06-693 june16 turbotwister® assembly and installation instructions srs australia, pty ltd 12 enterprise st richlands qld 4077 australia phone 07 3812 2283 • fax 07 3812 1187 www.Srsmith.Com/au s.R. Smith, llc corporate headquarters p.O. Box 400 • 1017 s.W. Berg parkway canby, oregon 97013 usa phone ...

2 table of contents introduction ........................................................................................................................................... 3 installed turbotwister structural & installation checklist ........................................ 4 maintenance instruction...

3 introduction danger – failure to follow these warnings, instructions, and the owner’s manual may result in serious injury or death. Turbotwister is designed and manufactured for installation and use on inground swimming pools only. Do not install this slide on above ground pools, houseboats, boat ...

4 installed turbotwister structural & installation checklist installer to review with slide owner upon completion of slide installation. 1. Inspect the runway for visible cracks or tears. 2. Inspect the ladder for sharp edges, protrusions, cracks, or tears. 3. Inspect all fasteners to make sure they...

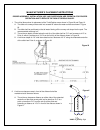

5 assembled turbotwister layout the left curve turbotwister is shown for illustration. The right curve turbotwister is a mirror image of the left. Figure a.

6 assembly instructions tools required 1. Ratchet handle 2. 9/16” deep socket 3. 9/16” wrench 4. 3/4" socket or wrench 5. 7/32” allen wrench 6. Phillips head screwdriver 7. 1/2"Ø (12.7 mm) concrete drill bit 8. 1/4"Ø (6.3 mm) drill bit 9. Power drill 10. Pvc pipe primer & glue 11. Anti-seize 12. Saw...

7 main section parts list visit srsmith.Com for hardware kit and replacement part information. Item no. Part no. Description qty. Kit a kit a 69-209-168 turobotwister hardware carton 1 ea. 1 5-139 3/8” hex nut 14 ea. ● 2 5-151 3/8” lock washer 14 ea. ● 3 05-14-115 1/2" lock washer 8 ea. ● 4 5-145 3/...

8 main section assembly 1. Place the pedestal on the ground and set the exit slide section on top as shown in figure c. 2. Attach the exit slide section to the middle slide section as shown in figure d. If necessary lift up on the end of the exit runway in order to keep the joint tight while fasteni...

9 3. Once the sidewall connections have been made, remove the assembled exit and middle slide sections from the pedestal. Turn the assembly upside down and fasten the underside as shown in figure e. The required hardware is as follows: 3/8” x 6” hex head cap screw (11), 3/8” flat washer (4), 3/8” fl...

10 5. Install four 3/8” x 2-1/2” studs (8) into the threaded inserts located at the top of the ladder as shown in figure g. 6. Assemble the top and bottom ladder sections as shown in figure h, figure i, and figure j. Do not fully tighten fasteners until all the hardware is in place. The hardware req...

11 7. The hardware required for the connections shown in figure i are as follows: 3/8” x 3-1/4” button head cap screw (7) and 3/8” flat washer (4). 8. The hardware required for the connections shown in figure j are as follows: 3/8” x 2-1/4” carriage bolt (5), 3/8” flat washer (4), 3/8” lock washer (...

12 9. In preparation for the assembly of the top runway section and ladder, make sure that the joint surfaces of the top runway section and ladder sections are clean and dry. Unroll the gasket (14) and hold it so that the length of the gasket is centered on the middle of the upper ladder joint surfa...

13 10. Lay the ladder assembly flat on the deck surface as shown in figure l. Align the upper slide runway’s mounting holes with the four studs in the top slide section. The required hardware for these connections is as follows: 3/8” flat washer (4), 3/8” lock washer (2), and 3/8” hex nut (1). Notes...

14 note: ensure gasket material at the runway joint is intact before assembling. 11. Stand the ladder upright and assemble the lower slide runway as shown in figure m. Loosely install the fasteners for both of the runway sidewall connections. The required hardware is as follows: 3/8” x 5” socket hea...

15 13. Drill a 1/4”Ø pilot hole through the center of the 6 circular indentations around the perimeter of the pedestal / runway connection. Then install a 3/8” x 3-1/2” lag screw (9) and 3/8” flat washer (4) as shown in figure n. Figure n.

16 concrete wedge anchor mounting instructions 1. Position the assembled slide on the deck relative to the pool wall. Ensure that the exit flume clears any coping. Slide may be angled slightly providing all dimensions are maintained as noted in the “manufacturer’s placement instructions” noted on pa...

17 8. Drive the assembled wedge anchors (12) through the slide mounting holes until the wedge anchor flat washers are flush with the slide’s surface material, as shown in figure p. 9. Ensure the slide ladder is plumb by placing a level on a ladder tread. If necessary, shims can be provided by s.R. S...

18 water system parts list visit srsmith.Com for hardware kit and replacement part information. Item no. Part no. Description qty. Kit a kit a 69-209-168 turobotwister hardware carton 1 ea. 15 5-242 #14 x 1” pan head tapping screw 6 ea. ● 16 05-787 2”Ø pvc pipe strap 2 ea. ● 17 05-788 1-1/2”Ø pipe c...

19 water system assembly note: it’s a good idea to dry fit all of the plumbing parts before gluing them together so you can make adjustments accordingly. 1. Temporarily assemble the two lengths of 1-1/2”Ø flex hose (18) and (19) to the 1-1/2”Ø ball valve (20). Then insert the 1-1/2”Ø coupling (21) t...

20 5. Glue assembled water supply pipe onto the 1-1/2ӯ pvc fitting at the top of the slide, as shown in figure t. 6. Secure the 1-1/2ӯ flex hose (18) to the ladder with the two 1-1/2ӯ pipe clamps (17) that were installed previously in step 4, on page 19. 7. Secure the 1-1/2ӯ ball valve (20) with...

21 8. The turbotwister is designed to connect to a 1-1/2”Ø water supply line. Plumb the water supply from the pool return line with a 1-1/2”Ø pvc pipe. Position the water supply “stub up” at the base of the slide’s ladder, where the lower end of the 1-1/2”Ø flex hose (18) is located. The “stub up” s...

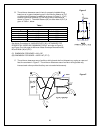

22 manufacturer’s placement instructions proper assembly, installation, use, and supervision are essential for proper operation and to reduce the risk of serious injury. 1. The critical dimensions for placement of the turbotwister are as shown in figure w and figure x. A. The slide exit runway surfa...

23 figure y b. The minimum clearance area in front of a properly installed diving board on an in-ground swimming pool is a minimum distance of 3’-6” on either side of the board’s centerline as shown in figure y. (pt.C) extends a minimum distance (c) from the tip end of the board as shown in figure y...