- DL manuals

- Saeco

- Coffee Maker

- PRIMEA LINE 2007

- Technical & Service Manual

Saeco PRIMEA LINE 2007 Technical & Service Manual

REV. 00 - Mar. 07

TECHNICAL SERVICE

MANUAL

PRIMEA LINE

2007

Issue March 2007

All parts of this document are property of Saeco International Group. All rights reserved.

This document and relative information herein is provided without liability deriving from any errors or omissions. Furthermore,

no part may be reproduced, used or collected with the exception of that authorized in writing or in accordance with a contrac-

tual clause.

Summary of PRIMEA LINE 2007

Page 1

Rev. 00 - mar. 07 technical service manual primea line 2007 issue march 2007 all parts of this document are property of saeco international group. All rights reserved. This document and relative information herein is provided without liability deriving from any errors or omissions. Furthermore, no p...

Page 2

Rev. 00 - mar. 07 primea 2007 contents 1/1 primea technical service manual (rev.00 march 07) 1. Introduction (rev.00) 1.1 documentation required 1.2 tools and equipment required 1.3 safety warnings 2. Technical data (rev.00) 2.1 product technical data 2.2 internal / external machine components 3. Su...

Page 3: Chapter 1

Rev. 00 - mar. 07 chapter 1 introduction rev.00 primea 2007 chapter 01.

Page 4

Rev. 00 - mar. 07 1.1 documentation required the following technical documentation l is required for repairs: instruction booklet for specific model technical documentation for specific model (diagrams, exploded drawings) 1.2 tools and equipment required as well as the standard equipment, the tools ...

Page 5: Chapter 2

Rev. 00 - mar. 07 chapter 2 technical data rev.00 primea 2007 chapter 02.

Page 6

Rev. 00 - mar. 07 2.1 product and component technical data power supply and output: 230v~, 50 hz, 1500 w / 120v~,50/60 hz, 1300w temperature control: 2 (ntc) variable resistor sensors – transmit the value to the electronic board safety system: thermostat at 190°c with manual reset on both boilers + ...

Page 7

Rev. 00 - mar. 07 grounds drawer service door main on/off switch pre-ground coffee shoot coffee bean hopper lid coffee bean coffee beans cup warmer touchscreen display sbs dispensing head drip tray touch sensor to raise/lower drip tray milk tank com- partment water tank hot water dispense pipe (spou...

Page 8

Rev. 00 - mar. 07 internal: brew drive assembly compartment multi-way valve boiler valve assembly cappuccino valve assembly grinder door microswitch cappuccino valve assembly power board primea 2007 chapter 02 3/3.

Page 9: Chapter 3

Rev. 00 - mar. 07 chapter 3 brief instructions rev.00 primea 2007 chapter 03.

Page 10

Rev. 00 - mar. 07 3.1 client and programming menu client menu: to access, press “programming menu” machine settings: modify main machine parameters beverage settings coffee preparation menu main menu machine settings set clock main- tenance standby the programming menu will open: machine function pr...

Page 11

Rev. 00 - mar. 07 maintenance: maintenance and appliance cleaning coffee circuit cleaning go back to menu maintenance display lock de- scaling milk circuit cleaning cycle go back from this menu you can: lock the touchscreen start milk circuit cleaning cycle start the dispensing head cleaning cycle r...

Page 12

Rev. 00 - mar. 07 timer settings: set clock go back to menu clock settings clock settings stand-by settings go back set date and display format set current time demo additional functions caffè in the world beverage counters go back go back to menu restore default settings save settings additional fu...

Page 13

Rev. 00 - mar. 07 3.2 maintenance and cleaning 4/5 primea 2007 chapter 03 steps a empty coffee grounds drawer as instructed b empty drip tray as necessary c clean water tank weekly d clean the coffee bean hopper as necessary e clean casing as necessary f clean and grease the dispensing head once a m...

Page 14

Rev. 00 - mar. 07 5/5 primea chapter 03 model function screen messages possible variations mode duration possibility to stop/ change primea cappuccino touch plus milk the appliance requests that the milk cir cuit is pulse-rinsed right a w a y; bev er ages can still be selected. Press k ey or select ...

Page 15: Chapter 4

Rev. 00 - mar. 07 chapter 4 diagrams rev.00 primea 2007 chapter 04.

Page 16

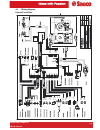

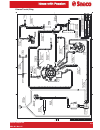

Rev. 00 - mar. 07 4.1 wiring diagram 1/6 primea 2007 chapter 04 primea touch plus.

Page 17

Rev. 00 - mar. 07 primea touch 2/6 primea chapter 04.

Page 18

Rev. 00 - mar. 07 primea ring 3/6 primea chapter 04.

Page 19

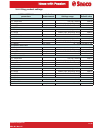

Rev. 00 - mar. 07 4/6 primea 2007 chapter 04 4.2 component load table component connector pin number resistance/voltage mains voltage/mains switch jp 46 1/3 230 v ac / 120v ac autocappuccino valve drive jp 30 304 ohm 24 v ac milk tank presence microswitch jp 31 3/4 3.3 v dc cappuccino valve presence...

Page 20

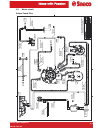

Rev. 00 - mar. 07 4.3 water circuit 5/6 primea 2007 chapter 04 primea touch plus -+0)4%563&-1) '2()" -/-'2156&) 8 '2() -/-'2156&) 8 '2() -/-'2156&) 8 '2() ! " " $ )4,/-1)(4-/-'2156&) 8 '2() )4,/-1)(4-/-'2156&) 8 '2() )4,/-1)(4-/-'2156&) 8 '2() )4,/-1)(4-/-'2156&) 8 '2() )4,/-1)(4-/-'2156&) 8 '2() )4...

Page 21

Rev. 00 - mar. 07 primea touch /ring 6/6 primea chapter 04 " " ! ! 273/-1+*24 9%6)4(4%-1 '2() %3*2407/6-9%; 8%/8) '2() )5,/-1)(5-/-'2167&) : '2() 157/%6-21'28)4-1+ *24,)%6)4 '2() -55-3%6)4*24 ,)%6)4 '2() -/-'2167&) :, '2() )5,/-1)(5-/-'2167&) : '2() ))67&)*24 0-/.()/-8)4; '2() #$ ! # $ " " -+0)5%674...

Page 22: Chapter 5

Rev. 00 - mar. 07 chapter 5 troubleshooting rev.00 primea 2007 chapter 05.

Page 23

Rev. 00 - mar. 07 4 2 3 1 5.1 primea touch plus and touch test functions during the first 3 seconds after start-up of the appliance (or on exit from standby mode) the user can access test mode by pressing the keys in the sequence shown alongside. In test mode, the machine functions can be checked, a...

Page 24

Rev. 00 - mar. 07 5.1.1 function group 1 - brew group, grinder, boiler power supply. Function group 3 - drip tray, cup illumination, cup warmer, boiler supply function group 2 - multi-way valve, cappuccino maker valve, pump dispensing head home: brew group in home position is home - rest position (g...

Page 25

Rev. 00 - mar. 07 5.1.2 microswitch and sensor check errors (errors) grounds drawer: grounds drawer micro (dregdraw:) ok drawer present er drawer missing service: door microswitch (door:) ok door closed er door open water tank: tank micro (watank:) ok tank engaged er tank empty or in reserve (see di...

Page 26

Rev. 00 - mar. 07 5.2.1 beverage counters total hot milk beverages • total beverages not modifiable • beverage dispense time (sec.) not modifiable total latte macchiato beverages • total beverages not modifiable • water used (ml.) not modifiable total cappuccino beverages • total beverages not modif...

Page 27

Rev. 00 - mar. 07 total pre-ground coffee beverages v total beverages not modifiable v water used (ml.) not modifiable total all beverages v total beverages not modifiable 5.2.2 total counters water used since production (ml.) not modifiable water used since last descaling (ml.) modifiable water use...

Page 28

Rev. 00 - mar. 07 5.2.4 ring buffer repair code buffer history repair this area records interventions of the service centres (up to a maximum of 10). The service centreentersthe fault codes via pc as transmitted by saeco i.G. (e.G: cld01) 1. Group errors 1. Code errors 1. Day errors 1. Month errors ...

Page 29

Rev. 00 - mar. 07 system settings parameters unit of measurement settings range default value hot milk beverage data modified by user yes/no no milk time seconds 0 ... 40 0 froth time seconds 0 ... 40 25 latte macchiato beverage data modified by user yes /no no temperature low, high, medium medium a...

Page 30

Rev. 00 - mar. 07 8/20 aroma medium, light, preground, strong medium grinding ratio percentage 0 ... 100 100 pre-brewing disabled, strong, normal normal water turb. Pulses. 50 ... 450 280 espresso beverage data modified by user yes /no no temperature low, high, medium high aroma medium, light, pregr...

Page 31

Rev. 00 - mar. 07 9/20 primea chapter 05 5.2.6 system settings system settings parameters unit of measurement settings range default value setting water boiler temperature enabled °c 70 ... 150 130 water boiler temperature disabled °c 70 ... 150 115 steam boiler temperature enabled °c 70 ... 150 145...

Page 32

Rev. 00 - mar. 07 5.2.7 emptying water circuit this option must be run when the coffee maker is delivered by courier in periods subject to winter temperatures. This function prevents damage to the appliance caused by very low temperatures. The cycle empties the water circuit by means of the followin...

Page 33

Rev. 00 - mar. 07 5.2.8 auto test on selection of this function, an automatic test is run on the machine functions, with results reported on the display. Before starting the test, all drawers and the tank must be inserted, all service doors closed and the relative recipients must be filledwith water...

Page 34

Rev. 00 - mar. 07 menu 5.3 ringtest function tmode l1 inputs 1245679abcdefgh aroma esc up down during the fi rst 3 seconds after start-up of the appliance (or on exit from standby mode) the user can access test mode by pressing the keys in the sequence shown alongside. Turn the touch-ring (p) (i-pod...

Page 35

Rev. 00 - mar. 07 - capp_door_closed (milk tank door closed). The display indicates e - capp_door_closed+capp_pres (door closed milk tank and cappuccino valve. The display indicates f - coffee_beans_door_closed (coffee container lid closed). The display indicates g - tank_pres (water tank) the displ...

Page 36

Rev. 00 - mar. 07 level 7 motor-driven tray test - press the up key (lower capacitive key) key 9 - press the down key (upper capacitive key) key a the display indicates d = lower stroke end position micro the display indicates c = upper stroke end position micro the display indicates a = upper capac...

Page 37

Rev. 00 - mar. 07 primea chapter 05 4 3 2 1 a window is displayed showing the following options: • beverage counters • total counters • error counters • beverage settings • system settings • exit diagnostics menu description of options available 5.4 ring diagnosis function procedure for access to di...

Page 38

Rev. 00 - mar. 07 primea 2007 chapter 05 1.9 total all beverages not modifiable 1.10 total descaler used (ml) not modifiable 5.4.2 total counters 2.1 water used since production (ml.) not modifiable 2.2 water used since last descaling (ml.) not modifiable 2.3 water used since second last descaling (...

Page 39

Rev. 00 - mar. 07 system settings parameters unit of measurement settings range default value 4.1 espressso 4.1.1 temperature low, high, medium medium 4.1.2 aroma medium, light, preground, strong strong 4.1.3 water turb. Pulses. 70 ... 450 std 165 it 110 4.2 coffee 4.2.1 temperature low, high, mediu...

Page 40

Rev. 00 - mar. 07 18/20 primea chapter 05 5.4.5 ring system settings system settings parameters unit of measure settings range default value setting water boiler temperature enabled °c 70 ... 150 130 water boiler temperature disabled °c 70 ... 150 115 steam boiler temperature enabled °c 70 ... 150 1...

Page 41

Rev. 00 - mar. 07 19/20 primea 2007 chapter 05 5.5 error messages for service personnel code applicable models: primea-odea-talea brief description description 01 all models grinder 1 block ed the grinder is block ed (burrs jammed or sensor not r eading pr operly). 02 primea grinder 2 block ed the g...

Page 42

Rev. 00 - mar. 07 5.6 problems, causes, remedies help messages displayed how to reset message turn the appliance off and on to solve the problem switch off and after 30 sec. Turn on the appliance to restore normal operating conditions. Call the service centre problem requiring assistance of service ...

Page 43: Chapter 6

Rev. 00 - mar. 07 chapter 6 operating logic rev.00 primea chapter 05.

Page 44

Rev. 00 - mar. 07 6.1 multi-way valve 1/9 touch plus multi-way valve opening operating diagram t wo f actors combine to giv e the fiv e phases of the multiw a y v alv e: 1) activ ation (or not) of two micr oswitches on the multiv alv e. 2) dir ection of rotation of the multiv alv e. Primea chapter 0...

Page 45

Rev. 00 - mar. 07 ring andtouch multi-way valve opening operating diagram 2/9 primea 2007 chapter 06 t wo f actors combine to giv e the fiv e phases of the multiw a y v alv e: 1) activ ation (or not) of two micr oswitches on the multiv alv e. 2) dir ection of rotation of the multiv alv e. 5 heater m...

Page 46

Rev. 00 - mar. 07 6.2 autocappuccino the autocappuccino system enables the automatic preparation of cappuccino, latte macchiato, caffè macchiato and hot milk. The milk tank (a), with a capacity of approx. 0.4 l. Is removable to enable storage of the contents in the fridge when not used. At the time ...

Page 47

Rev. 00 - mar. 07 the system consists of a motor-driven valve (b), which opens orifice (c) to allow air to enter and remove milk from inside the cappuccino maker. Motor (1) is a stepper motor which resets the position after each beverage is dis- pensed. Air/milk flow regulator which can be turned to c...

Page 48

Rev. 00 - mar. 07 5/9 primea 2007 chapter 06 positions position 1 init position 2 milk drainage air inlet (vernay) open closed milk drain open open micro on disabled cappuccino valve positions and functions position 2 milk drainage milk drain) position 1 init repositioning) the circuit pressure is d...

Page 49

Rev. 00 - mar. 07 6.3 motor-driven tray 6/9 the movement of the motor-driven tray is mechanical by means of a stepper motor (1) in 24v dc, controlled by two capacitive touch sensors (2) located at the front of the tray. The two microswitches (3) are for the limit switch, and operation can be checked...

Page 50

Rev. 00 - mar. 07 7/9 operating logic with “aqua prima” filter for primea ring when use of the “aqua prima” filter is selected on the user menu or via the control panel, the system water count logic is as follows: if the “aqua prima” function has been enabled, the electronics perform a pulse count of...

Page 51

Rev. 00 - mar. 07 6.5 sbs valve 8/9 primea 2007 chapter 06 beverage dispensing the sbs brew unit valve (see fig. 2) can be used to vary (increasing or decreasing depending on the position of the knob) the amount of water passing through the brew unit. This adjusts coffee brewing time (extraction tim...

Page 52

Rev. 00 - mar. 07 ! ! ! #& $ $ %"$ ""! " "#& ""! " $#& "! " " ! ! To ensure correct operation of the sbs valve a caffe lungo should be made. During preparation of the latter, check the difference in speed of delivery between the maximum and minimum positions. The difference in dispensing speed is ap...

Page 53: Chapter 7

Rev. 00 - mar. 07 chapter 7 component assembly and disassembly rev.00 primea 2007 chapter 07.

Page 54

Rev. 00 - mar. 07 7.1 top cover open cover (a). Remove pre-ground shoot (b). Remove lid latch (c). Loosen the three fixing screws of the hopper, complete with cover. Release the end section of the top cover by loosening the three screws (p). A b c 1/22 primea 2007 chapter 07.

Page 55

Rev. 00 - mar. 07 move the drip tray to the lower limit position. Disassemble the start touch sensors (e). Remove the door (f) protecting the connec- tion socket of the setting device, by means of a #10 torx driver. Loosen the screws as indicated. 7.2 right-side cover raise the rear section of the t...

Page 56

Rev. 00 - mar. 07 7.3 left-side cover loosen the screws as indicated. Raise the rear section of the top cover slightly. Push the upper section of the left side cover up- wards to release from hooks (c) from slots (b). To facilitate release, push the front section of the cover downwards. 3/22 primea ...

Page 57

Rev. 00 - mar. 07 7.4 brew unit slide the central dispensing body (a) and remove it from the milk dispensing spout (b). Loosen the two screws (c) and remove therear dispensing body (d). Remove the knob with the saeco logo by pulling outwards. Loosen the central screw retaining the internal dispensin...

Page 58

Rev. 00 - mar. 07 extract the hot water dispensing spout (e). Remove the spacer of the dispensing head bodies (f). Loosen the two screws securing the display protection. Loosen the two screws securing the front cover. 5/22 primea 2007 chapter 07 assembly: to assemble, follow the above sequence in re...

Page 59

Rev. 00 - mar. 07 7.5 electronics to access board (f) loosen the board protection screws (g). 6/22 loosen the screws as indicated and remove all connectors. Primea 2007 chapter 07.

Page 60

Rev. 00 - mar. 07 7.6 gearmotor remove the casing (a) by loosening the three screws. Loosen the two screws and remove the boiler valve (b). To remove protection plate (c), remove the indicated screws. The following are located inside the compartment protected by the guard: - brew drive (a) with gear...

Page 61

Rev. 00 - mar. 07 install the brew drive and transmission shaft, inserting the guides (l) in the relative seat. Flat side of the guide face up. Insert the gear (b), taking care that the arrow stamped on the element is within the opening that contains pin (p). Insert the gear so that it meshes with t...

Page 62

Rev. 00 - mar. 07 when installing the boiler valve (b), verify both o-rings (g) are present on the spout that is inserted into the pipe opening (d). Tighten the screws of the boiler valve. Warning: ensure both screws are pushed fully down before tightening. 9/22 primea 2007 chapter 07.

Page 63

Rev. 00 - mar. 07 7.7 pump remove the silicon tube that comes from the turbine. Loosen the screw securing the pump carriage. Move the pump carriage forward and extract the unit (carriage, pump and membrane). Detach the electrical con- nections and silicon tube of the valve stem. Assembly: to assembl...

Page 64

Rev. 00 - mar. 07 7.8 boilerand multi-way valve assembly loosen the screw securing the protection casing (a) of the water tank, detach the base of the casing from the retainer by lifting it using a screwdriver and pulling it outwards. 11/22 loosen the boiler valve screws. Detach the milk connector (...

Page 65

Rev. 00 - mar. 07 remove the drain tube connector. Remove the boiler assembly by sliding it along its guide (e). 12/22 depending on the work required, access the boiler assembly or multi-way valve. Remove the silicon tube that comes from the non-return valve. Primea 2007 chapter 07.

Page 66

Rev. 00 - mar. 07 remove the safety guard by loosening screw (f) and withdraw the boiler assembly from the casing. To separate the boilers from the plastic support, loosen the internal screw (g) to release the coffee boiler. To remove the temperature sensor, remove the red indicated screw. Loosen th...

Page 67

Rev. 00 - mar. 07 7.10 multiway valve remove the multi-way valve from the casing protecting the boilers, by loosening the screw as indicated. Remove the cover of the microswitches and disconnect the wires from the latter. Disconnect all water hoses from the opposite side of the multi-way valve. The ...

Page 68

Rev. 00 - mar. 07 cof fee dissipater filter steam pump dissipa- tor release boiler multi- valve drain closed 15/22 touch and ring multi-way valve assembly the pressure must be released on single boiler models to reset the coffee or hot water functions. The steam will be cooled in the dissipator and r...

Page 69

Rev. 00 - mar. 07 7. 11 oetiker clamp assembly and disassembly boiler clamps figure (1) shows the assembly position of the clamp on the boiler connector. Boiler multi-way valve illustration (2) shows the assembly position of the clamp on the plastic connector of the multi- way valve. Multi-way valve...

Page 70

Rev. 00 - mar. 07 7.12 coffee grinders detach the connectors from the board and remove the grinder by pulling it upwards to release slot (d) from pin (f). Ensure that the spring indicated is aligned correctly in its seat. 17/22 primea 2007 chapter 07.

Page 71

Rev. 00 - mar. 07 7.13 grinder adjustment/assembly and disassembly remove the coffee container and rubber seal. 18/22 primea chapter 07 to remove the upper burr support, loosen the three screws as indicated, then use a hex key, turning it clockwise to release the grinder support from the bayonet cou...

Page 72

Rev. 00 - mar. 07 19/22 7.14 grinding adjustment remove the screw from the door + - to adjust grinding, press on the element with a hex key. (+) = coarse ground. (-) = finely ground. Warning: - grinder must be adjusted with the motor stationary. - adjust the grinding level by one step at a time. - a...

Page 73

Rev. 00 - mar. 07 7.15 autocappuccino. Withdraw the connector from the electronic board and loosen the three screws as shown. 20/22 primea 2007 chapter 07.

Page 74

Rev. 00 - mar. 07 7.16 motor-driven drip tray. Move the tray to the lower position. Loosen the screws as shown and lift the upper part off. Remove the motor-driven tray from its seat by pulling upwards. For access to the sensors, loosen the two screws to remove the casing below the drip tray. Remove...

Page 75

Rev. 00 - mar. 07 loosen the two screws to release the brew drive with worm gear to withdraw the stop (a) use pliers to grip the tabs securing the lifting system to the base and pull outwards. Withdraw the brew drive with worm gear from above. 22/22 primea chapter 07 disassembling the motor-driven t...

Page 76: Chapter 8

Rev. 00 - mar. 07 chapter 8 service schedule rev.00 primea 2007 chapter 08.

Page 77

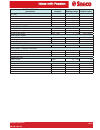

Rev. 00 - mar. 07 s= replacement r= service p= cleaning d= descaling c= inspection *= number of beverages dispensed parts task reason item maintenance 5,000* 10,000* casing, tanks, containers, power cable c c c dirty, damaged see documentation (exploded drawings) water coffee andmilk pipes gaco dim ...

Page 78: Chapter 9

Rev. 00 - mar. 07 chapter 9 amendments made to technical service manual primea chapter 09 rev.00

Page 79

Rev. 00 - mar. 07 list of amendments made to manual rev.00 march 07 date rev. Chapter section sub-section description 28/03 0 2 2.2 photo showing milk tank compartment 28/03 0 5 5.1 various 28/03 0 5 5.2 5.2.2 28/03 0 5 5.2.3 28/03 0 5 5.2.4 28/03 0 5 5.2.5 28/03 0 6 6.1 touch plus, touch and ring m...