- DL manuals

- Riso

- Disc Duplicator

- RZ2xx Series

- Technical Manual

Riso RZ2xx Series Technical Manual

RISO Inc. Technical Communications

us.riso.com

Copyright : 2005 Riso Kagaku Corporation

All Rights Reserved. This Technical Manual was prepared and

written for the exclusive use of RISO International Group Certified

Dealers. Reproduction and/or transmittal of this material in any

form or by any means, including photocopying or recording of the

information is strictly prohibited without the consent of a member

of RISO International Group.

RISO INTERNATIONAL GROUP

RISO KAGAKU CORPORATION (JAPAN)

RISO DEUTSCHLAND GMBH (GERMANY)

RISO, INC. (U.S.A.)

RISO FRANCE (FRANCE)

RISO EUROPE LIMITED (U.K.)

RISO IBERICA (SPAIN)

RISO HONG KONG (HONG KONG)

RISO CANADA (CANADA)

RISO UK (U.K.)

ZHUHAI RISO TECHNOLOGY (CHINA)

RISO THAILAND LIMITED (THAILAND)

RISO AFRICA (SOUTH AFRICA)

RISO KOREA LIMITED (KOREA)

RISOGRAPH ITALIA (ITALY)

RZ2xx

RZ3xx

SERIES

TECHNICAL MANUAL

REVISION 3.0

FEBRUARY 200

5

Summary of RZ2xx Series

Page 1

Riso inc. Technical communications us.Riso.Com copyright : 2005 riso kagaku corporation all rights reserved. This technical manual was prepared and written for the exclusive use of riso international group certified dealers. Reproduction and/or transmittal of this material in any form or by any mean...

Page 2

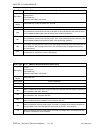

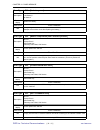

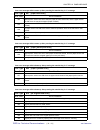

Riso inc. Technical communications us.Riso.Com index chapter 1 : maintenance chapter 2 : machine summary chapter 3 : main drive chapter 4 : first paper feed section chapter 5 : second paper feed section chapter 6 : press section chapter 7 : paper ejection section chapter 8 : print drum section chapt...

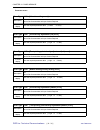

Page 3: Contents

Riso inc. Technical communications us.Riso.Com chapter 1: maintenance [ 1 - 1 ] contents preface ..................................................................................................................................... 1-2 caution ............................................................

Page 4

Riso inc. Technical communications us.Riso.Com chapter 1: maintenance [ 1 - 2 ] preface this manual provides technical service information for the riso printer model rz series. This manual provides procedures for removing and installing major components. Following these procedures will minimize mach...

Page 5: Caution

Riso inc. Technical communications us.Riso.Com chapter 1: maintenance [ 1 - 3 ] [handling of lithium battery] - never fail to follow the following instructions when you discard the used lithium battery. 1. Never let the battery short-circuited. If the (+) and (-) terminals contact each other or meta...

Page 6: !! Warning !!

Riso inc. Technical communications us.Riso.Com chapter 1: maintenance [ 1 - 4 ] !! Warning !! Important safety precautions 1. Always disconnect electrical supply before placing hands in the machine. I. To avoid injuries: be sure to disconnect the electrical power before disassembling, assembling, or...

Page 7

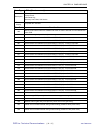

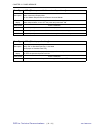

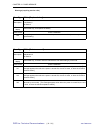

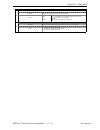

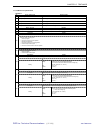

Riso inc. Technical communications us.Riso.Com chapter 1: maintenance [ 1 - 5 ] type tip size shaft length, etc. Phillips screw driver no. 2 no. 2 no. 2 no. 1 (250 mm) (100 mm–150 mm) (stubby type) (75 mm–100 mm) high frequency driver 2.5 mm 5.0 mm 4.0 mm 3.0 mm 2.5 mm 2.0 mm 1.5 mm (for 3.0mm, 2 pi...

Page 8

Riso inc. Technical communications us.Riso.Com chapter 1: maintenance [ 1 - 6 ] sensor types • photoelectric sensors may be broadly divided into the following four types: interrupt types (u- shaped), actuator types, reflective types, and transmittive types. • magnetic sensors use hall ics, which rea...

Page 9

Riso inc. Technical communications us.Riso.Com chapter 1: maintenance [ 1 - 7 ] installation location do not install the machine in any of the following locations. (1) those subject to direct sunlight or any bright location such as by a window (if you must install in such a location, put a curtain o...

Page 10

Riso inc. Technical communications us.Riso.Com chapter 1: maintenance [ 1 - 8 ] 2. Jigs 021-16007-005 spring; screen (2 pieces required) cut the ring end to make into hook, as shown on the photograph, and attach wire tie bar on the other end. 016-16141-003 8mm dia. X 160mm shaft (jig) (2 pieces requ...

Page 11

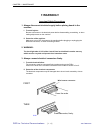

Riso inc. Technical communications us.Riso.Com chapter 1: maintenance [ 1 - 9 ] 3. Exterior cover removal front cover (1) open the front door, remove screws ( m4x8: 5pcs). (2) close the front door, remove screws (m4x8: 2pcs) on the paper feed side and screws (m4x8: 2pcs) on the paper ejection side, ...

Page 12

Riso inc. Technical communications us.Riso.Com chapter 1: maintenance [ 1 - 10 ] stage cover (1) open the stage cover, remove a screw (m4x10: 1pc each) from each of the two hinges (right and left) of the stage cover, and then attach those screws in the screw holes behind. Lift the stage cover off th...

Page 13

Riso inc. Technical communications us.Riso.Com chapter 1: maintenance [ 1 - 11 ] rear cover rear cover - remove screws (m4x8: 4pcs), and dismount the rear cover. Download cover - remove screws(m4x8: 2pcs), and dismount the download cover. Side cover; paper feed - remove screws ( m4x8: 2pcs), and dis...

Page 14

Riso inc. Technical communications us.Riso.Com chapter 1: maintenance [ 1 - 12 ] scanner cover; paper feed - remove screws ( m4x8: 3pcs), and dismount the scanner cover;paper feed. Scanner cover; paper ejection - remove screws( m4x8: 4pcs), and dismount the scanner cover;paper ejection. Scanner cove...

Page 15

Riso inc. Technical communications us.Riso.Com chapter 1: maintenance [ 1 - 13 ] pcb bracket on which the power supply and mechanical control pcbs are mounted. 4. Opening the pcb bracket (1) switch off the power, and dismount the rear cover. (2) remove screws (m4x8: 5pcs) and slowly swing open the p...

Page 16

Riso inc. Technical communications us.Riso.Com chapter 1: maintenance [ 1 - 14 ] memo.

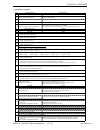

Page 17: Contents

Riso inc. Technical communications us.Riso.Com chapter 2: machine summary [ 2 - 1 ] contents 1. Cross-sectional diagram ................................................................................................... 2-2 2. Operation outline ..........................................................

Page 18

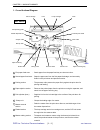

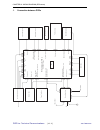

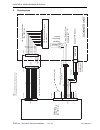

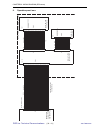

Riso inc. Technical communications us.Riso.Com [ 2 - 2 ] chapter 2: machine summary 1. Cross-sectional diagram mirror carriage lens lamp carriage ccd cutter thermal print head write roller compressing plate master disposal box scraper roller pickup roller paper feed tray guide roller timing roller p...

Page 19

Riso inc. Technical communications us.Riso.Com chapter 2: machine summary [ 2 - 3 ] set an original, and press the start key. Master removal operation removes the used master from the print drum, and sends it to the master disposal box. Master-making operation the original is scanned by the image se...

Page 20

Riso inc. Technical communications us.Riso.Com [ 2 - 4 ] chapter 2: machine summary (1) when the print drum rotates, the scraper roller and pickup roller also turn to feed paper. The stripper pad allows only one sheet to pass through to the second paper-feed area. (2) the paper sent from the first p...

Page 21

Riso inc. Technical communications us.Riso.Com chapter 2: machine summary [ 2 - 5 ] master-removal operation (1) the clamp plate holding the leading edge of the master opens, and the master-release bar rises to lift the master out from under the clamp plate (2) the vertical transport rollers and pri...

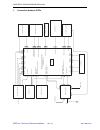

Page 22: Optional Accessories

Riso inc. Technical communications us.Riso.Com [ 2 - 6 ] chapter 2: machine summary optional accessories a variety of optional accessories are available to enhance the capabilities of the machine. For details about the optional accessories, see their respective user's manuals. Color cylinder(drum) a...

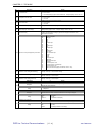

Page 23: Specifications

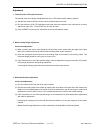

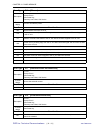

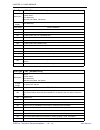

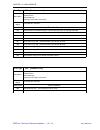

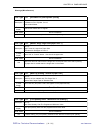

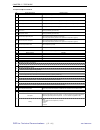

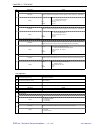

Riso inc. Technical communications us.Riso.Com chapter 2: machine summary [ 2 - 7 ] specifications riso rz390 ui note: • the specifications are subject to change without prior notice. Master-making/printing methods high-speed digital master-making/full automatic stencil printing original type book (...

Page 24

Riso inc. Technical communications us.Riso.Com [ 2 - 8 ] chapter 2: machine summary riso rz370 ep note: • the specifications are subject to change without prior notice. Master-making/printing methods high-speed digital master-making/full automatic stencil printing original type book (10 kg or less),...

Page 25

Riso inc. Technical communications us.Riso.Com chapter 2: machine summary [ 2 - 9 ] riso rz370 aw, an note: • the specifications are subject to change without prior notice. Master-making/printing methods high-speed digital master-making/full automatic stencil printing original type book (22lb(10 kg)...

Page 26

Riso inc. Technical communications us.Riso.Com [ 2 - 10 ] chapter 2: machine summary riso rz310 ui note: • the specifications are subject to change without prior notice. Master-making/printing methods high-speed digital master-making/full automatic stencil printing original type book (22lb(10 kg) or...

Page 27

Riso inc. Technical communications us.Riso.Com chapter 2: machine summary [ 2 - 11 ] riso rz300 ep note: • the specifications are subject to change without prior notice. Master-making/printing methods high-speed digital master-making/full automatic stencil printing original type book (10 kg or less)...

Page 28

Riso inc. Technical communications us.Riso.Com [ 2 - 12 ] chapter 2: machine summary riso rz230 ep note: • the specifications are subject to change without prior notice. Master-making/printing methods high-speed digital master-making/full automatic stencil printing original type book (10 kg or less)...

Page 29

Riso inc. Technical communications us.Riso.Com chapter 2: machine summary [ 2 - 13 ] riso rz230 aw, an note: • the specifications are subject to change without prior notice. Master-making/printing methods high-speed digital master-making/full automatic stencil printing original type book (22lb(10 kg...

Page 30

Riso inc. Technical communications us.Riso.Com [ 2 - 14 ] chapter 2: machine summary riso rz220 ui, as note: • the specifications are subject to change without prior notice. Master-making/printing methods high-speed digital master-making/full automatic stencil printing original type book (22lb(10 kg...

Page 31

Riso inc. Technical communications us.Riso.Com chapter 2: machine summary [ 2 - 15 ] riso rz200 ep note: • the specifications are subject to change without prior notice. Master-making/printing methods high-speed digital master-making/full automatic stencil printing original type book (10 kg or less)...

Page 32

Riso inc. Technical communications us.Riso.Com [ 2 - 16 ] chapter 2: machine summary riso rz200 aw note: • the specifications are subject to change without prior notice. Master-making/printing methods high-speed digital master-making/full automatic stencil printing original type book (22lb(10 kg) or...

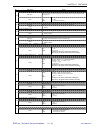

Page 33

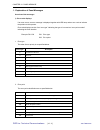

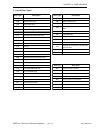

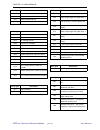

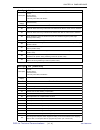

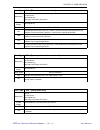

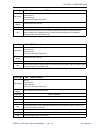

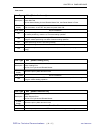

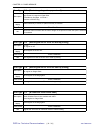

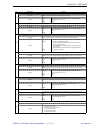

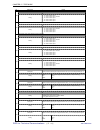

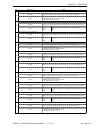

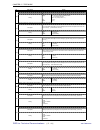

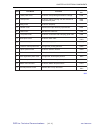

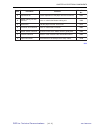

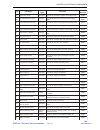

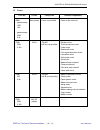

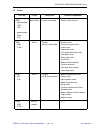

Riso inc. Technical communications us.Riso.Com chapter 2: machine summary [ 2 - 17 ] 7. Feature list (excludes china market models).

Page 34

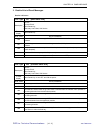

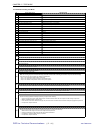

Riso inc. Technical communications us.Riso.Com [ 2 - 18 ] chapter 2: machine summary 8. Optional accessories (china market models only).

Page 35

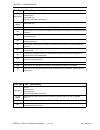

Riso inc. Technical communications us.Riso.Com chapter 2: machine summary [ 2 - 19 ] 9. Machine specification (china market models only).

Page 36

Riso inc. Technical communications us.Riso.Com [ 2 - 20 ] chapter 2: machine summary.

Page 37

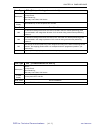

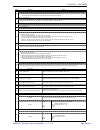

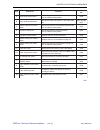

Riso inc. Technical communications us.Riso.Com chapter 2: machine summary [ 2 - 21 ] 10. Feature list (china market models only).

Page 38

Riso inc. Technical communications us.Riso.Com [ 2 - 22 ] chapter 2: machine summary memo.

Page 39: Chapter

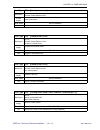

Riso inc. Technical communications us.Riso.Com chapter 3: main drive [ 3 - 1 ] chapter 3 : main drive contents mechanism 1. Main drive section ............................................................................................................. 3-2 2. Print drum angle detection ................

Page 40

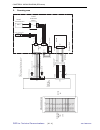

Riso inc. Technical communications us.Riso.Com chapter 3: main drive [ 3 - 2 ] mechanism 1. Main drive mechanism when the main motor is turned on, the motor pulley rotates and the rotation is transmitted to the main pulley by the main belt. The main motor fg sensor detects the speed and the angle po...

Page 41

Riso inc. Technical communications us.Riso.Com chapter 3: main drive [ 3 - 3 ] 2. Print drum angle detection print drum angles are calculated from the main motor fg sensor count by using following parts. - main motor fg sensor. - position-b sensor on the main cover assembly. - position-b actuator pl...

Page 42

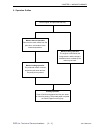

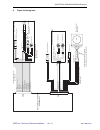

Riso inc. Technical communications us.Riso.Com chapter 3: main drive [ 3 - 4 ] 0305 3. Main motor safety mechanism five safety switches (serviceman safety sw, master disposal box safety sw, master making unit safety sw and print drum safety sw) prevent the main motor, clamp motor, master removal ver...

Page 43

Riso inc. Technical communications us.Riso.Com chapter 3: main drive [ 3 - 5 ] 0306 print drum safety sw master making unit safety sw.

Page 44

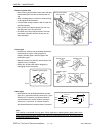

Riso inc. Technical communications us.Riso.Com chapter 3: main drive [ 3 - 6 ] 0307 0308 disassembly 1) when performing maintenance on the main drive section and pressure section, remove the pressure spring at the start of the disassembly, and attach it only at the end of the reassembly. 2) set the ...

Page 45

Riso inc. Technical communications us.Riso.Com chapter 3: main drive [ 3 - 7 ] 0309 0310 1. Removing the pressure spring (1) run test mode no.908 ( pressure control maintenance positioning adjustment), unplug the print drum and switch off the machine power. (2) remove the rear cover and swing open t...

Page 46

Riso inc. Technical communications us.Riso.Com chapter 3: main drive [ 3 - 8 ] 0311 2. Removing the main belt (1) remove the pressure spring. (2) insert 8mm diameter shaft jig into the position-b phase alignment hole on the paper feed timing area (refer to page 3-6.) (3) unplug the position b sensor...

Page 47

Riso inc. Technical communications us.Riso.Com chapter 3: main drive [ 3 - 9 ] 0312 main belt main motor pulley main shaft assembly (7) remove the main belt from the main shaft assembly and main motor pulley. - when putting the main cover assembly back on the machine, push it firmly against the mach...

Page 48

Riso inc. Technical communications us.Riso.Com chapter 3: main drive [ 3 - 10 ] 0313 0314 0315 3. Removing the main motor pulley assembly (1) remove the main belt from the machine (refer to page 3-8). (2) loosen set screws (m6x8: 2pcs), and detach the main motor pulley assembly. Groove on the back o...

Page 49

Riso inc. Technical communications us.Riso.Com chapter 3: main drive [ 3 - 11 ] 0316 4. Removing the main shaft assembly (1) remove the main belt from the machine (refer to page 3-8). (2) remove the following springs. - separator spring - follower spring - sector gear spring - guide roller pressure ...

Page 50

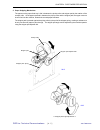

Riso inc. Technical communications us.Riso.Com chapter 3: main drive [ 3 - 12 ] reusable wire harness band switch connectors torsion spring e-ring serviceman safety sw 0317 0318 0319 0320 5. Removing the serviceman safety sw (1) switch off the power, and remove the rear cover and scanner cover;rear....

Page 51

Riso inc. Technical communications us.Riso.Com chapter 3: main drive [ 3 - 13 ] 0321 master loading cover adjustment 1. Print-drum “position-a” adjustment checks and adjustment (1) open the front door. (2) remove a screw ( m4x8: 1pc) to detach the master loading cover. (3) go into the test mode, and...

Page 52

Riso inc. Technical communications us.Riso.Com chapter 3: main drive [ 3 - 14 ] memo.

Page 53: Chapter

Riso inc. Technical communications us.Riso.Com chapter 4: first paper feed section [ 4 - 1 ] chapter 4 : first paper feed section contents mechanism 1. Paper feed tray mechanism .............................................................................................. 4-2 2. Paper feed tray elev...

Page 54

Riso inc. Technical communications us.Riso.Com chapter 4: first paper feed section [ 4 - 2 ] mechanism 1. Paper feed tray mechanism 1) horizontal positioning (horizontal print positioning) of the paper feed tray the paper feed tray can be moved 10 mm to the right or left by turning the tray sliding ...

Page 55

Riso inc. Technical communications us.Riso.Com chapter 4: first paper feed section [ 4 - 3 ] 2. Paper feed tray elevation mechanism the presence of the paper in the paper-feed tray is detected by the paper-detection sensor. When the paper is detected on the paper feed tray, and the start key is pres...

Page 56

Riso inc. Technical communications us.Riso.Com chapter 4: first paper feed section [ 4 - 4 ] 0405 > rz2 models: there is only one upper limit sensor, which is upper limit sensor b. The upper limit position of the paper feed tray is when the upper-limit actuator plate (standard paper) blocks the ligh...

Page 57

Riso inc. Technical communications us.Riso.Com chapter 4: first paper feed section [ 4 - 5 ] 3. Paper feed tray safety mechanism the paper feed tray upper safety switch and the paper feed tray lower safety switch ensure the safety while the paper feed tray is being raised or lowered. If the paper fe...

Page 58

Riso inc. Technical communications us.Riso.Com chapter 4: first paper feed section [ 4 - 6 ] 4. First paper feed drive mechanism when the start key is pressed for a printing job, the main motor activates and the drive is transferred by the main belt to rotate the print drum. When the print drum rota...

Page 59

Riso inc. Technical communications us.Riso.Com chapter 4: first paper feed section [ 4 - 7 ] 5. Paper stripping mechanism the papers on the paper feed tray is fed in between the pickup roller and stripper pad by the rotation of the scraper roller. Of the papers pushed in between the pickup roller an...

Page 60

Riso inc. Technical communications us.Riso.Com chapter 4: first paper feed section [ 4 - 8 ] 6. Paper feed pressure adjustment mechanism the paper feed pressure adjust lever is located on the left-hand side of the first paper feed stay assembly. Sliding the lever to the right or left changes the pap...

Page 61

Riso inc. Technical communications us.Riso.Com chapter 4: first paper feed section [ 4 - 9 ] disassembly 1. Removing the paper feed tray unit (1) lower the paper feed tray all the way down and switch off the machine power. (2) close the paper feed tray and detach the hinge cover by removing screws (...

Page 62

Riso inc. Technical communications us.Riso.Com chapter 4: first paper feed section [ 4 - 10 ] flat wire harness cover connector cover connector flat wire harness paper feed tray mount wiire harness holder 0416 0417 0418.

Page 63

Riso inc. Technical communications us.Riso.Com chapter 4: first paper feed section [ 4 - 11 ] 2. Removing paper det. Sensor, paper size det. Sensor and paper width potentiometer (1) lower the paper-feed tray all the way down, switch off the power to the machine. (2) remove the paper feed tray from t...

Page 64

Riso inc. Technical communications us.Riso.Com chapter 4: first paper feed section [ 4 - 12 ] removing the paper detection sensor and paper size detection sensor (6) unplug connectors from each sensor and unhook the craws of the sensors and remove from the tray. Removing the paper width potentiomete...

Page 65

Riso inc. Technical communications us.Riso.Com chapter 4: first paper feed section [ 4 - 13 ] 3. Removing the scraper roller and pick up roller removing the scraper rollers (1) lower the paper feed tray all the way down, and switch off the machine power. (2) remove the snap ring from the scraper sha...

Page 66

Riso inc. Technical communications us.Riso.Com chapter 4: first paper feed section [ 4 - 14 ] 4. Removing the paper feed roller assembly (1) lower the paper feed tray all the way down, and switch off the machine power. (2) remove the paper feed cover by removing screws (m4x8: 2pcs). (3) remove a cap...

Page 67

Riso inc. Technical communications us.Riso.Com chapter 4: first paper feed section [ 4 - 15 ] 5. Removing the paper feed tray button and paper feed tray upper safety switch (1) lower the paper feed tray all the way down and turn off the machine power. (2) remove the following components. - paper fee...

Page 68

Riso inc. Technical communications us.Riso.Com chapter 4: first paper feed section [ 4 - 16 ] 6. Removing paper feed tray upper limit sensor and paper feed pressure sensor (1) lower the paper feed tray fully and switch off the power. (2) remove the paper feed cover. Removing the paper feed upper lim...

Page 69

Riso inc. Technical communications us.Riso.Com chapter 4: first paper feed section [ 4 - 17 ] 7. Removing the paper feed clutch (1) switch off the power and remove the rear cover. (2) remove screws (m4x8: 2pcs), and detach the pickup unit clutch bracket and the bearing metal. (3) unplug the connecto...

Page 70

Riso inc. Technical communications us.Riso.Com chapter 4: first paper feed section [ 4 - 18 ] 8. Removing the elevator motor (1) lower the paper feed tray all the way down and turn off the machine power. (2) remove the front cover. (3) of the elevator springs on each side of the machine, front and b...

Page 71

Riso inc. Technical communications us.Riso.Com chapter 4: first paper feed section [ 4 - 19 ] 9. Removing the paper feed tray lower safety switch (1) switch off the machine power and remove the rear cover. (2) detach the paper feed tray lower safety switch spring. (3) unplug the connector and detach...

Page 72

Riso inc. Technical communications us.Riso.Com chapter 4: first paper feed section [ 4 - 20 ] 10. Removing the stripper unit (1) lower the paper feed tray all the way down and turn off the machine power. (2) lower the slide-lock to release the lock on the stripper unit. (3) push the stripper release...

Page 73

Riso inc. Technical communications us.Riso.Com chapter 4: first paper feed section [ 4 - 21 ] 11. Removing the stripper pad assembly (1) lower the paper feed tray all the way down and turn off the machine power. (2) remove the stripper unit. (3) lift up the stripper pad assembly by hand and detach f...

Page 74

Riso inc. Technical communications us.Riso.Com chapter 4: first paper feed section [ 4 - 22 ] adjustment 1. Upper limit sensor position adjustment adjustment (1) remove papers from the paper feed tray, and slide the paper-feed pressure lever to “normal”. (2) start test mode no. 681 (paper feed tray ...

Page 75

Riso inc. Technical communications us.Riso.Com chapter 4: first paper feed section [ 4 - 23 ] 2. Stripper unit adjustment adjustment (1) slide the paper feed pressure adjust lever to the proper position to match the paper type before printing. (2) if multiple feeding or non-feeding occurs, adjust th...

Page 76

Riso inc. Technical communications us.Riso.Com chapter 4: first paper feed section [ 4 - 24 ] 3. Paper-feed clutch on angle adjustment checks and adjustment (1) make prints to confirm whether the first paper feeding is smooth or not. (2) if the first paper feeding timing is not smooth, make adjustme...

Page 77

Riso inc. Technical communications us.Riso.Com chapter 4: first paper feed section [ 4 - 25 ] 5. Paper-width potentiometer adjustment checks and adjustment (1) access into protected area test mode by activating test mode no. 9874. (2) set the paper fence to the 105mm line on the paper feed tray, and...

Page 78

Riso inc. Technical communications us.Riso.Com chapter 4: first paper feed section [ 4 - 26 ] memo.

Page 79: Chapter

Riso inc. Technical communications us.Riso.Com chapter 5: second paper feed section [ 5 - 1 ] chapter 5 : second paper feed section contents mechanism 1. Second paper feed mechanism ........................................................................................ 5-2 2. Vertical print positio...

Page 80

Riso inc. Technical communications us.Riso.Com chapter 5: second paper feed section [ 5 - 2 ] sector gear cam timing cam sector gear spring sector gear assembly load spring guide roller pressure spring mechanism 1. Second paper feed mechanism during the printing, the sector gear cam and timing cam r...

Page 81

Riso inc. Technical communications us.Riso.Com chapter 5: second paper feed section [ 5 - 3 ] first paper feed starts when the first paper feed starts by the rotation of the rotation of the scraper roller and pickup roller, the leading edge of the paper arrives to the second paper feed area, between...

Page 82

Riso inc. Technical communications us.Riso.Com chapter 5: second paper feed section [ 5 - 4 ] vertical print positioning assembly planetary gear cam shaft outer vertical positioning gear print positioning pulse motor vertical centering sensor sector gear cam timing cam 2. Vertical print position con...

Page 83

Riso inc. Technical communications us.Riso.Com chapter 5: second paper feed section [ 5 - 5 ] pressing the key on the panel (print image up) when the key is pressed, the print positioning pulse motor moves the vertical print positioning assembly in the counterclockwise direction and the outer vertic...

Page 84

Riso inc. Technical communications us.Riso.Com chapter 5: second paper feed section [ 5 - 6 ] disassembly 1. Removing the guide roller (1) pull out the print drum and switch off the machine power. (2) from the opening on the machine for the print drum, remove the snap ring. Then remove the bearing m...

Page 85

Riso inc. Technical communications us.Riso.Com chapter 5: second paper feed section [ 5 - 7 ] 2. Removing the paper sensor (1) pull out the print drum and switch off the machine power. (2) remove the guide roller. (3) remove a screw ( m3x14: 1pc), and unplug the connector to remove the paper sensor....

Page 86

Riso inc. Technical communications us.Riso.Com chapter 5: second paper feed section [ 5 - 8 ] 3. Removing the timing roller (1) pull out the print drum and switch off the machine power. (2) remove the rear cover. > (3) open the pcb support plate of the power supply pcb and mechanical control pcb. (4...

Page 87

Riso inc. Technical communications us.Riso.Com chapter 5: second paper feed section [ 5 - 9 ] > (8) remove screw (m3x8: 1pc) from the load spring collar. Then remove load spring and load spring collar. (9) remove the washer, and also the bearing from the timing roller adjusting plate. > (10) remove ...

Page 88

Riso inc. Technical communications us.Riso.Com chapter 5: second paper feed section [ 5 - 10 ] 4. Removing the vertical centering sensor (1) switch off the machine power and remove the rear cover. (2) unplug the sensor connector, and by removing a screw (m4x8: 1pc), detach the vertical centering sen...

Page 89

Riso inc. Technical communications us.Riso.Com chapter 5: second paper feed section [ 5 - 11 ] 5. Removing the print-positioning intermediate gear (1) switch off the machine power and remove the rear cover. (2) remove the e-ring and detach the print-positioning intermediate gear. > mount the print-p...

Page 90

Riso inc. Technical communications us.Riso.Com chapter 5: second paper feed section [ 5 - 12 ] 6. Removing the idler gear (1) switch off the machine power and remove the rear cover. (2) remove the print-positioning intermediate gear. (3) remove e-ring and remove the idler gear together with the idle...

Page 91

Riso inc. Technical communications us.Riso.Com chapter 5: second paper feed section [ 5 - 13 ] 7. Removing the paper feed drive unit (1) switch off the machine power, remove the rear cover, and then swing open the pcb bracket of the power supply and mechnical control pcb. (2) insert jig (8mm dia.) i...

Page 92

Riso inc. Technical communications us.Riso.Com chapter 5: second paper feed section [ 5 - 14 ] (4) unplug the connector of the print positioning pulse motor. (5) unplug the connector of the vertical centering sensor, and unhook the reusable band. (6) remove screws ( m4x8: 4pcs) of the paper feed dri...

Page 93

Riso inc. Technical communications us.Riso.Com chapter 5: second paper feed section [ 5 - 15 ] > mount the paper feed drive unit on the machine so that one positioning mark on the main gear aligns in between the two positioning marks on the inner vertical positioning gear, making sure that 8mm diame...

Page 94

Riso inc. Technical communications us.Riso.Com chapter 5: second paper feed section [ 5 - 16 ] 8. Removing the print positioning pulse motor (1) switch off the machine power, remove the rear cover, and swing open the pcb bracket of the power supply and mechanical control pcbs. (2) remove the paper f...

Page 95

Riso inc. Technical communications us.Riso.Com chapter 5: second paper feed section [ 5 - 17 ] adjustment 1. G-lever mounting position adjustment checks and adjustment (1) run test mode no.889 (g-lever mounting position) and then switch off the machine power. (2) remove the rear cover. (3) loosen th...

Page 96

Riso inc. Technical communications us.Riso.Com chapter 5: second paper feed section [ 5 - 18 ] 2. Paper feed skew adjustment checks and adjustment (1) load a3-size papers on the paper feed tray, run test mode no. 81 to make cross-line image, and make 5 prints, and use the 5th print to check. (2) mea...

Page 97

Riso inc. Technical communications us.Riso.Com chapter 5: second paper feed section [ 5 - 19 ] 3. Print start position adjustment checks and adjustment (1) load a3-size papers on the paper feed tray, run test mode no. 80 to make checker-flag image, and make 10 prints at speed 3 and use the 10th prin...

Page 98

Riso inc. Technical communications us.Riso.Com chapter 5: second paper feed section [ 5 - 20 ] memo.

Page 99: Chapter

Riso inc. Technical communications us.Riso.Com chapter 6: press section [ 6 - 1 ] chapter 6 : press section contents mechanism 1. Press mechanism ............................................................................................................... 6-2 2. Pressure control mechanism (rz3 ser...

Page 100

Riso inc. Technical communications us.Riso.Com chapter 6: press section [ 6 - 2 ] clamp plate base pressure cam print drum pressure lever;spring pressure spring pressure lever;cam pressure shaft main motor solenoid lever pressure solenoid 0601 mechanism 1. Press mechanism at the start of a printing ...

Page 101

Riso inc. Technical communications us.Riso.Com chapter 6: press section [ 6 - 3 ] pressure roller is raised pressure roller is lowered print drum pressure cam pressure lever;spring pressure roller pressure lever;cam pressure shaft print drum clamp plate base 0602.

Page 102

Riso inc. Technical communications us.Riso.Com chapter 6: press section [ 6 - 4 ] 2. Pressure control mechanism (rz3 series) pressing the or button of the print density key on the operation panel activates the pressure control pulse motor and moves the pressure spring tension plate. The movement of ...

Page 103

Riso inc. Technical communications us.Riso.Com chapter 6: press section [ 6 - 5 ] disassembly 1. Removing the pressure roller (1) pull out the print drum and switch off the machine power. (2) insert a screwdriver through the hole of the front frame, and remove the shouldered screw. (3) pull the pres...

Page 104

Riso inc. Technical communications us.Riso.Com chapter 6: press section [ 6 - 6 ] 2. Removing the pressure lever:spring & pressure lever;cam (1) remove the main belt. (refer to chapter 3) (2) unhook the follower spring. (3) loosen cap screws (m6x10: 2pcs), and remove the pressure;spring and pressure...

Page 105

Riso inc. Technical communications us.Riso.Com chapter 6: press section [ 6 - 7 ] 3. Removing the pressure hp sensor (rz 3 series) (1) switch off the machine power, remove the rear cover, and swing open the pcb bracket of the power supply pcb and mechanical control pcb. (2) remove the pressure hp se...

Page 106

Riso inc. Technical communications us.Riso.Com chapter 6: press section [ 6 - 8 ] 4. Removing the pressure control motor (rz 3 series) (1) switch off the machine power, remove the rear cover, and swing open the pcb bracket of the power supply pcb and mechanical control pcb. (2) remove the pressure s...

Page 107

Riso inc. Technical communications us.Riso.Com chapter 6: press section [ 6 - 9 ] adjustment 1. Mounting position of the pressure lever;spring checks and adjustment (1) make confidential master on the print drum and turn off the machine power. (2) remove the main cover assembly. (refer to chapter 3)...

Page 108

Riso inc. Technical communications us.Riso.Com chapter 6: press section [ 6 - 10 ] (6) if step (5) is out of the specification, remove the pressure spring and loosen the two cap screws on the pressure lever;spring. (7) align the hole on the pressure lever;spring with the position-b phase alignment h...

Page 109: Contents

Riso inc. Technical communications us.Riso.Com chapter 7: paper ejection section [ 7 - 1 ] contents mechanism 1. Paper ejection mechanism ................................................................................................. 7-2 2. Paper separator mechanism ..................................

Page 110

Riso inc. Technical communications us.Riso.Com chapter 7: paper ejection section [ 7 - 2 ] mechanism 1. Paper ejection mechanism the printed paper is removed from the print drum by the separator, air blown from the separator and air blown from two separation fans (one separation fan for model rz2 se...

Page 111

Riso inc. Technical communications us.Riso.Com chapter 7: paper ejection section [ 7 - 3 ] 2. Paper separator mechanism the tip of the separator is positioned close to the print drum surface when separating the paper from the print drum. As the print drum rotates and the clamp plate base approaches ...

Page 112

Riso inc. Technical communications us.Riso.Com chapter 7: paper ejection section [ 7 - 4 ] 3. Paper-ejection-wing mechanism (rz 3 series) the paper-ejection-wing position can be set to a desired position manually by rotating a dial knob in following three positions. (2) both the wing-m and belt roll...

Page 113

Riso inc. Technical communications us.Riso.Com chapter 7: paper ejection section [ 7 - 5 ] disassembly 1. Removing the paper receiving tray (1) open the paper receiving tray to an angle of about 45 degrees and lift it vertically upwards to detach from the machine. Paper receiving tray 0708.

Page 114

Riso inc. Technical communications us.Riso.Com chapter 7: paper ejection section [ 7 - 6 ] 2. Removing the suction unit (1) switch off the machine power and detach the paper receiving tray. (2) remove the paper ejection cover by removing screws (m4x8: 4pcs). (3) remove the wing cam assembly. (only o...

Page 115

Riso inc. Technical communications us.Riso.Com chapter 7: paper ejection section [ 7 - 7 ] 3. Removing the paper ejection motor and paper ejection fg sensor (1) switch off the machine power and remove following components . - paper receiving tray - paper ejection cover - suction unit (2) remove the ...

Page 116

Riso inc. Technical communications us.Riso.Com chapter 7: paper ejection section [ 7 - 8 ] 4-1. Removing the suction upper assembly (rz3 series) (1) switch off the machine power and remove following components. - paper receiving tray - paper ejection cover - suction unit (2) remove the timing belt (...

Page 117

Riso inc. Technical communications us.Riso.Com chapter 7: paper ejection section [ 7 - 9 ] fixed-wing;front 4-2. Removing the suction upper assembly (rz2 series) (1) switch off the power, and remove the following components. - paper receiving tray - paper ejection cover - suction unit (2) remove the...

Page 118

Riso inc. Technical communications us.Riso.Com chapter 7: paper ejection section [ 7 - 10 ] 5. Removing the paper ejection sensor (1) switch off the machine power and remove the following components. - paper receiving tray - paper ejection cover - suction unit (2) remove the suction upper assembly. ...

Page 119

Riso inc. Technical communications us.Riso.Com chapter 7: paper ejection section [ 7 - 11 ] joint plate-s joint plate-m suction box shaft-2 assembly wing-s transfer base transfer base transfer belts 6-1. Removing the transfer belts (rz3 series) (1) switch off the machine power and remove the followi...

Page 120

Riso inc. Technical communications us.Riso.Com chapter 7: paper ejection section [ 7 - 12 ] 6-2. Removing the transfer belts (rz2 series) (1) switch off the machine power, remove the following components. - paper receiving tray - paper ejection cover - suction unit (2) remove the suction upper assem...

Page 121

Riso inc. Technical communications us.Riso.Com chapter 7: paper ejection section [ 7 - 13 ] 7. Removing the separation fan unit (1) switch off the machine power and remove the paper receiving tray. (2) remove screws (m4x8: 2pcs), unplug the connector, and remove the separation fan. - precaution in a...

Page 122

Riso inc. Technical communications us.Riso.Com chapter 7: paper ejection section [ 7 - 14 ] (1) insert the u-shaped hooks on the separation fan unit into the shafts on the right and left of the machine frame. (2) fit the flat pins on the machine frame into the small rectangular holes on the far righ...

Page 123

Riso inc. Technical communications us.Riso.Com chapter 7: paper ejection section [ 7 - 15 ] 8. Removing the separator (1) switch off the machine power and remove the following components. - paper receiving tray - separation fan unit (2) pinch the power-band, slide it away from the separator, and pul...

Page 124

Riso inc. Technical communications us.Riso.Com chapter 7: paper ejection section [ 7 - 16 ] 9. Removing the separation lever (1) remove the main shaft assembly. (refer to chapter 3) (2) remove the cap screw (m3x10: 1pc) and detach the separator lever assembly. 0739 pressure lever;spring separator le...

Page 125

Riso inc. Technical communications us.Riso.Com chapter 7: paper ejection section [ 7 - 17 ] 10. Removing the o-ring, piston and cylinder of the air pump. (1) switch off the machine power, remove the rear cover, and swing open the pcb bracket of the power supply pcb and mechanical control pcb. (2) re...

Page 126

Riso inc. Technical communications us.Riso.Com chapter 7: paper ejection section [ 7 - 18 ] (1) when installing the piston assembly back into the cylinder, make sure that the concave side of the rib on the arm faces out. (2) when installing the air pump gear assembly back on the machine, make sure t...

Page 127

Riso inc. Technical communications us.Riso.Com chapter 7: paper ejection section [ 7 - 19 ] removing the piston (6) remove the e-ring, detach the arm shaft, and remove the piston. > (1) apply white plastic grease on the piston and o-ring. (2) when installing the piston assembly back into the cylinde...

Page 128

Riso inc. Technical communications us.Riso.Com chapter 7: paper ejection section [ 7 - 20 ] removing the air pump cylinder (6) remove screws (m4x8: 5pcs) and detach the air pump base. (7) remove screws (m4x8: 4pcs) and detach the air pump cylinder. Caution: (1) be careful not to misplace the air rel...

Page 129

Riso inc. Technical communications us.Riso.Com chapter 7: paper ejection section [ 7 - 21 ] adjustment 1. Separator mounting position checks and adjustment (1) using test chart no.15, create a master and make prints. Confirm that neither paper jamming on the drum nor black thin line (caused by the s...

Page 130

Riso inc. Technical communications us.Riso.Com chapter 7: paper ejection section [ 7 - 22 ] symptoms (1) if the tip of the separator touches the print drum surface, it will scratch the surface of the master, causing a black line in the center of the prints. (2) if the gap is too wide, the separator ...

Page 131: Contents

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 1 ] contents mechanism 1. Master on the drum check mechanism (before printing) .................................................. 8-2 2. Print drum set mechanism ..........................................................

Page 132

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 2 ] mechanism 1. Master on the drum check mechanism (before printing) the machine checks for the presence of the master on the print drum at the start of a print job.. With a push of the start key to begin the printin...

Page 133

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 3 ] 2. Print drum set mechanism the removal and insertion of the print drum is done at print drum position-b stop position. Whether the print drum is set in the machine or not is checked by the drawer connector of the...

Page 134

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 4 ] 3. Print drum rotation mechanism when the main motor rotates, the drive is transferred in following sequence. The main motor drive is transferred to the main shaft assembly via main belt, and via the drive joint t...

Page 135

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 5 ] 4. Inking mechanism the ink is pumped into the print drum from the ink bottle when the ink sensor in the print drum no longer detects the ink in the drum while the drum is rotating with the main motor on. The pump...

Page 136

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 6 ] disassembly 1. Removing the drum lock sensor, drum solenoid, drum safety switch (1) remove the print drum from the machine, switch off the machine power and remove the front cover. (2) remove screws (m4x8: 3pcs), ...

Page 137

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 7 ] removing the print drum lock solenoid (3) remove screws (m3x6: 2pcs) and detach the print drum lock solenoid. Removing the print drum safety switch (3) unhook the torsion spring, remove the e-ring, and detach the ...

Page 138

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 8 ] tail hanger 2. Removing the screen assembly (1) make a confidential master on the print drum and pull the print drum out of the machine. (2) remove screws from the tail hanger (m3x6: 2pcs). (3) remove screws from ...

Page 139

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 9 ] (1) mount and screw the top hanger on the print drum and wrap the screen around the drum. Then tentatively attach the screws on the tail hanger, very lightly. 2) hook the screen jigs through the holes on the left ...

Page 140

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 10 ] 3. Removing the master clamp base assembly (1) make a confidential master on the print drum and pull out the drum from the machine. (2) remove screws (m3x6: 4pcs) and detach the master clamp base assembly from th...

Page 141

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 11 ] 4. Removing the drum body (1) make a confidential master on the print drum and pull out the drum from the machine. (2) remove the following components. - screen assembly - master clamp base assembly (3) loosen sc...

Page 142

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 12 ] (1) on the outskirts of the tail end of the drum body, close to the drum flanges are marked with arrow marks and f & r imprints. The f imprint should face the flange-f, and r imprint should face the flange-r. Wit...

Page 143

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 13 ] tape (6) on the second screw holes from the top at the top end of the drum body, use screws (m3x6: 2pcs from another part of the drum) to tightly hod the drum body onto the drum flanges. (7) remove the screen jig...

Page 144

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 14 ] 5. Removing the ink scraper plate assembly f & r (1) make a confidential master on the print drum and pull out the drum from the machine. (2) remove the following components. - screen assembly - master clamp base...

Page 145

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 15 ] 6. Removing the ink pump assembly (1) make a confidential master on the print drum and pull out the drum from the machine. (2) remove the following components. - screen assembly - master clamp base assembly - dru...

Page 146

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 16 ] ink bottle guide assembly inspection cap antenna connector pin 7. Removing the ink bottle guide assembly (1) make a confidential master on the print drum and pull out the drum from the machine. (2) remove the fol...

Page 147

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 17 ] 8. Removing the ink bottle lock assembly & antenna pcb (1) make a confidential master on the print drum and pull out the drum from the machine. (2) remove the following components. - screen assembly - master clam...

Page 148

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 18 ] connector 9. Removing the ink sensor pcb (1) make a confidential master on the print drum and pull out the drum from the machine. (2) remove the following components. - screen assembly - master clamp base assembl...

Page 149

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 19 ] print drum pcb 10. Removing the print drum pcb (1) remove the print drum from the machine, and detach the drum cover from the drum by removing screws (m3x6: 4pcs). (2) disconnect wire harness connectors (6 locati...

Page 150

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 20 ] drum joint drum rear frame assembly drum side frame drum side frame drum side frame 11. Removing the drum joint (1) remove the print drum from the machine. (2) detach both the left and right drum side frames by r...

Page 151

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 21 ] flange-r 12. Removing the flange-r (1) make a confidential master on the print drum and pull out the drum from the machine. (2) remove the following components. - screen assembly - master clamp base assembly - dr...

Page 152

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 22 ] 13. Removing the flange-f (1) make a confidential master on the print drum and pull out the drum from the machine. (2) remove the following components. - screen assembly - master clamp base assembly - drum body -...

Page 153

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 23 ] ink drive gear squeegee drive gear drive shaft lock plate squeegee gear squeegee idle gear 14. Removing the squeegee roller (1) make a confidential master on the print drum and pull out the drum from the machine....

Page 154

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 24 ] (8) remove screws (m4x8: 3pcs) and also the shoulder screw from the front of the print drum. Shoulder screw shoulder screw 0859 0860 (9) remove screws (m4x8: 2pcs) and also the shoulder screw from the rear of the...

Page 155

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 25 ] squeegee-gap cam (10) detach the squeegee unit from the print drum by unhooking the hook portion on the squeegee unit from the plastic squeegee-gap cam in the front and rear of the print drum. - continues on next...

Page 156

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 26 ] (11) pull out the driven shaft from the squeegee unit. * be careful not to lose the bearing metal and o-ring as these will come off together with the shaft. (12) pull the squeegee side frames f & r off from the e...

Page 157

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 27 ] adjustment 1. Squeegee gap adjustment checks and adjustment (1) remove the print drum from the machine and detach following components off the print drum. - screen assembly - drum body - drum cover (2) detach the...

Page 158

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 28 ] flange-r squeegee-gap adjustment plate securing screw on the squeegee-gap adjustment plate symptoms: (1) if the squeegee gap is too wide, too much ink is transferred onto the inner surface of the print drum and m...

Page 159

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 29 ] 2. Squeegee pressure balance adjustment checks and adjustment (1) create a master using test chart no.14 and make prints. Check the left and right of the prints to compare the print density and confirm that the d...

Page 160

Riso inc. Technical communications us.Riso.Com chapter 8: print drum section [ 8 - 30 ] (3) remove the print drum from the machine. (4) looking at the rear of the print drum, find two securing screws of the squeegee side frame-r (indicated by the arrow marks on the photograph) and loosen the two scr...

Page 161: Chapter

Riso inc. Technical communications us.Riso.Com chapter 9: clamp unit [ 9 - 1 ] chapter 9 : clamp unit contents mechanism 1. Clamp unit home positioning mechanism ......................................................................... 9-2 2. Clamp plate opening mechanism ..............................

Page 162

Riso inc. Technical communications us.Riso.Com chapter 9: clamp unit [ 9 - 2 ] mechanism 1. Clamp unit home positioning mechanism the clamp unit is checked if the unit is at home position or not each time the machine power is turned on or the all-reset key is pressed. The unit is judged to be at hom...

Page 163

Riso inc. Technical communications us.Riso.Com chapter 9: clamp unit [ 9 - 3 ] 2. Clamp plate opening mechanism when the start key is pressed for the master-making or confidential-master making, the print drum starts to rotate from its position-b. After the presence of the master on the print drum i...

Page 164

Riso inc. Technical communications us.Riso.Com chapter 9: clamp unit [ 9 - 4 ] 3. Drum position-a compensation the print drum rotates to remove the master and as it comes back to position-a, the clamp opening cam at its lowered position opens the clamp plage and lifts up the ejection plate. As the p...

Page 165

Riso inc. Technical communications us.Riso.Com chapter 9: clamp unit [ 9 - 5 ] 4. Clamp plate master clamp mechanism once the load pulse motor on the master-making area feeds a set length of the master material onto the print drum, the clamp motor activates to rotate the clamp cam until the light pa...

Page 166

Riso inc. Technical communications us.Riso.Com chapter 9: clamp unit [ 9 - 6 ] disassembly 1. Removing the clamp unit (1) switch off the machine power, remove the rear cover, and swing open the pcb bracket of the power supply pcb and mechanical control pcb. (2) disconnect the clamp motor connector a...

Page 167

Riso inc. Technical communications us.Riso.Com chapter 9: clamp unit [ 9 - 7 ] spur gear connector clamp motor 2. Removing the clamp motor (1) switch off the machine power, remove the rear cover, and swing open the pcb bracket of the power supply pcb and mechanical control pcb. (2) detach the clamp ...

Page 168

Riso inc. Technical communications us.Riso.Com chapter 9: clamp unit [ 9 - 8 ] 3. Removing the clamp sensors a & b (1) switch off the machine power, remove the rear cover, and swing open the pcb bracket of the power supply pcb and mechanical control pcb. (2) detach the clamp unit. (3) unplug the reu...

Page 169: Contents

Riso inc. Technical communications us.Riso.Com chapter 10: master removal section [ 10 - 1 ] contents mechanism 1. Master removal mechanism ............................................................................................ 10-2 2. Master on the drum check mechanism (before master removal) ...

Page 170

Riso inc. Technical communications us.Riso.Com chapter 10: master removal section [ 10 - 2 ] mechanism 1. Master removal mechanism master on the print drum is removed from the print drum and disposed in following sequence. (1) at the start of master removal, the master sensor checks for the presence...

Page 171

Riso inc. Technical communications us.Riso.Com chapter 10: master removal section [ 10 - 3 ] 2. Master on the drum check mechanism (before master removal) when creating a confidential or normal master, the print drum makes one rotation from its position-b. During this rotation, the master sensor che...

Page 172

Riso inc. Technical communications us.Riso.Com chapter 10: master removal section [ 10 - 4 ] 3. Removed master vertical transport mechanism at the start of the clamp plate opening action to remove the master from the drum, the master removal motor activates to rotate the master removal rollers to ca...

Page 173

Riso inc. Technical communications us.Riso.Com chapter 10: master removal section [ 10 - 5 ] 4. Disposed master compression mechanism 1) initializing movement the initialization action of the master compression plate is made in two occasions. (1) if the master compression plate hp sensor is found op...

Page 174

Riso inc. Technical communications us.Riso.Com chapter 10: master removal section [ 10 - 6 ] 5. Master disposal box safety sw the master disposal box safety switch checks whether the master disposal box is correctly set on the machine. When the master disposal box is not set on the machine, the mast...

Page 175

Riso inc. Technical communications us.Riso.Com chapter 10: master removal section [ 10 - 7 ] reusable band disassembly 1. Removing the master compression fg sensor (1) switch off the machine power and remove the front cover. (2) disconnect the connector to the sensor and unplug the reusable band fro...

Page 176

Riso inc. Technical communications us.Riso.Com chapter 10: master removal section [ 10 - 8 ] 2. Removing the master compression motor (1) switch off the machine power and remove the front cover. (2) remove a screw (m3x6: 1pc) and detach the compression gear cover. (3) as the master compression plate...

Page 177

Riso inc. Technical communications us.Riso.Com chapter 10: master removal section [ 10 - 9 ] 3. Removing the master removal unit (1) switch off the machine power, remove the master disposal box and detach the front cover. (2) remove the master removal covers f & r by removing screw (m3x8: 1pc each)....

Page 178

Riso inc. Technical communications us.Riso.Com chapter 10: master removal section [ 10 - 10 ] 4. Removing the master removal sensor & master sensor (1) switch off the machine power and detach the master removal unit from the machine. Removing the master sensor (2) disconnect the sensor connector, re...

Page 179

Riso inc. Technical communications us.Riso.Com chapter 10: master removal section [ 10 - 11 ] spur gear 5. Removing the master removal motor & master removal motor fg sensor removing the master removal motor (1) switch off the machine power and detach the master removal unit. (2) remove an e-ring an...

Page 180

Riso inc. Technical communications us.Riso.Com chapter 10: master removal section [ 10 - 12 ] 6. Removing the master compression plate hp sensor (1) switch off the machine power and detach the master removal unit. (2) remove the compression gear cover and spur gear, and then lower the master compres...

Page 181

Riso inc. Technical communications us.Riso.Com chapter 10: master removal section [ 10 - 13 ] master disposal box safety sw 7. Removing the master disposal box safety sw (1) switch off the machine power and detach the master removal unit. (2) remove a screw (m3x6: 1pc) and detach the master disposal...

Page 182

Riso inc. Technical communications us.Riso.Com chapter 10: master removal section [ 10 - 14 ] 8. Removing the master removal roller (bottom) (1) switch off the machine power and detach the master removal unit. (2) remove the master disposal roller lock lever and master disposal box guiding plate. (3...

Page 183

Riso inc. Technical communications us.Riso.Com chapter 10: master removal section [ 10 - 15 ] (5) remove e-rings and metal bushings from both ends of the roller hook shaft, and detach the master removal roller (bottom) assembly by lifting it upwards. (6) from the rear tip of the master removal rolle...

Page 184

Riso inc. Technical communications us.Riso.Com chapter 10: master removal section [ 10 - 16 ] 9. Removing the master compression plate (1) switch off the machine power and detach the master removal unit. (2) detach the compression gear cover and spur gear to lower the master compression plate. (3) r...

Page 185

Riso inc. Technical communications us.Riso.Com chapter 10: master removal section [ 10 - 17 ] 10. Removing the pulley shaft (1) switch off the machine power and detach the master removal unit. (2) press the master removal roller release lever to release the master removal roller (bottom). (3) detach...

Page 186

Riso inc. Technical communications us.Riso.Com chapter 10: master removal section [ 10 - 18 ] 11. Removing the master removal roller (upper) (1) switch off the machine power and detach the master removal unit. (2) press the master removal roller release lever to release the master removal roller (bo...

Page 187

Riso inc. Technical communications us.Riso.Com chapter 10: master removal section [ 10 - 19 ] 12. Removing the round belts (1) switch off the machine power and detach the master removal unit. (2) press the master removal roller release lever to release the master removal roller (bottom). (3) removin...

Page 188

Riso inc. Technical communications us.Riso.Com chapter 10: master removal section [ 10 - 20 ] 13. Removing the master removal housing assembly (1) switch off the machine power and detach the master removal unit. (2) detach the compression gear cover and spur gear to lower the master compression plat...

Page 189

Riso inc. Technical communications us.Riso.Com chapter 10: master removal section [ 10 - 21 ] boss on the release lever groove on the roller hook-f 1055 1056 1057.

Page 190

Riso inc. Technical communications us.Riso.Com chapter 10: master removal section [ 10 - 22 ] memo.

Page 191: Contents

Riso inc. Technical communications us.Riso.Com chapter 11: fb original scanning section (600 dpi) [ 11 - 1 ] contents mechanism 1. Original scanning mechanism .......................................................................................... 11-2 2. Flatbed initialization movement .............

Page 192

Riso inc. Technical communications us.Riso.Com chapter 11: fb original scanning section (600 dpi) [ 11 - 2 ] mechanism 1. Original scanning mechanism the fb read pulse motor drives the front and rear wire drum by timing belts with the speed reduced by two speed reduction pulleys. The wire drive syst...

Page 193

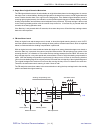

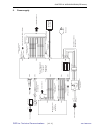

Riso inc. Technical communications us.Riso.Com chapter 11: fb original scanning section (600 dpi) [ 11 - 3 ] drive system diagram optical system diagram fb read pulse motor timing belt 1 timing belt 2 pulley 1 lamp carriage pulley 2 mirror carriage wire wire spool pulley mirror no.2 reflector origin...

Page 194

Riso inc. Technical communications us.Riso.Com chapter 11: fb original scanning section (600 dpi) [ 11 - 4 ] 2. Flatbed initialization movement initialization is performed in the following situations to bring the flatbed unit to the home position. - when the machine power is switched on. - when reco...

Page 195

Riso inc. Technical communications us.Riso.Com chapter 11: fb original scanning section (600 dpi) [ 11 - 5 ] 2.5mm 2.5mm 10mm 6.5mm 3.5mm 15mm 32mm 8mm 3. Stage-glass original detection mechanism the fb original detection sensor checks whether an original has been placed on the stage glass. As soon ...

Page 196

Riso inc. Technical communications us.Riso.Com chapter 11: fb original scanning section (600 dpi) [ 11 - 6 ] 5. Fb scanning mechanism when the start key is pressed, the fb read pulse motor activates to move the lamp carriage in the scanning direction. After the top 4 mm of the original is skipped, t...

Page 197

Riso inc. Technical communications us.Riso.Com chapter 11: fb original scanning section (600 dpi) [ 11 - 7 ] disassembly 1. Removing the scanner unit (1) switch off the machine power and remove the following covers. - stage cover - scanner cover;paper feed - scanner cover;paper ejection - scanner co...

Page 198

Riso inc. Technical communications us.Riso.Com chapter 11: fb original scanning section (600 dpi) [ 11 - 8 ] 2. Removing the stage glass (1) switch off the machine power and remove the following covers. - stage cover - scanner cover;paper feed - scanner cover;paper ejection - scanner cover;rear - op...

Page 199

Riso inc. Technical communications us.Riso.Com chapter 11: fb original scanning section (600 dpi) [ 11 - 9 ] 3. Removing the fb original detection sensor (1) switch off the machine power and remove the stage glass. (2) remove screws (m3x6: 3pcs), lift the sensor cover with the fb original detection ...

Page 200

Riso inc. Technical communications us.Riso.Com chapter 11: fb original scanning section (600 dpi) [ 11 - 10 ] 4. Removing the scanner lamp (1) run test mode no.287 (scanner lamp replace positioning) and switch off the machine power. (2) remove the stage glass. (3) remove screws( m3x6: 2pcs) and deta...

Page 201

Riso inc. Technical communications us.Riso.Com chapter 11: fb original scanning section (600 dpi) [ 11 - 11 ] 5. Removing the ccd unit (1) switch off the machine power and remove the stage glass. (2) remove screws (m3x6: 3pcs) and detach the ccd cover. (3) disconnect the ccd cable from the ccd pcb w...

Page 202

Riso inc. Technical communications us.Riso.Com chapter 11: fb original scanning section (600 dpi) [ 11 - 12 ] 6. Removing the fb/af hp sensor (1) switch off the machine power and remove the scanner cover;paper feed. (2) detach the fb/af hp sensor, together with the sensor bracket, from the scanner u...

Page 203

Riso inc. Technical communications us.Riso.Com chapter 11: fb original scanning section (600 dpi) [ 11 - 13 ] 7. Removing the fb read pulse motor (1) switch off the machine power and remove the scanner cover;paper feed. (2) remove the mounting screws (m3x6: 4pcs) of the fb read pulse motor mounting ...

Page 204

Riso inc. Technical communications us.Riso.Com chapter 11: fb original scanning section (600 dpi) [ 11 - 14 ] adjustment 1. Fb read pulse motor speed adjustment (image elongation & shrinkage in scanning) checks and adjustment (1) set a3-size papers on the paper feed tray and place test chart no.11 o...

Page 205: Contents

Riso inc. Technical communications us.Riso.Com chapter 12: fb original scanning section (300dpi) [ 12 - 1 ] contents mechanism 1. Scanning mechanism ....................................................................................................... 12-2 2. Flatbed initialization movement ..........

Page 206

Riso inc. Technical communications us.Riso.Com chapter 12: fb original scanning section (300 dpi) [ 12 - 2 ] mechanism 1. Scanning mechanism the fb read pulse motor drives the front and rear wire drum by timing belts with the speed reduced by two speed reduction pulleys. The wire drive system for th...

Page 207

Riso inc. Technical communications us.Riso.Com chapter 12: fb original scanning section (300dpi) [ 12 - 3 ] 2. Flatbed initialization movement initialization is performed in the following situations to bring the flatbed unit to the home position. - when the machine power is switched on. - when recov...

Page 208

Riso inc. Technical communications us.Riso.Com chapter 12: fb original scanning section (300 dpi) [ 12 - 4 ] 3. Stage-glass original detection mechanism the fb original detection sensor checks whether an original has been placed on the stage glass. As soon as the stage cover is closed halfway, block...

Page 209

Riso inc. Technical communications us.Riso.Com chapter 12: fb original scanning section (300dpi) [ 12 - 5 ] disassembly 1. Removing the scanner unit (1) switch off the power, and remove the following covers: - stage cover - scanner cover;paper feed - scanner cover;paper ejection - scanner cover;rear...

Page 210

Riso inc. Technical communications us.Riso.Com chapter 12: fb original scanning section (300 dpi) [ 12 - 6 ] 2. Removing the stage glass (1) switch off the power, and remove the following covers: - scanner cover;paper feed - scanner cover;paper ejection (2) remove one stepped screw and the three fla...

Page 211

Riso inc. Technical communications us.Riso.Com chapter 12: fb original scanning section (300dpi) [ 12 - 7 ] 3. Removing the fb original detection sensor (1) switch off the machine power and remove the stage glass. (2) disconnect the connector to the sensor, remove a screw (m3x6: 1pc) and detach the ...

Page 212

Riso inc. Technical communications us.Riso.Com chapter 12: fb original scanning section (300 dpi) [ 12 - 8 ] 4. Removing the fb/af hp sensor (1) switch off the machine power and remove the scanner cover;paper feed. (2) disconnect the connector, remove screw (m3x6: 1pc) and remove the fb/af hp sensor...

Page 213

Riso inc. Technical communications us.Riso.Com chapter 12: fb original scanning section (300dpi) [ 12 - 9 ] 5. Removing the image scanner (1) switch off the machine power and remove the stage glass. (2) remove the four sliders. (these are to be reused on the new image scanner). * be careful not to l...

Page 214

Riso inc. Technical communications us.Riso.Com chapter 12: fb original scanning section (300 dpi) [ 12 - 10 ] 6. Removing the fb read pulse motor (1) switch off the machine power and remove the stage glass. (2) remove the following covers: - stage cover - scanner cover;rear (3) remove the wire-tensi...

Page 215

Riso inc. Technical communications us.Riso.Com chapter 12: fb original scanning section (300dpi) [ 12 - 11 ] adjustment 1. Fb read pulse motor speed adjustment (image elongation & shrinkage in scanning) checks and adjustment (1) set b4-size papers on the paper feed tray and place test chart no.15 on...

Page 216

Riso inc. Technical communications us.Riso.Com chapter 12: fb original scanning section (300 dpi) [ 12 - 12 ] 4. Image scanner position adjustment for this adjustment to be effective, the paper feeding area, especially the skew of the paper needs to be pre- adjusted. Also the three adjustments on th...

Page 217: Chapter

Riso inc. Technical communications us.Riso.Com chapter 13: af scanning section [ 13 - 1 ] chapter 13 : af scanning section contents mechanism 1. Af original set mechanism .............................................................................................. 13-2 2. Af original scanning mecha...

Page 218

Riso inc. Technical communications us.Riso.Com chapter 13: af scanning section [ 13 - 2 ] mechanism 1. Af original set mechanism when the original are set along the original guide fences and the leading edge against the original stopper gate, the af original detection sensor turns on (receives light...

Page 219

Riso inc. Technical communications us.Riso.Com chapter 13: af scanning section [ 13 - 3 ] registration roller gear af read pulse motor af original detection sensor original stopper gate original guide fence pickup roller read roller original ejection roller registration roller timing belt af registr...

Page 220

Riso inc. Technical communications us.Riso.Com chapter 13: af scanning section [ 13 - 4 ] note: abc is an abbreviation for auto base control. 2. Af original scanning mechanism (with auto-base control) -- [available only on rz3 models] this operation occurs only when the original scanning density is ...

Page 221

Riso inc. Technical communications us.Riso.Com chapter 13: af scanning section [ 13 - 5 ] 3. Af original scanning mechanism after the af original setting operation is completed and if the start key is pressed for the scanning operation, the scanner lamp turns on. The fb read pulse motor activates im...

Page 222

Riso inc. Technical communications us.Riso.Com chapter 13: af scanning section [ 13 - 6 ] disassembly 1. Removing the original feed roller assembly (1) switch off the machine power and open the af unit. (2) remove screws (m3x10: 2pcs) and remove the af cover. (3) close the af unit. (4) remove the sn...

Page 223

Riso inc. Technical communications us.Riso.Com chapter 13: af scanning section [ 13 - 7 ] 2. Removing the pickup roller (1) switch off the machine power and open the af unit. (2) remove the af cover and close the af unit. (3) detach the pickup roller by spreading out the tip of pickup-roller-arm by ...

Page 224

Riso inc. Technical communications us.Riso.Com chapter 13: af scanning section [ 13 - 8 ] 3. Removing the original stripper roller (1) switch off the machine power and open the af unit. (2) remove the af cover and close the af unit. (3) remove the original feed roller assembly. (4) remove the pickup...

Page 225

Riso inc. Technical communications us.Riso.Com chapter 13: af scanning section [ 13 - 9 ] 4. Removing the af original detection sensor, af read sensor and af original ejection sensor (1) switch off the machine power and open the af unit. (2) remove the af cover and close the af unit. Removing the or...

Page 226

Riso inc. Technical communications us.Riso.Com chapter 13: af scanning section [ 13 - 10 ] 5. Removing the af read pulse motor (1) switch off the machine power and open the af unit. (2) remover the af cover and close the af unit. (3) disconnect the af-pcb connectors cn1 and cn3. Then remove the grou...

Page 227

Riso inc. Technical communications us.Riso.Com chapter 13: af scanning section [ 13 - 11 ] h-upper guide assembly af read pulse motor 1311 1312.

Page 228

Riso inc. Technical communications us.Riso.Com chapter 13: af scanning section [ 13 - 12 ] 6. Removing the af registration sensor (1) switch off the machine power and open the af unit. (2) remove the af cover and close the af unit. (3) disconnect the connector, move the actuator to the left while li...

Page 229

Riso inc. Technical communications us.Riso.Com chapter 13: af scanning section [ 13 - 13 ] 7. Removing the registration roller, read roller and original ejection roller (1) switch off the machine power and open the af unit. (2) remove the af cover and close the af unit. (3) disconnect the af-pcb con...

Page 230

Riso inc. Technical communications us.Riso.Com chapter 13: af scanning section [ 13 - 14 ] removing the registration roller (8) remove the e-rings, timing pulley, washers, thrust spring and metal bushings off the registration roller. * be careful that the washer and the thrust spring may fly out of ...

Page 231

Riso inc. Technical communications us.Riso.Com chapter 13: af scanning section [ 13 - 15 ] removing the original ejection roller (8) remove the e-ring, timing pulley and metal bushing from the front side of the original ejection roller. Then, remove the e-ring, washers, thrust spring and metal bushi...

Page 232

Riso inc. Technical communications us.Riso.Com chapter 13: af scanning section [ 13 - 16 ] adjustment 1. Af read pulse motor speed adjustment (image elongation & shrinkage control in af scanning) checks and adjustment (1) set a3-size paper in the paper-feeding tray, place test chart no.11 on the af ...

Page 233: Contents

Riso inc. Technical communications us.Riso.Com chapter 14: master making section [ 14 - 1 ] contents mechanism 1. Master making unit components ..................................................................................... 14-2 2. Set detection mechanism .........................................

Page 234

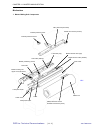

Riso inc. Technical communications us.Riso.Com chapter 14: master making section [ 14 - 2 ] 1401 master end sensor (receive) tph (thermal print head) thermal pressure motor thermal pressure sensor write roller master stocker roller (bottom) master stocker roller (top) load roller (top) load roller (...

Page 235

Riso inc. Technical communications us.Riso.Com chapter 14: master making section [ 14 - 3 ] 2. Set detection mechanism master making unit set detection mechanism as flatbed section cannot be opened or closed, the unit has a mechanism in which the master making unit can be pulled out. The pulling out...

Page 236

Riso inc. Technical communications us.Riso.Com chapter 14: master making section [ 14 - 4 ] 3-1. Master cutting mechanism (rotary cutter : a3 machine) the master is cut by the rotary cutter of the cutter unit, which is rotated by the cutter motor. The cutter motor rotates in one direction. The cutte...

Page 237

Riso inc. Technical communications us.Riso.Com chapter 14: master making section [ 14 - 5 ] 3-2. Master cutting mechanism (shuttle cutter : excluding a3 machine) the master is cut by the round disc shuttle cutter blade sliding from the home position at one end to the cutter stop position on the othe...

Page 238

Riso inc. Technical communications us.Riso.Com chapter 14: master making section [ 14 - 6 ] 4. Tph (thermal print head) elevation mechanism when the machine is at standby or when loading the master onto the print drum after master making, the tph is elevated away from the write roller. The tph is lo...

Page 239

Riso inc. Technical communications us.Riso.Com chapter 14: master making section [ 14 - 7 ] 5. Master set mechanism when the master making unit upper cover is closed and the set sensor detects the closed cover, the master set operation, described below, takes place. First, the tph is elevated down a...

Page 240

Riso inc. Technical communications us.Riso.Com chapter 14: master making section [ 14 - 8 ] 1412 6. Master making movement the start of master making to the start of master loading on the print drum is explained in sequence below. (1) at the start of the master making, the tph comes down to pinch th...

Page 241

Riso inc. Technical communications us.Riso.Com chapter 14: master making section [ 14 - 9 ] safety sw cover disassembly 1. Removing the master making u lock sensor (1) pull out the master making unit and switch off the machine power. (2) detach the safety sw cover by removing a screw (m4x8: 1pc). (3...

Page 242

Riso inc. Technical communications us.Riso.Com chapter 14: master making section [ 14 - 10 ] 2. Removing the print drum, master making u release button, lock solenoid, and safety switch (1) detach the front cover. (2) pull out the master making unit and switch off the machine power. (3) detach the s...

Page 243

Riso inc. Technical communications us.Riso.Com chapter 14: master making section [ 14 - 11 ] removing the master making u safety sw (5) unplug the connectors (2 locations), remove a screw (m4x8: 1pc) and detach the master making u safety sw assembly. (6) unhook the torsion spring, remove an e-ring a...

Page 244

Riso inc. Technical communications us.Riso.Com chapter 14: master making section [ 14 - 12 ] master making unit upper cover 3. Removing the print thermal head assembly (1) pull out the master making unit and switch off the machine power. (2) disconnect the ground wire by removing a screw (m3x6: 1pc)...

Page 245

Riso inc. Technical communications us.Riso.Com chapter 14: master making section [ 14 - 13 ] (6) unplug the connectors (2 locations), detach the snap ring and remove the metal bushing. (7) slide off the metal bushing from the tph bracket and remove the print thermal head assembly. Snap ring metal bu...

Page 246

Riso inc. Technical communications us.Riso.Com chapter 14: master making section [ 14 - 14 ] 4. Removing the thermal pressure motor assembly (1) pull out the master making unit and switch off the machine power. (2) remove the thermal print head assembly. (3) detach the thermal pressure gear cover by...

Page 247

Riso inc. Technical communications us.Riso.Com chapter 14: master making section [ 14 - 15 ] thermal pressure motor assembly (6) detach the thermal pressure motor assembly by disconnecting the connectors to the motor and sensor and removing screws (m3x6: 2pcs). 1428 1429.

Page 248

Riso inc. Technical communications us.Riso.Com chapter 14: master making section [ 14 - 16 ] 5. Removing the master end sensor (receive) assembly (1) pull out the master making unit and switch off the machine power. (2) open the master making unit upper cover. (3) remove a screw (m3x6: 1pc), unplug ...

Page 249

Riso inc. Technical communications us.Riso.Com chapter 14: master making section [ 14 - 17 ] 6. Removing the master detection sensor and master end sensor (send) assembly (1) pull out the master making unit and switch off the machine power. (2) open the master making unit upper cover and remove the ...

Page 250

Riso inc. Technical communications us.Riso.Com chapter 14: master making section [ 14 - 18 ] set guide plate-b spring (front) set guide plate-b set guide plate-b spring (rear) 1436 1437 stopper plate (front) stopper plate (rear) set guide plate-b 1435 1434 screw screw 1488 1487 master flange assembl...

Page 251