- DL manuals

- Rivet King

- Power Tool

- KS5

- Instruction manual

Rivet King KS5 Instruction manual

Summary of KS5

Page 1

For sales, service or tech support call: 1800-buy-rivet or 1-800-289-7483 instruction manual rk-4500 ks5 & ks6 automatic hand riveter. Continuous riveting machine..

Page 2

2 c ontents safety precautions page 3 specifications page 4 standard rivets page 5 types of connecting tape / standard accessories page 6 preparing the tool for service page 7-8 maintenance page 9-14 installing and removing connecting tape page 15-16 troubleshooting page 17-18 assembly drawings part...

Page 3

3 s afety d o not use outside deisng intent or with equipment that is not recommended by the manufacturer . A lways disconnect the air supply before attempting any maintenance or adjustment / fitting of nose equipment d o not operate a tool that is directed towards any person ( s ) or with the nose ...

Page 4

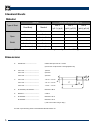

4 s pecifications the specifications and information contained in this manual are applicable only to the tool with which it was supplied. Industrial rivet & fastener co reserve the right to make any changes without notice as part of industrial rivet & fastener co policy of continuous improvement. S ...

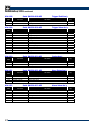

Page 5

5 c d e a f b standard rivets material type of rivet material rivet outer diameter (mm) (in) rivet body mandrel size 4 size 5 size 6 (φ3.2) (φ1/8) (φ4.0) (φ5/32) (φ4.8) (φ3/16) aluminum aluminum ○ ○ ○ open aluminum steel ○ ○ ○ aluminum stainless steel ○ ○ ○ shield steel steel ○ ○ ○ stainless steel s...

Page 6

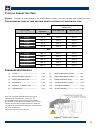

6 t ypes of c onnecting t ape d anger ! I n order to avoid damage to the riveter and accidents , use only the rivet king connecting tape . T able showing types of tape and tape selection o pen type and s hield type . S tandard a ccessories (1) jet oiler ------------------------------------ 1 pcs (7)...

Page 7

7 a ir supply the rivet tool is powered by compressed air at an optimum pressure of 90 psi (6 bar) the use of a pressure regulator filter/lubricator unit within 3 meters of the tool is highly recommended to extend the life of the tool. Dirt and/or water in the air supply can seriously impact the per...

Page 8

8 n osepiece – check to make sure it is the correct one 1 11 . .. Measure the diameter of the rivet to be placed. 2 22 . .. Insure the proper nose piece is provided with the tool. (see rivet & nose piece selection, page13). If the proper nose piece is not provided with the tool, call the sales depar...

Page 9

9 m aintenance in order to maintain the tool in a safe working order it is important to carry out regular maintenance as prescribed by the manufacturer. A thorough inspection replacement of all seals within the tool should be carried out after 500,000 placings or annually, whichever is the sooner. I...

Page 10

10 3. While holding the trigger, affix the nose piston as far back as it will go, and remove the air plug. (drawing 2) 4. Using the pipe spanner and screwdriver supplied, remove (drawing 3) the slide pipe. (drawing 4-d) use the pipe spanner by aligning with the jaw case piston at the back and affixi...

Page 11

11 7. Insert 3 jaws into the tip of the tube on the the outside of the jaw setting jig. (drawing 5, drawing 6) as shown in drawing 6, apply an over-the-counter molybdenum grease. (note that applying grease to the jaw teeth will cause the teeth to slip on the rivets, and may make riveting impossible ...

Page 12

12 9. Insert the parts in the order shown in (drawing 9), and use the screwdriver and pipe spanner supplied to attach the slide pipe. If the slide pipe is tightened too hard, it will be difficult to remove, and could cause damage to the head of the screwdriver. 10. Connect the air coupler, return th...

Page 13

13 air removal (bubbles) and refilling methods air release and refilling are needed in the following cases. A. Operating speed seems to have slowed b. After around 20,000 rivetings. C. A gap can be seen in the nose tip (drawing 1-a) when disconnecting the air coupler. 1. Remove any rivets still atta...

Page 14

14 4. Cover the fuel inlet with a rag. (drawing 3) 5. With the rag still in place, open the cap, and press hard on the slide pipe with the refilling maintenance bolt. (drawing 3) * check that the gap in drawing 1-a has disappeared. 6. Cover the fuel inlet with the thumb, and turn the riveter upside ...

Page 15

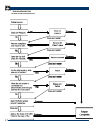

15 installing the connecting tape removing the connecting tape 1) push the magazine latch 1) push the magazine latch towards the magazine towards the magazine and open it. And open it. 2) roll up the connecting 2) still holding the trigger, tape containing the rivets, pull the finished tape and put ...

Page 16

16 removing the connecting tape (1) use the speed controller to raise the vacuum pressure until the rivet is held in place. (2) affix with the lock nut. Always disconnect the air hose when loading the connecting tape. The following explanation should be read and clearly understood before starting op...

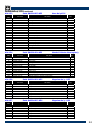

Page 17

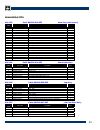

17 troubleshooting rk-4500 trouble countermeasures.

Page 18

18 t roubleshooting symptom cause action nose piston does not stop moving backwards and forwards. Air was supplied when the trigger's main axis was at the air passage changeover point. With the air supply connected, pull the trigger for 3 seconds or more. The mandrels do not break. Air pressure is t...

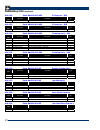

Page 19

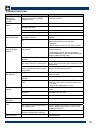

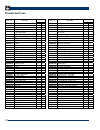

19 t roubleshooting parts no. Parts name q'ty parts no. Parts name q'ty ks5 ks6 ks5 ks6 rk4500-1 nose piston 1 1 rk4500-80 o-ring s4 5 5 rk4500-2 jaw case 1 1 rk4500-81 o-ring p10 1 1 rk4500-3 trigger shaft 1 1 rk4500-82 o-ring p6 2 2 rk4500-4 trigger cover 1 1 rk4500-83 o-ring s2 3 3 rk4500-5 trigg...

Page 20

20 common parts parts no. Parts name q'ty parts no. Parts name q'ty ks5 ks6 ks5 ks6 rk4500-126 jaw case piston hydraulic seal 1 1 rk4500-163 magazine latch pin 1 1 rk4500-127 steel ball - 4mm 2 2 rk4500-164 magazine latch spring 1 1 rk4500-128 set screw - sus m5x5, flat point 1 1 rk4500-174 torx hea...

Page 21

21 assembly parts parts no. Parts name q'ty parts no. Parts name q'ty ks5 ks5 ks5 ks6 rk4500-603 nose assembly - 5 1 - rk4500-620 centering assembly - 5 1 - rk4500-604 alarm valve assembly - 5 1 - rk4500-621 centering assembly - 6 - 1 rk4500-605 cap assembly 1 1 rk4500-622 booster cylinder assembly ...

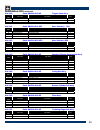

Page 22

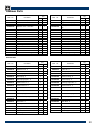

22 assemblies/kits kit# 603 part# rk4500-603-ks5 nose ass’y (cut version) kck part# irf part# part name q'ty 48 rk4500-048-ks indexer exhaust bolt 1 52 rk4500-052-ks5 plate spring - 5 1 53 rk4500-053-ks5 plate spring support - 5 1 54 rk4500-054-ks5 indexer piston a - 5 1 55 rk4500-055-ks5 indexer pi...

Page 23

23 assemblies/kits continued kit# 608 part# rk4500-608-ks5 trigger shaft ass’y kck part# irf part# part name q'ty 3 rk4500-003-ks trigger shaft 1 83 rk4500-083-ks o-ring s2 2 kit# 609 part# rk4500-609-ks5 trigger valve ass’y kck part# irf part# part name q'ty 4 rk4500-004-ks trigger cover 1 5 rk4500...

Page 24

24 assemblies/kits continued kit# 613 part# rk4500-613-ks5 nose ass’y ks-6 kck part# irf part# part name q'ty 48 rk4500-048-ks indexer exhaust bolt 1 78 rk4500-078-ks o-ring s40 1 80 rk4500-080-ks o-ring s4 2 85 rk4500-085-ks o-ring p18 2 113 rk4500-113-ks socket set screw - sus m4x8, cone point 1 1...

Page 25

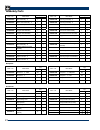

25 assemblies/kits continued kit# 618 part# rk4500-618-ks5 3 piece jaw – ks5 kck part# irf part# part name q'ty 417 rk4500-417-ks5 unit jaw-5 1 kit# 619 part# rk4500-619-ks6 3 piece jaw – ks6 kck part# irf part# part name q'ty 26 rk4500-026-ks6 3-part jaw 6 3 kit# 620 part# rk4500-620-ks5 centering ...

Page 26

26 assemblies/kits continued kit# 640 part# rk4500-640-ks trigger valve ass’y kck part# irf part# part name q'ty 12 rk4500-012-ks trigger block 1 127 rk4500-127-ks steel ball - 4mm 1 133 rk4500-133-ks steel ball - 3mm 3 kit# 641 part# rk4500-641-ks5 nose sub ass’y – ks5 kck part# irf part# part name...

Page 27

27.

Page 28

28.

Page 29

29 msds lubricant details moly grease (msc p/n: 60002136) (rk4500-moly) manufacturer: t.S. Moly-lubricants, inc., houston, tx emergency: (713)671-2676 msds number: ts-122 lithium ep-2 moly poly grease first aid: skin: prolonged or repeated skin contact with this product tends to remove skin oils, po...

Page 30

30 warranty statement: industrial rivet & fastener co. Inc. (hereinafter “irf”), hereby warrants to the initial retail customer and original distributor (“warrantee”) only that its products will be free from defects in material and workmanship for a period of 1 year from the purchase date, provided ...