- DL manuals

- S.E.P.

- Tractor

- REV. 1000 Diesel (2+2)

- Use And Maintenance Manual

S.E.P. REV. 1000 Diesel (2+2) Use And Maintenance Manual

Summary of REV. 1000 Diesel (2+2)

Page 1

Rev. 1000 (2+2) rev. 1000 e (2+2) rev. 1000 diesel (2+2) rev. 1000 special (3+2) rev. 1000 diesel special (3+2) ® use and maintenance manual gb.

Page 3: Given In This Manual

Gb reversible two-wheel tractors rev. 1000 (2+2) rev. 1000 diesel (2+2) rev. 1000 special (3+2) rev. 1000 diesel special (3+2) rev. 1000 e (2+2) before using the two-wheel tractor carefully read the instructions given in this manual.

Page 4

2 table of contents page page introduction.................................................... 3 safety regulations ....................................... 3 general notices............................................. 3 starting the engine ...................................... 4 operating of the t...

Page 5

Gb 3 introduction • this manual provides use and maintenance in- structions, technical specifications, and safety pre- cautions for reversible two-wheel tractor: − model rev. 1000 (2+2) − model rev. 1000 e (2+2) − model rev. 1000 special (3+2) in the versions with diesel and gasoline engine. • for t...

Page 6

Gb 4 safety devices • do not use the two-wheel tractor if the safety de- vices are missing or defective. • do not interfere with safety devices. Starting the engine • disengage all control levers before starting the mo- tor. Keep your feet clear of the attachments fitted to the two-wheel tractor. • ...

Page 7

Gb 5 − in case of excessive vibrations (investigate cause immediately). • stop the engine before adjusting attachments. • periodically check that all nuts and bolts are tight. • do not leave your two-wheel tractor in closed am- bient with fuel in the tank. Fuel vapour is a potential source of danger...

Page 8

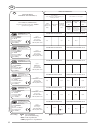

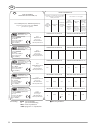

Gb 6 test conditions: - p.T.O.: disengaged - machinestationary on a concrete plane surface test conditions: - p.T.O.: engaged sound pressure on operator’s ears db(a) sound pressure on operator’s ears db(a) (macchine stationary on a grass surface) (macchine stationary on a concrete surface with an in...

Page 9

Gb 7 test conditions: - p.T.O.: disengaged - machinestationary on a concrete plane surface test conditions: - p.T.O.: engaged sound pressure on operator’s ears db(a) sound pressure on operator’s ears db(a) (macchine stationary on a grass surface) (macchine stationary on a concrete surface with an in...

Page 10

Gb 8 modello tipo: n. Serie: mot.: potenza: kw/ rpm anno di fabbricazione: massa: kg 1000 special (3+2) 1 im 359 6,6 3600 111,000 bh50x00000 engine: mass (weight): lombardini 1 im 359 with wheels 4.00-10 with rotary tiller cm. 60 84,5 2,63 87,5 103,5 12,48 with sickle bar mower cm. 117 type of marki...

Page 11

Gb 9 technical specifications engine the two-wheel tractor may be fitted with the following engines: − honda gc 160; 4 stroke gasoline; 3,7 kw (5 hp); 160 cm 3 . − honda gx 160; 4 stroke gasoline; 4 kw (5,5 hp); 163 cm 3 . − honda gx 200; 4 stroke gasoline; 4,8 kw (6,5 hp); 198 cm 3 . − robin ex 27;...

Page 12

Gb 10 note the instructions covering track adjustment, based on machine model and type of wheel, are given in a spe- cific paragraph in this manual. Accessories the two-wheel tractor can be fitted with a wide range of additional easy-to-fit accessories. These are, for instance, several types of iron...

Page 13

Gb 11 safety devices the two-wheel tractor is fitted with the following safety devices to ensure maximum safety: − automatic pto disengagement device. This is a mechanical device that prevents shift into reverse speed when the pto is rotating (two-wheel tractor configuration only). − engine shut-off...

Page 14

Gb 12 transfer printing - instructions and safety please find below the adhesive transfer printing shown on the machine. For accident prevention purposes, they must always be clearly readable. Should they be damaged, it is compulsory to replace them by request- ing the original spare part from the m...

Page 15

Gb 13 two-wheel tractor controls see fig. 4. 1. Clutch lever. 2. Engine stop lever. 3. Differential lock lever. 4. Pto control lever (note 1). 5. Handlebar vertical lock release lever. 6. Gear lever (note 2). 7. 3rd speed preselection control lever (versions 3+2). 8. Throttle control lever. 9. R.H. ...

Page 16

Gb 14 gear lever caution when using the machine as a motor mower, the han- dlebars must be rotated through 180°. The gear and pto control levers therefore inter- change position. See page 17 for details. Use the gear lever as shown below (see fig. 6): a. Turn the throttle control lever to idle posit...

Page 17

Gb 15 handlebar vertical lock release lever (see fig. 8) this allows the handle to be adjusted vertically to suit driving comfort and tilling depth. Simply push lever (1) down to release the handles. Handlebar sideway lock release lever (see fig. 9) by releasing the lock, you can rotate the handleba...

Page 18

Gb 16 pto instant adaptor this allows attachments to be coupled and de- coupled quickly and easily to and from the pto. The lever (1) has two positions (see fig. 11): − locked position: pull up lever (1). − released position: push down lever (1). A decal (see detail a) near the pto instant adaptor l...

Page 19

Gb 17 g. Lock the clutch lever (2) in position with locking device (3). H. Turn throttle control lever (4) for 1/4 turn. I. Gasoline engines: grip the pull-rope handle and pull firmly and quickly. When the engine starts, al- low the rope to wind back onto the reel slowly. Diesel engines: manually wi...

Page 20

Gb 18 removal of 3rd speed preselection control lever when front-mounted attachments are used, it is nec- essary to remove the 3rd speed preselection control lever from the machine. To do this, proceed as follows (see fig. 17): a. Move the preselection control lever (1) to the fully forward position...

Page 21

Gb 19 coupling attachments to the pto the pto is fitted with an instant adaptor device to fit attachments quickly and easily. Proceed as follows to fit your attachments (see fig. 19): a. Check that lever (1) is in “disengaged” position. B. Push the shaft of the attachment (2) into the pto (3). Make ...

Page 22

Gb 20 wheels (4.00-8) with adjustable track (35-40-45-50 cm) these wheels have hexagonal axle holes and a hub with two through holes. To adjust track width, fit wheel (fig. 20/3, item 1) to hub (4) by means of pin (2) at the through hole which gives the desired width. For wide track settings, use sp...

Page 23

Gb 21 every 20 hours check the level of the oil in the gearbox. The level must be between the maximum and minimum notch on the dip-stick (1). Note check the oil level with the motor cold and with the two-wheel tractor on level ground. Every 300 hours change the gearbox and transmission oil following...

Page 24

Gb 22 rotary tiller warning • do not use the rotary tiller without the hood. • do not proceed to tilling in proximity of children and/or animals. • keep your hands and feet clear of the tiller at- tachment when the motor is running. Stop the en- gine before touching the tiller for any reason. • make...

Page 25

Gb 23 tilling width adjustment the adjustable tiller model allows you to set working widths of 40, 50, 60 cm, to suit the type of crop. Adjustment of tilling width is obtained by reversing the position of the two pairs of outside tiller rotors of each tilling element, and by removing or adding one t...

Page 26

Gb 24 every 300 hours change the tiller drive unit oil as instructed above..

Page 27

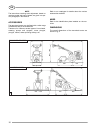

Gb 25 cutter bar mower warning • when you transport your machine, and when you fin- ish work, always fit the knife guard over the cutter bar. • keep your hands and feet clear of the cutter bar when in motion. • do not operate the motor mower in proximity of children and/or animals. • stop the engine...

Page 28

Gb 26 cutter bar mower technical specifications sickle bar mowers − drive: mechanical con-rod. − cutting width: 95 cm, 110 cm, 127 cm. E.S.M. Mowers − drive: mechanical con-rod. − cutting width: 97 cm, 117 cm. Special type bar mowers − drive: mechanical con-rod. − cutting width: 115 cm. Operating cu...

Page 29

Gb 27 cutting height adjustment proceed as follows to adjust cutting height. Sickle bar mowers with middle cut fingers and adjustable shoes (fig. 4) a. Loosen the screw (1) that fastens each skid (2). B. Adjust the skids (2) as necessary to set the re- quired cutting height. C. Tighten again the scr...

Page 30

Gb 28 cutter bar mower maintenance lubrication after the first 5 hours of work, and subsequently af- ter every 10 hours, grease the mower mechanism at point (1) and (2) as shown in fig. 8..

Page 31

Ec certificate of conformity according to ecc 89/392 directives and successive modifications declare on their own responsibility, that the machine conforms to the basic safety and health requirements as stated in , and successive modifications. In order to verify the correct application of the afore...

Page 32

Edizione aprile 2008 cod . 218262 m6 ® valpadana s.P.A. Società unipersonale appartenente al gruppo industriale argo s.P.A. 42018 s. Martino in rio (re) italy via don pasquino borghi, 6 tel. 0522 73.17.11 - fax 0522 73.17.31 e-mail: infosep@sep.It - http://www.Sep.It.