Summary of Combi Konverter Solar System

Page 1

Installation manual issue 1 combi konverter solar system.

Page 2

These instructions are specific to the integration of the rmsolar combi konverter system with the combi boiler. The rmsolar instructions should be used in terms of the overall solar installation. Particular attention should also be paid to the cylinder instructions bearing in mind that the system us...

Page 3

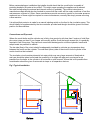

Fig 2 charging sequence preparing for installation the installation can be carried out by any competent person in accordance with the relevant building regulations. In order to properly commission the system the installer should be equipped with a suitable digital thermometer to check flow temperatu...

Page 4

Before contemplating an installation the installer should check that the combi boiler is capable of providing domestic hot water at circa 60oc. This might mean operating the appliance at a reduced flow rate and adjusting the external and internal controls (if possible). The combis instructions or ma...

Page 5

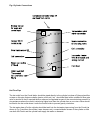

Fig 4 cylinder connections hot flow pipe the hot outlet from the combi boiler should be piped directly to the cylinder hot draw off (there should be no taps on this pipe that serve baths, basins, sinks ect), but should be fitted with a suitable full flow gate valve or similar so that if required the...

Page 6

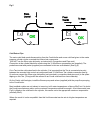

Fig 5 cold return pipe the mains cold feed needs disconnecting from the combi boiler and a new cold feed given to the mains pressure cylinder via the unvented inlet control set components. (do not use the 22mm pipe laid early, as instructed in connections and pipe work) connection at the cylinder sh...

Page 7

Fig 6 cold inlet thermostat circulation pump the pump should always be sited with the motor spindle horizontal .Care should be taken to ensure there is a minimum hydraulic restriction on the inlet side of the pump as this could cause a significantly reduced pressure zone thus encouraging dissolved a...

Page 8

Wiring and controls the important points are as follows. To meet g3 requirements the live feed to the solar controller circuit should be taken via the energy cut out at the top of the cylinder. The system should be fitted with an isolating switch to disable the feed to the circulating pump, a timer ...

Page 9

Fig 8 sensor attachment commissioning the important factor here is to ensure that the combi fires in response to the circulation pump and delivers water at a suitably high temperature circa 60oc. The flow rate through the combi should be reduced to a level at which a 60oc charging temperature is ach...

Page 10

Setting the shr controller there are 3 settings that need to be changed in order for the system to operate correctly; - factory setting re-set to arr - 1 2 aho - 40.0 oc 50.0 oc ahf - 45.0 oc 55.0 oc optional; - s mx 60.0 oc not above 75.0 oc (s mx = the maximum store temperature achievable by solar...

Page 11

Hydraulic balancing as part of the commissioning process the installer should ensure that adequate hot temperature, albeit at reduced flow rate, is provided from the combi under conditions when the cylinder is depleted of hot water. To ensure this, it is essential that the hydraulic resistance throu...

Page 12

Rm solar ltd unit 4, gilcar way, wakefield europort, castleford wf10 5qs tel: 01924 224282 fax: 01924 224283 web: www.Rmsolar.Com.