- DL manuals

- RKI Instruments

- Measuring Instruments

- EAGLE 2

- Operator's Manual

RKI Instruments EAGLE 2 Operator's Manual

Summary of EAGLE 2

Page 1

Www.Rkiinstruments.Com eagle 2 operator’s manual part number: 71-0154rk revision: v released: 11/3/16.

Page 2: Warning

Eagle 2 operator’s manual warning read and understand this instruction manual before operating instrument. Improper use of the gas monitor could result in bodily harm or death. Periodic calibration and maintenance of the gas monitor is essential for proper operation and correct readings. Please cali...

Page 3: Table Of Contents

Eagle 2 operator’s manual table of contents table of contents chapter 1: introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 about the eagle 2 . . . . ...

Page 4

Table of contents eagle 2 operator’s manual measuring mode, normal operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 monitoring an area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 using optional sample hoses . . . . . . . . . . . . . . . . . . ...

Page 5

Eagle 2 operator’s manual table of contents chapter 5: maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70 overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70 troubleshooting . . . . . . . . . . . . . . . ....

Page 6

Table of contents eagle 2 operator’s manual updating the alarm point settings . . . . . . . . . . . . . . . . . . . . . . . . . 116 updating the alarm latching setting . . . . . . . . . . . . . . . . . . . . . . . 117 updating the alarm silence setting . . . . . . . . . . . . . . . . . . . . . . . ....

Page 7

Eagle 2 operator’s manual table of contents pid probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138 start up and normal operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139 pid relative response feature . . . . . . . . . . . . ...

Page 8

Table of contents eagle 2 operator’s manual tc calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208 maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217 replacing the tc sensor . . . . ....

Page 9

Eagle 2 operator’s manual table of contents infrared hydrocarbon sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254 infrared sub pcb. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254 start up and normal operation . . . . . . . . . . . . . . . . . . . ...

Page 10

Table of contents eagle 2 operator’s manual start up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290 alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292 calibration . . . . . . . ...

Page 11: Chapter 1: Introduction

Eagle 2 operator’s manual overview • 1 chapter 1: introduction overview this chapter briefly describes the eagle 2 gas monitor. This chapter also describes the eagle 2 operator’s manual (this document). Table 1 at the end of this chapter lists the specifications for the eagle 2. About the eagle 2 us...

Page 12

2 • about the eagle 2 eagle 2 operator’s manual • data logging functions (when used in normal mode) • alarm trend data (when used in normal mode) • stel and twa (when used in normal mode) and over range alarms • peak readings (when used in normal mode) • built-in time function • lunch break feature ...

Page 13: Specifications

Eagle 2 operator’s manual specifications • 3 specifications table 1: standard sensor specifications table 2: eagle 2 specifications combustible gas, methane (ch 4 ) calibration standard oxygen (o 2 ) hydrogen sulfide (h 2 s) carbon monoxide (co) detection range 0 - 100 %lel 0 - 40 volume% 0 - 100.0 ...

Page 14: About This Manual

4 • about this manual eagle 2 operator’s manual about this manual the eagle 2 operator’s manual uses the following conventions for notes, cautions, and warnings. Note: describes additional or critical information. Caution: describes potential damage to equipment. Warning: describes potential danger ...

Page 15

Eagle 2 operator’s manual about this manual • 5 • chapter 3 describes the operation of the eagle 2. • chapter 4 describes calibration mode which allows you to calibrate the eagle 2’s active channels. • chapter 5 describes the eagle 2’s maintenance requirements and procedures. • appendix a describes ...

Page 16: Chapter 2: Description

6 • overview eagle 2 operator’s manual chapter 2: description overview this chapter describes the eagle 2 instrument and accessories. Instrument description the eagle 2 includes the case, sensors, lcd, control buttons, printed circuit boards, alarm leds, infrared communication port, buzzer, battery ...

Page 17

Eagle 2 operator’s manual instrument description • 7 figure 2: component location, side view figure 3: component location, front & back top case bottom case strap case foot, 6x handle case screw, 3x (hidden from view) buzzer inlet fitting exhaust fitting battery case thumbscrew charging jack infrare...

Page 18: Case

8 • instrument description eagle 2 operator’s manual case the eagle 2’s sturdy, high-impact plastic case is radio frequency (rf) resistant and is suitable for use in many environmental conditions, indoors and out. The case is dust proof and water resistant. It’s two main components, the top case and...

Page 19: Lcd

Eagle 2 operator’s manual instrument description • 9 oxygen sensor the o 2 sensor is a galvanic type of sensor. A membrane behind the openings on the sensor face allows gas to diffuse into the sensor at a rate proportional to the partial pressure of oxygen. The oxygen reacts in the sensor and produc...

Page 20: Control Buttons

10 • instrument description eagle 2 operator’s manual control buttons four control buttons are located below the lcd. They are, from left to right, power enter reset, display adjust no, air ▲ yes, and range ▼ shift. Table 3: eagle 2 control button functions button function(s) power enter reset • tur...

Page 21

Eagle 2 operator’s manual instrument description • 11 printed circuit boards (pcbs) figure 4: eagle 2 pcbs the eagle 2’s pcbs analyze, record, control, store, and display the information collected. The main pcb and i.S. Barrier pcb are located in the bottom case. The display pcb is located in the to...

Page 22: Alarm Leds

12 • instrument description eagle 2 operator’s manual figure 5: main pcb the main pcb is located on the right side of the bottom case. It slides into guiding grooves at the bottom, front, and rear of the bottom case. It is held in place by the top case. Connectors for the sensors, differential press...

Page 23: Buzzer

Eagle 2 operator’s manual instrument description • 13 infrared port or an irda/usb cable connected to a usb port can be used to download data saved by the eagle 2 to a computer using the eagle 2 data logger management program. See the data logger management program operator’s manual for data logging...

Page 24: Flow System

14 • instrument description eagle 2 operator’s manual flow system the eagle 2 flow system consists of the inlet fitting, hydrophobic filter, pump, internal tubing, differential pressure (dp) switch, sensor chamber, charcoal filter, and exhaust fitting. Inlet fitting the inlet fitting is on the right...

Page 25: Standard Accessories

Eagle 2 operator’s manual standard accessories • 15 the o-ring compression force. Charcoal filter the charcoal filter is located in the front of the flow chamber next to the co sensor. It contains activated charcoal. The co sensor will respond if exposed to h 2 s and certain hydrocarbon gases. The c...

Page 26: Optional Accessories

16 • optional accessories eagle 2 operator’s manual caution: sample hose lengths of more than 125 feet are not recommended for the eagle 2 because of flow rate reduction and increased response time. Consult rki instruments, inc. For hose lengths longer than 125 feet. The probe includes a replaceable...

Page 27: Battery Chargers

Eagle 2 operator’s manual optional accessories • 17 rechargeable ni-mh batteries rechargeable ni-mh batteries are available for the eagle 2. A fully charged set of ni-mh batteries will power the eagle 2 for 18 hours. The batteries will last for a minimum of 500 charge cycles. See “general parts list...

Page 28: Optional Probes

18 • optional accessories eagle 2 operator’s manual dc charger an optional dc powered charger is available with a vehicle plug 12 vdc adapter. It uses the same charging module as the standard ac charger. Figure 8: eagle 2 dc charger ac/dc charger a charger is also available that includes both the ac...

Page 29

Eagle 2 operator’s manual optional accessories • 19 • 30 inch stainless steel probe figure 10: 30 inch stainless steel probe this probe is physically the same as the 30 inch aluminum probe and is intended for applications where a high level of corrosion resistance is required in the long probe tube....

Page 30

20 • optional accessories eagle 2 operator’s manual • 10 inch probe with dust filter figure 13: 10 inch probe with dust filter this probe is designed for use where drawing water or moisture into the eagle 2 is not a concern. Instead of a hydrophobic filter, a cotton dust filter is used. • 32 inch te...

Page 31: External Dilution Fittings

Eagle 2 operator’s manual optional accessories • 21 external dilution fittings two external dilution fittings are available for the eagle 2, a 1:1 dilution fitting and a 3:1 dilution fitting. They are designed to mate with the inlet fitting and accept a sample hose or probe. The fittings are made wi...

Page 32: Chapter 3: Operation

22 • overview eagle 2 operator’s manual chapter 3: operation overview this chapter explains how to use the eagle 2 to perform confined space entry monitoring or general area monitoring in normal mode. There are three operational modes in normal mode: measuring mode, display mode, and calibration mod...

Page 33

Eagle 2 operator’s manual start up • 23 4. The lcd will show the following screen for about ten seconds. 5. The battery voltage screen appears for a few seconds. 6. The active gases screen appears for a few seconds indicating which channels are active and their target gas. 7. If lunch break is turne...

Page 34

24 • start up eagle 2 operator’s manual from the last time the eagle 2 was used. See “time in operation screen” on page 51 for more information about how the eagle 2 tracks the operating time. The short-term exposure limit (stel) reading is reset each time the eagle 2 is turned on. • to reset the ac...

Page 35

Eagle 2 operator’s manual start up • 25 • if the unit is due for calibration and cal past due act is set to confirm to cal, then the following screen displays and the buzzer sounds in a double pulsing pattern. To perform a calibration, press and release the air ▲ yes button. The eagle 2 will enter c...

Page 36

26 • start up eagle 2 operator’s manual will again appear in the startup sequence. • if the unit is due for calibration and cal past due act is set to notification only, then the following alert screen displays and the buzzer sounds in a double pulsing pattern. Press and release the power enter rese...

Page 37: Performing A Demand Zero

Eagle 2 operator’s manual start up • 27 if you wish to continue, press and release the power enter reset button to acknowledge the failure. The gas reading for the failed sensor will be replaced by “xxx”. Replace the failed sensor as soon as possible. 13. The eagle 2 is now monitoring for gas in mea...

Page 38: Continuous Operation

28 • using the battery charger for continuous operation eagle 2 operator’s man - using the battery charger for continuous operation the battery charger can be used with an ac adapter or a vehicle plug dc adapter to run the eagle 2 in continuous operation instead of charging the batteries. Batteries ...

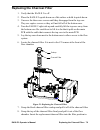

Page 39: Measuring Mode, Normal

Eagle 2 operator’s manual measuring mode, normal operation • 29 7. Insert the module’s round plug into the eagle 2’s charging jack as shown in figure 15 below. Figure 15: connecting the eagle 2 to the charger 8. See “chapter 3: operation” on page 22 for instructions for start-up and operation of the...

Page 40: Monitoring An Area

30 • measuring mode, normal operation eagle 2 operator’s manual monitoring an area 1. Start up the eagle 2 as described above in “start up” on page 22. It is now in measuring mode. 2. Take the eagle 2 to the monitoring area. Put the probe tip in the area to be monitored. Note: if the particle filter...

Page 41: Using Exhaust Tubing

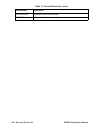

Eagle 2 operator’s manual measuring mode, normal operation • 31 caution: sample hose lengths of more than 125 feet are not recommended for the eagle 2 because of flow rate reduction and increased response time. Consult rki instruments, inc. For hose lengths longer than 125 feet. The chart below illu...

Page 42

32 • measuring mode, normal operation eagle 2 operator’s manual are detecting pentane and the display reads 10% lel for the catalytic combustible channel, you actually have 10% lel x 1.95 = 19.5% lel pentane present. • the eagle 2 provides the catalytic combustible sensor with some protection agains...

Page 43: Range

Eagle 2 operator’s manual measuring mode, normal operation • 33 caution: do not expose the catalytic combustible sensor to high concentrations of combustible gas such as that from a butane lighter. Exposure to high concentrations of combustible gas may adversely affect the performance of the sensor....

Page 44

34 • measuring mode, normal operation eagle 2 operator’s manual if the catalytic units menu item in setup mode is set to change ok, the standard factory setting, then you can change the catalytic combustible channel’s units by pressing and releasing range ▼ shift. Monitoring combustible gas in the p...

Page 45: Measuring Mode, Alarms

Eagle 2 operator’s manual measuring mode, alarms • 35 the %lel and %volume unit readings will still increase up to 100% lel and 15 %volume respectively, which are equivalent to 150,000 ppm. The catalytic combustible sensor is slightly affected by humidity. This is not apparent when the eagle 2 is us...

Page 46: Alarm Indications

36 • measuring mode, alarms eagle 2 operator’s manual alarm indications the eagle 2 will sound an alarm and flash the led arrays when one of the target gas concentrations rises above the low alarm level, or in the case of oxygen falls below the low alarm level, for that gas. The eagle 2 also sounds ...

Page 47

Eagle 2 operator’s manual measuring mode, alarms • 37 resetting and silencing alarms you can set the eagle 2’s gas alarms as latching or self-resetting alarms (see “updating the alarm latching setting” on page 117). • self-resetting alarms (alarm latching set to self reset) self-resetting alarms aut...

Page 48: Responding To Alarms

38 • measuring mode, alarms eagle 2 operator’s manual are the factory settings. When the eagle 2 goes into gas alarm, press and release any button to silence the buzzer. If the gas concentration was still above the alarm level when the button was pressed, the led arrays continue to flash, and the ea...

Page 49

Eagle 2 operator’s manual measuring mode, alarms • 39 responding to over range alarms warning: an over range condition may indicate an extreme combustible gas, toxic gas, or oxygen concentration. Confirm a normal condition with a different eagle 2 or with another gas detecting device. 1. Determine w...

Page 50: Display Mode

40 • display mode eagle 2 operator’s manual 3. If the sensor failure continues, replace the sensor as described in “replacing a sensor” on page 80. 4. If the sensor failure condition continues after you have replaced the sensor, contact rki instruments, inc. For further instructions. Display mode tw...

Page 51: Peak Screen

Eagle 2 operator’s manual display mode • 41 no button. • to enter an item when a question is asked, press and release the air ▲ yes button. • to change a flashing parameter, use either the air ▲ yes button or range ▼ shift button. Note: each screen displays for 20 seconds. If you do not press a butt...

Page 52: Battery Voltage Screen

42 • display mode eagle 2 operator’s manual battery voltage screen the battery voltage screen displays the minimum operating voltage and the current battery voltage. Fully charged alkaline batteries typically indicate 6.0 volts; fully charged ni-mh batteries typically indicate 5.2 volts. This screen...

Page 53

Eagle 2 operator’s manual display mode • 43 if you do not want to change the setting, press and release the display adjust no button and the unit will return to the gas display screen. Catalytic (lel) sensor screen this screen appears only when either a tc sensor or an infrared combustible sensor is...

Page 54

44 • display mode eagle 2 operator’s manual catalytic combustible channel. You can select from a list of gases whose response relative to the configured gas, normally methane, is programmed into the eagle 2’s memory. This includes several pre-defined gases and 5 gases that can be entered into the ea...

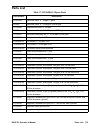

Page 55

Eagle 2 operator’s manual display mode • 45 the following is the complete list of factory defined gases. 2. Use the air ▲ yes or range ▼ shift buttons to move the cursor next to the desired gas. 3. Press and release power enter reset. The catalytic combustible channel will be configured to the selec...

Page 56: Stel Screen

46 • display mode eagle 2 operator’s manual stel screen the stel screen displays the short term exposure limit (stel) readings for h 2 s and co only. The stel reading is the average reading over the last 15 minutes. Twa screen the twa screen displays the time weighted average (twa) readings for h 2 ...

Page 57

Eagle 2 operator’s manual display mode • 47 air ▲ yes button. The following screen appears showing channel 1 alarm points. 2. If the channel description is too long to fit across the screen, press and release the power enter reset button to view the remainder of the displayed channel’s description. ...

Page 58: Select User Id Screen

48 • display mode eagle 2 operator’s manual 4. Press and release the air ▲ yes button to scroll through screens that display the rest of the active channels’ alarm settings. Select user id screen this screen displays only if user/station id in the setup mode menu is set to on (see “turning the user/...

Page 59

Eagle 2 operator’s manual display mode • 49 user ids stored in the eagle 2, see the eagle 2 maintenance data loader program operator’s manual. To select a different user id: 1. With the select user id screen displayed, press and release the air ▲ yes button. A screen appears that includes the curren...

Page 60: Select Station Id Screen

50 • display mode eagle 2 operator’s manual select station id screen this screen displays only if user/station id in the setup mode menu is set to on (see “turning the user/station id function on or off” on page 119). Use this screen to select a station id from the station id list in the eagle 2’s m...

Page 61: Time In Operation Screen

Eagle 2 operator’s manual display mode • 51 screen if the cursor is moved up from the first station id or to the next screen if the cursor is moved down from the last station id. Any of the station ids in the list that have not been changed from the factory setting will be shown as dashes (-). 2. Us...

Page 62: Date/time Screen

52 • display mode eagle 2 operator’s manual date/time screen the date/time screen displays the current date and time. Data logging screen caution: once you clear the data logger, you cannot retrieve any data previously stored in the data logger. The data logging screen displays the time remaining un...

Page 63: Data Logging

Eagle 2 operator’s manual data logging • 53 3. If you want to clear the data logger memory, press and release the air ▲ yes button. The following screen appears asking you to reconfirm that you want to clear the data logger memory. 4. If you want to clear the data logger memory, press and release th...

Page 64

54 • data logging eagle 2 operator’s manual data logger management program and a computer with an infrared port or a usb port that runs one of the following operating systems: windows 2000, windows xp, or windows vista. If your computer has an infrared port, then no additional accessories are needed...

Page 65: Chapter 4: Calibration Mode

Eagle 2 operator’s manual overview • 55 chapter 4: calibration mode overview this section describes the eagle 2 in calibration mode. In calibration mode, you can move through a menu of screens to do the following: • perform a span adjustment on all channels simultaneously using auto calibration • pe...

Page 66: Calibration Supplies and

56 • calibration supplies and equipment eagle 2 operator’s manual calibration supplies and equipment to calibrate the eagle 2, you will need: • known calibrating samples of the gases being detected. The combustible and toxic gas samples should have concentrations between 10 and 50% of the full scale...

Page 67: Entering Calibration Mode

Eagle 2 operator’s manual entering calibration mode • 57 cylinder. This chapter also includes instructions for calibrating one channel at a time using single calibration. Entering calibration mode to enter calibration mode, do the following: 1. Find a fresh-air environment. This is an environment fr...

Page 68: Calibration Method

58 • calibrating using the auto calibration method eagle 2 operator’s manual calibrating using the auto calibration method this method allows you to calibrate the ch 4 (%lel sensor), oxygen, h 2 s, and co sensors simultaneously. It is designed for use with the rki 4-gas calibration cylinder and is t...

Page 69

Eagle 2 operator’s manual calibrating using the auto calibration method • 59 4. The eagle 2 will indicate that it is adjusting the zero reading for a few seconds, then indicate that the operation is complete before returning to the calibration mode screen. Performing a span adjustment in auto calibr...

Page 70

60 • calibrating using the auto calibration method eagle 2 operator’s manual 4. Move the cursor next to the auto calibration menu item by using the air ▲ yes button. 5. Press and release the power enter reset button to display the calibration gas values screen. The gas concentrations displayed in th...

Page 71

Eagle 2 operator’s manual calibrating using the auto calibration method • 61 channel. The calibration gas value begins to flash. 9. Use the air ▲ yes and range ▼ shift buttons to adjust the calibration gas setting to the desired value. Note: the calibration gas value cannot be set lower than the low...

Page 72

62 • calibrating using the auto calibration method eagle 2 operator’s manual changes when the unit is turned off and will load the previous set of auto calibration values when it is turned on again. 15. When you make your selection and press the desired button, the unit returns to the calibration ga...

Page 73

Eagle 2 operator’s manual calibrating using the auto calibration method • 63 19. If all channels passed calibration, the following screen sequence occurs. If any of the sensors cannot be adjusted to the proper value, a screen displays that indicates a calibration failure and lists the sensor(s) that...

Page 74: Calibration Method

64 • calibrating using the single calibration method eagle 2 operator’s manual calibrating using the single calibration method single calibration allows you to calibrate one channel at a time. This is useful if you only want to calibrate one or two channels. Setting the fresh air reading 1. While in...

Page 75

Eagle 2 operator’s manual calibrating using the single calibration method • 65 4. The eagle 2 will indicate that it is adjusting the zero reading for a few seconds, then indicate that the operation is complete before returning to the calibration mode screen. Performing a span adjustment in single ca...

Page 76

66 • calibrating using the single calibration method eagle 2 operator’s manual 4. Move the cursor next to the single calibration menu item by using the air ▲ yes button. 5. Press and release the power enter reset button. The select sensor screen appears with the cursor flashing. 6. Move the cursor n...

Page 77

Eagle 2 operator’s manual calibrating using the single calibration method • 67 7. Press and release the power enter reset button to proceed to the single calibration gas value screen for the selected channel. The calibration gas value is flashing. 8. If necessary, adjust the calibration gas value to...

Page 78

68 • calibrating using the single calibration method eagle 2 operator’s manual response level to the applied gas. This calculated range is independent of the calibration gas value that was entered in step 8 and step 9 above. The adjustment range is included on the result screen to indicate the condi...

Page 79

Eagle 2 operator’s manual calibrating using the single calibration method • 69 caution: when calibrating the oxygen sensor, verify the concentration of oxygen listed on the cylinder’s label. For oxygen-free samples (100% nitrogen for example), set the oxygen calibration value to 0.0%. 15. After the ...

Page 80: Chapter 5: Maintenance

70 • overview eagle 2 operator’s manual chapter 5: maintenance overview this chapter describes troubleshooting procedures for the eagle 2. It also includes procedures for replacing and recharging the batteries and replacing various consumable parts. Warning: rki instruments, inc. Recommends that ser...

Page 81

Eagle 2 operator’s manual troubleshooting • 71 • the unit indicates flow failure and does not recover when power enter reset is pressed and released. • the probe tube is clogged. • the hydrophobic filter disk in the probe is dirty. • the sample hose has a kink or obstruction. • the internal hydropho...

Page 82: Batteries

72 • replacing or recharging the batteries eagle 2 operator’s manual replacing or recharging the batteries warning: to prevent ignition of a hazardous atmosphere, batteries must only be changed or charged in an area known to be nonhazardous. Replace or charge the batteries when the eagle 2 indicates...

Page 83

Eagle 2 operator’s manual replacing or recharging the batteries • 73 figure 16: removing the battery case 3. Pull the battery case away from the bottom case. The thumbscrew is captive and will not fall out. 4. Carefully remove the old batteries. Verify that the battery compartment and electrical con...

Page 84

74 • replacing or recharging the batteries eagle 2 operator’s manual recharging the ni-mh batteries caution: use with ni-mh battery p/n 49-1330rk. Charge only with rki charger model 49-2175rk, 49-2176rk, or 49-2177rk. Use of other rechargeable batteries or chargers or charging of other rechargeable ...

Page 85

Eagle 2 operator’s manual replacing the hydrophobic probe’s particle filter and hydro - 6. While the batteries are charging, the green indicator led will be off and the amber one will be on. 7. The charging module has an internal timeout feature set at 9.5 hours. A full charge should be reached in l...

Page 86

76 • replacing the hydrophobic probe’s particle filter and hydrophobic filter figure 19: replacing the particle filter and hydrophobic filter disk 2. Remove the white hydrophobic filter disk from the top of the particle filter or from the probe body. 3. Remove the particle filter from the probe body...

Page 87

Eagle 2 operator’s manual replacing the hydrophobic filter • 77 7. Place the new filter disk flat on top of the particle filter. Make sure it is centered over the particle filter. 8. Carefully screw the other half of the probe body onto the half with the particle filter and filter disk while keeping...

Page 88

78 • replacing the hydrophobic filter eagle 2 operator’s manual 6. Locate the hydrophobic filter. It is over the oxygen sensor. Note which side of the hydrophobic filter has the rki logo and part number. This is the inlet side and should be facing toward the front of the eagle 2. Figure 20: replacin...

Page 89

Eagle 2 operator’s manual replacing the charcoal filter • 79 replacing the charcoal filter 1. Verify that the eagle 2 is off. 2. Place the eagle 2 upside down on a flat surface or hold it upside down. 3. Unscrew the three case screws until they disengage from the top case. They are captive screws so...

Page 90: Sensor’S Condition

80 • checking the combustible gas sensor’s conditioneagle 2 operator’s manual the flow chamber and push it in until it bottoms out. 9. Insert the charcoal filter endcap into the end of the charcoal filter and push it in until it bottoms out. 10. Confirm that the main pcb is seated in its slots and t...

Page 91

Eagle 2 operator’s manual replacing a sensor • 81 5. Lay the top case down next to the bottom case to allow access to the flow system. 6. Locate the sensor you want to replace and remove it from the flow chamber. Figure 22: replacing a sensor 7. To remove the lel sensor, do the following: • unscrew ...

Page 92

82 • replacing a sensor eagle 2 operator’s manual • if the sensor stayed in the flow chamber, grasp the sensor and pull it out of the flow chamber. 8. To remove the oxygen sensor, do the following: • unscrew the two screws that hold the oxygen sensor bracket a few turns so that you can rotate and re...

Page 93

Eagle 2 operator’s manual replacing a sensor • 83 • insert the lel sensor into the lel sensor chamber in the flow chamber. • line up the holes in the lel sensor bracket with the two standoffs on either side of the lel sensor chamber. • install the two sensor bracket screws tightening them a little a...

Page 94: General Parts List

84 • general parts list eagle 2 operator’s manual general parts list table 11 lists part numbers for the eagle 2’s replacement parts and accessories. Table 11: general parts list part number description 06-1248rk-03 calibration kit tubing,3 foot length 07-7210rk o-ring for inlet fitting half of prob...

Page 95

Eagle 2 operator’s manual general parts list • 85 49-2177rk 115/220 vac and 12 vdc charger 65-0601rk oxygen sensor 65-2005rk carbon monoxide (co) sensor 71-0154rk operator’s manual, eagle 2 (this document) 71-0170rk operator’s manual, eagle 2 data logger management program 71-8003rk eagle 2 product ...

Page 96

86 • general parts list eagle 2 operator’s manual es-87rw-h2s hydrogen sulfide (h 2 s) sensor nc-6260b lel combustible sensor, catalytic table 11: general parts list (cont.) part number description.

Page 97: Overview

Eagle 2 operator’s manual overview • 87 appendix a: calibrating with a sample bag overview the eagle 2 can be calibrated with a gas bag calibration kit instead of a demand flow regulator kit. This appendix describes how to use a sample bag calibration kit to calibrate the eagle 2. A parts list at th...

Page 98: Entering Calibration Mode

88 • entering calibration mode eagle 2 operator’s manual to calibrate the eagle 2, you will need: • known calibrating samples of the gases being detected. The combustible and toxic gas samples should have concentrations between 10 and 50% of the full scale value. For example, if you are calibrating ...

Page 99: Calibration Method

Eagle 2 operator’s manual calibrating using the auto calibration method • 89 3. If the unit prompts you for the password, enter it by using the air ▲ yes and range ▼ shift buttons to select each password number and then pressing and releasing power enter reset to enter the number and move on to the ...

Page 100

90 • calibrating using the auto calibration method eagle 2 operator’s manual 2. Press and release the power enter reset button. The following screen appears. 3. Press and release the air ▲ yes button to continue. If you do not want to continue, press the display adjust no button and the unit will re...

Page 101

Eagle 2 operator’s manual calibrating using the auto calibration method • 91 2. Install the probe on the eagle 2 inlet fitting. Make sure the probe is complete with internal o-ring and membrane and that the two halves of the probe are tightened firmly together to avoid leaks that can affect the cali...

Page 102

92 • calibrating using the auto calibration method eagle 2 operator’s manual 5. To adjust the values on the screen, hold down the range ▼ shift button, then press the display adjust no button and release both. The following screen appears with the cursor next to ch4. 6. Place the cursor next to the ...

Page 103

Eagle 2 operator’s manual calibrating using the auto calibration method • 93 12. Press and release the power enter reset button. The following screen appears. 13. If you select yes by pressing and releasing the air ▲ yes button, the changes that you made will be saved in the eagle 2’s memory as the ...

Page 104

94 • calibrating using the auto calibration method eagle 2 operator’s manual 17. Fill the gas collection bag by screwing the fixed flow regulator or dispensing valve onto the calibration cylinder and turning the knob counterclockwise. 18. Allow the gas to dispense until the gas collection bag is a l...

Page 105: Calibration Method

Eagle 2 operator’s manual calibrating using the single calibration method • 95 if any of the sensors cannot be adjusted to the proper value, a screen displays that indicates a calibration failure and lists the sensor(s) that failed to calibrate. In the example below, the oxygen and h 2 s channels fa...

Page 106

96 • calibrating using the single calibration method eagle 2 operator’s manual 2. Press and release the power enter reset button. The following screen appears. 3. Press and release the air ▲ yes button to continue. If you do not want to continue, press the display adjust no button and the unit will ...

Page 107

Eagle 2 operator’s manual calibrating using the single calibration method • 97 performing a span adjustment in single calibration 1. Slide the tubing clamp onto the tubing and connect the tubing to the sample bag’s inlet. Leave the clamp unclamped for now. 2. Connect the other end of the tubing to t...

Page 108

98 • calibrating using the single calibration method eagle 2 operator’s manual and press and release power enter reset to return to the calibration mode screen. If you do want to continue with the calibration, proceed with the next step. 7. Press and release the power enter reset button to proceed t...

Page 109

Eagle 2 operator’s manual calibrating using the single calibration method • 99 12. Turn the knob clockwise to stop the gas flow, clamp down the hose clamp and remove the regulator or dispensing valve from the cylinder. 13. Disconnect the tubing from the regulator or dispensing valve. 14. Open the ho...

Page 110

100 • calibrating using the single calibration method eagle 2 operator’s manual in the example above, the eagle 2 could have adjusted the reading as low as 11 %lel and as high as 43 %lel. Since the calibration gas value entered was 50 %lel, the unit failed the span adjustment. The buzzer and alarm l...

Page 111: Parts List

Eagle 2 operator’s manual parts list • 101 parts list table 12: sample bag calibration kit spare parts part number description 06-1248rk-03 calibration kit tubing,3 foot length 81-0090rk-01 calibration cylinder, 3-gas mix, lel/oxygen/co, 34 liter steel 81-0154rk-04 calibration cylinder, 4-gas mix, l...

Page 112: Appendix B: Setup Mode

102 • overview eagle 2 operator’s manual appendix b: setup mode overview this appendix describes the eagle 2 in setup mode. In setup mode, you can: • set the date and time • set the date format • set the battery type • configure the channels • configure the gas for a catalytic or pid channel • set t...

Page 113: Tips For Using Setup Mode

Eagle 2 operator’s manual tips for using setup mode • 103 • turn the confirmation alert feature on or off • turn the password feature on or off and set the password • reset the instrument parameters to their default settings • turn the lunch break function on or off • turn the span factor on or off ...

Page 114: Using Setup Mode

104 • using setup mode eagle 2 operator’s manual • press the display adjust no button while in a screen where you are entering or updating parameters to exit the screen without saving any changes. Using setup mode warning: the eagle 2 is not in operation as a gas detector while in setup mode. 1. Tak...

Page 115: Setting The Date And Time

Eagle 2 operator’s manual using setup mode • 105 5. If the unit prompts you for the password, enter it by using the air ▲ yes and range ▼ shift buttons to select each password number and then pressing and releasing the power enter reset button to enter it and move on to the next number until all of ...

Page 116: Setting The Battery Type

106 • using setup mode eagle 2 operator’s manual 2. Press and release power enter reset. The set date format screen appears with the current setting flashing. 3. Use air ▲ yes or range ▼ shift to display the desired setting. 4. Press and release power enter reset to save the setting and return to th...

Page 117

Eagle 2 operator’s manual using setup mode • 107 configuration. Caution: before changing the channel configuration, confirm that the correct sensors and electronic hardware are installed in the eagle 2 and that its construction and flow system are appropriate for the installed sensors. Operation of ...

Page 118

108 • using setup mode eagle 2 operator’s manual 4. Press and release power enter reset. The available configuration options are shown. In the example below, channel 3 has been selected for configuration. 5. Use air ▲ yes and range ▼ shift to move the cursor next to the desired configuration for the...

Page 119

Eagle 2 operator’s manual using setup mode • 109 8. Use range ▼ shift to move the cursor next to the end menu item. Note: if you want to exit to the main menu without saving any channel configuration changes, press and release display adjust no. 9. Press and release power enter reset to save the cha...

Page 120

110 • using setup mode eagle 2 operator’s manual lel is shown in terms of ppm. The available choices are on two screens. All of the gases except for the one with the asterisk (*) next to it are pre- defined. The gas with the asterisk next to it is user defined. The user defined gas can be used if th...

Page 121

Eagle 2 operator’s manual using setup mode • 111 warning: do not configure the catalytic sensor gas to hydrogen if you are monitoring for general hydrocarbons. Only use this selection if you are monitoring exclusively for hydrogen or if you do not want to see a significant response to other combusti...

Page 122

112 • using setup mode eagle 2 operator’s manual • 10000 ppm - - - * this selection is a user defined selection. The factory setting is 10000 ppm - - - *, with the asterisk (*) indicating that it is user defined. If this selection has been updated in the field, it will appear differently, but the as...

Page 123

Eagle 2 operator’s manual using setup mode • 113 note: if you define a gas whose lel is above 50,000 ppm, the %lel reading in measuring mode will reflect the defined ppm ratio, but the ppm reading in measuring mode will not indicate above 50,000 ppm. For example, if you set the ratio to be 150,000 p...

Page 124

114 • using setup mode eagle 2 operator’s manual mode. 13. Use air ▲ yes or range ▼ shift to display the desired catalytic sensor voltage, 1.30 volts or 2.40 volts. 14. Press and release power enter reset. The confirmation screen appears. In the example below, the user defined gas has been selected ...

Page 125

Eagle 2 operator’s manual using setup mode • 115 2. Press and release power enter reset. The catalytic units screen appears with the current setting flashing at the bottom of the screen. 3. Use air ▲ yes or range ▼ shift to scroll through the choices, change ok, vol% only, %lel only, and ppm only. 4...

Page 126

116 • using setup mode eagle 2 operator’s manual updating the alarm point settings this menu item allows you to update one or more alarm points (the reading at which the eagle 2 recognizes the alarm condition). 1. From the main menu, place the cursor next to alarm points. 2. Press and release power ...

Page 127

Eagle 2 operator’s manual using setup mode • 117 5. Press and release power enter reset. The alarm point or alarm operation (oxygen only) will begin to flash. 6. Use air ▲ yes and range ▼ shift to adjust the alarm point or alarm operation (oxygen only) to the desired setting. Keep the following in m...

Page 128

118 • using setup mode eagle 2 operator’s manual 1. From the main menu, place the cursor next to alarm latching. 2. Press and release power enter reset. The alarm latching screen appears. 3. Use air ▲ yes or range ▼ shift to display the desired setting. 4. Press and release power enter reset to save...

Page 129

Eagle 2 operator’s manual using setup mode • 119 3. Use air ▲ yes or range ▼ shift to display the desired setting. 4. Press and release power enter reset to save the setting and return to the main menu. Turning the user/station id function on or off with user/station id set to on, the id screen disp...

Page 130

120 • using setup mode eagle 2 operator’s manual 2. Press and release power enter reset. The adjust auto calibration values screen appears. The auto calibration value for each channel is shown. 3. Use air ▲ yes or range ▼ shift to place the cursor next to the auto calibration value you want to chang...

Page 131

Eagle 2 operator’s manual using setup mode • 121 3. Use air ▲ yes and range ▼ shift to adjust the time to the desired setting. 4. Press and release power enter reset to save the setting and return to the main menu. Updating the auto fresh air setting this setting allows you to configure the eagle 2 ...

Page 132

122 • using setup mode eagle 2 operator’s manual 2. Press and release power enter reset. The data log interval screen appears. 3. Use air ▲ yes or range ▼ shift to display the desired setting. 4. Press and release power enter reset to save the setting and return to the main menu. Updating the data l...

Page 133

Eagle 2 operator’s manual using setup mode • 123 shows the remaining log time and does not give you the opportunity to clear the logged data. 1. From the main menu, place the cursor next to data log memory. 2. Press and release power enter reset. The prompt to clear data log memory? Screen appears. ...

Page 134

124 • using setup mode eagle 2 operator’s manual 1. From the main menu, place the cursor next to cal reminder. 2. Press and release power enter reset. The calibration reminder screen appears. 3. Use air ▲ yes or range ▼ shift to display the desired setting. 4. Press and release power enter reset to ...

Page 135: Updating Lc/bh Mode Setting

Eagle 2 operator’s manual using setup mode • 125 2. Press and release power enter reset. The calibration past due action screen appears. 3. Use air ▲ yes or range ▼ shift to display the desired setting. 4. Press and release power enter reset to save the setting and return to the main menu. Updating ...

Page 136

126 • using setup mode eagle 2 operator’s manual with lc/bh mode select set to leak check only, the mode select screen appears when the unit is turned on. You are able to select from normal mode and leak check mode. With lc/bh mode select set to off, the mode select screen does not appear when the u...

Page 137: Zero Follower Settings

Eagle 2 operator’s manual using setup mode • 127 4. Press and release power enter reset to save the setting and return to the main menu. Zero follower settings the zero follower setting is not intended for field adjustment. The default setting for most target gases is on. The default setting for car...

Page 138

128 • using setup mode eagle 2 operator’s manual turning the password function on or off with change password set to on, the eagle 2 prompts you for a password when you enter calibration mode or setup mode. Note: if a calibration is due and cal reminder is set to on and cal past due act is set to mu...

Page 139

Eagle 2 operator’s manual using setup mode • 129 password is saved and you return to the main menu. Restoring the default settings each of the eagle 2 setup parameters, such as the auto calibration values, zero and span settings, or parameters in setup mode, has a default setting. For the items in s...

Page 140

130 • using setup mode eagle 2 operator’s manual 4. Press and release air ▲ yes. A screen appears asking you to confirm that you want to restore the default configuration. 5. Press and release air ▲ yes. The screen will indicate that the default configuration has been restored and return to the main...

Page 141

Eagle 2 operator’s manual using setup mode • 131 1. From the main menu, place the cursor next to span factor. 2. Press and release power enter reset. The span factor screen appears. 3. Use air ▲ yes or range ▼ shift to display the desired setting. 4. Press and release power enter reset to save the s...

Page 142: Exiting Setup Mode

132 • using setup mode eagle 2 operator’s manual exiting setup mode 1. From the main menu, place the cursor in front of normal operation at the bottom of the menu. 2. Press and release power enter reset. 3. A screen appears that asks if you want to save the changes you have made. Note: if you entere...

Page 143: Appendix C: Sub Pcbs

Eagle 2 operator’s manual overview • 133 appendix c: sub pcbs overview an eagle 2 that has one or more of the standard four sensors, catalytic lel, oxygen, h 2 s, and co, and no optional sensors does not have any sub pcbs installed. The sub pcbs are used to add circuitry to the eagle 2 that supports...

Page 144: Channel Setup & Sub Pcbs

134 • channel setup & sub pcbs eagle 2 operator’s manual retained in place with a screw/flat washer/lock washer. Any sub pcb can be installed in any of the sub pcb positions. A sensor that is supported by a sub pcb connects to that sub pcb with a cable. There are four types of sub pcbs, each support...

Page 145

Eagle 2 operator’s manual channel setup & sub pcbs • 135 configure channels lcd screen below illustrates this situation. The “---” to the right of op1 indicates that no sub pcb is installed in position sub1. See “configuring the channels” on page 106 for a complete description of the configure chann...

Page 146

136 • channel setup & sub pcbs eagle 2 operator’s manual • the currently configured gas the catalytic sensor is always defined and configured even if it is not setup as active in configure channels. If any of the sub pcbs are not installed, then the corresponding sensor is undefined and the next two...

Page 147: Appendix D: Pid Sensors

Eagle 2 operator’s manual overview • 137 appendix d: pid sensors overview the pid (photo ionization detector) sensors are used for applications where high sensitivity is needed to monitor ppm levels of vocs (volatile organic compounds). This appendix describes the eagle 2’s pid sensors and includes ...

Page 148: Pid Sensor & Sensor Adapter

138 • description eagle 2 operator’s manual figure 25: typical pid sensor location pid sensor & sensor adapter the pid sensor is a cylindrical sensor with a diffusion opening on the front and 3 pins on the back. It is plugged into a sensor adapter with a 5 wire cable that terminates in a 5-position ...

Page 149

Eagle 2 operator’s manual start up and normal operation • 139 use the probe intended for pid use that does not have a particle filter installed and that you install the probe directly to the inlet fitting when monitoring for gas with the pid sensor. The figure below shows an exploded drawing of the ...

Page 150

140 • start up and normal operation eagle 2 operator’s manual state, the alternating numbers will be replaced by a gas reading. If the sensor doesn’t exit its warm up state after 5 minutes, see “troubleshooting” on page 161. • if using a probe, be sure to use the pid probe that does not have a parti...

Page 151

Eagle 2 operator’s manual pid relative response feature • 141 pid relative response feature the relative response feature enables you to change the pid sensor’s response to gas on the fly so that the pid channel is roughly calibrated to an alternate gas. This is done by temporarily changing the gas ...

Page 152

142 • pid relative response feature eagle 2 operator’s manual 2. With the pid sensor relative response screen displayed, press and release air ▲ yes. A list of gases will appear on the screen with exit at the top of the list. There are multiple screens of gases. The following is the complete list of...

Page 153

Eagle 2 operator’s manual pid relative response feature • 143 table 15: high range relative response gas list the last choice in each list, pid, can be defined by the user and loaded in the eagle 2 using the eagle 2 maintenance data loader program. See the eagle 2 maintenance data loader program ope...

Page 154: Pid Calibration

144 • pid calibration eagle 2 operator’s manual pid calibration a pid channel can be calibrated using the auto calibration method or the single calibration method. To calibrate a pid channel using the single calibration method, see “calibrating using the single calibration method” on page 64 and fol...

Page 155

Eagle 2 operator’s manual pid calibration • 145 5. The calibration mode screen displays with the cursor next to auto calibration. 6. Move the cursor to the perform air adjust menu item by using the range ▼ shift button. 7. Press and release the power enter reset button. The following screen appears....

Page 156

146 • pid calibration eagle 2 operator’s manual 9. The eagle 2 will indicate that it is adjusting the zero reading for a few seconds, then indicate that the operation is complete before returning to the calibration mode screen. 10. Install the demand flow regulator onto the multi-gas calibration cyl...

Page 157

Eagle 2 operator’s manual pid calibration • 147 13. Move the cursor next to the auto calibration menu item by using the air ▲ yes button. 14. Press and release the power enter reset button to display the calibration gas values screen. The gas concentrations displayed in the calibration gas values sc...

Page 158

148 • pid calibration eagle 2 operator’s manual channel. The calibration gas value begins to flash. 18. Use the air ▲ yes and range ▼ shift buttons to adjust the calibration gas setting to the desired value. Note: the calibration gas value cannot be set lower than the low alarm setting. If the calib...

Page 159

Eagle 2 operator’s manual pid calibration • 149 changes when the unit is turned off and will load the previous set of auto calibration values when it is turned on again. 24. When you make your selection and press the desired button, the unit returns to the calibration gas values screen. 25. Press an...

Page 160

150 • pid calibration eagle 2 operator’s manual 28. If all channels passed calibration, the following screen sequence occurs. If any of the sensors cannot be adjusted to the proper value, a screen displays that indicates a calibration failure and lists the sensor(s) that failed to calibrate. In the ...

Page 161

Eagle 2 operator’s manual pid calibration • 151 31. If you want to change the pid channel’s calibration gas value, follow step 5 - step 24 above beginning with the pid calibration gas value screen below instead of the standard channel calibration gas value screen. 32. With the pid calibration gas va...

Page 162

152 • pid calibration eagle 2 operator’s manual 36. If the pid channel passed calibration, the following screen sequence occurs. If the pid channel cannot be adjusted to the proper value, a screen displays that indicates a calibration failure and indicates that the pid sensor failed to calibrate. Th...

Page 163

Eagle 2 operator’s manual pid calibration • 153 calibrating with a 5-gas cylinder 1. See “calibration supplies and equipment” on page 56 for a description of the necessary calibration supplies. See table 17 on page 179 for available cylinders. Make sure your calibration cylinder is appropriate for t...

Page 164

154 • pid calibration eagle 2 operator’s manual 7. Press and release the power enter reset button. The following screen appears. 8. Press and release the air ▲ yes button to continue. If you do not want to continue, press the display adjust no button and the unit will return to the calibration mode ...

Page 165

Eagle 2 operator’s manual pid calibration • 155 complete with internal o-ring and membrane and that the two halves of the probe are tightened firmly together to avoid leaks that can affect the calibration. See figure 19, “replacing the particle filter and hydrophobic filter disk” on page 76 for an i...

Page 166

156 • pid calibration eagle 2 operator’s manual 15. To adjust the values on the screen, press and hold the range ▼ shift button, then press the display adjust no button and release both. The following screen appears with the cursor next to ch4. 16. Place the cursor next to the channel whose gas valu...

Page 167

Eagle 2 operator’s manual pid calibration • 157 22. Press and release the power enter reset button. The following screen appears. 23. If you select yes by pressing and releasing the air ▲ yes button, the changes that you made will be saved in the eagle 2’s memory as the new auto calibration gas valu...

Page 168

158 • pid calibration eagle 2 operator’s manual 27. Press and release the power enter reset button to set the span adjustment for each channel to the programmed values. 28. If all channels passed calibration, the following screen sequence occurs. If any of the sensors cannot be adjusted to the prope...

Page 169

Eagle 2 operator’s manual pid calibration • 159 29. If you want to change the pid channel’s calibration gas value, follow step 5 - step 24 above beginning with the pid calibration gas value screen below instead of the standard channel calibration gas value screen. 30. With the pid calibration gas va...

Page 170

160 • pid calibration eagle 2 operator’s manual 33. If the pid channel passed calibration, the following screen sequence occurs. If the pid channel cannot be adjusted to the proper value, a screen displays that indicates a calibration failure and indicates that the pid sensor failed to calibrate. Th...

Page 171: Maintenance

Eagle 2 operator’s manual maintenance • 161 maintenance the pid sensor includes user serviceable parts. They are the lamp and the electrode stack. The following sections include troubleshooting instructions as well as procedures for cleaning the lamp, replacing the lamp, replacing the electrode stac...

Page 172

162 • maintenance eagle 2 operator’s manual • a small vial of aluminum oxide powder • 40 cotton swabs • 10 finger cots perform the following procedure to clean the pid lamp: 1. Verify that the eagle 2 is off. 2. Place the eagle 2 upside down on a flat surface or hold it upside down. 3. Unscrew the t...

Page 173

Eagle 2 operator’s manual maintenance • 163 10. Hold the pid sensor steady on the working surface with one hand and using the other hand, locate the tabs on the electrode stack removal tool and insert them into the slots on the side of the pid sensor near the face. Figure 27: using removal tool 11. ...

Page 174

164 • maintenance eagle 2 operator’s manual 16. Use this cotton swab to polish the pid lamp window. Use a circular motion, applying light pressure to clean the lamp window. Do not touch the lamp window with your fingers. Figure 29: polishing the electrode lamp window 17. Continue polishing until you...

Page 175

Eagle 2 operator’s manual maintenance • 165 20. Hold the electrode stack between the thumb and forefinger of one hand and place the window end of the lamp inside the o-ring seal in the electrode stack with the other hand as shown below. Figure 30: reinstalling the electrode lamp 21. Twisting the lam...

Page 176

166 • maintenance eagle 2 operator’s manual 28. Confirm that the main pcb is seated in its slots and that its bottom edge is resting on the bottom of the bottom case. If the main pcb is not seated properly, it may be damaged when the top case is re-installed. 29. Make sure that the top case gasket i...

Page 177

Eagle 2 operator’s manual maintenance • 167 using the other hand, locate the tabs on the electrode stack removal tool and insert them into the slots on the side of the pid sensor near the face. Figure 31: using removal tool 11. Squeeze the removal tool to push the tabs into the sensor slots until th...

Page 178

168 • maintenance eagle 2 operator’s manual figure 32: reinstalling the electrode lamp 16. Twisting the lamp slightly during insertion will help to ensure the lamp window is snug against the stack's front electrode. The lamp should be supported by the o-ring. 17. Continuing to hold the electrode sta...

Page 179

Eagle 2 operator’s manual maintenance • 169 24. Make sure that the top case gasket is fully seated in its groove and carefully put the top case back on the bottom case. If you have any difficulty mating the top and bottom cases, inspect the placement of the main pcb and the placement of the top case...

Page 180

170 • maintenance eagle 2 operator’s manual note: at this point it is recommended that the finger cots be used on the fingers handling the lamp. Finger cots are included with the lamp cleaning kit. 10. Hold the pid sensor steady on the working surface with one hand and using the other hand, locate t...

Page 181

Eagle 2 operator’s manual maintenance • 171 figure 34: reinstalling electrode lamp 16. Twisting the lamp slightly during insertion will help to ensure the lamp window is snug against the stack's front electrode. The lamp should be supported by the o-ring. 17. Continuing to hold the electrode stack b...

Page 182: Replacing The Pid Sensor

172 • maintenance eagle 2 operator’s manual is resting on the bottom of the bottom case. If the main pcb is not seated properly, it may be damaged when the top case is re-installed. 24. Make sure that the top case gasket is fully seated in its groove and carefully put the top case back on the bottom...

Page 183: Configuring The Pid Gas In

Eagle 2 operator’s manual configuring the pid gas in setup mode • 173 12. Insert the sensor adapter into the pid flow chamber and push it in until it bottoms out. 13. Plug the pid cable connector into the pid sub pcb on the main pcb. 14. Confirm that the main pcb is seated in its slots and that its ...

Page 184

174 • configuring the pid gas in setup mode eagle 2 operator’s manual 4. The “s” will then disappear and the following screen will appear for a few seconds. 5. If the unit prompts you for the password, enter it by using air ▲ yes and range ▼ shift to select each password number and then pressing and...

Page 185

Eagle 2 operator’s manual configuring the pid gas in setup mode • 175 8. Use range ▼ shift to move the cursor down the menu to the pid sensor. 9. To change the pid sensor gas configuration, press and release power enter reset. 10. A screen appears that indicates the pid type, low range or high range...

Page 186

176 • configuring the pid gas in setup mode eagle 2 operator’s manual 12. Use air ▲ yes and range ▼ shift to place the cursor next to the desired gas. In the example below, the cursor is placed next to isopropanol (ipa). Table 16: pid gas configurations gas name (lcd abbreviation) detection range fu...

Page 187

Eagle 2 operator’s manual configuring the pid gas in setup mode • 177 13. Press and release the power enter reset button. The lcd will ask for confirmation that you want to change the configured gas. 14. To change the gas configuration, press and release air ▲ yes. The unit will return to the config...

Page 188

178 • configuring the pid gas in setup mode eagle 2 operator’s manual 19. A screen appears that asks if you want to save the changes you have made. Note: if you entered setup mode and did not make any changes, the above screen will still appear. In this case, press and release display adjust no to p...

Page 189: Parts List

Eagle 2 operator’s manual parts list • 179 parts list table 17: pid eagle 2 spare parts part number description 33-0560rk electrode stack, 0 - 50 ppm, 2 pack 33-0562 electrode stack, 0 - 2,000 ppm, hppm type 51-1500rk replacement lamp, 0 - 50 ppm 51-1502 replacement lamp, 0 - 2,000 ppm, hppm type 51...

Page 190: Overview

180 • overview eagle 2 operator’s manual appendix e: esm-01 toxic sensors overview the esm-01 sensors are used to monitor levels of a variety of toxic gases. This appendix describes the eagle 2’s esm-01 sensors and includes instructions to use an eagle 2 that has one or more esm-01 sensors installed...

Page 191: Esm-01 Sensor

Eagle 2 operator’s manual description • 181 see “replacing the esm-01 sensor or changing sensor type” on page 200 for instructions to replace or change an esm-01 sensor. Figure 35: typical esm-01 sensor location the esm-01 sensor is installed in a single sensor flow chamber which is located in the a...

Page 192: Esm-01 Sub Pcb

182 • start up and normal operation eagle 2 operator’s manual esm-01 sub pcb the esm-01 sub pcb is a circuit board that is installed on the main pcb in one of the 3 sub pcb positions when an esm-01 sensor is used with the eagle 2. The esm-01 sensor connects to the sub pcb with a 12-position connecto...

Page 193: Esm-01 Cylinder

Eagle 2 operator’s manual esm-01 calibration • 183 described below in “calibrating with a 5-gas cylinder” on page 192, uses a multi-gas cylinder that contains the target gas for all installed sensors. Follow the set of instructions appropriate for your cylinder configuration. Note: if your instrumen...

Page 194

184 • esm-01 calibration eagle 2 operator’s manual 6. Move the cursor to the perform air adjust menu item by using the range ▼ shift button. 7. Press and release the power enter reset button. The following screen appears. 8. Press and release the air ▲ yes button to continue. If you do not want to c...

Page 195

Eagle 2 operator’s manual esm-01 calibration • 185 9. The eagle 2 will indicate that it is adjusting the zero reading for a few seconds, then indicate that the operation is complete before returning to the calibration mode screen. 10. Install the demand flow regulator onto the multi-gas calibration ...

Page 196

186 • esm-01 calibration eagle 2 operator’s manual 13. Move the cursor next to the auto calibration menu item by using the air ▲ yes button. 14. Press and release the power enter reset button to display the calibration gas values screen. The gas concentrations displayed in the calibration gas values...

Page 197

Eagle 2 operator’s manual esm-01 calibration • 187 channel. The calibration gas value begins to flash. 18. Use the air ▲ yes and range ▼ shift buttons to adjust the calibration gas setting to the desired value. Note: the calibration gas value cannot be set lower than the low alarm setting. If the ca...

Page 198

188 • esm-01 calibration eagle 2 operator’s manual changes when the unit is turned off and will load the previous set of auto calibration values when it is turned on again. 24. When you make your selection and press the desired button, the unit returns to the calibration gas values screen. 25. Press...

Page 199

Eagle 2 operator’s manual esm-01 calibration • 189 28. If all channels passed calibration, the following screen sequence occurs. If any of the sensors cannot be adjusted to the proper value, a screen displays that indicates a calibration failure and lists the sensor(s) that failed to calibrate. In t...

Page 200

190 • esm-01 calibration eagle 2 operator’s manual 31. If you want to change the esm-01 channel’s calibration gas value, follow step 15 - step 24 above beginning with the esm-01 calibration gas value screen below instead of the standard channel calibration gas value screen. 32. With the esm-01 calib...

Page 201

Eagle 2 operator’s manual esm-01 calibration • 191 36. If the esm-01 channel passed calibration, the following screen sequence occurs. If the esm-01 channel cannot be adjusted to the proper value, a screen displays that indicates a calibration failure and indicates that the esm-01 sensor failed to c...

Page 202

192 • esm-01 calibration eagle 2 operator’s manual calibrating with a 5-gas cylinder the calibration instructions below show a 5 channel instrument which has the four standard channels, lel/oxygen/h 2 s/co, and an esm-01 channel for sulfur dioxide (so 2 ). 1. See “calibration supplies and equipment”...

Page 203

Eagle 2 operator’s manual esm-01 calibration • 193 7. Press and release the power enter reset button. The following screen appears. 8. Press and release the air ▲ yes button to continue. If you do not want to continue, press the display adjust no button and the unit will return to the calibration mo...

Page 204

194 • esm-01 calibration eagle 2 operator’s manual the probe are tightened firmly together to avoid leaks that can affect the calibration. See figure 19 on page 76 for an illustration of the internal parts of the probe. 13. Move the cursor next to the auto calibration menu item by using the air ▲ ye...

Page 205

Eagle 2 operator’s manual esm-01 calibration • 195 16. Place the cursor next to the channel whose gas value you want to change using the air ▲ yes and range ▼ shift buttons. 17. Press and release the power enter reset button to select the channel. The calibration gas value begins to flash. 18. Use t...

Page 206

196 • esm-01 calibration eagle 2 operator’s manual if you select no by pressing and releasing the display adjust no button, the changes you made will be used for any calibrations performed during the current operating session only. The eagle 2 will delete the changes when the unit is turned off and ...

Page 207

Eagle 2 operator’s manual esm-01 calibration • 197 28. If all channels passed calibration, the following screen sequence occurs. If any of the sensors cannot be adjusted to the proper value, a screen displays that indicates a calibration failure and lists the sensor(s) that failed to calibrate. In t...

Page 208

198 • esm-01 calibration eagle 2 operator’s manual 29. If you want to change the esm-01 channel’s calibration gas value, follow step 15 - step 24 above beginning with the esm-01 calibration gas value screen below instead of the standard channel calibration gas value screen. 30. With the esm-01 calib...

Page 209

Eagle 2 operator’s manual esm-01 calibration • 199 33. If the esm-01 channel passed calibration, the following screen sequence occurs. If the esm-01 channel cannot be adjusted to the proper value, a screen displays that indicates a calibration failure and indicates that the esm-01 sensor failed to c...

Page 210: Maintenance

200 • maintenance eagle 2 operator’s manual maintenance the so 2 and hcn esm-01 sensors are the only esm-01 sensors that include user serviceable parts. This section includes a procedure for replacing an esm-01 sensor and for replacing the h 2 s scrubber in the so 2 and hcn sensors. When replacing a...

Page 211: Replacing The H

Eagle 2 operator’s manual maintenance • 201 the esm-01 chamber. 14. Install the two sensor bracket screws. 15. Confirm that the main pcb is seated in its slots and that its bottom edge is resting on the bottom of the bottom case. If the main pcb is not seated properly, it may be damaged when the top...

Page 212

202 • maintenance eagle 2 operator’s manual in the sensor body by a threaded collar on the connector end of the sensor. Unscrew the collar from the sensor body. Figure 36: esm-01 sensor component location 12. Grasp the connector and lift the electrolyte reservoir assembly out of the sensor body. 13....

Page 213: Parts List

Eagle 2 operator’s manual parts list • 203 the esm-01 chamber. 21. Install the two sensor bracket screws. 22. Confirm that the main pcb is seated in its slots and that its bottom edge is resting on the bottom of the bottom case. If the main pcb is not seated properly, it may be damaged when the top ...

Page 214

204 • parts list eagle 2 operator’s manual 81-0185rk-02 calibration cylinder, 0.5 ppm ph 3 in nitrogen, 58 liter 81-0192rk-02 calibration cylinder, 2 ppm cl 2 in nitrogen, 58 liter 81-0192rk-04 calibration cylinder, 2 ppm cl 2 in nitrogen, 34 liter 81-0196rk-02 calibration cylinder, 10 ppm hcn in ni...

Page 215: Appendix F: Tc Sensors

Eagle 2 operator’s manual overview • 205 appendix f: tc sensors overview the tc sensors are used to monitor high levels of combustible gas. This appendix describes the eagle 2’s tc sensor and includes instructions to use an eagle 2 that has a tc sensor installed. It also includes instructions to cal...

Page 216: Tc Sensor

206 • description eagle 2 operator’s manual figure 37: typical tc sensor location tc sensor the tc sensor’s appearance is exactly the same as that of the lel sensor. Its housing includes a sintered metal flame arrestor on one end that allows gas to diffuse into the sensor. On the other end, five pin...

Page 217

Eagle 2 operator’s manual start up and normal operation • 207 tc sensor cable connects to the sub pcb. The sub pcb plugs into the main pcb and is held in place with a screw/flat washer/lock washer. There are no user serviceable parts on the tc sub pcb. Start up and normal operation for instructions ...

Page 218: Tc Calibration

208 • tc calibration eagle 2 operator’s manual 1. Use the display adjust no button to enter display mode and scroll to the catalytic (lel) sensor screen. The current setting will be flashing. The screen below indicates the warning that appears when a tc sensor and a catalytic lel sensor are both ins...

Page 219

Eagle 2 operator’s manual tc calibration • 209 appropriate for the tc detection range. If the eagle 2 is intended for use in a landfill, rki instruments, inc. Recommends using the carbon dioxide/methane mix calibration cylinder because it is representative of gases present in a landfill. Note: if yo...

Page 220

210 • tc calibration eagle 2 operator’s manual 7. Press and release the power enter reset button. The following screen appears. 8. Press and release the air ▲ yes button to continue. If you do not want to continue, press the display adjust no button and the unit will return to the calibration mode s...

Page 221

Eagle 2 operator’s manual tc calibration • 211 complete with internal o-ring and membrane and that the two halves of the probe are tightened firmly together to avoid leaks that can affect the calibration. See figure 19, “replacing the particle filter and hydrophobic filter disk” on page 76 for an il...

Page 222

212 • tc calibration eagle 2 operator’s manual 15. To adjust the values on the screen, press and hold the range ▼ shift button, then press the display adjust no button and release both. The following screen appears with the cursor next to ch4. 16. Place the cursor next to the channel whose gas value...

Page 223

Eagle 2 operator’s manual tc calibration • 213 22. Press and release the power enter reset button. The following screen appears. 23. If you select yes by pressing and releasing the air ▲ yes button, the changes that you made will be saved in the eagle 2’s memory as the new auto calibration gas value...

Page 224

214 • tc calibration eagle 2 operator’s manual 27. Press and release the power enter reset button to set the span adjustment for each channel to the programmed values. 28. If all channels passed calibration, the following screen sequence occurs. If any of the sensors cannot be adjusted to the proper...

Page 225

Eagle 2 operator’s manual tc calibration • 215 31. If you want to change the tc channel’s calibration gas value, follow step 15 - step 24 above beginning with the tc calibration gas value screen below instead of the standard channel calibration gas value screen. 32. With the tc calibration gas value...

Page 226

216 • tc calibration eagle 2 operator’s manual 36. If the tc channel passed calibration, the following screen sequence occurs. If the tc channel cannot be adjusted to the proper value, a screen displays that indicates a calibration failure and indicates that the tc sensor failed to calibrate. The bu...

Page 227: Maintenance

Eagle 2 operator’s manual maintenance • 217 maintenance the tc sensor does not include any user serviceable parts. This section includes a procedure for replacing the tc sensor. Replacing the tc sensor 1. Verify that the eagle 2 is off. 2. Place the eagle 2 upside down on a flat surface or hold it u...

Page 228: Configuring The Tc Gas In

218 • configuring the tc gas in setup mode eagle 2 operator’s manual properly, it may be damaged when the top case is reinstalled. 16. Make sure that the top case gasket is fully seated in its groove and carefully put the top case back on the bottom case. If you have any difficulty mating the top an...

Page 229

Eagle 2 operator’s manual configuring the tc gas in setup mode • 219 4. The “s” will then disappear and the following screen will appear for a few seconds. 5. If the unit prompts you for the password, enter it by using air ▲ yes and range ▼ shift to select each password number and then pressing and ...

Page 230

220 • configuring the tc gas in setup mode eagle 2 operator’s manual 8. Use range ▼ shift to move the cursor down the menu to the tc sensor. 9. To change the tc sensor gas configuration, press and release power enter reset. 10. A screen appears that indicates the detection range for the currently co...

Page 231

Eagle 2 operator’s manual configuring the tc gas in setup mode • 221 warning: do not use the user defined gas configuration without consulting rki instruments, inc. 14. Enter the gas name. There are 3 characters available for the gas name. The factory setting of tc uses only 2 characters. Use air ▲ ...

Page 232

222 • configuring the tc gas in setup mode eagle 2 operator’s manual 21. Press and release power enter reset. 22. A screen appears that asks if you want to save the changes you have made. Note: if you entered setup mode and did not make any changes, the above screen will still appear. In this case, ...

Page 233: Parts List

Eagle 2 operator’s manual parts list • 223 parts list table 21: tc eagle 2 parts list part number description 47-5010rk tc/lel sensor cable te-7568 tc sensor 81-0013rk-01 calibration cylinder, 50% vol ch 4 in n 2 , 34 liter steel 81-0013rk-05 calibration cylinder, 50% vol ch 4 in n 2 , 58 liter stee...

Page 234: Overview

224 • overview eagle 2 operator’s manual appendix g: infrared carbon dioxide sensors overview the infrared co 2 sensors are used to monitor levels of carbon dioxide. This appendix describes the eagle 2’s infrared co 2 sensors and includes instructions to use an eagle 2 that has one or more infrared ...

Page 235: Infrared Co

Eagle 2 operator’s manual description • 225 figure 38: typical infrared co 2 sensor location the infrared co 2 sensor is installed in a single sensor flow chamber which is located in the area next to the standard 4-sensor flow chamber. This area can accommodate up to three single sensor flow chamber...

Page 236: Scrubber

226 • description eagle 2 operator’s manual one of the 3 sub pcb positions when an infrared co 2 sensor is used with the eagle 2. The infrared co 2 sensor connects to the sub pcb with a 12- position connector. The sub pcb plugs into the main pcb and is held in place with a screw/flat washer/lock was...

Page 237

Eagle 2 operator’s manual start up and normal operation • 227 start up and normal operation for instructions to startup and use an eagle 2 that includes an infrared co 2 sensor, reference “start up” on page 22, “measuring mode, normal operation” on page 29, and “measuring mode, alarms” on page 35. F...

Page 238: Infrared Co

228 • infrared co 2 calibration eagle 2 operator’s manual 5. Put the caps back on the scrubber. Infrared co 2 calibration an infrared co 2 channel can be calibrated using the auto calibration method or the single calibration method. To calibrate an infrared co 2 channel using the single calibration ...

Page 239

Eagle 2 operator’s manual infrared co 2 calibration • 229 5. The calibration mode screen displays with the cursor next to auto calibration. 6. Move the cursor to the perform air adjust menu item by using the range ▼ shift button. 7. Remove the black caps from the ends of the carbon dioxide scrubber....

Page 240

230 • infrared co 2 calibration eagle 2 operator’s manual 11. The eagle 2 will indicate that it is adjusting the zero reading for a few seconds, then indicate that the operation is complete before returning to the calibration mode screen. 12. Remove the co 2 scrubber from the eagle 2 inlet fitting. ...

Page 241

Eagle 2 operator’s manual infrared co 2 calibration • 231 17. Move the cursor next to the auto calibration menu item by using the air ▲ yes button. 18. Press and release the power enter reset button to display the calibration gas values screen. The gas concentrations displayed in the calibration gas...

Page 242

232 • infrared co 2 calibration eagle 2 operator’s manual channel. The calibration gas value begins to flash. 22. Use the air ▲ yes and range ▼ shift buttons to adjust the calibration gas setting to the desired value. Note: the calibration gas value cannot be set lower than the low alarm setting. If...

Page 243