specify the enlargement/reduction ratio between 50% and 200% in increments of 1%. 1 press the key to select the zoom mode. The c...

Page 37: Or Dark Contents

Setting up for scanning originals scanning originals having faint or dark contents [scanning level adjustment] 37 scanning originals having faint or dark contents [scanning level adjustment] you can adjust the scanning level according to the density of text and images on originals. With “auto” selec...

Page 38: Reproducing Bound Documents

Setting up for scanning originals reproducing bound documents [book shadow edit] 38 reproducing bound documents [book shadow edit] this function erases the binding “spine” shadow when printing from such bound originals with facing pages as mag- azines and books. Important!: • the initial settings ha...

Page 39: [2-Up Printing]

Setting up for scanning originals printing originals side-by-side [2-up printing] 39 printing originals side-by-side [2-up printing] the same or different originals can be printed side by side. This is called 2-up printing. 2-up printing allows you to place a single original or two different origina...

Page 40

Setting up for scanning originals printing originals side-by-side [2-up printing] 40 restrictions on 2-up printing 2-up printing restricts the sizes of paper to be used, paper orientations, and the enlargement/reduction ratios. Enlargement/reduction ratio the table shows enlargement/reduction ratios...

Page 41

Setting up for scanning originals printing originals side-by-side [2-up printing] 41 note: • you can specify the enlargement/reduction ratio by selecting the standard ratios or specify it in increments of 1% using the zoom function. ) p.35 • originals must have sufficient margins. Insufficient margi...

Page 42

Setting up for scanning originals printing originals side-by-side [2-up printing] 42 4 start the master-making process. Z when placing originals on the platen glass z single-original printing press the key to start the first scan. After the scan a interval time alarm sounds. Before the alarm stops, ...

Page 43: Automatic Printing

Setting up for scanning originals automatic printing [auto-process] 43 automatic printing [auto-process] with “auto-process” selected, enter the number of copies to be printed, and then press the key. The master-mak- ing and printing processes are automatically executed in a sequence. Press the key ...

Page 44: Saving Ink [Ink Saving]

Setting up for scanning originals saving ink [ink saving] 44 saving ink [ink saving] setting the ink saving mode before making masters will allow the machine to save ink when printing. Because of ink consumption save processing, the print density will be lower than usual. Press the key to turn on it...

Page 45

Setting up for scanning originals saving ink [ink saving] 45 orch_gb.Book page 45 thursday, february 19, 2004 2:08 pm.

Page 46: Setting Up For Printing

Producing proof copies [proof] 46 setting up for printing producing proof copies [proof] after adjusting the print position and density, you can produce proof copies to check the print quality. Press the key. Proof copy does not affect the number shown on the print quantity display. Note: • by holdi...

Page 47: Adjusting The Print Density

Setting up for printing adjusting the print density [print density adjustment] (for rz2xx, unavailable) 47 adjusting the print density [print density adjustment] (for rz2xx, unavailable) you can select the print density from five levels. Press the / keys under to adjust the print density. Each time ...

Page 48: Adjusting The Print Position

Setting up for printing adjusting the print position [print position adjustment] 48 adjusting the print position [print position adjustment] use the vertical print position adjustment keys to adjust the print position in the vertical direction; and use the hor- izontal print position adjustment dial...

Page 49

Setting up for printing adjusting the print position [print position adjustment] 49 important!: • if you have adjusted the horizontal position, also adjust the receiving tray paper guides. • if you have adjusted the horizontal position, make sure to reset to the centre after printing is finished. Or...

Page 50: Changing The Print Speed

Setting up for printing changing the print speed [print speed adjustment] 50 changing the print speed [print speed adjustment] you can select the print speed from five levels; 60 copies per minute to 130 copies per minute. Press the / keys under to select the print speed. Each time you press the key...

Page 51

Setting up for printing changing the print speed [print speed adjustment] 51 orch_gb.Book page 51 thursday, february 19, 2004 2:08 pm.

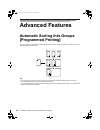

Page 52: Advanced Features

Automatic sorting into groups [programmed printing] 52 advanced features automatic sorting into groups [programmed printing] from a single sheet of original, this function prints and sorts into various groups having different number of copies per set and/or different number of sets. Note: • up to fi...

Page 53

Advanced features automatic sorting into groups [programmed printing] 53 1 press the [p] key to turn on its indi- cator. The print quantity entry mode is started. Note: • to clear the mode, press the [p] key again to turn off its indicator. If the mode is quitted, the setting is cancelled. 2 enter t...

Page 54

Advanced features automatic sorting into groups [programmed printing] 54 5 press the [ ] key. The machine then allows you to enter the number of copies for the second group. Repeat steps 2 through 5 to specify the number of copies and sets for each group. 6 place an original. Z when placing on the p...

Page 55: Idling Action [Idling]

Advanced features idling action [idling] 55 idling action [idling] idling action prevents the machine from printing the first several copies with faint ink after the print drum has been exchanged or the machine has not been used for an extended period of time. Idling action before the master-making ...

Page 56: [Confidential Mode]

Advanced features protecting confidential documents [confidential mode] 56 protecting confidential documents [confidential mode] after printing is complete, the master remains on the print drum and is ready for printing another set of copies. To protect confidential documents from unauthorized dupli...

Page 57

Advanced features printing with a linked printer (option) (for rz2xx, unavailable) 57 printing with a linked printer (option) (for rz2xx, unavailable) with optional linked printer connected, an original is scanned by the machine but printed out by the linked printer. Important!: • when connecting a ...

Page 58

Advanced features printing with a linked printer (option) (for rz2xx, unavailable) 58 4 make necessary settings. You can set the following functions: • image processing mode • pencil • enlargement/reduction ratio • scanning level 5 enter the number of copies to be printed, using the print quantity k...

Page 59: [Custom Setting Mode]

Advanced features customising the initial settings [custom setting mode] 59 customising the initial settings [custom setting mode] you can change the initial settings that are restored when the power is turned on or when the key is pressed. Changed settings are effective until they are changed again...

Page 60

Advanced features customising the initial settings [custom setting mode] 60 10 energy saving mode when the machine is not used for a certain period of time, it is automatically turned off or placed into the sleep status. • off the machine remains on until its power switch is turned off. • auto-sleep...

Page 61

Advanced features customising the initial settings [custom setting mode] 61 15 beep sound specify how an alarm should sound when keys are operated or errors occur. • level 2 a beep sounds at all preset occasions; for example at the time of key operations and event generation/end. • level 1 a beep so...

Page 62

Advanced features customising the initial settings [custom setting mode] 62 30 total quantity display the total number of copies printed with the machine is displayed. This number is displayed by two switching screens; a 3-digit number preceded by an under bar and a 4- digit number. Example: for 1,2...

Page 63

Advanced features customising the initial settings [custom setting mode] 63 changing procedure 1 press the key to turn on its indi- cator. Note: • to clear the mode, press the key again to turn off its indicator. 2 enter an item number to be changed, using the print quantity keys. The print quantity...

Page 64

Advanced features customising the initial settings [custom setting mode] 64 5 press the key to complete the set- tings. The changed contents are programmed and the normal mode is restored. Orch_gb.Book page 64 thursday, february 19, 2004 2:08 pm.

Page 65

Advanced features customising the initial settings [custom setting mode] 65 ip address setting (for rz2xx, unavailable) when connecting a linked printer (option) or a computer, you need to set ip addresses on the machine and the linked printer. 1 press the key to turn on its indi- cator. Note: • to ...

Page 66

Advanced features customising the initial settings [custom setting mode] 66 5 repeat steps 3 and 4 to enter an ip address up to the fourth field. 6 press the key. The ip address setting is completed. Orch_gb.Book page 66 thursday, february 19, 2004 2:08 pm.

Page 67

Advanced features customising the initial settings [custom setting mode] 67 setting the link-free volume (for rz2xx, unavailable) when entered print quantity is smaller than the specified link-free volume (number of copies), a linked printer is automatically selected for printing. If entered print q...

Page 68: Replacing and Disposing

Replacing the ink cartridge 68 replacing and disposing consumables replacing the ink cartridge when the ink cartridge becomes empty, the ink replacement indicator lights. Replace with a new ink cartridge. Important!: • for the ink cartridge, it is recommended to use the products specified by riso. •...

Page 69

Replacing and disposing consumables replacing the ink cartridge 69 4 insert the new ink cartridge. Align the arrow on the ink cartridge with the mark on the holder, and push the ink cartridge until it stops. 5 lock the ink cartridge. Turn the ink cartridge clockwise ( ) to lock it. :lock 6 close the...

Page 70: Replacing The Master Roll

Replacing and disposing consumables replacing the master roll 70 replacing the master roll when the entire master roll is consumed, the master replacement indicator lights. Replace with a new master roll. Important!: • for the master roll, it is recommended to use the products specified by riso. 1 o...

Page 71

Replacing and disposing consumables replacing the master roll 71 6 remove the depleted master roll. Note: • dispose the depleted master roll according to the disposal rule of your local community. ) p.74 7 install a new master roll. Remove the shrink package (transparent film) from the new master ro...

Page 72

Replacing and disposing consumables replacing the master roll 72 tip: • if you cannot insert the leading edge of the master well, use the following procedure: 1) raise the master guide flap. Turn the wheel beside the master guide flap inward to raise the master guide flap. 2) pull out the master rol...

Page 73

Replacing and disposing consumables emptying the master disposal box 73 emptying the master disposal box 1 pull out the master disposal box. Grasp the handle of the master disposal box and pull out the box to the left. 2 discard the ejected masters. Note: • if masters adhere to the inside of the mas...

Page 74

Replacing and disposing consumables disposal of depleted consumables 74 disposal of depleted consumables dispose the depleted ink cartridges, master rolls and ejected masters according to the regulations in your local community. If required, separate the specific components using the following proce...

Page 75

Replacing and disposing consumables removing and installing the print drum 75 removing and installing the print drum when replacing with a colour drum or dealing with paper jams, remove the print drum, take a necessary procedure, and then install the drum. Important!: • make sure to place and keep t...

Page 76

Replacing and disposing consumables removing and installing the print drum 76 5 install the print drum. Align the mark with the mark on the guide and position the print drum horizontal relative to the guide. Note: • if you manually rotate the print drum, make sure to rotate it so that the and marks ...

Page 77

Replacing and disposing consumables removing and installing the print drum 77 orch_gb.Book page 77 thursday, february 19, 2004 2:08 pm.

Page 78: Cleaning

Safety guide - cleaning 78 cleaning safety guide - cleaning this section describes the precautions to be observed when cleaning the machine. Read this section before cleaning the machine. A warning: • before cleaning any part of the machine, turn off the power. • do not remove any fixed covers. • co...

Page 79: Cleaning

Cleaning cleaning 79 cleaning thermal print head clean the thermal print head each time you replace the master roll. Open the master making unit cover, and then gently wipe the thermal print head in the back of the unit several times with a soft cloth or tissue. B caution: • since the thermal print ...

Page 80

Cleaning cleaning 80 pressure roller if the pressure roller, which presses print paper against the print drum, is stained, smudged strips may appear on the back of copies. If this happens, gently wipe the pressure roller with a soft cloth dampened with alcohol. B caution: • when putting your hand in...

Page 81

Cleaning cleaning 81 scanner glass and white sheet of the adf unit (option) gently wipe the scanner glass (for rz2xx, unavailable), and the white sheet several times with a soft cloth or tissue. B caution: • since the platen glass is very delicate, avoid shocks or scratches with a hard object. Note:...

Page 82: Troubleshooting

Check & error display 82 troubleshooting check & error display when an error occurs on the machine or when consumables or other sections are not yet ready, the check & error display shows error locations and numbers indicating error types. For some errors, error numbers are shown on the error number...

Page 83

Troubleshooting check & error display 83 when the indicator [area *3] blinks check error locations and error numbers (error number display) and take the following procedures: location no. Error no. Cause action a-06 any obstacle exists under the paper feed tray or on paper. Check if any obstacle exi...

Page 84

Troubleshooting check & error display 84 a-02 a master has not been correctly wrapped around the print drum. B caution: • the print drum is equipped with many metallic components. Touch the print drum only when necessary. These components may cut your fingers. • when turning the print drum with hand...

Page 85

Troubleshooting check & error display 85 a-01 a-34 a master has not been correctly set. Open the master making unit cover, remove the master roll, and set the master correctly. If the master is loose, turn the right flange inward to correct it, and close the master making unit cover. ) p.70 a-17 a m...

Page 86

Troubleshooting check & error display 86 j-02 a paper jam has occurred on the paper receiving tray section. Remove the paper jammed on the paper receiving tray section. If the error indications do not disappear, press the key. J-01 a paper jam has occurred in the adf unit (option). Remove the origin...

Page 87

Troubleshooting check & error display 87 when the indicator [area *3] blinks check error locations and error numbers (error number display) and take the following procedures. If an error number is not shown, press the [ ] key. Location no. Error no. Cause action c-04 the tray has run out of paper. P...

Page 88

Troubleshooting check & error display 88 f-01 a master has not been wrapped around the print drum. Place an original and start with the master- making process. If you leave the machine without a master wrapped around the print drum, malfunction may occur. Press the key, and then press the key. Or pe...

Page 89

Troubleshooting check & error display 89 when the indicator [area *3] lights because the entire master roll has been consumed, set a new master roll. ) p.70 when the indicator [area *3] lights because the master disposal box is full, remove the box and discard the ejected masters. ) p.73 when the in...

Page 90

Troubleshooting check & error display 90 when the indicator [*2] is off and “h” is shown on the print quantity display [*4]. In order to assure optimum printing, the machine acquires information from the consumables. If acquired matching information is not proper, “h” is shown on the print quantity ...

Page 91

Troubleshooting check & error display 91 use the following procedure to enter necessary information. 1 enter a parameter using the print quantity keys. The parameters that can be entered differ among the consumables. 2 press the key to complete the set- ting. If the next h no. Appears, repeat steps ...

Page 92: Troubleshooting Tips

Troubleshooting troubleshooting tips 92 troubleshooting tips if any problems occur during printing, check the following items and take appropriate procedures before calling your authorized service representative. Problem cause action the machine does not start when the power switch is pressed. The p...

Page 93

Troubleshooting troubleshooting tips 93 an error indication does not disappear even though consumables (ink, master roll) are set. The consumables (ink, master roll) have not been correctly set. After inserting the ink cartridge, turn it clockwise ( ) to lock. Or set the ink cartridge again. ) p.68 ...

Page 94

Troubleshooting troubleshooting tips 94 in the book shadow editing, the position for shadow erasure is shifted. Custom-size paper has been placed on the paper feed tray. The book shadow editing does not allow custom-size paper to be used. Set standard-size paper. Custom-size book or magazine was pla...

Page 95

Troubleshooting troubleshooting tips 95 the edges of printed copies are smudged with ink. Larger size of paper than the original was placed on the paper feed tray at the time of the master-making process. Because a master was made according to a larger size than the original, the edges of the origin...

Page 96

Troubleshooting troubleshooting tips 96 paper sticks to the surface of the print drum. (the indicator blinks frequently.) the margin at the top of the original or print is too small. The margin of the original (top of the print in the paper output direction) must be 5 mm at least. Lower the vertical...

Page 97

Troubleshooting troubleshooting tips 97 paper is not smoothly fed from the paper feed tray. (no paper is fed.) the position of the paper feed pressure adjustment lever was inappropriate. For thick or smooth-surface paper, set the paper feed pressure adjustment lever to “ ”. )p.19 the angle of the st...

Page 98

Troubleshooting troubleshooting tips 98 the indicator lights even when a paper jam has not occurred. Lifted paper was ejected at the time of the second rotation of the print drum. Check the printed copies, and if the top margin is less than 5 mm, slightly lower the print position. Because sunlight w...

Page 99

Troubleshooting troubleshooting tips 99 orch_gb.Book page 99 thursday, february 19, 2004 2:08 pm.

Page 100: Appendixes

Optional accessories 100 appendixes optional accessories a variety of optional accessories are available to enhance the capabilities of the machine. For details about the optional accessories, see their respective user's manuals. Z colour drum a variety of colours are available, such as blue, red, g...

Page 101: Specifications

Appendixes specifications 101 specifications riso rz370 note: • the specifications are subject to change without prior notice. Master-making/printing methods high-speed digital master-making/full automatic stencil printing original type book (10 kg or less), sheet original size (max./min.) when usin...

Page 102

Appendixes specifications 102 riso rz300 note: • the specifications are subject to change without prior notice. Master-making/printing methods high-speed digital master-making/full automatic stencil printing original type book (10 kg or less), sheet original size (max./min.) when using the platen gl...

Page 103

Appendixes specifications 103 riso rz230 note: • the specifications are subject to change without prior notice. Master-making/printing methods high-speed digital master-making/full automatic stencil printing original type book (10 kg or less), sheet original size (max./min.) when using the platen gl...

Page 104

Appendixes specifications 104 riso rz200 note: • the specifications are subject to change without prior notice. Master-making/printing methods high-speed digital master-making/full automatic stencil printing original type book (10 kg or less), sheet original size (max./min.) when using the platen gl...

Page 105: Feature List

Appendixes feature list 105 feature list feature rz370/rz300 rz230/rz200 standard reproduction ratio { { zoom { na dot process { na scanning level (five manually variable steps) { { scanning level (auto) { na book shadow edit { { programmed printing { { 2-up printing { { ink saving { { pencil { na c...

Page 106: Index

106 index symbols * key ......................................................................... 8 + key ........................................................................ 9 × key ........................................................................9 numerics 1:1 key .........................

Page 107

Index 107 ink cartridge replacement ................................... 68 ink handling ........................................................... 25 ink saving .............................................................. 44 ink saving indicator .........................................10, 44 ink...

Page 108

Index 108 r receiving tray paper guide .............................7, 21 reduction ............................................................... 35 replace ink cartridge indicator ......................82, 89 replace master roll indicator ..................70, 82, 89 reproduction size selection k...