Instruction 106-4500 10-29-08 copyright ® 2008 by s&s cycle, inc. All rights reserved. Printed in the u.S.A. Installation instructions: s&s ® t111 engine assembly s&s ® ® cycle, inc. 14025 cty hwy g viola, wisconsin 54664 phone: 608-627-1497 • fax: 608-627-1488 technical service phone: 608-627-tech ...

2 safe installation and operation rules: before installing your new s&s part it is your responsibility to read and follow the installation and maintenance procedures in these instructions and follow the basic rules below for your personal safety. Gasoline is extremely flammable and explosive under c...

1- introduction s&s ® t111 engines are designed and intended for installation in a stock harley-davidson ® twin cam 88 ® chassis. It will bolt directly to the stock transmission and engine mounts of chassis designed for stock twin cam 88 ® engines. The t111 engine is available in silver powder coat ...

2- additional features: greater overall strength than stock crankcases, especially in the front motor mount, an important consideration in high performance applications. All oil passages between the crankcase and cam support plate are o-ring sealed. Compatible with stock components. Use stock oil pu...

5 3 - modification notes s&s ® cycle cautions against modifying these crankcases due to the possibility of damaging or weakening them. Modifying s&s crankcases in any fashion voids all manufacturer warranties. Should the customer elect to modify the crankcases regardless, it is imperative that they ...

6 5 - ignition system installation a- all carbureted s&s t111 assemblies come with an s&s ist (intelligent spark technology) ignition. Use of this ignition system is highly recommended. All aspects of ignition timing- advance, retard, and curves are handled automatically by the s&s ist ignition. B- ...

7- oil line installation a- for 1999-2006 harley-davidson ® fl models oil line installation is crucial to engine life. If you are not sure that you can properly perform this operation, please contact the s&s tech department for a referral to a shop in your area. Note- installation instructions are b...

7- mount the oil line block on the crankcase using 5 ⁄ 16 - 18 x 1 3 ⁄ 4 ” long screw (s&s ® pn 50-0437)—do not final tighten as it will be removed again. 8- the next step is to measure and then cut the oil hoses. The straight hose connects the 90 degree fittings of the oil line block and oil pan. T...

9 1- block, oil line .........................................................106-1168 2- bhshcs, 5 ⁄ 16 -18 x 1 3 ⁄ 4 (10 pack) .................................106-1169 3- o-ring (10 pack) .........................................................50-8066 4- fitting, pipe, 90 degree (2 pack) ..........

5- remove the transmission top cover. Remove the neutral indicator switch, vent line and fitting from the transmission top cover. 6- install the neutral indictor switch, vent line and fitting on the new s&s transmission top cover (s&s pn 56-1615). 7- slide the oil feed line (s&s pn 31-0449) through ...

12- press the oil line retention plates into place until they seat. Install the two screws ( 5 ⁄ 16 -18 x 3 ⁄ 4 button head) through the oil line retention plates. First screw goes in the transmission top cover and the second mounts into the crankcase near the rear motor mount. Treat both screws wit...

12 c- oil recommendations notes s&s ® cycle recommends the use of mobil 1 ® v-twin 20w- 50 synthetic oil in our engines. S&s cycle recommends the use of s&s ® oil filters, pn 31-4103 (black), or pn 31-4104 (chrome). All reference to harley-davidson ® part numbers is for identification purposes only....

9- initial start-up and engine break-in note - engines are designed for high performance and as such are not as tolerant of inadequate break-in as stock or lower performance engines. Correct break-in will assure longer engine life and will prevent unnecessary engine damage. Engine damage caused by i...

10- tuning guidelines ignition timing and carburetor jetting are responsibilities of the customer. If not thoroughly familiar with these procedures, contact a professional mechanic. A- exhaust systems muffled exhaust systems. If you have an existing 2-into-2 system that uses slip- on style mufflers,...

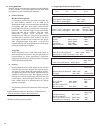

15 torque values specification s&s suggestion rocker box hardware 1 ⁄ 4 ” 120 in-lbs. Loctite ® 243 rocker box hardware 5 ⁄ 16 ” 18 ft-lbs. Loctite 243 tappet guide fasteners 120 in-lbs. Loctite 243 pushrod locknuts 120 in-lbs. Cylinder head bolts see chart on page 11. Crankcase fasteners 1 ⁄ 4 ” 12...

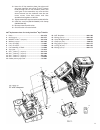

16 1. Bolt, stator 10-24 x1” shc - 4 required (h-d#2720) (10 pack) ....................................................50-0194 2. Seal, sprocket shaft (h-d#12068) ..............................31-4035 3. Bearing, timken ® sprocket shaft (h-d#9028 )...........31-4013 4. Bolt, case 5 ⁄ 16 ” -24 x 2 3 ...