- DL manuals

- Sabo

- Lawn Mower

- SABO 108-17 HS

- Operator's Manual

Sabo SABO 108-17 HS Operator's Manual

Summary of SABO 108-17 HS

Page 1

Omgx20997 b2 gx20997 b2 lawn tractor sabo 108-17 hs operator’s manual export version litho in u.S.A..

Page 2: Introduction

Introduction introduction introduction thank you for purchasing a sabo product we appreciate having you as a customer and wish you many years of safe and satisfied use of your machine. Using your operator’s manual this manual is an important part of your machine and should remain with the machine wh...

Page 3: Product Identification

Product identification product identification product identification record identification numbers sabo lawn tractor sabo 108-17 hs pin (010001 - ) if you need to contact a sabo dealer for information on servicing, always provide the product model and identification numbers. You will need to locate ...

Page 4: Table of Contents

Table of contents table of contents all information, illustrations and specifications in this manual are based on the latest information at the time of publication. The right is reserved to make changes at any time without notice. Copyright© 2006 deere & co. John deere worldwide commercial and consu...

Page 5: Safety

Safety - 1 safety safety pictorial safety signs safety-alert symbol at several important places on this machine safety signs are affixed intended to signify potential danger. The hazard is identified by a pictorial in a warning triangle. An adjacent pictorial provides information how to avoid person...

Page 6: Safety

Safety - 2 safety avoid injury from battery gases and acids m133159x; mx7686 • batteries contain explosive gases and sulfuric acid. Use extreme caution when handling battery. Read operator’s manual before operating machine. Avoid injury from getting caught in belt mx10511x; m121912 • do not operate ...

Page 7: Safety

Safety - 3 safety ce certification, specification and sound label gx21069 • these labels on your machine indicate that this model has been certified and is in compliance with european directive 98/37ec (89/392eec) and 2000/14/ec standards. Operating safely • read, understand and follow all instructi...

Page 8: Safety

Safety - 4 safety parking safely 1. Stop machine on a level surface, not on a slope. 2. Disengage mower blades. 3. Lower attachments to the ground. 4. Lock the park brake. 5. Stop the engine. 6. Remove the key. 7. Wait for engine and all moving parts to stop before you leave the operator’s seat. 8. ...

Page 9: Safety

Safety - 5 safety avoid tipping • slopes are a major factor related to loss-of-control and tip-over accidents, which can result in severe injury or death. All slopes require extra caution. If you cannot back up the slope or if you feel uneasy on it, do not mow it. • keep all movement on slopes slow ...

Page 10: Safety

Safety - 6 safety wear appropriate clothing • always wear safety goggles or safety glasses with side shields when operating the machine. • wear close fitting clothing and safety equipment appropriate for the job. • wear a suitable protective device such as earplugs. Loud noise can cause impairment o...

Page 11: Safety

Safety - 7 safety or hot. Allow engine to cool for several minutes. • never store equipment with fuel in the tank inside a building where fumes may reach an open flame or spark. Tire safety explosive separation of a tire and rim parts can cause serious injury or death: • do not attempt to mount a ti...

Page 12: Safety

Safety - 8 safety a truck bed or trailer. • for gasoline engines, do not use gas with methanol. Methanol is harmful to your health and to the environment. Handling waste product and chemicals waste products, such as, used oil, fuel, coolant, brake fluid, and batteries, can harm the environment and p...

Page 13: Operating

Operating - 9 operating operating daily operating checklist ❏ test safety systems. ❏ check tire pressure. ❏ check fuel level. ❏ check engine oil level. ❏ remove grass and debris from engine compartment and muffler area, before and after operating machine. ❏ clean air intake screen. ❏ check area belo...

Page 14: Operating

Operating - 10 operating mx7698 a - seat adjustment lever miscellaneous controls mx10513 a - mower deck leveling bracket mx7695 a - fuel level window mx7691x a - free-wheeling lever (foot control models) miscellaneous accessories mx7694 a - front and rear cargo mount system™ mx10524 a - glove storag...

Page 15: Operating

Operating - 11 operating adjusting seat mx7698 1. Sit in seat. 2. Lift up on bracket (a). 3. Lean forward and slide seat forward or rearward to desired position. Do not lean back on seat to push rearward. 4. Release bracket to lock in position. Adjusting cutting height cutting height can be adjusted...

Page 16: Operating

Operating - 12 operating note: bottom of wheels should be approximately 3-13 mm (1/8-1/2 in.) from the ground. Mx10509 4. Check mower wheel position. Remove bolt (a), bushing (b), and nut (c) and move mower wheels to proper hole. M92897 mif a - 38 mm (1.5-in.) b - 51 mm (2-in.) c - 64 mm (2.5-in.) d...

Page 17: Operating

Operating - 13 operating mx4896a a. Turn right blade (e) so blade tip points straight forward. B. Measure from blade tip to the surface. Take measurement for both blades. The front blade tip must be 3–6 mm (1/8 -1/4 in.) lower than rear blade tip. C. Adjust mower level, if necessary. Adjusting mower...

Page 18: Operating

Operating - 14 operating mx7674x 7. Loosen leveling nut (d), one on each side, and make sure bolts and leveling brackets slide freely in slots. 8. Raise lift handle to highest position and then lower back down to 25 mm (1 in.) cutting height to position the deck and brackets. 9. Apply slight pressur...

Page 19: Operating

Operating - 15 operating mx7694 3. Unlock the park brake (a). 4. Try to start engine. Result: engine must not start. If engine starts, there is a problem with your safety interlock circuit. Testing park brake 1. Park machine safely. (see parking safely in the safety section.) mx7694 2. Lock the park...

Page 20: Operating

Operating - 16 operating mx7697 picture note: machine with mechanical pto shown. B. Move throttle lever (a) up to maximum engine speed. C. Unlock park brake and release brake pedal (b). D. Engage pto (c). E. Raise up off seat. Do not get off tractor. Result: engine and mower blades should begin to s...

Page 21: Operating

Operating - 17 operating using the park brake locking park brake: mx7694 1. Push and hold brake pedal (a) down. 2. Pull park brake lever (b) up to lock park brake. 3. Release brake pedal. Pedal should stay down and park brake lever should stay locked. Unlocking park brake: 1. Push and hold brake ped...

Page 22: Operating

Operating - 18 operating mx7697 • if engine is cold: move throttle/choke lever (a) up to the choke position. • if engine is warm: move throttle lever to the half- speed position. M94336a 6. Turn key to start position (b) for no more than five seconds. 7. Release key to run position (c) when engine s...

Page 23: Operating

Operating - 19 operating m94336a 2. Turn key to stop position (b). Engine will stop and headlights will turn off. 3. Remove key. 4. Lock the park brake. Using headlights m94336a a - stop position b - headlights on position c - run position d - start position engine off note: headlights will drain th...

Page 24: Operating

Operating - 20 operating bystanders nearby. Mx10530 3. Touch the reverse travel pedal (c) with front of foot and slide foot over pedal from front to rear. Emergency stopping • push down brake pedal. Using the reverse implement option (rio) note: backing up while the mower is engaged is strongly disc...

Page 25: Operating

Operating - 21 operating engage cruise control mx7696 1. Push forward pedal down until you reach desired travel speed. 2. Pull lever (a) up and release forward pedal to lock the cruise control. Disengage cruise control • depress brake pedal, tap on forward pedal or push cruise control lever down to ...

Page 26: Operating

Operating - 22 operating 1. Unlock the park brake. 2. Put transmission in n (neutral). Mx7691 3. On automatic models: pull out on free-wheeling lever (a). 4. Push machine to desired location. 5. On automatic models: push free-wheeling lever back in. Unplugging mower or optional bagger before getting...

Page 27: Operating

Operating - 23 operating using mulch cover side discharge 1. Disconnect hooks from slot and wheel bracket and remove mulch cover when side discharge is preferred. 2. Make sure the correct blades are installed for maximum side discharge operation. Mulching mx8868 1. Raise discharge chute (a) and meta...

Page 28: Operating

Operating - 24 operating note: see your authorized service center for recommended weights. • install rear weights when using the snow blade. • remove weights when not required. Using tire chains tire chains are recommended for use with front attachments. See your authorized service center for tire c...

Page 29: Replacement Parts

Replacement parts - 25 replacement parts replacement parts parts we recommend sabo quality parts and lubricants, available at your sabo dealer. Part numbers may change, use part numbers listed below when you order. If a number changes, your dealer will have the latest number. When you order parts, y...

Page 30: Service Intervals

Service intervals - 26 service intervals service intervals servicing your machine please use the following timetables to perform routine maintenance on your machine. Intervals before each use • check fuel level. • check engine oil level. • clean air intake screen. • check safety systems. • check tir...

Page 31: Service Intervals

Service intervals - 27 service intervals lubricating seat in the service lubrication section.) after storage • charge battery. • check safety systems. • check/tighten loose hardware. • check tire pressure..

Page 32: Service Lubrication

Service lubrication - 28 service lubrication service lubrication grease use grease based on the expected air temperature range during the service interval. Greases that may be used are: • sae multipurpose ep grease with 3 to 5 percent molybdenum disulfide. • sae multipurpose ep grease. • greases mee...

Page 33: Service Lubrication

Service lubrication - 29 service lubrication mx10512 picture note: 107 cm (42 in.) deck used for illustration. A - blade brake pivots (107 cm (42 in.) deck only) b - deck idler pivot • lubricate these pivot points with a general all-purpose spray lubricant. A b.

Page 34: Service Engine

Service engine - 30 service engine service engine avoid fumes engine oil ts1412 use oil viscosity based on the expected air temperature range during the period between oil changes. Oils may be used if they meet one of the following specifications: • api service classification sg • api service classi...

Page 35: Service Engine

Service engine - 31 service engine changing engine oil and filter 1. Run engine to warm oil. 2. Park machine safely. (see parking safely in the safety section.) 3. Lift hood. 4. Put drain pan under drain valve. Mx13772 picture note: right side of engine. 5. Rotate and remove drain cap (b) and drain ...

Page 36: Service Engine

Service engine - 32 service engine safety section). 2. Let engine cool. 3. Lift hood. 4. Clean dirt and debris from the air cleaner cover. Mx13773 5. Loosen knob (a) to remove air cleaner cover (b). Mx13767 6. Inspect the foam precleaner (c) without removing it. If the foam precleaner is dirty: • re...

Page 37: Service Engine

Service engine - 33 service engine 6. Clean spark plug carefully with a wire brush. 7. Inspect spark plug for: • cracked porcelain. • pitted or damaged electrodes. • other wear or damage. 8. Replace spark plug as necessary. M85200 9. Check plug gap (b) with a wire feeler gauge. To change gap, move t...

Page 38: Service Transmission

Service transmission - 34 service transmission service transmission checking transmission the transmission is a sealed component. No maintenance is required on this transmission. If you suspect any transmission problems, please contact your authorized dealer..

Page 39: Service Mower

Service mower - 35 service mower service mower removing mower 1. Park machine safely. (see parking safely in safety section.) 2. Put wood blocks under each side of mower deck. 3. Put lift lever in lowest position, bringing deck down onto blocks. Mx10517; mx7681 4. Disconnect pto drive cable (a). A. ...

Page 40: Service Mower

Service mower - 36 service mower mx10514 • push pto drive cable into clip (l) and hook end of cable spring with hardware (m) into peg on left side of machine frame. Installing mower 1. Park machine safely. (see parking safely in safety section.) 2. Put lift lever in the transport position. 3. Slide ...

Page 41: Service Mower

Service mower - 37 service mower mx7681; mx10517 a. Route cable under mower belt and brake rod and attach cable spring (h) to idler sheave bracket (i). B. Pull out on cable (j), align black end of cable with slot in bracket (k) and release cable into slot. Secure with spring locking pin (l). 11.Leve...

Page 42: Service Mower

Service mower - 38 service mower necessary. Adjusting mower belt tension (107 cm (42 in.) deck) mx7681 1. Park machine safely. (see parking safely in the safety section.) 2. Loosen nuts (a) and move cable bracket (b) away from the center of deck to tighten belt tension. Tighten nuts. Adjusting spind...

Page 43: Service Mower

Service mower - 39 service mower mx4897 picture note: mower deck with side discharge used for illustration. 3. Measure distance (a) between blade tip and flat ground surface. 4. Rotate blade 180° and measure distance between other blade tip and flat ground surface. 5. Install new blade if the differ...

Page 44: Service Mower

Service mower - 40 service mower sharpening blades • sharpen blades with grinder, hand file, or electric blade sharpener. Mx8333 • keep original bevel (a) when grinding. • blade should have 0.40 mm (1/64 in.) cutting edge (b) or less. • balance blades before installing. Balancing blades 1. Clean bla...

Page 45: Service Electrical

Service electrical - 41 service electrical service electrical service the battery safely removing and installing the battery removing 1. Park machine safely and lift hood. (see parking safely in the safety section.) mx7686 2. Disconnect negative (–) battery cable (a). 3. Push red cover (b) away from...

Page 46: Service Electrical

Service electrical - 42 service electrical m71044 a - booster battery b - disabled vehicle battery 1. Connect positive (+) booster cable to booster battery (a) positive (+) post (c). 2. Connect the other end of positive (+) booster cable to the disabled vehicle battery (b) positive (+) post (d). 3. ...

Page 47: Service Miscellaneous

Service miscellaneous - 43 service miscellaneous service miscellaneous filling fuel tank use regular grade 87 octane unleaded fuel. Add fuel stabilizer to fuel before using it in your machine to prevent engine damage due to stale fuel. Follow directions on stabilizer container. 1. Stop engine, let i...

Page 48: Service Miscellaneous

Service miscellaneous - 44 service miscellaneous (a) towards rear of tractor and remove from bolt (b), one on each side. Mx10519 4. Open hood. 5. Disconnect wiring harness (c). 6. Lower hood slightly and lift hood from brackets (d). Installing 1. Align hood brackets with tractor brackets and install...

Page 49: Troubleshooting

Troubleshooting - 45 troubleshooting troubleshooting using troubleshooting chart if you are experiencing a problem that is not listed in this chart, see your sabo distributor for service. When you have checked all the possible causes listed and you are still experiencing the problem, see your sabo d...

Page 50: Troubleshooting

Troubleshooting - 46 troubleshooting engine vapor locks fuel tank vent plugged. Dirt in fuel filter. Cooling fins plugged. Loose hose connection at fuel filter or fuel pump. Engine overheats engine air intake screen plugged. Cooling fins plugged. Engine oil low or too high. Engine operated too long ...

Page 51: Troubleshooting

Troubleshooting - 47 troubleshooting electrical tractor mower if check starter does not work or will not turn engine brake pedal is not depressed. Pto is engaged. Battery terminals are corroded. Battery not charged. Blown fuse. Fusible link in starting circuit is blown - see your authorized dealer b...

Page 52: Troubleshooting

Troubleshooting - 48 troubleshooting belt slipping debris in sheaves. Worn belt. Too much vibration debris on mower deck or in sheaves. Damaged sheaves or sheaves out of alignment. Damaged drive belt. Blades out of balance. Blades scalping grass cutting too low. Mower wheels not adjusted correctly. ...

Page 53: Storage

Storage - 49 storage storage storing safety preparing machine for storage 1. Repair any worn or damaged parts. Replace parts if necessary. Tighten loose hardware. 2. Repair scratched or chipped metal surfaces to prevent rust. 3. Remove grass and debris from machine. 4. Clean under the deck and remov...

Page 54: Storage

Storage - 50 storage 5. Check spark plug gap. Install and tighten plugs to specified torque. 6. Lubricate all grease points. 7. Run the engine 5 minutes without the mower or any attachments running to allow oil to be distributed throughout engine. 8. Be sure all shields and guards or deflectors are ...

Page 55: Assembly

Assembly - 51 assembly assembly charge and connect battery 1. Remove and discard the red positive (+) protective cap from the positive (+) battery terminal. 2. Charge the battery. • battery is fully charged at 12.6 volts. Mx7686 3. Connect positive (+) battery cable (a) to battery. 4. Connect negati...

Page 56: Specifications

Specifications - 52 specifications specifications automatic model 108-17 hs engine manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Briggs and stratton horsepower . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 57: Specifications

Specifications - 53 specifications mower deck - 107 cm (42 in.) blades-rotary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 blade bolt torque . . . . . . . . . . . . . . . . . . ...

Page 58: Declaration of Conformity

Declaration of conformity - 54 declaration of conformity declaration of conformity sabo 108-17 hs lawn tractor sabo 108-17 hs lawn tractor with 107 cm (42 in.) mower deck . . . . . Cutting width . . . . . . . . . . . . 107 cm (42 in.) serial number . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 59: Index

Index - 55 index index a accessories, miscellaneous ........................................... 10 air cleaner elements, checking and cleaning .............. 31 axle pivot, lubricating front .......................................... 28 b balancing blades ...............................................

Page 60: Index

Index - 56 index oil and filter, changing engine ..................................... 31 oil, engine ...................................................................... 30 operating checklist, daily ................................................ 9 p pto switch, testing ...........................

Page 61: Notes

Notes notes notes.

Page 62: Notes

Notes notes notes.

Page 63: Service Statement

Service statement - 59 service statement service statement sabo parts the right tools well-trained technicians prompt service we help minimize downtime by putting genuine sabo parts in your hands in a hurry. That’s why we maintain a large and varied inventory - to stay a jump ahead of your needs. Pr...

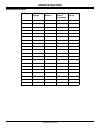

Page 64: Service Record

Service record - 60 service record service record record service dates oil change oil filter change lubricate machine air cleaner element check/clean fuel filter change.