- DL manuals

- RKC INSTRUMENT

- Temperature Controller

- RB100

- Instruction Manual

RKC INSTRUMENT RB100 Instruction Manual

Summary of RB100

Page 1

Rb series imr02c15-e4 rkc instrument inc. ® digital temperature controller rb100/rb400 rb500/rb700 rb900 instruction manual.

Page 2

All rights reserved, copyright 2009, rkc instrument inc. Modbus is a registered trademark of schneider electric. Company names and product names used in this manual are the trademarks or registered trademarks of the respective companies..

Page 3: Notice

Imr02c15-e4 i-1 thank you for purchasing this rkc product. In order to achieve maximum performance and ensure proper operation of your new instrument, carefully read all the instructions in this manual. Please place the manual in a convenient location for easy reference. Notice this manual assumes t...

Page 4: Caution

Imr02c15-e4 i-2 this product is intended for use with industrial machines, test and measuring equipment. (it is not designed for use with medical equipment and nuclear energy.) this is a class a instrument. In a domestic environment, this instrument may cause radio interference, in which case the us...

Page 5: Symbols

Imr02c15-e4 i-3 symbols safety symbols: : this mark indicates important information on installation, handling and operating procedures. : this mark indicates supplemental information on installation, handling and operating procedures. : this mark indicates where additional information may be located...

Page 6

Imr02c15-e4 i-4 unit character symbols °c °f % abbreviation symbols these abbreviations are used in this manual: abbreviation symbols name pv measured value (pv) sv set value (sv) at autotuning st startup tuning hba1 heater break alarm 1 hba2 heater break alarm 2 ct1 current transformer 1 ct2 curren...

Page 7: Document Configuration

Imr02c15-e4 i-5 document configuration there are six manuals pertaining to this product. Please be sure to read all manuals specific to your application requirements. If you do not have a necessary manual, please contact rkc sales office, the agent, or download from the official rkc website. The fol...

Page 8: Contents

I-6 imr02c15-e4 contents page 1. Outline ...........................................................................1-1 1.1 features .......................................................................................................1-2 1.2 input/output and function blocks...........................

Page 9: The

Imr02c15-e4 i-7 page digital input (di1, di2) [optional]...........................................................................3-13 current transformer (ct) input [optional]..............................................................3-13 communication [optional] ..................................

Page 10

Imr02c15-e4 i-8 page 6.3 startup tuning (st) ....................................................................................6-11 caution for using the startup tuning (st) .............................................................6-11 requirements for startup tuning (st) start...................

Page 11

Imr02c15-e4 i-9 page 7.3 transmission output function....................................................................7-12 setting procedure .................................................................................................7-12 output calibration ......................................

Page 12

Imr02c15-e4 i-10 page 9. Troubleshooting.......................................................9-1 9.1 error display.................................................................................................9-2 display when input error occurs ......................................................

Page 13: Outline

Outline imr02c15-e4 1-1 this chapter describes features, package contents and model code, etc. 1.1 features ...........................................................................................1-2 1.2 input/output and function blocks.....................................................1-3 1.3 ...

Page 14: 1.1 Features

1. Outline 1-2 imr02c15-e4 1.1 features this high performance digital controller has the following features: panel space saving: 60 mm depth (rb400/500/700/900), 63 mm (rb100) 11-segment lcd display for the pv display sampling time 250 ms advanced autotuning with arw function “fine tuning” that chan...

Page 15

1. Outline imr02c15-e4 1-3 1.2 input/output and function blocks this section describes the input/output and function blocks of the instrument. Communication function is not available with di1 and di2 on rb100. Control processing • pid control • heat/cool pid control • on/off control • autotuning (at...

Page 16: 1.3 Checking The Product

1. Outline 1-4 imr02c15-e4 1.3 checking the product before using this product, check each of the following: model code check that there are no scratches or breakage in external appearance (case, front panel, or terminal, etc.) check that all of the items delivered are complete. (refer to below) acce...

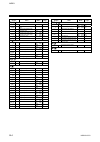

Page 17: 1.4 Model Code

1. Outline imr02c15-e4 1-5 1.4 model code check that the product received is correctly specified by referring to the following model code list: if the product is not identical to the specifications, please contact rkc sales office or the agent. Suffix code □ □□□-□□-□*□□-□□/□□/y (1) (2) (3) (4) (5) (...

Page 18

1. Outline imr02c15-e4 1-6 input range code table [thermocouple input (temperature input group)] * [resistance temperature detector input (temperature input group)] * type code range (measured range) code range (measured range) type code range (measured range) code range (measured range) k01 0 to 20...

Page 19

1. Outline imr02c15-e4 1-7 quick start code (initial setting code) quick start code tells the factory to ship with each parameter preset to the values detailed as specified by the customer. Quick start code is not necessarily specified when ordering, unless the preset is requested. These parameters ...

Page 20: 1.5 Parts Description

1. Outline 1-8 imr02c15-e4 1.5 parts description this section describes various display units and the key functions. Front panel view measured value (pv) display [green] unit display [green] set value (sv) display [orange] set lock display [orange] autotuning (at) lamp [green] output (out) lamp [gre...

Page 21

1. Outline imr02c15-e4 1-9 set r/s pv sv1 sv2 sv3 sv4 8888 ! ‡‡‡‡ ‰ at out1 out2 man stop do1 do2 do3 do4 rb900 rb900 measured value (pv) display [green] autotuning (at) lamp [green] output (out) lamp [green] manual (man) mode lamp [green] stop lamp [green] digital output (do) lamp [orange] step set...

Page 22

1. Outline imr02c15-e4 1-10 display units measured value (pv) display [green] displays measured value (pv) or various parameter symbols. Unit display [green] displays the temperature units ( °c or °f) of displayed data and the units (%) of the manipulated output value (mv). Set value (sv) display [o...

Page 23

1. Outline imr02c15-e4 1-11 bottom view loader communication connector (standard equipment) setting and monitoring on a personal computer (pc) is possible if the controller is connected with our cable to a pc via our usb communication converter com-k-1 (sold separately) 1 . Our communication softwar...

Page 24

1. Outline imr02c15-e4 1-12 how to connect the controller to a pc via loader communication port connect the controller, com-k, and personal computer using a usb cable and a loader communication cable. Make sure the connectors are oriented correctly when connecting. Usb communication converter com-k ...

Page 25

1. Outline imr02c15-e4 1-13 1.6 handling procedure to operation after installation and wiring, follow the procedure below to configure settings required for operation. Change from stop to run change from pid to at (parameter setting mode: pid/at transfer) at end when the at is finished, the controll...

Page 26: Memo

1-14 imr02c15-e4 memo.

Page 27: Mounting

Mounting imr02c15-e4 2-1 this chapter describes installation environment, mounting cautions, dimensions and mounting procedures. 2.1 mounting cautions............................................................................2-2 2.2 dimensions ..........................................................

Page 28: 2.1 Mounting Cautions

2. Mounting 2-2 imr02c15-e4 2.1 mounting cautions (1) this instrument is intended to be used under the following environmental conditions. (iec61010-1) [overvoltage category ii, pollution degree 2] (2) use this instrument within the following environment conditions: • allowable ambient temperature: ...

Page 29: 2.2 Dimensions

2. Mounting imr02c15-e4 2-3 2.2 dimensions panel thickness: 1 to 10 mm (when mounting multiple rb series controllers close together, the panel strength should be checked to ensure proper support.) rb100 (unit: mm) rb400 (unit: mm) *1 case rubber packing (optional) [waterproof/dustproof] *2 terminal ...

Page 30

2. Mounting imr02c15-e4 2-4 panel thickness: 1 to 10 mm (when mounting multiple rb series controllers close together, the panel strength should be checked to ensure proper support.) rb500 (unit: mm) rb700 (unit: mm) *1 case rubber packing (optional) [waterproof/dustproof] *2 terminal cover (optional...

Page 31

2. Mounting imr02c15-e4 2-5 panel thickness: 1 to 10 mm (when mounting multiple rb series controllers close together, the panel strength should be checked to ensure proper support.) rb900 (unit: mm) *1 case rubber packing (optional) [waterproof/dustproof] *2 terminal cover (optional) [sold separatel...

Page 32

2. Mounting 2-6 imr02c15-e4 2.3 procedures of mounting and removing the mounting position of the mounting bracket (1) mounting positions for single controller * if two mounting brackets are used on the waterproof/dustproof type controller as shown in the figure (marked*), sufficient waterproof/dustp...

Page 33

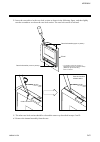

2. Mounting imr02c15-e4 2-7 mounting procedures (not supplied) 1. Prepare the panel cutout as specified in 2.2 dimensions. (panel thickness: 1 to 10 mm) 2. Insert the instrument through the panel cutout. (fig. 2.2) 3. Insert the mounting bracket into the mounting groove of the instrument. (fig. 2.3)...

Page 34

2. Mounting imr02c15-e4 2-8 mounting procedures (waterproof/dustproof type) the front of the instrument conforms to ip66 (nema4x) [specify when ordering] when mounted on the panel. For effective waterproof/dustproof, the gasket must be securely placed between instrument and panel without any gap. If...

Page 35

2. Mounting imr02c15-e4 2-9 removal procedures 1. Turn the power off. 2. Remove the wiring. 3. Loosen the screw of the mounting bracket. (fig. 2.11) 4. Lift the latch of the mounting bracket ( ), then pull the mounting bracket ( ), to remove it from the case. (fig. 2.11) 5. The other mounting bracke...

Page 36: Memo

2-10 imr02c15-e4 memo.

Page 37: Wiring

Wiring imr02c15-e4 3-1 this chapter describes wiring cautions, wiring layout and wiring of terminals. 3.1 wiring cautions ................................................................................3-2 3.2 terminal layout .............................................................................

Page 38: 3.1 Wiring Cautions

3. Wiring 3-2 imr02c15-e4 3.1 wiring cautions • for thermocouple input, use the appropriate compensation wire. • for rtd input, use low resistance lead wire with no difference in resistance between the three lead wires. • to avoid noise induction, keep input signal wire away from instrument power li...

Page 39

3. Wiring imr02c15-e4 3-3 • when wiring of rb100/400/700/900, wire from the left direction toward the backside terminals as shown in fig. 3.2. For rb100, the wiring surfaces of the central and right side lines of terminals are inclined to make it easier to wire from the left side. When using the ter...

Page 40

3. Wiring imr02c15-e4 3-4 • caution for the terminal cover usage: − to prevent electric shock or instrument failure, always turn off the power before mounting or removing the terminal cover. − when mounting and removing the terminal cover, apply pressure very carefully to avoid damage to the termina...

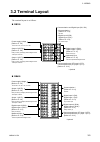

Page 41: 3.2 Terminal Layout

3. Wiring imr02c15-e4 3-5 3.2 terminal layout the terminal layout is as follows. Rb100 rb400 output 2 (out2) [refer to p. 3-9] relay contact (1)/voltage pulse/voltage/current/ triac/open collector power supply voltage [refer to p. 3-8] 100 to 240 v ac, 24 v ac, 24 v dc output 1 (out1) [refer to p. 3...

Page 42

3. Wiring imr02c15-e4 3-6 rb500 rb700 * optional 13 14 15 16 17 18 19 20 21 22 23 24 1 2 3 4 5 6 7 8 9 10 11 12 communication * [refer to p. 3-14] rs-485 digital output 4 (do4), digital output 3 (do3) * [refer to p. 3-11] relay contact (2) digital input 2 (di2), digital input 1 (di1) * [refer to p. ...

Page 43

3. Wiring imr02c15-e4 3-7 rb900 isolations of input and output for isolated device input/output blocks, refer to the following: power supply isolated isolated isolated commu- nication (rs-485) digital input di1 di2 digital output 2 do1 do2 do3 do4 output1 1 ( out1 ) output2 1 (out2) non-isolated non...

Page 44: 3.3 Wiring of Each Terminal

3. Wiring 3-8 imr02c15-e4 3.3 wiring of each terminal always check the polarity of each terminal prior to wiring. Power supply • connect the power to terminal numbers 1 and 2. • power supply types must be specified when ordering. Power supply voltage for the controller must be within the range shown...

Page 45

3. Wiring imr02c15-e4 3-9 output 1 (out1)/output 2 (out2) • terminal 5 and 6 are for output 1 (out1); terminal 3 and 4 are for output 2 (out2). • connect an appropriate load according to the output type. (specify when ordering) heat control heat/cool control wiring example relay contact output volta...

Page 46

3. Wiring imr02c15-e4 3-10 continued from the previous page. • number of outputs and output types must be specified when ordering. The specifications of each output are as follows. Output 1 (out1) [pid control: control output, heat/cool pid control: heat output] output 2 (out2) [heat/cool pid contro...

Page 47

3. Wiring imr02c15-e4 3-11 digital output 1 to 4 (do1 to do4) [optional] • models that were specified with digital output when ordering can use the following terminal numbers. Rb100: terminal no. 7 to 9 (do1, do2) rb700: terminal no. 10 to 12 (do1, do2), terminal no. 7 to 9 (do3, do4) rb400/500/900:...

Page 48

3. Wiring imr02c15-e4 3-12 measured input (thermocouple/rtd/voltage/current) [universal input] • for the measured input type, terminals 10 through 12 (rb700: terminals 16 through 18) are allocated to the measured input. • the input types (input group) are as follows. Input group input type thermocou...

Page 49

3. Wiring imr02c15-e4 3-13 digital input (di1, di2) [optional] • models that were specified with digital input when ordering can use the following terminal numbers. Rb100: terminal no. 13 to 15 (di1, di2) rb700: terminal no. 22 to 24 (di1, di2) rb400/500/900: terminal no. 16 to 18 (di1, di2) • digit...

Page 50

3. Wiring imr02c15-e4 3-14 communication [optional] • with communication function, terminals 13 through 15 (rb700: terminals 25 through 27) are allocated to communication. For the wiring, refer to communication quick instruction manual (imr02c41-e ) or communication instruction manual (imr02c16-e )....

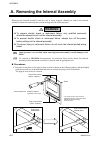

Page 51: Warning

3. Wiring imr02c15-e4 3-15 3.4 handling of the terminal cover [optional] when mounting and removing the terminal cover, take the following steps: when mounting and removing the terminal cover, apply pressure very carefully to avoid damage to the terminal cover. Mounting procedures 1. Check the mount...

Page 52

3. Wiring imr02c15-e4 3-16 removal procedures release the protrusions of terminal cover from the insertion slots ( ) shown in the following figure, and then pull the terminal cover ( ) to remove it from the case. Drawing of rb100 with terminal cover drawing of rb400 with terminal cover this section ...

Page 53: Basic

Basic operation imr02c15-e4 4-1 this chapter explains the basic operations of switching modes and changing set values. 4.1 operation menu ................................................................................4-2 4.2 changing set value ..........................................................

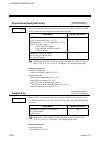

Page 54: 4.1 Operation Menu

4. Basic operation 4-2 imr02c15-e4 4.1 operation menu the controller has five different modes. All settable parameters belong to one of them. The following chart show how to access different setting mode. For the details of changing set value, refer to 4.2 changing set value (p. 4-4). Power on monit...

Page 55

4. Basic operation imr02c15-e4 4-3 parameter setting mode f01 to f10 indicate group numbers used in non-display of block and set lock level in engineering mode. Parameters in f01 to f03 as well as f10 are not displayed with the factory default setting. Monitor display mode [figures on the sv display...

Page 56: 4.2 Changing Set Value

4. Basic operation 4-4 imr02c15-e4 4.2 changing set value • the flashing digit indicates which digit can be set. Press key to go to a different digit. Every time the shift key is pressed, the flashing digit moves as follows. 8 flashing sv1 8 8 8 r/s r/s r/s r/s • the following is also available when...

Page 57: Setup

Setup procedures prior to running the instrument imr02c15-e4 5-1 this chapter explains basic setup procedures prior to running the instrument. 5.1 initial setting...................................................................................5-3 check the parameter related to the input .............

Page 58

5. Setup procedures prior to running the instrument 5-2 imr02c15-e4 setup the controller prior to operating the instrument. Refer to the following setup example. Operation procedure setup example: input specification: thermocouple (k) 0 to 400 °c control action: pid action with at (reverse action) e...

Page 59: 5.1 Initial Setting

5. Setup procedures prior to running the instrument imr02c15-e4 5-3 5.1 initial setting check the parameter related to the input parameter settings related to the control input specifications such as the input type, can be checked in engineering mode. Parameters which are not specified when ordering...

Page 60

5. Setup procedures prior to running the instrument 5-4 imr02c15-e4 check the parameter related to the event parameter settings related to event action can be checked in engineering mode. Parameters which are not specified when ordering must be set before use. For event 1 parameter, refer to functio...

Page 61

5. Setup procedures prior to running the instrument imr02c15-e4 5-5 check the parameter related to the control action parameter settings related to control action can be checked in engineering mode. Parameters which are not specified when ordering must be set before use. For control action parameter...

Page 62: 5.2 Operation Setting

5. Setup procedures prior to running the instrument 5-6 imr02c15-e4 5.2 operation setting set the control set value after finishing the initial settings, set the control target value, sv. [setting example: set the control set value 1 (sv1) to 200 °c.] 1. Make sure that the pv/sv monitor screen is di...

Page 63

5. Setup procedures prior to running the instrument imr02c15-e4 5-7 set the event set value after finishing the initial settings, set the event set values if they are used. [setting example: set the event 1 set value (ev1) to 20 °c] 1. Press and hold the key for 2 seconds or more at the pv/sv monito...

Page 64: 5.3 Operation Start

5. Setup procedures prior to running the instrument 5-8 imr02c15-e4 5.3 operation start check the following precautions before starting operation. Caution power on there is no power switch on this instrument, so the instrument starts operation immediately following initial power on. [factory set val...

Page 65

5. Setup procedures prior to running the instrument imr02c15-e4 5-9 change from stop to run to start control, change the run/stop mode from stop (stop control) to run (start control). Press and hold the key for 2 seconds or more at the pv/sv monitor screen and the instrument will switch from stop to...

Page 66

5. Setup procedures prior to running the instrument imr02c15-e4 5-10 tuning pid parameters suitable pid values are automatically calculated by autotuning (at) function. The autotuning (at) function automatically measures, computes and sets the optimum pid values. Before start autotuning, make sure t...

Page 67

5. Setup procedures prior to running the instrument imr02c15-e4 5-11 to manually adjust the pid parameters if the autotuning (at) function does not match the controlled object requirements, the optimum pid values may not be calculated by autotuning (at). In that case, adjust the pid parameters manua...

Page 68

5. Setup procedures prior to running the instrument imr02c15-e4 5-12 changing control response with fine tuning after suitable pid values are calculated and stored by autotuning or manual pid setting, the fine tuning allows you to change the control response of the same pid constant control. The con...

Page 69: Operations

Operations of the basic functions imr02c15-e4 6-1 this chapter describes the basic functions and the procedures for using basic functions. 6.1 run/stop transfer........................................................................6-2 6.2 autotuning (at) ...............................................

Page 70: 6.1 Run/stop Transfer

6. Operations of the basic functions 6-2 imr02c15-e4 6.1 run/stop transfer it is possible to transfer between control start (run) and control stop (stop). Run/stop transfer can be performed by key operation, by key operation using the run/stop setting in engineering mode, by digital input (di) [opti...

Page 71

6. Operations of the basic functions imr02c15-e4 6-3 run/stop transfer by front key operation press and hold the key for 2 seconds or more at the pv/sv monitor screen and the instrument will switch from stop to run. To change from run mode to stop mode, press and hold the key for 2 seconds or more. ...

Page 72

6. Operations of the basic functions imr02c15-e4 6-4 3. Press the key to change the number to 1 (1: stop). Press the key to store the new value. 4. To return the pv/sv monitor, press the key while pressing the key. To change from stop mode to run mode 1. Press the key while pressing the key for 4 se...

Page 73

6. Operations of the basic functions imr02c15-e4 6-5 3. Press the key to change the number to 0 (0:run). Press the key to store the new value. 4. To return the pv/sv monitor, press the key while pressing the key. Run/stop transfer by digital input (di) [optional] run/stop transfer by digital input (...

Page 74

6. Operations of the basic functions imr02c15-e4 6-6 terminal configuration when the initial set code of di assignment is “2: sv1 to sv2 selection + run/stop transfer” when the initial set code of di assignment is “5: run/stop transfer + auto/man transfer,” “6: run/stop transfer + interlock release”...

Page 75

6. Operations of the basic functions imr02c15-e4 6-7 run/stop transfer state the table below shows the actual run/stop modes, displays, and stop lamp states under different combinations of settings by key operation, communication, digital input (di), and stop by the timer function. Run/stop mode fro...

Page 76: 6.2 Autotuning (At)

6. Operations of the basic functions 6-8 imr02c15-e4 6.2 autotuning (at) the autotuning (at) function automatically measures, computes and sets the optimum pid values. Caution for using the autotuning (at) • when a temperature change (up and/or down) is 1 °c or less per minute during autotuning (at)...

Page 77

6. Operations of the basic functions imr02c15-e4 6-9 autotuning (at) start/stop operation the autotuning function can start from any state after power on, during a rise in temperature or in stable control. Start at 1. Press and hold the key for 2 seconds or more at the pv/sv monitor screen to go to ...

Page 78

6. Operations of the basic functions imr02c15-e4 6-10 autotuning (at) cancellation when canceling the autotuning function (at), press the key to be set to “0000” with the autotuning (at) screen. Return the pv/sv monitor to return the pv/sv monitor, press and hold the key for 2 seconds or more. As th...

Page 79: 6.3 Startup Tuning (St)

6. Operations of the basic functions imr02c15-e4 6-11 6.3 startup tuning (st) startup tuning (st) is a function which automatically computes and sets the pid values (proportional band: heat-side only) from the response characteristics of the controlled system at power on, transfer from stop to run, ...

Page 80

6. Operations of the basic functions imr02c15-e4 6-12 requirements for startup tuning (st) start start the startup tuning (st) when all following conditions are satisfied: pid control operation state run st is set to on. (execute once, execute always) parameter setting output limiter high ≥ 0.1 %, o...

Page 81

6. Operations of the basic functions imr02c15-e4 6-13 startup tuning (st) setting the setting procedure when executing startup tuning (st) only one time at power on is shown below as a setting example. Set the st start condition first, set “when the power is turn on” to st start condition by enginee...

Page 82

6. Operations of the basic functions imr02c15-e4 6-14 set “128” (128: display f21 and following) in the mode selection (no display) screen and then press the key to store the set value. Press the key several times until the function block 00 screen is displayed. 4. Press the key several times until ...

Page 83

6. Operations of the basic functions imr02c15-e4 6-15 7. Press the key several times until function block 00 screen is displayed. 8. Press the key several times until mode selection (no display) screen is displayed. Change the value in the mode selection (no display) screen to the original value and...

Page 84

6. Operations of the basic functions imr02c15-e4 6-16 4. In the startup tuning (st) screen, press the key to set the value of the flashing digit to “1” (1: execute once). Press the key to store the new value. 5. Thus, the startup tuning (st) setting has been finished. To return the pv/sv monitor, pr...

Page 85: 6.4 Fine Tuning

6. Operations of the basic functions imr02c15-e4 6-17 6.4 fine tuning the fine tuning function allows you to change the response of the set pid constant control. To make control response faster when the control response is set to the fast side, the measured value (pv) will reach the set value (sv) m...

Page 86

6. Operations of the basic functions imr02c15-e4 6-18 continued from the previous page. 4. Press the key to store the new value. The display goes to the next parameter. Fine tuning begins when the key is pressed. To make the control response slower when the control response is set to slow side, over...

Page 87

6. Operations of the basic functions imr02c15-e4 6-19 4. Press the key to store the new value. The display goes to the next parameter. Fine tuning begins when the key is pressed. If the set value of fine tuning is returned to “0: unused,” fine tuning correction will be turned off. After a new value ...

Page 88: 6.5 Auto/manual Transfer

6. Operations of the basic functions 6-20 imr02c15-e4 6.5 auto/manual transfer the auto/manual transfer can be made by digital input (di) * or communication * other than the key operation. * optional for details of auto/manual transfer by communication, refer to the communication instruction manual ...

Page 89

6. Operations of the basic functions imr02c15-e4 6-21 auto/manual transfer by front key operation this is performed in auto/manual transfer of mode switching. Auto/manual transfer can be done in the mode switching. Every time the key or the key is pressed, the auto (auto) mode is changed to the manu...

Page 90

6. Operations of the basic functions imr02c15-e4 6-22 auto/manual transfer by digital input (di) auto/manual transfer by the digital input (di) is possible with the di assignment of the engineering mode. For the di assignment, refer to 8.5 engineering mode (p. 8-95). Terminal configuration contact i...

Page 91

6. Operations of the basic functions imr02c15-e4 6-23 procedure for setting the manipulated output value (mv) in manual mode when the controller is in manual mode, the manipulated output value (mv) can be manually set. 1. Make sure the manual (man) mode lamp is lit. 2. Press the key at pv/sv monitor...

Page 92

6. Operations of the basic functions 6-24 imr02c15-e4 6.6 protecting setting data (data lock function) to protect setting data in the instrument, the setting data can be locked so that no changes can be made (data lock function). Parameters that can be locked are described below. • parameters of par...

Page 93

6. Operations of the basic functions imr02c15-e4 6-25 set lock level of parameter setting mode the same parameters exist in engineering mode, grouped by group number (f01 to f10) as shown below. In the set lock level (lock) screen, you can lock the group number that contains the parameter(s) that yo...

Page 94

6. Operations of the basic functions imr02c15-e4 6-26 locking all data which can be locked parameters that can be locked: − parameters of parameter setting mode − parameters of f01 to f91 of engineering mode 1. In pv/sv monitor, press the key for 4 seconds or more while pressing the key. The display...

Page 95

6. Operations of the basic functions imr02c15-e4 6-27 5. Press the key while pressing the key. The display goes to the engineering mode. 6. In pv/sv monitor, press the key while pressing the key. The display goes to the mode switching. 7. Press the key until set data unlock/lock transfer screen is d...

Page 96

6. Operations of the basic functions imr02c15-e4 6-28 selecting the parameter to lock setting example: locking the proportional band [heat-side] and following parameters in parameter setting mode to lock proportional band [heat-side] and following parameters, choose a suitable set lock level by whic...

Page 97

6. Operations of the basic functions imr02c15-e4 6-29 5. Press the key while pressing the key. The display goes to the pv/sv monitor. 6. In pv/sv monitor, press the key while pressing the key. The display goes to the mode switching. 7. Press the key until set data unlock/lock transfer screen is disp...

Page 98

6. Operations of the basic functions imr02c15-e4 6-30 locking f21 to f91 data to lock f21 to f91, set any value from “1” to “10” in the set lock level, and enable the data lock function in the set data unlock/lock screen. When locked, the screens of f21 to f91 will not be displayed even if “128” is ...

Page 99

6. Operations of the basic functions imr02c15-e4 6-31 5. Press the key while pressing the key. The display goes to the pv/sv monitor. 6. In pv/sv monitor, press the key while pressing the key. The display goes to the mode switching. 7. Press the key until set data unlock/lock transfer screen is disp...

Page 100

6. Operations of the basic functions 6-32 imr02c15-e4 6.7 display/no display setting of mode screens the instrument can be set not to display parameters that are not used (note that some parameters cannot be set to “no display”). Parameters that can be set to “no display” are shown below. Monitor di...

Page 101

6. Operations of the basic functions imr02c15-e4 6-33 engineering mode: function block 00 (f00) function block 01 (f01) function block 03 (f03) function block 04 (f04) function block 06 (f06) function block 07 (f07) function block 08 (f08) function block 09 (f09) function block 10 (f10) cannot be se...

Page 102

6. Operations of the basic functions imr02c15-e4 6-34 hiding the parameters of the monitor display mode setting example: the current transformer 1 (ct1) input value monitor and current transformer 2 (ct2) input value monitor are set to no display. 1. In pv/sv monitor, press the key for 4 seconds or ...

Page 103

6. Operations of the basic functions imr02c15-e4 6-35 hiding the parameters of the mode switching screen setting example: set data unlock/lock transfer is set to no display. 1. In pv/sv monitor, press the key for 4 seconds or more while pressing the key. The display goes to the engineering mode. 2. ...

Page 104: Warning

6. Operations of the basic functions imr02c15-e4 6-36 screen displays of function block 21 (f21) to function block 91 (f91) display of f21 to f91 is set to “no display” as factory set value. To display f21 to f91, set mode selection (no display) screen to “128.” to display f21 to f91 while any mode ...

Page 105

6. Operations of the basic functions imr02c15-e4 6-37 hiding the parameters of the parameter setting mode setting example: setting the pv bias screen and pv digital filter screen to no display the pv bias and pv digital filter screens are set by the f09 block selection (no display) of engineering mo...

Page 106: Warning

6. Operations of the basic functions imr02c15-e4 6-38 displaying function block 21 (f21) to function block 91 (f91) of the engineering mode 1. In pv/sv monitor, press the key for 4 seconds or more while pressing the key. The display goes to the engineering mode. 2. Press the key until mode selection...

Page 107: 6.8 Interlock Release

6. Operations of the basic functions imr02c15-e4 6-39 6.8 interlock release the interlock action holds the event state even if the measured value is out of the event zone after it enters the event zone once. The interlock release can be made by digital input (di) [optional], or communication [option...

Page 108

6. Operations of the basic functions imr02c15-e4 6-40 interlock release by front key operation 1. In pv/sv monitor, press the key while pressing the key. 2. Press the key until interlock release screen is displayed. 3. Press the key to release the interlock. 4. Press the key twice to release the int...

Page 109

6. Operations of the basic functions imr02c15-e4 6-41 interlock release by digital input (di) interlock release by the digital input (di) is possible with the di assignment of the engineering mode. For the di assignment, refer to 8.5 engineering mode (p. 8-95). Terminal configuration di2: interlock ...

Page 110: Memo

6-42 imr02c15-e4 memo.

Page 111: Operating

Operating additional functions imr02c15-e4 7-1 this chapter describes the setting procedure for additional functions. 7.1 sv selection function (step sv function) ......................................7-2 setting procedure ................................................................................

Page 112: 7.1 Sv Selection Function

7. Operating additional functions 7-2 imr02c15-e4 7.1 sv selection function (step sv function) the sv selection function enables control by switching to any one of the stored set values of up to four points (sv1 to sv4). The set value (sv) selecting can be made by digital input (di) [optional] or co...

Page 113

7. Operating additional functions imr02c15-e4 7-3 sv selection by front key operation to switch to sv1 to sv4 by front key operation, use the sv selection parameter of parameter setting mode. If timer function 3 or timer function 4 is in use, it will not be possible to switch sv (among sv1 and sv4) ...

Page 114

7. Operating additional functions imr02c15-e4 7-4 sv selection by digital input (di) to switch to sv1 to sv4 using digital input (di) [optional], assign the sv selection function in the di assignment parameter of engineering mode before operation. If timer function 3 or timer function 4 is in use, i...

Page 115: 7.2 Timer Function

7. Operating additional functions imr02c15-e4 7-5 7.2 timer function control start (run) by timer function (timer function 1) timer function 1 can be used to start control using the set value (sv) selected by the sv selection parameter after the timer time elapses. Timer setting before operation, se...

Page 116

7. Operating additional functions 7-6 imr02c15-e4 timer start when the settings for the timer function 1 are finished, start the timer. In the stop state, press and hold the key for 2 seconds or more to start the timer. When the set timer time elapses, the state changes to run and control starts. In...

Page 117

7. Operating additional functions imr02c15-e4 7-7 control stop (stop) by timer function (timer function2) using the set value (sv) selected in the sv selection parameter, timer function 2 stops control when the timer time elapses. Timer setting before operation, set the set value (sv) selection used...

Page 118

7. Operating additional functions imr02c15-e4 7-8 timer start when the settings for the timer function 2 are finished, start the timer. In the stop state, press and hold the key for 2 seconds or more to switch to run (control run). The timer starts, and when the set timer time elapses, the state cha...

Page 119

7. Operating additional functions imr02c15-e4 7-9 ramp/soak control (timer function 3, timer function 4) timer function 3 and timer function 4 can be used to link set values 1 to 4 (sv1 to sv4) for ramp/soak control. In addition, the repeat function can be used to execute repeated ramp/soak control....

Page 120

7. Operating additional functions imr02c15-e4 7-10 timer setting the parameters below must be set for timer function 3 and timer function 4 in parameter setting mode before operation. • set value 1 (sv1) to set value 4 (sv4) • timer time 1 (timer 1) to timer time 4 (timer 4) • timer function • repea...

Page 121

7. Operating additional functions imr02c15-e4 7-11 timer start when the settings of timer function 3 and timer function 4 are completed, start the timer. Timer function 3: in the stop state, press and hold the key for 2 seconds or more to switch to run (start control). During the set timer time, con...

Page 122

7. Operating additional functions 7-12 imr02c15-e4 7.3 transmission output function the transmission output function (optional) is outputting the state of measured value (pv), set value (sv), or manipulated output value (mv1) as a voltage or current signal. It is possible to record the state of meas...

Page 123

7. Operating additional functions imr02c15-e4 7-13 output calibration the ao full scale adjustment value and ao zero adjustment value of transmission output can be adjusted within the range −10.0 to +10.0 %. Do not change the factory set adjustment value for the ao full scale adjustment value and or...

Page 124: Memo

7-14 imr02c15-e4 memo.

Page 125: Parameter

Parameter description imr02c15-e4 8-1 this chapter describes of each parameters and data range. 8.1 monitor display mode .......................................................................8-2 8.2 sv setting mode...............................................................................8-6 8....

Page 126: 8.1 Monitor Display Mode

8. Parameter description 8-2 imr02c15-e4 8.1 monitor display mode in monitor display mode, the following monitors are possible. • measured value (pv)/set value (sv) monitor • current transformer 1 (ct1) input value monitor • current transformer 2 (ct2) input value monitor • manipulated output value ...

Page 127: 8.1.2 Monitor Item

8. Parameter description imr02c15-e4 8-3 8.1.2 monitor item measured value (pv)/set value (sv) monitor measured value (pv) display (hereafter called pv display): the measured value (pv) is displayed. Set value (sv) display (hereafter called sv display): the target value for control is displayed. The...

Page 128

8. Parameter description imr02c15-e4 8-4 ダミー current transformer 1 (ct1) input value monitor current transformer 2 (ct2) input value monitor the current value captured by the current transformer (ct) is displayed on the sv display. Display range factory set value when ct type is ctl-6-p-n: 0.0 to 30...

Page 129: Remaining Time Monitor

8. Parameter description imr02c15-e4 8-5 ダミー manipulated output value (mv2) monitor [cool-side] the manipulated output value (mv2) of cool-side is displayed on the sv display. Display range factory set value within output limiter range when the control method is heat/cool pid action, the manipulated...

Page 130: 8.2 Sv Setting Mode

8. Parameter description 8-6 imr02c15-e4 8.2 sv setting mode the sv setting mode is used to sets the set value (sv) or manipulated output value (mv). • when the operation mode is the auto (auto) mode, the set value (sv) can be set. • when the operation mode is the manual (man) mode, the manipulated ...

Page 131: 8.2.2 Setting Item

8. Parameter description imr02c15-e4 8-7 8.2.2 setting item measured value (pv)/set value (sv) pv display: the measured value (pv) is displayed. Sv display: the set value (sv1 to sv4) for control can be set. Only the set value of the sv indicated in the step set value lamp can be set. Display or dat...

Page 132

8. Parameter description imr02c15-e4 8-8 ダミー measured value (pv)/manipulated output value (mv) pv display: the measured value (pv) is displayed. Sv display: when the operation mode is the manual (man) mode, the manipulated output value (mv) can be set. Display or data range factory set value pid con...

Page 133: 8.3 Mode Switching

8. Parameter description imr02c15-e4 8-9 8.3 mode switching in mode switching, the following operations are possible. • auto (auto)/manual (man) transfer • set data unlock/lock transfer • interlock release to hide the parameters, set “no display” to mode selection (no display) (p.8-58) at the functi...

Page 134: 8.3.2 Setting Item

8. Parameter description imr02c15-e4 8-10 8.3.2 setting item auto (auto)/manual (man) transfer factory default setting: the screen is displayed. Use to transfer the auto (auto) mode or manual (man) mode. Auto (auto) mode: automatic control is performed. Manual (man) mode: the manipulated output valu...

Page 135: Interlock Release

8. Parameter description imr02c15-e4 8-11 ダミー interlock release factory default setting: the screen is displayed. Release the interlock state of event. Data range factory set value 0000: interlock release 0001: interlock state (only monitor) 0000 in order to validate the event interlock function, it...

Page 136: 8.4 Parameter Setting Mode

8. Parameter description 8-12 imr02c15-e4 8.4 parameter setting mode set values (sv), event set values, timer parameters and control parameters can be set in this mode. 8.4.1 display sequence parameters will not be displayed if the relevant function is not activated or no relevant specification is s...

Page 137: 8.4.2 Parameter Setting Item

8. Parameter description imr02c15-e4 8-13 8.4.2 parameter setting item set value 1 (sv1) set value 2 (sv2) set value 3 (sv3) set value 4 (sv4) factory default setting: the screen is not displayed. Set value (sv) for control can be set. Up to four set values (sv) can be stored. The (sv) selection fun...

Page 138: Sv Selection

8. Parameter description imr02c15-e4 8-14 sv selection factory default setting: the screen is not displayed. Select set value (sv) for control from sv 1 to sv 4. Data range factory set value 1 to 4 1 this function is not available when sv selection is operated by timer function 3, timer function 4 o...

Page 139: Timer 1

8. Parameter description imr02c15-e4 8-15 timer 1 timer 2 timer 3 timer 4 factory default setting: the screen is not displayed. Set timer time in the timer function to change set value (sv). Data range factory set value 00 minute 01 seconds to 99 minutes 59 seconds or 00 hour 01 minutes to 99 hours ...

Page 140: Timer Function

8. Parameter description imr02c15-e4 8-16 timer function factory default setting: the screen is not displayed. Up to four types of timer functions are available. Data range factory set value 0 (unused), 1 (timer function 1) to 4 (timer function 4) 0 • timer function 1: use the set value (sv) set at ...

Page 141: Repeat Execution Times

8. Parameter description imr02c15-e4 8-17 repeat execution times factory default setting: the screen is not displayed. Set repeat execution times to repeat the ramp/soak control using timer function 3 or 4. Data range factory set value 0 to 9999 (9999: infinite times) 0 timer function 3 or 4 should ...

Page 142

8. Parameter description imr02c15-e4 8-18 setting change rate limiter (up) setting change rate limiter (down) factory default setting: the screen is not displayed. Set the values for setting change rate limiter up and down. Data range factory set value 1 (0.1) to input span (unit °c [°f])/unit time ...

Page 143

8. Parameter description imr02c15-e4 8-19 continued from the previous page. Description of function this function is to allow the set value (sv) to be automatically changed at specific rates when a new set value (sv). Svru is used when the sv is changed to a higher sv. Svrd is used when the sv is ch...

Page 144

8. Parameter description imr02c15-e4 8-20 event 1 set value (ev1), event 1 set value (ev1) [high] event 2 set value (ev2), event 2 set value (ev2) [high] event 3 set value (ev3), event 3 set value (ev3) [high] event 4 set value (ev4), event 4 set value (ev4) [high] factory default setting: the scree...

Page 145

8. Parameter description imr02c15-e4 8-21 continued from the previous page. Related parameters parameter setting mode: • event 1 set value (ev1’) [low] to event 4 set value (ev4’) [low] (p. 8-22) engineering mode: • event 1 set value (ev1) to event 4 set value (ev4) (p. 8-68) • event 1 set value (ev...

Page 146

8. Parameter description imr02c15-e4 8-22 event 1 set value (ev1’) [low] event 2 set value (ev2’) [low] event 3 set value (ev3’) [low] event 4 set value (ev4’) [low] factory default setting: the screen is displayed. When high/low individual setting is selected for the event type, the value is the ev...

Page 147

8. Parameter description imr02c15-e4 8-23 continued from the previous page. Related parameters parameter setting mode: • event 1 set value (ev1) [high] to event 4 set value (ev4) [high] (p. 8-20) engineering mode: • event 1 set value (ev1’) [low] to event 4 set value (ev4’) [low] (p. 8-69) • event 1...

Page 148: Autotuning (At)

8. Parameter description 8-24 imr02c15-e4 autotuning (at) factory default setting: the screen is displayed. To set autotuning (at), set the value to “1.” this allows automated calculating of proportional, integral and derivation. Data range factory set value 0: pid control 1: autotuning (at) 0 autot...

Page 149: Startup Tuning (St)

8. Parameter description imr02c15-e4 8-25 startup tuning (st) factory default setting: the screen is displayed. Use to set the number of execution times of startup tuning (st). Data range factory set value 0: st unused 1: execute once 2: execute always 0 startup tuning (st) is not displayed when the...

Page 150: Integral Time

8. Parameter description imr02c15-e4 8-26 proportional band [heat-side] factory default setting: the screen is displayed. This is a proportional band in p, pi, pd or pid control. When in heat/cool pid control, it becomes the proportional band on the heat side. Data range factory set value tc/rtd inp...

Page 151: Derivative Time

8. Parameter description imr02c15-e4 8-27 derivative time factory default setting: the screen is displayed. Derivative action is to prevent rippling and make control stable by monitoring output change. For heat/cool pid control, the derivative time is same on both heat-side and cool-side. Data range...

Page 152

8. Parameter description imr02c15-e4 8-28 proportional band [cool-side] factory default setting: the screen is displayed. This is a proportional band for the cool side in heat/cool pid control. Data range factory set value 1 to 1000 % of proportional band [heat-side] 100 proportional band [cool-side...

Page 153: Overlap/deadband

8. Parameter description imr02c15-e4 8-29 overlap/deadband factory default setting: the screen is displayed. This is the overlapped range of proportional bands (on the heat and cool sides) or the deadband range when heat/cool pid control is performed. Data range factory set value tc/rtd inputs: −10 ...

Page 154: Fine Tuning Setting

8. Parameter description imr02c15-e4 8-30 fine tuning setting factory default setting: the screen is displayed. Fine tuning function allows the operator to adjust the control response speed without changing pid values. Data range factory set value −3 to +3 (0: unused) 0 positive values quicken the c...

Page 155

8. Parameter description imr02c15-e4 8-31 heater break alarm 1 (hba1) set value heater break alarm 2 (hba2) set value factory default setting: the screen is displayed. Hba1 and hba2 are to set the set values for the heater break alarm (hba) function. Data range factory set value 0.0 to 30.0 a (ctl-6...

Page 156

8. Parameter description imr02c15-e4 8-32 control loop break alarm (lba) time factory default setting: the screen is displayed. The lba time sets the time required for the lba function to determine there is a loop failure. When the lba is output (under alarm status), the lba function still monitors ...

Page 157

8. Parameter description imr02c15-e4 8-33 continued from the previous page. [alarm action] lba determination range: thermocouple/rtd input: 2 °c [°f] fixed voltage/current input: 0.2 % of span fixed • when the output reaches 0 % (low limit with output limit function) for direct action: when the lba ...

Page 158: Lba Deadband (Lbd)

8. Parameter description imr02c15-e4 8-34 lba deadband (lbd) factory default setting: the screen is displayed. The lba deadband gives a neutral zone to prevent the control loop break alarm (lba) from malfunction caused by disturbance. Data range factory set value 0 to input span 0 lbd displays when ...

Page 159

8. Parameter description imr02c15-e4 8-35 continued from the previous page. Lba function is not operative when: • when at function is activated. • when the controller is in stop mode. • lba time is set to “0.” • lba function is not assigned to event 1 (es1) to event 4 (es4). If the lba time is too s...

Page 160

8. Parameter description imr02c15-e4 8-36 proportional cycle time [heat-side] factory default setting: the screen is displayed. Proportional cycle time is to set control cycle time for time based control output such as voltage pulse for ssr, triac, relay and open-collector output. When in heat/cool ...

Page 161: [Heat-Side]

8. Parameter description imr02c15-e4 8-37 minimum on/off time of proportioning cycle [heat-side] factory default setting: the screen is displayed. This is the minimum on/off time of the time proportioning cycle [heat-side]. Data range factory set value 0 to 1000 ms 0 minimum on/off time of proportio...

Page 162: Output Limiter High

8. Parameter description imr02c15-e4 8-38 output limiter high [heat-side output limiter (high)] output limiter low [cool-side output limiter (high)] factory default setting: the screen is displayed. Output limiter high [heat-side output limiter (high)]: use to set the high limit value of manipulated...

Page 163

8. Parameter description imr02c15-e4 8-39 proportional cycle time [cool-side] factory default setting: the screen is displayed. This is a proportional cycle time of cool-side in the heat/cool pid control. Proportional cycle time [cool-side] is to set control cycle time for time based control output ...

Page 164: [Cool-Side]

8. Parameter description imr02c15-e4 8-40 minimum on/off time of proportioning cycle [cool-side] factory default setting: the screen is displayed. This is the minimum on/off time of the time proportioning cycle [cool-side]. Data range factory set value 0 to 1000 ms 0 this parameter is displayed when...

Page 165: Pv Bias

8. Parameter description imr02c15-e4 8-41 pv bias factory default setting: the screen is displayed. Pv bias adds bias to the measured value (pv). The pv bias is used to compensate the individual variations of the sensors or correct the difference between the measured value (pv) of other instruments....

Page 166

8. Parameter description imr02c15-e4 8-42 manual manipulated output value (mv) factory default setting: the screen is not displayed. Setting manipulated output value (mv) in manual (man) mode. Data range factory set value pid control: output limiter low to output limiter high heat/cool pid control: ...

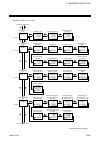

Page 167: 8.5 Engineering Mode

8. Parameter description imr02c15-e4 8-43 8.5 engineering mode the engineering mode allows the control to be set according to application requirements. For parameter details, refer to the 8.5.3 engineering item list (p. 8-57). To configure settings in engineering mode (f21 to f70), the following ste...

Page 168

8. Parameter description imr02c15-e4 8-44 continued from the previous page. * if any of the following event functions are selected, this parameter will be event set value (ev) [high]. (event number at parameter setting shows up in .) ・ band (high/low individual setting) [event type code: u] ・ de...

Page 169

8. Parameter description imr02c15-e4 8-45 continued from the previous page. Continued on the next page. Function block 04 (f04) function block 05 (f05) f05. Sv1 (p. 8-71) atu 0000 sv1 autotuning (at) stu 0000 sv1 startup tuning (st) s .F05 0000 sv1 f05 block selection (no display) (p. 8-71) (p. 8-71...

Page 170

8. Parameter description imr02c15-e4 8-46 continued from the previous page. Continued on the next page. Function block 08 (f08) function block 09 (f09) f09. Sv1 (p. 8-84) pb $ 0000 sv1 pv bias タイ df 0001 sv1 pv digital filter s .F09 0000 sv1 f09 block selection (no display) (p. 8-84) (p. 8-84) (p. 8...

Page 171

8. Parameter description imr02c15-e4 8-47 continued from the previous page. Continued on the next page. Function block 43 (f43) function block 33 (f33) f33. Sv1 (p. 8-98) ao 0001 sv1 transmission output type ahs 1372 sv1 transmission output scale high als -200 sv1 transmission output scale low aofs ...

Page 172

8. Parameter description imr02c15-e4 8-48 continued from the previous page. Continued on the next page. Function block 43 (f43) f43. Sv1 (p. 8-101) es3 0000 sv1 event 3 type eho3 0000 sv1 event 3 hold action eh3 $ 0002 sv1 event 3 differential gap ebo3 0000 sv1 event 3 output action at input burnout...

Page 173

8. Parameter description imr02c15-e4 8-49 continued from the previous page. Continued on the next page. Function block 51 (f51) f51. Sv1 (p. 8-124) os 0000 sv1 direct/reverse action osc 0000 sv1 cool action ohh $ 0001 sv1 on/off action differential gap (upper) ohl $ 0001 sv1 on/off action differenti...

Page 174

8. Parameter description imr02c15-e4 8-50 continued from the previous page. Function block 70 (f70) f70. Sv1 (p. 8-136) svrt 0000 sv1 setting change rate limiter unit time tmu 0000 sv1 timer time unit (p. 8-136) (p. 8-136) function block 60 (f60) function block 00 (f00) function block 91 (f91) f91. ...

Page 175

8. Parameter description imr02c15-e4 8-51 function block (f ) structure in the engineering mode setting items are classified into groups (function block: f ) within the engineering mode. Function block 00 (f00) no display screen settings (monitor display mode, mode switching), set lock level setting...

Page 176

8. Parameter description imr02c15-e4 8-52 8.5.2 precaution against parameter change if any of the following parameters are changed, the set values of relevant parameters are initialized or automatically converted according to the new setting. It may result in malfunction or failure of the instrument...

Page 177

8. Parameter description imr02c15-e4 8-53 item default value item default value event 1 differential gap event 1 timer event 2 differential gap event 2 timer event 3 differential gap event 3 timer event 4 differential gap tc/rtd inputs: 2 (2.0) °c [°f] voltage (v)/current (i) inputs: 0.2 event 4 tim...

Page 178

8. Parameter description imr02c15-e4 8-54 when output limiter high [olh] is changed the following parameter will be automatically converted. • manual manipulated output value (mv) • output limiter low when output limiter low [oll] is changed the following parameter will be automatically converted. •...

Page 179

8. Parameter description imr02c15-e4 8-55 when input scale low (pgsl) is changed the following parameter will be automatically converted. • input scale high • event 2 set value (ev2) • setting limiter high • event 2 set value (ev2) [high] • setting limiter low • event 2 set value (ev2’) [low] • set ...

Page 180

8. Parameter description imr02c15-e4 8-56 example of automatic conversion • decimal point position moves in accordance with the setting change. Example: when the setting of the decimal point position (pgdp) is changed from 1 (one decimal place) to 0 (no decimal place) with input scale high (pgsh) se...

Page 181: Function Block 00 (F00)

8. Parameter description imr02c15-e4 8-57 8.5.3 engineering setting item function block 00 (f00) this is the first parameter symbol of function block 00 (f00). F00 set lock level lock and protect set data of parameters in each parameter group. Data range factory set value 0: all parameters can be ch...

Page 182: Dummy

8. Parameter description imr02c15-e4 8-58 dummy f00 monitor selection (no display) hide parameters in the monitor display mode. To select more than one parameter, set the total value of the parameters. Data range factory set value 0: display all 1: current transformer 1 (ct1) input value monitor [no...

Page 183: Dummy

8. Parameter description imr02c15-e4 8-59 dummy f00 run/stop setting run/stop transfer is can be set in the engineering mode state. Select run or stop and press the key. Data range factory set value 0: run 1: stop (stop lamp lights) 0 set run mode “0: run” prior to transfer run/stop mode by digital ...

Page 184: Dummy

8. Parameter description imr02c15-e4 8-60 dummy function block 01 (f01) this is the first parameter symbol of function block 01 (f01). F01. Set value 1 (sv1) set value 2 (sv2) set value 3 (sv3) set value 4 (sv4) link to the set values sv1 to sv4 of parameter setting mode and the set values (sv) of s...

Page 185: Dummy

8. Parameter description imr02c15-e4 8-61 dummy f01 sv selection link to the sv selection in parameter setting mode. For details of sv selection, refer to 8.4.2 parameter setting item (p. 8-14). Related parameter sv setting mode: • measured value (pv)/set value (sv) (p. 8-7) parameter setting mode: ...

Page 186: Dummy

8. Parameter description imr02c15-e4 8-62 dummy f01 f01 block selection (no display) hide parameter symbols of the parameter setting mode from the display. Data range factory set value 0: display 1: no display 1 when “no display” is selected, the parameters of parameter setting mode are not displaye...

Page 187: Dummy

8. Parameter description imr02c15-e4 8-63 dummy function block 02 (f02) this is the first parameter symbol of function block 02 (f02). F02 timer 1 timer 2 timer 3 timer 4 link to timer 1, 2, 3 or 4 in the parameter setting mode. For details of timer 1 to timer 4, refer to 8.4.2 parameter setting ite...

Page 188: Dummy

8. Parameter description imr02c15-e4 8-64 dummy f02 timer function link to the timer function in the parameter setting mode. For details of timer function, refer to 8.4.2 parameter setting item (p. 8-16). Related parameter parameter setting mode: • timer 1, timer 2, timer 3, and timer 4 (p. 8-15) • ...

Page 189: Dummy

8. Parameter description imr02c15-e4 8-65 dummy f02 f02 block selection (no display) hide parameter symbols of in the parameter setting mode from the display. Data range factory set value 0: display 1: no display 1 when “no display” is selected, the parameters of parameter setting mode are not displ...

Page 190: Dummy

8. Parameter description imr02c15-e4 8-66 dummy function block 03 (f03) this is the first parameter symbol of function block 03 (f03). F03 setting change rate limiter (up) setting change rate limiter (down) link to the setting change rate limiter in parameter setting mode. For details of setting cha...

Page 191: Dummy

8. Parameter description imr02c15-e4 8-67 dummy f03 f03 block selection (no display) hide parameter symbols of in the parameter setting mode from the display. Data range factory set value 0: display 1: no display 1 when “no display” is selected, the parameters of parameter setting mode are not displ...

Page 192: Dummy

8. Parameter description imr02c15-e4 8-68 dummy function block 04 (f04) this is the first parameter symbol of function block 04 (f04). F04 event 1 set value (ev1), event 1 set value (ev1) [high] event 2 set value (ev2), event 2 set value (ev2) [high] event 3 set value (ev3), event 3 set value (ev3) ...

Page 193: Dummy

8. Parameter description imr02c15-e4 8-69 dummy f04 event 1 set value (ev1’) [low] event 2 set value (ev2’) [low] event 3 set value (ev3’) [low] event 4 set value (ev4’) [low] link to the event 1 to event 4 set value [low] in the parameter setting mode. For details of event 1 set value (ev1’) [low] ...

Page 194: Dummy

8. Parameter description imr02c15-e4 8-70 dummy f04 f04 block selection (no display) hide parameter symbols of in the parameter setting mode from the display. Data range factory set value 0: display 1: no display 0 when “no display” is selected, the parameters of parameter setting mode are not displ...

Page 195: Dummy

8. Parameter description imr02c15-e4 8-71 dummy function block 05 (f05) this is the first parameter symbol of function block 05 (f05). F05 autotuning (at) link to the autotuning (at) in the parameter setting mode. For details of autotuning (at), refer to 8.4.2 parameter setting item (p. 8-24). Relat...

Page 196: Dummy

8. Parameter description imr02c15-e4 8-72 dummy f05 f05 block selection (no display) hide parameter symbols of in the parameter setting mode from the display. Data range factory set value 0: display 1: no display 0 when “no display” is selected, the parameters of parameter setting mode are not displ...

Page 197: Dummy

8. Parameter description imr02c15-e4 8-73 dummy function block 06 (f06) this is the first parameter symbol of function block 06 (f06). F06 proportional band [heat-side] link to the proportional band [heat-side] in the parameter setting mode. For details of proportional band [heat-side], refer to 8.4...

Page 198: Dummy

8. Parameter description imr02c15-e4 8-74 dummy f06 derivative time link to the derivative time in the parameter setting mode. For details of derivative time, refer to 8.4.2 parameter setting item (p. 8-27). Related parameter parameter setting mode: • derivative time (p. 8-27) engineering mode: • de...

Page 199: Dummy

8. Parameter description imr02c15-e4 8-75 dummy f06 overlap/deadband link to the overlap/deadband in the parameter setting mode. For details of overlap/deadband, refer to 8.4.2 parameter setting item (p. 8-29). Related parameter parameter setting mode: • proportional band [heat-side] (p. 8-26) • pro...

Page 200: Dummy

8. Parameter description imr02c15-e4 8-76 dummy f06 f06 block selection (no display) hide parameter symbols of in the parameter setting mode from the display. Data range factory set value 0: display 1: no display 0 when “no display” is selected, the parameters of parameter setting mode are not displ...

Page 201: Dummy

8. Parameter description imr02c15-e4 8-77 dummy function block 07 (f07) this is the first parameter symbol of function block 07 (f07). F07 heater break alarm 1 (hba1) set value heater break alarm 2 (hba2) set value link to the heater break alarm 1 (hba1) set value and heater break alarm 2 (hba2) set...

Page 202: Dummy

8. Parameter description imr02c15-e4 8-78 dummy f07 control loop break alarm (lba) time link to the control loop break alarm (lba) time in the parameter setting mode. For details of control loop break alarm (lba) time, refer to 8.4.2 parameter setting item (p. 8-32). Related parameter parameter sett...

Page 203: Dummy

8. Parameter description imr02c15-e4 8-79 dummy f07 f07 block selection (no display) hide parameter symbols of in the parameter setting mode from the display. Data range factory set value 0: display 1: no display 0 when “no display” is selected, the parameters of parameter setting mode are not displ...

Page 204: Dummy

8. Parameter description imr02c15-e4 8-80 dummy function block 08 (f08) this is the first parameter symbol of function block 08 (f08). F08 proportional cycle time [heat-side] link to the proportional cycle time [heat-side] in the parameter setting mode. For details of proportional cycle time [heat-s...

Page 205: Dummy

8. Parameter description imr02c15-e4 8-81 dummy f08 output limiter high [heat-side output limiter (high)] output limiter low [cool-side output limiter (high)] link to the output limiter high and output limiter low in the parameter setting mode. For details of output limiter high and output limiter l...

Page 206: Dummy

8. Parameter description imr02c15-e4 8-82 dummy f08 minimum on/off time of proportioning cycle [cool-side] link to the minimum on/off time of proportioning cycle [cool-side] in the parameter setting mode. For details of minimum on/off time of proportioning cycle [cool-side], refer to 8.4.2 parameter...

Page 207: Dummy

8. Parameter description imr02c15-e4 8-83 dummy f08 f08 block selection (no display) hide parameter symbols of in the parameter setting mode from the display. Data range factory set value 0: display 1: no display 0 when “no display” is selected, the parameters of parameter setting mode are not displ...

Page 208: Dummy

8. Parameter description imr02c15-e4 8-84 dummy function block 09 (f09) this is the first parameter symbol of function block 09 (f09). F09 pv bias link to the pv bias in the parameter setting mode. For details of pv bias, refer to 8.4.2 parameter setting item (p. 8-41). Related parameter parameter s...

Page 209: Dummy

8. Parameter description imr02c15-e4 8-85 dummy f09 f09 block selection (no display) hide parameter symbols of in the parameter setting mode from the display. Data range factory set value 0: display 1: no display 0 when “no display” is selected, the parameters of parameter setting mode are not displ...

Page 210: Dummy

8. Parameter description imr02c15-e4 8-86 dummy function block 10 (f10) this is the first parameter symbol of function block 10 (f10). F10 manual manipulated output value (mv) link to the manual manipulated output value (mv) in the parameter setting mode and measured value (pv)/manipulated output va...

Page 211: Dummy

8. Parameter description imr02c15-e4 8-87 dummy f10 f10 block selection (no display) hide parameter symbols of in the parameter setting mode from the display. Data range factory set value 0: display 1: no display 1 when “no display” is selected, the parameters of parameter setting mode are not displ...

Page 212: Function Block 21 (F21)

8. Parameter description 8-88 imr02c15-e4 to display f21 and after, setting mode (mode selection [no display]) in f00 to 128 is required. (refer to p. 8-52) function block 21 (f21) this is the first parameter symbol of function block 21 (f21). F21 input type data range: 0 to 38 (refer to the followi...

Page 213

8. Parameter description imr02c15-e4 8-89 continued from the previous page. Data range factory set value 33: voltage input 0 to 1 v dc 34: voltage input 0 to 5 v dc 35: voltage input 0 to 10 v dc 36: voltage input 1 to 5 v dc 37: current input 0 to 20 ma dc 38: current input 4 to 20 ma dc programmab...

Page 214: Dummy

8. Parameter description imr02c15-e4 8-90 dummy f21 decimal point position use to select the decimal point position of the input range. Data range factory set value 0: no decimal place 1: one decimal place 2: two decimal places 3: three decimal places tc/rtd input: 0 or 1 voltage (v)/current (i) inp...

Page 215: Dummy

8. Parameter description imr02c15-e4 8-91 dummy f21 input scale high input scale low use to set the high limit and low limit of the input scale range. Data range factory set value input scale high tc/rtd inputs: input scale low to maximum value of the selected input range maximum value of the select...

Page 216

8. Parameter description imr02c15-e4 8-92 description of function the input range can be changed for temperature input (tc/rtd). Example [temperature input]: when the range of −200 to +1372 °c for thermocouple type k is changed to 0 to 400 °c input scale low 0 °c input scale high 400 °c input span 4...

Page 217: Dummy

8. Parameter description imr02c15-e4 8-93 dummy f21 setting limiter high setting limiter low setting limiter high: use to set a high limit of the set value. Setting limiter low: use to set a low limit of the set value. Data range factory set value setting limiter high setting limiter low to input sc...

Page 218: Dummy

8. Parameter description imr02c15-e4 8-94 dummy f21 pv flashing display at input error it can also be set so that the pv display does not flash “1: non-flashing display.” the measured value (pv) of this instrument flashes in the range of an “input span of 5 %” if exceeding the input range. Data rang...

Page 219: Dummy

8. Parameter description imr02c15-e4 8-95 dummy function block 23 (f23) this is the first parameter symbol of function block 23 (f23). F23 di assignment use to assign the function (sv selection function, interlock release, run/stop transfer, or auto/manual transfer) for the digital inputs (di1, di2)...

Page 220: Dummy

8. Parameter description imr02c15-e4 8-96 dummy function block 30 (f30) this is the first parameter symbol of function block 30 (f30). F30 output action at stop mode use to select action of event output or transmission output when the controller is set to stop (control stop). Data range factory set ...

Page 221: Dummy

8. Parameter description imr02c15-e4 8-97 dummy f30 stop display selection stop message for control stop mode can be displayed either on the upper display or the lower display. Spch is to select the display to show the stop message. Data range factory set value 0: stop on pv display + stop lamp (gre...

Page 222: Dummy

8. Parameter description imr02c15-e4 8-98 dummy function block 33 (f33) this is the first parameter symbol of function block 33 (f33). Transmission output (optional) function must be specified. F33 transmission output type use to select the transmission output type. Data range factory set value 0: m...

Page 223: Dummy

8. Parameter description imr02c15-e4 8-99 dummy f33 transmission output scale high transmission output scale low use to set a scale high limit value or low limit value of the transmission output. Data range factory set value transmission output scale high when mv1 is selected: transmission output sc...

Page 224: Dummy

8. Parameter description imr02c15-e4 8-100 dummy f33 ao full scale adjustment value ao zero point adjustment value to correct error between instruments, set ao full scale/zero point adjustment value. Data range factory set value −10.0 to +10.0 % adjustment value do not change the factory set adjustm...

Page 225: Dummy

8. Parameter description imr02c15-e4 8-101 dummy function block 41 (f41) function block 42 (f42) function block 43 (f43) function block 44 (f44) this is the first parameter symbol of function block 41 (f41). This is the first parameter symbol of function block 42 (f42). This is the first parameter s...

Page 226

8. Parameter description imr02c15-e4 8-102 event type set value event type initial setting code 0 none n 1 deviation high (using sv monitor value) 1 a (with hold action: e with re-hold action: q) 2 deviation low (using sv monitor value) 1 b (with hold action: f with re-hold action: r) 3 deviation hi...

Page 227

8. Parameter description imr02c15-e4 8-103 description of function fail operation stops if fail occurs (fail output [fixed at de-energized]: contact open when error occurs) fail output is on (contact open) when power is supplied to the instrument only through loader communication. Monitor during run...

Page 228

8. Parameter description imr02c15-e4 8-104 deviation action (high, low, high/low, band) when the deviation (pv − sv) reaches the event set value, event on occurs. Sv monitor value type and local sv value type are available for deviation action. Sv monitor value type the event set value is set for th...

Page 229

8. Parameter description imr02c15-e4 8-105 some examples of deviation high are described in the following: deviation high: when the deviation (pv – sv) is more than the event set value, the event on occurs. Sv monitor value type (example: when setting change rate limiter is set.) local sv type [even...

Page 230

8. Parameter description imr02c15-e4 8-106 diagrams of the deviation action type are shown in the following: on: event action turned on off: event action turned off deviation high when the deviation (pv – sv) is more than the event set value, the event on occurs. Deviation low when the deviation (pv...

Page 231

8. Parameter description imr02c15-e4 8-107 set value action (high, low) when the set value (sv) reaches the event set value, event on occurs. Sv monitor value type and local sv value type are available for set value action. Sv monitor value type event turns on when sv monitor value reaches event set...

Page 232

8. Parameter description imr02c15-e4 8-108 diagrams of the set value action type are shown in the following: on: event action turned on off: event action turned off sv high sv low when the set value (sv) is more than when the set value (sv) is less than the event set value, the event on occurs. The ...

Page 233

8. Parameter description imr02c15-e4 8-109 control loop break alarm (lba) the control loop break alarm (lba) function is used to detect a load (heater) break or a failure in the external actuator (power controller, magnet relay, etc.), or a failure in the control loop caused by an input (sensor) bre...

Page 234: Dummy

8. Parameter description imr02c15-e4 8-110 dummy f41 event 1 hold action f42 event 2 hold action f43 event 3 hold action f44 event 4 hold action use to set an event hold action for the event 1. Use to set an event hold action for the event 2. Use to set an event hold action for the event 3. Use to s...

Page 235

8. Parameter description imr02c15-e4 8-111 continued from the previous page. When high alarm with hold action/re-hold action is used for event function, alarm does not turn on while hold action is in operation. Use in combination with a high alarm without hold action in order to prevent overheating ...

Page 236

8. Parameter description imr02c15-e4 8-112 (2) re-hold action when re-hold action is on, the event action is also suppressed at the control set value change until the measured value has entered the non-event range. Action condition 1: hold action on (only hold action) 2: re-hold action on (hold and ...

Page 237: Dummy

8. Parameter description imr02c15-e4 8-113 dummy f41 event 1 differential gap f42 event 2 differential gap f43 event 3 differential gap f44 event 4 differential gap use to set a differential gap of the event 1. Use to set a differential gap of the event 2. Use to set a differential gap of the event ...

Page 238

8. Parameter description imr02c15-e4 8-114 description of function it prevents chattering of event output due to the measured value fluctuation around the event set value. Differential gap measured value (pv) event set value on off off event status time measured value (pv) process high differential ...

Page 239: Dummy

8. Parameter description imr02c15-e4 8-115 dummy f41 event 1 output action at input burnout f42 event 2 output action at input burnout f43 event 3 output action at input burnout f44 event 4 output action at input burnout use to select the output action of the event 1 at input burnout. Use to select ...

Page 240: Dummy

8. Parameter description imr02c15-e4 8-116 dummy f41 energized/de-energized of event 1 output f42 energized/de-energized of event 2 output f43 energized/de-energized of event 3 output f44 energized/de-energized of event 4 output use to select the energized or de-energized for the digital output 1 (d...

Page 241

8. Parameter description imr02c15-e4 8-117 description of function energized: relay contact is closed during the event or alarm. De-energized: relay contact opens during the event or alarm. Diagram for explaining operation (at power-on) energized non-event status event status de- energized non-event...

Page 242: Dummy

8. Parameter description imr02c15-e4 8-118 dummy f41 event 1 timer f42 event 2 timer f43 event 3 timer f44 event 4 timer event 1 timer is to set an output delay time for event outputs. Event 2 timer is to set an output delay time for event outputs. Event 3 timer is to set an output delay time for ev...

Page 243

8. Parameter description imr02c15-e4 8-119 description of function when an event condition becomes on, the output is suppressed until the event timer set time elapses. If the event output is still on after time is up, the output will resume. Example: when the setting of event 1 timer is 50 seconds o...

Page 244: Dummy

8. Parameter description imr02c15-e4 8-120 dummy f41 event 1 interlock f42 event 2 interlock f43 event 3 interlock f44 event 4 interlock use to select the interlock function for the event 1. Use to select the interlock function for the event 2. Use to select the interlock function for the event 3. U...

Page 245

8. Parameter description imr02c15-e4 8-121 description of function the event interlock function is used to hold the event state. [example] when the event interlock function is used for deviation high event set value set value (sv) event status off on measured value (pv) time event interlock deviatio...

Page 246: Dummy