Riverside Hydronics EMX SERIES Installation & Maintenance Manual

34-503 07/13

INSTALLATION & MAINTENANCE MANUAL

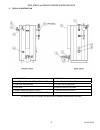

EMX, EMXO and EMXGO SERIES WATER BOILERS

Installation and service must be performed by a qualified service installer, service agency or the gas supplier.

IMPORTANT: THIS MANUAL CONTAINS INFORMATION REQUIRED FOR INSTALLATION, OPERATION AND

MAINTENANCE OF THIS EQUIPMENT. READ AND FOLLOW THE INFORMATION IN THIS MANUAL AND ALL

OTHER PROVIDED INSTRUCTIONS, LABELS AND MARKINGS BEFORE INSTALLING, OPERATING OR

SERVICING THIS UNIT.

FOR YOUR SAFETY

• Do not store or use gasoline or other flammable vapors or

liquids in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in your

building.

• Immediately call your gas supplier from a neighbor's phone.

Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department

This product contains, or may come to contain materials identified

as carcinogenic, or possibly carcinogenic to humans. Before

installing, servicing or removing this product, read and follow the

supplied instructions.

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause property damage,

personal injury, exposure to hazardous materials or loss of life. Refer to the information contained in this

manual. A qualified installer, service agency or the gas supplier, who must read and follow the supplied

instructions before installing, servicing or removing this appliance, must perform installation and service.

This appliance contains, or may come to contain materials that have been identified as carcinogenic, or

possibly carcinogenic to humans.

WARNING: Do not use this appliance if any part has been under water. Immediately call a qualified service

technician to inspect the unit and to replace any part of the control system, any gas controls and any other

items affecting safe appliance operation and which has been under water. Failure to follow these instructions

can cause property damage, personal injury, exposure to hazardous materials or loss of life.

TO THE INSTALLER: After installation, these instructions must be given to the equipment user or left near the

appliance.

SPECIAL INSTRUCTIONS TO THE OWNER: Retain this manual for future reference. These instructions contain

important information that will help you in maintaining and operating this appliance.

Riverside Hydronics

®

, LLC - 990 Haltom Road - Fort Worth, Texas 76117 - Tel 1-800-990-5918