- DL manuals

- RKI Instruments

- Security Sensors

- SP-220 TYPE F

- Operating Manual

RKI Instruments SP-220 TYPE F Operating Manual

Summary of SP-220 TYPE F

Page 1

Portable gas leak detector sp-220 series type f operating manual part number: 71-0421 revision: p1 released: 10/20/17.

Page 2: Contents

- 2 - contents table of contents 1. Outline of the product ..................................................................................................................................... 3 preface ....................................................................................................

Page 3: Outline Of The Product

- 3 - 1 1. Outline of the product preface thank you for choosing our portable gas leak detector sp-220 type f (hereinafter referred to as the detector). Please check that the model number of the product you purchased is included in the specifications on this manual. This manual explains how to use t...

Page 4: Specifications

- 4 - how to check the standards and explosion-proof specifications the detector has different specifications depending on the standards or explosion-proof certification type. Check the specifications of the product you have before use. See the declaration of conformity at the end of this operating ...

Page 5: Important Notices On

- 5 - 2 2. Important notices on safety to maintain the performance and use the detector safely, observe the following instructions of danger, warning, and caution. 2-1. Danger cases danger about use • while conducting measurement in a manhole or confined space, do not lean over or look into the manh...

Page 6: 2-2. Warning Cases

- 6 - 2-2. Warning cases warning sampling point pressure • the concentration meter is designed to draw gases under the atmospheric pressure. If excessive pressure is applied to the gas inlet and outlet of the detector, measured gases may leak out from its inside and may cause dangerous conditions. B...

Page 7: 2-3. Precautions

- 7 - 2-3. Precautions caution do not use the detector where it is exposed to oil, chemicals, etc. Do not submerge the detector under water on purpose. • do not use in a place where the detector is exposed to liquids such as oil and chemicals. • the detector is not water-pressure-resistant. Do not u...

Page 8

- 8 - caution others • after a gas continuously comes into contact or a highly-concentrated gas comes into contact, the detector may stay in alarm. In such a case, draw fresh air for more than five minutes (recommended) and perform air calibration again. • pressing buttons unnecessarily may change t...

Page 9

- 9 - 2-4. Safety information (for atex/iecex specifications) portable gas leak detector sp-220 is a gas detector to continuously detect combustible gases. The detector draws gases with the internal micro pump. Use only two toshiba aa alkaline batteries (lr6t) connected in series for power supply. D...

Page 10: Product Components

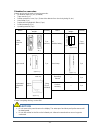

- 10 - 3 3. Product components 3-1. Names and functions for each part this section describes names and functions of main unit, the battery unit parts, and the lcd display. Main unit no. Name function (1) gas inlet collects gases. (2) alarm led arrays blinks or lights up in response to an alarm. (3) ...

Page 11

- 11 - standard accessories unpack and check the main unit and accessories. • aa alkaline battery (2 pcs) (installed) • taper nozzle (1 pc) • rubber protection cover (1 pc) (protect the detector from shocks by being hit, etc.) • hand strap (1 pc) • replacement hydrophobic filters (5 pcs) • product w...

Page 12

- 12 - lcd display no. Name function (1) operating state display displays the operating status in the detection mode. Normal: blinking (2) flow check display displays the drawing status. Normal: rotating (3) gas concentration display displays gas concentration and units (ppm). (4) alarm sound displa...

Page 13: How to Use

- 13 - 4 4. How to use 4-1. Before using the detector first-time users and users who have already used the detector must follow the operating precautions. Ignoring the precautions may damage the unit, resulting in inaccurate gas measurement. 4-2. Preparation for start-up before use, read and underst...

Page 14

- 14 - caution • never fail to turn off the power of the detector before replacing the batteries. • replace the batteries in a safe place. • replace both of the two batteries with new ones at one time. • pay attention to the polarities during replacement. Replace while checking the battery polaritie...

Page 15

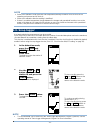

- 15 - 4-4. How to start the detector when the power is turned on, a self-diagnostic starts, and then the detector enters the detection mode. Power-on press and hold the power button until the buzzer blips (one second or longer) to turn on the power. When the power is turned on, the lcd display chan...

Page 16

- 16 - note • when powering on after leaving the detector for more than five minutes with the batteries removed, such as when powering on for the first time, replacing the batteries, etc., or powering on with the batteries inserted with incorrect polarities, a clock abnormality (fail clock) may be t...

Page 17

- 17 - 4-5. Basic operating procedures the detection mode is used after power-on. Gas is detected in the ppm range. Buttons hold down for 3 secs illumination lamp lights up button hold down for 1 sec hold down for 3 secs button buttons buttons hold down for 3 secs * displayed only when the clock fun...

Page 18: 4-6. How To Detect

- 18 - 4-6. How to detect while the detector is operating in detection mode, put the tip of the taper nozzle close to the detection area and draw sample. The detector measures gas in the ppm range. If a gas is drawn, the detected gas concentration is displayed with the bar meter on the lcd display. ...

Page 19

- 19 - 4-7. Changing the concentration measuring mode in the detector, the detection gas type is factory set to r600a (isobutane) and the alarm setpoint is factory set to 30 ppm. The detector has 5 preset alarm setpoints that the user can cycle through (10 ppm, 30 ppm, 150 ppm, 500 ppm, and 2000 ppm...

Page 20

- 20 - gas alarm setpoint for differential measuring mode 1 in the detection mode, press the air and mode buttons at the same time. The alarm setpoint is changed to the next pre-defined setpoint every time the air and mode buttons are pressed. There are 6 setpoints total. Changing the gas alarm sens...

Page 21

- 21 - note • for switching to the differential measuring mode, see "change of the measuring mode" in the display mode on page 31. Caution • performing an air calibration in the presence of gas will decrease the bar meter. • for excessive temperature/humidity changes, the bar meter may increase. • w...

Page 22

- 22 - 4-8. Performing air calibration after a high-concentration gas is detected or an alarm is triggered by temperature/humidity changes, perform air calibration in the measured atmosphere. * before performing air calibration, verify a fresh air environment. 1 in the detection mode, hold down the ...

Page 23: 4-9. Snap Logger

- 23 - note • perform air calibration under pressure and temperature/humidity conditions close to those in the operating environment and in fresh air. • perform air calibration after the reading is stabilized. • if there is a sudden temperature change between the storage and operational locations, t...

Page 24: 4-10. Peak Hold Function

- 24 - 4-10. Peak hold function when the peak hold function is enabled, the latest peak value is always displayed with the bar meter. 1 in the detection mode, hold down the mode button (for three seconds or longer). The peak hold function is enabled. While the peak hold function is enabled, "p" is d...

Page 25: 4-13. Power-Off

- 25 - 4-12. How to turn on the illumination lamp the illumination lamp can be turned on, if necessary. 1 hold down the air and power buttons at the same time (for three seconds or longer). The illumination lamp lights up. The illumination lamp will automatically go off two minutes after it lights u...

Page 26: Display Mode

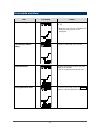

- 26 - 5 5. Display mode 5-1. Entering the display mode this mode allows users to view and change various display settings and perform other operation. (display example: for city gases) 1 in the detection mode, press the mode button. The detector enters the peak value display in the display mode. 2 ...

Page 27

- 27 - display mode overview item lcd display details peak display displays the maximum concentration detected during the period from power-on to the point of checking. * to clear the peak display, hold down the air button until "peak clr" is displayed. Measured gas reading setting by changing the s...

Page 28

- 28 - entering user mode enters the user mode. (p. 33) detection mode returns to the detection mode..

Page 29

- 29 - 5-2. Measured gas reading setting normally, the concentration display of the detector is "isobutane (r600a)" depending on the specification; however, a pre-registered gas can be read instead to detect its concentration. 1 on the "gas list" screen in the display mode, press the power button. T...

Page 30

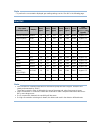

- 30 - note ・ to perform the concentration displayed gas reading setting, see the "gas list" in the following page. Gas list gas name (standard name) display grid 1 (ppm) grid 2 (ppm) grid 3 (ppm) grid 4 (ppm) grid 5 (ppm) grid 6 (ppm) unit conversion 【only as a guide】 (g/year) r600a(isobutane) r600...

Page 31

- 31 - 5-3. Changing the measuring mode the measuring mode of the detector (for fumigation gases) can be switched from "concentration measuring mode" to "differential measuring mode", where lower concentration detection can be conducted. 1 on the "mode chg" screen in the display mode, press the powe...

Page 32: 5-4. Log Data Display

- 32 - 5-4. Log data display the data recorded by the snap logger can be viewed. The "rec data" screen is displayed only when the clock function is enabled (see "6-3. Clock function on/off setting" on page 36). 1 on the "rec data" screen in the display mode, press the power button. The detector ente...

Page 33: User Mode

- 33 - 6 6. User mode 6-1. Entering the user mode the maintenance including internal clock correction, etc. Can be performed. 1 in the detection mode, press the mode button a few times to display "user" and then press the power button. The detector enters the date/time setting in the user mode. 2 ne...

Page 34

- 34 - user mode overview item lcd display details date/time setting set the date/time of the internal clock. (p. 35) * when the clock function is disabled, the date/time setting screen is not displayed. Clock function on/off setting enable or disable the clock function. Rom/sum display displays the...

Page 35: 6-2. Date/time Setting

- 35 - 6-2. Date/time setting set the date/time of the internal clock. The date/time setting screen is displayed only when the clock function is enabled. Enable the clock function in "6-3. Clock function on/off setting" on page 36 before setting the date/time. 1 on the "date" screen in the user mode...

Page 36

- 36 - 6-3. Clock function on/off setting enable or disable the clock function. The clock function is disabled by default. If the date/time needs to be displayed on start-up or the snap logger function is used, enable the clock function. 1 on the "clock" screen in the user mode, press the power butt...

Page 37: Alarm Function

- 37 - 7 7. Alarm function 7-1. Gas alarm activation when the concentration of detected gas reaches or exceeds the alarm setpoint values, a "gas alarm" is triggered in the detector. The alarm lamp blinks, the buzzer sounds, and the bar meter display indicates an alarm condition. (auto-reset operatio...

Page 38: Maintenance

- 38 - 8 8. Maintenance the detector is a precision device. To maintain the performance of the detector and improve the reliability of detecting leakage, perform a regular maintenance. 8-1. Maintenance intervals and items perform the following maintenance regularly before use. ・ daily maintenance: p...

Page 39

- 39 - about maintenance services we provide services on regular maintenance including span adjustment, other adjustments and maintenance. Our qualified service engineers have expertise, knowledge and other information on the dedicated tools used for services, along with other products. To maintain ...

Page 40: 8-2. How To Clean

- 40 - 8-2. How to clean clean the detector if it becomes extremely dirty. The detector must be turned off while cleaning it. Use a waste cloth or the like to remove dust. Do not use water or organic solvent for cleaning because they may cause malfunctions. Because an extremely contaminated inside o...

Page 41

- 41 - 3 replace the hydrophobic filter with a new one. Make sure it’s seated in the rubber seal correctly. 4 attach the rubber seal, with the filter installed, to the cap. Make sure the rubber seal’s rib has been firmly inserted into the cap’s groove. 5 attach the cap, with the rubber seal attached...

Page 42

- 42 - sensor replacement the sensor comes with a 1-year warranty. It has a typical life of 2-3 years, depending on the operating environment. The sensor life has expired if, for example, the reading fluctuates or does not respond during calibration. Contact rki for sensor replacement. Battery repla...

Page 43: Calibration Mode

- 43 - 9 9. Calibration mode this section describes how to perform a fresh air adjustment, an automatic span adjustment, and a manual span adjustment on the sp-220. It also describes how to turn on the calibration mode password function. 9-1. Fresh air adjustment rki instruments, inc. Recommends tha...

Page 44

- 44 - 4 the air cal menu item will be displayed. 5 press and release the power button. 6 make sure you are in a fresh air area (area known to be free of toxic and combustible gases and of normal oxygen content, 20.9%). 7 press and hold the air button. Release the air button when the screen says “re...

Page 45

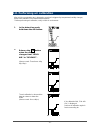

- 45 - 9 see the following sections for span adjustment descriptions. To return to detection mode without performing a span adjustment, scroll to the measure menu item and press and release the power button. To turn the instrument off, press and hold the power. 9-2. Preparing for a span adjustment (...

Page 46: Regulator)

- 46 - 9-3. Preparing for a span adjustment (demand flow regulator) this section describes how to prepare for calibration if you are using a calibration kit that includes: • demand flow regulator • calibration tubing • calibration cylinder 1. Screw the demand flow regulator onto the calibration cyli...

Page 47

- 47 - use the air and mode buttons to adjust each character and press the power button to move to the next character. 4 the air cal menu item will be displayed. 5 use the air or mode button to scroll to the auto cal menu item. 6 press and release the power button. The auto cal value will be display...

Page 48

- 48 - 8 press and release the power button. The gas reading will begin to flash. 9 apply calibration gas for 1 minute. Depending on your calibration kit, you will need to either: a. Connect the gas bag tubing to the instrument’s inlet or b. Connect the tubing from the demand flow regulator to the i...

Page 49

- 49 - 9-5. Manual span adjustment these instructions describe a manual calibration of the sp-220. Be sure you have performed a fresh air adjustment and prepared for calibration as described in the previous sections before continuing. 1 if you have just performed a fresh air adjustment and the instr...

Page 50

- 50 - 5 use the air or mode button to scroll to the manu_cal menu item. 6 press and release the power button. The gas reading will begin to flash. 7 apply calibration gas for 1 minute. Depending on your calibration kit, you will need to either: a. Connect the gas bag tubing to the instrument’s inle...

Page 51: 9-6. Password

- 51 - 10 disconnect the calibration gas source from the instrument’s inlet fitting. 11 to enter detection mode, scroll to the measure menu item and press and release the power button. To turn off the instrument, press and hold the power button. 9-6. Password these instructions describe how to turn ...

Page 52

- 52 - 3 the air cal menu item will be displayed. 4 use the air or mode button to scroll to the password menu item. 5 press and release the power button. The current setting will be displayed. 6 use the air or mode button to adjust the on/off setting. If the password is set to on, a user-defined pas...

Page 53

- 53 - 9 to enter detection mode, scroll to the measure menu item and press and release the power button. To turn off the instrument, press and hold the power button..

Page 54: Storage And Disposal

- 54 - 10 9. Storage and disposal 10-1. Procedures to store the detector or leave it for a long time the detector must be stored under the following environmental conditions. • in a dark place under the normal temperature and humidity away from direct sunlight • in a place where gases, solvents, vap...

Page 55

- 55 - 10-3. Disposal of products when the detector is disposed of, it must be treated properly as an industrial waste in accordance with the local regulations, etc. When disposing of the detector in eu member states, sort the batteries as specified. Handle the removed batteries according to the cla...

Page 56: Troubleshooting

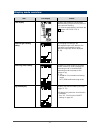

- 56 - 11 10. Troubleshooting the troubleshooting does not explain the causes of all the malfunctions which occur on the detector. This simply helps to find the causes of malfunctions which may frequently occur. If the detector shows a symptom which is not explained in this manual, or still has malf...

Page 57

- 57 - symptoms causes actions air calibration impossible fail air cal fresh air is not supplied around the detector. Supply fresh air and then perform air calibration in the measured atmosphere. Clock abnormalities fail clock abnormalities of the internal clock make a setting of date/time. If such ...

Page 58: Spare Parts List

- 58 - 12 10. Spare parts list part number description 06-1248rk-03 calibration tubing, 3 feet 81-0021rk-01 calibration cylinder, 3600 ppm isobutane in air, 34 liter steel 81-1001rk dispensing valve, without knob, for 17 liter and 34 liter steel cylinders (cylinders with external threads) 81-1054rk ...

Page 59: Product Specifications

- 59 - 13 11. Product specifications model sp-220(type f) gas to be detected single channel (r600a:refer to "gas list") detection principle hot-wire semiconductor measurement range depends on the measured gas (r600a:0-10000ppm) alarm type gas alarm: triggered when the concentration of detected gas r...

Page 60

Error! Use the home tab to apply 見出し 1 to the text that you want to appear here. Error! Use the home tab to apply 見出し 2 to the text that you want to appear here. - 60 -.