- DL manuals

- Saftronics

- Inverter

- FP5 Series

- User Manual

Saftronics FP5 Series User Manual

Summary of FP5 Series

Page 1

Fp5/gp5 series user’s manual variable torque inverter (with software version 5110/5120 and newer) efesotomasyon.Com - control techniques,emerson,saftronics -ac drive-servo motor.

Page 2: Warning

2 fp5/gp5user’s manual precautions 1) read this manual in its entirety before installing or operating the fp5/gp5 inverter. This manual applies to inverters with software versions 5110 and 5120 only and is not intended to be used in con- junction with any other software. 2) do not connect or disconn...

Page 3

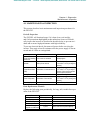

Fp5/gp5 user’s manual 3 contents section description page 1 receiving & installation 1.1 i ntroduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 1.2 s pecifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 gp5/fp5 . . . . . . . . . . . . ....

Page 4

4 fp5/gp5 user’s manual current limit (stall prevention). . . . . . . . . . . . . . . . . . . . 52 dc injection braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54 energy savings control . . . . . . . . . . . . . . . . . . . . . . . . . . 55 frequency agree set point . . . . . . . . ....

Page 5: - Chapter 1 -

Fp5/gp5 user’s manual 5 - chapter 1 - receiving & installation section description page 1 receiving & installation 1.1 i ntroduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 1.2 s pecifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 fp5...

Page 6

6 fp5/gp5 user’s manual 1.1 introduction the fp5/gp5 is a series of high quality, full featured inverters. With a power range of 5 to 500 hp, it provides all the functionality of prior series, in a compact, low cost package. This functionality includes proprietary features like full-range automatic ...

Page 7

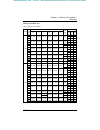

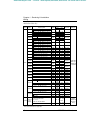

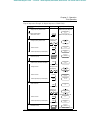

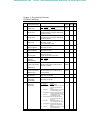

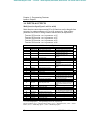

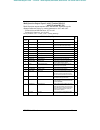

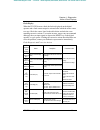

Fp5/gp5 user’s manual 7 1.2 specifications fp5/gp5 inverter model cimr-p5u 20p4 20p7 21p5 22p2 23p7 25p5 27p5 2011 2015 - o ut pu t c ha ra ct er ist ics motor output (hp) * 0.5 1 2 3 5 7.5 10 20 25 - capacity (kva) 1.2 2.3 3.0 4.2 6.7 9.5 13 19 24 - rated output current (a)-vt** 3.2 6 8 11 17.5 27 ...

Page 8

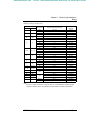

8 fp5/gp5 user’s manual co nt ro l c ha ra ct er ist ics control method sine wave pwm with full-range, automatic torque boost frequency control range 0.1 to 400 hz frequency accuracy digital command: 0.01%, analog command: 0.1% frequency setting reso- lution digital operator reference: 0.1hz, analog...

Page 9

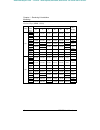

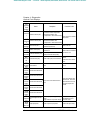

Fp5/gp5 user’s manual 9 fp5/gp5 inverter model cimr-p5u 2018 2022 2030 2037 2045 2055 2075 — o ut pu t c ha ra ct er ist ics motor output (hp) * 30 40 50 60 75 100 125 capacity (kva) 30 37 50 61 70 85 110 rated output current (a) - vt ** 80 104 130 160 192 248 312 rated output current (a) - ct ** 64...

Page 10

10 fp5/gp5 user’s manual co nt ro l c ha ra ct er ist ics control method sine wave pwm with full-range, automatic torque boost frequency control range 0.1 to 400 hz frequency accuracy digital command: 0.01%, analog command: 0.1% frequency setting resolution digital operator reference: 0.1hz, analog ...

Page 11

Fp5/gp5 user’s manual 11 1.3 preliminary inspection receiving after unpacking the fp5/gp5: · verify that the part numbers on the drive nameplate match the num- bers on your purchase order or packing slip. · check the unit for physical damage which may have occurred during shipping. If any part of th...

Page 12

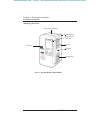

12 fp5/gp5 user’s manual identifying the parts figure 3 parts identification - model p5u43p7 protective cover (top/bottom) front cover 4 mounting holes digital operator jvop-130p heatsink nameplate ventilation slots 0 p drive fwd rev chapter 1 - receiving & installation preliminary inspection efesot...

Page 13: Caution

Fp5/gp5user’s manual 13 1.4 mounting precautions 1) when preparing to mount the fp5/gp5, lift it by its base. Never lift it by the front cover. 2) mount the inverter onto nonflammable material. 3) the fp5/gp5 generates heat. For the most effective cooling possible, mount it vertically. For more deta...

Page 14

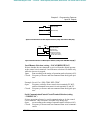

14 fp5/gp5 user’s manual removing and replacing the digital operator to remove the digital operator from the front cover, push the operator lever in the direction shown by arrow 1 and lift the digital operator in the direction shown by arrow 2 (see figure 4). To replace the digital operator, engage ...

Page 15

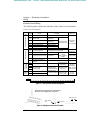

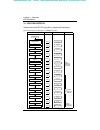

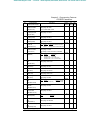

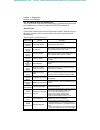

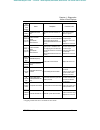

Fp5/gp5user’s manual 15 dimensions/heat loss open chassis type (ip00) voltage model cimr -p5u open chassis dimensions in inches (mm) mass lbs (kg) heat loss (w) w h d w1 h1 h2 heat sink inside unit total 230v 20p4 5.51 (140) 11.02 (280) 6.30 (160) 4.96 (126) 10.47 (266) 0.28 (7) 6.5 (3) 15 50 65 20p...

Page 16

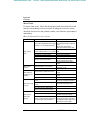

16 fp5/gp5 user’s manual enclosed type (nema 1, ip20) voltage model (cimr- p5u) nema 1 dimensions in inches (mm) mass lbs (kg) w h d w1 h1 h2 230v 20p4 5.51 (140) 11.02 (280) 6.30 (160) 4.96 (126) 10.47 (266) 0.28 (7) 6.5 (3) 20p7 21p5 22p2 5.51 (140) 11.02 (280) 7.09 (180) 4.96 (126) 10.47 (266) 0....

Page 17

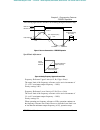

Fp5/gp5 user’s manual 17 clearances when mounting the fp5/gp5, allow sufficient clearances for effec- tive cooling as shown below: notes: 1) the required clearances at the top, bottom, and both sides of the inverter are the same for both open chassis and nema 1 enclosures. 2) for inverter models 25h...

Page 18: Caution

18 fp5/gp5 user’s manual 1.5 wiring precautions 1) do not connect or disconnect wiring, or perform signal checks while the power supply is turned on. 2) connect the power supply wiring to terminals l1, l2 and l3 on the main circuit input section. Do not connect the power supply wiring to output term...

Page 19

Fp5/gp5 user’s manual 19 fp5/gp5 standard connection diagram figure 9 fp5/gp5 terminal diagram digital rs-232 serial port analog inputs (250 Ω ) operator input fi selectable 4~20ma or 0~10v (10-pin) im ⊕ 1 ⊕ 2 b1 b2 230v: models 20p4 through 27p5 460v: models 40p4 through 4015 s1 - fixed s2 s3 sc (c...

Page 20

20 fp5/gp5user’s manual fp5/gp5 standard connection diagram figure 10 fp5/gp5 terminal diagram digital rs-232 serial port analog inputs (250 Ω ) operator input fi selectable 4~20ma or 0~10v (10-pin) s1 - fixed s2 s3 sc (com) s4 s5 s6 fs fv fi fc pwm 8 bit multi-function inputs g (+15v) (20k Ω ) (0v)...

Page 21

Fp5/gp5 user’s manual 21 main circuit wiring input wiring · molded-case circuit breaker (mccb) be sure to connect mccbs or fuses between the ac main circuit power supply and fp5/gp5 input terminals l1, l2 and l3, to protect the power supply wiring. · ground fault interrupter when connecting a ground...

Page 22

22 fp5/gp5 user’s manual · surge suppressor for inductive loads (i.E. Magnetic contactors, magnetic relays, magnetic valves, solenoids, magnetic brakes, etc.) connected near the inverter, use a surge suppressor across the coils to limit the transients on the sup- ply lines. Output wiring · motor con...

Page 23

Fp5/gp5 user’s manual 23 chapter 1 - receiving & installation wiring grounding · ground resistance 230v class: 100 Ω or less, 460v class: 10 Ω or less. · never ground the fp5/gp5 in common with welding machines, motors, or other high-current electrical equipment. Run all ground wir- ing in a separat...

Page 24

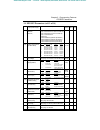

24 fp5/gp5 user’s manual chapter 1 - receiving & installation wiring terminal functions 230v class terminal functions 460v class terminal functions model cimr-p5u 20p4 to 27p5 2011 to 2015 2018 to 2075 nominal motor output 0.5 to 10hp 20 to 25hp 30 to 125hp l1 main circuit input power supply main ci...

Page 25

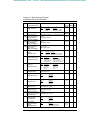

Fp5/gp5 user’s manual 25 chapter 1 - receiving & installation wiring wire and terminal screw sizes 230v class wire size * wire sizes are based on 75°c copper wire. Note: voltage drop should be considered when determining wire size. Voltage drop can be calculated using the following equation: select ...

Page 26

26 fp5/gp5 user’s manual chapter 1 - receiving & installation wiring 460v class wire size * wire sizes are based on 75°c copper wire. Circuit model cimr- terminal symbol terminal screw wire size * max. Torque lb-in (n·m) wire type awg mm 2 main p5u40p4 l1, l2, l3, , ⊕ 1, ⊕ 2, b1, b2, t1, t2, t3 m4 1...

Page 27

Fp5/gp5 user’s manual 27 chapter 1 - receiving & installation wiring jst closed loop connectors note: the use of a jst closed-loop connector (lug) is recommended to maintain proper clearances. Please contact your saftronics representative for more information. Wire size * terminal screw jst closed-l...

Page 28

28 fp5/gp5 user’s manual chapter 1 - receiving & installation wiring control circuit wiring the following table outlines the functions of the control circuit terminals. Control circuit terminals classifi- cation terminal function description signal level m ul ti- fu nc tio n in pu t s ig na l s1 for...

Page 29: - Chapter 2 -

Fp5/gp5 user’s manual 29 - chapter 2 - operation section description page 2 operation precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 2.1 t rial o peration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 digital operator display at power-up . ...

Page 30: Warning

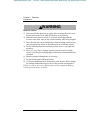

30 fp5/gp5 user’s manual precautions 1) only turn on the input power supply after replacing the front cover. Do not remove the cover while the inverter is powered up. 2) when the retry function (n060) is selected, do not approach the inverter or the load, since it may restart suddenly after being st...

Page 31

Fp5/gp5 user’s manual 31 2.1 trial operation to ensure safety, prior to initial operation, disconnect the machine cou- pling so that the motor is isolated from the machine. If initial operation must be performed while the motor is still coupled to the machine, use great care to avoid potentially haz...

Page 32

32 fp5/gp5 user’s manual operation checkpoints: · motor rotates smoothly. · motor rotates in the correct direction. · motor has no abnormal vibration and is not noisy. · acceleration and deceleration are smooth. · unit is not overloaded. · status indicator leds and digital operator display are corre...

Page 33

Fp5/gp5 user’s manual 33 typical operation example by digital operator (jvop-130p) description key sequence digital operator display (1) power on · displays frequency reference value. Operation condition setting · select local mode. (2) frequency setting · change frequency reference value. (3) forwa...

Page 34

34 fp5/gp5 user’s manual operation by control circuit terminal signal the diagram below shows a typical operation pattern using the control circuit terminal signals. Typical operation example by control circuit terminal signal description key sequence digital operator display (1) power on · displays...

Page 35

Fp5/gp5 user’s manual 35 2.2 digital operator display all functions of the fp5/gp5 are accessed using the jvop-130p digi- tal operator. Below are descriptions of the display and keypad sections. Local remote enter dspl run stop reset digital operator jvop-130p prgm kwout fref fout iout f/r montr acc...

Page 36

36 fp5/gp5 user’s manual 2.3 led description simple operation of the fp5/gp5 is possible, by using the quick-start displays. Quick-start displays (example of cimr-p5u23p7) description key sequence digital operator display remarks depress [enter] key to display the monitor value. Power on frequency r...

Page 37

Fp5/gp5 user’s manual 37 2.4 operation mode selection (n002, oper mode select) the fp5/gp5 has two operation modes: local and remote (see table below for description). These two modes can be selected by the digital operator “local/remote” key only when operation is stopped. The operation mode select...

Page 38

38 fp5/gp5 user’s manual this page intentionally left blank. Efesotomasyon.Com - control techniques,emerson,saftronics -ac drive-servo motor.

Page 39: - Chapter 3 -

Fp5/gp5 user’s manual 39 - chapter 3 - programming features section description page 3 programming features 3.1 fp5/gp5 p arameters (n001~n116) . . . . . . . . . . . 41 3.2 p arameter s et - up & i nitialization . . . . . . . . . . . . . . . 49 3.3 fp5/gp5 o peration . . . . . . . . . . . . . . . . ...

Page 40

40 fp5/gp5 user’s manual stopping method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70 torque adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72 torque detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73 tripless operation . . . . . . ....

Page 41

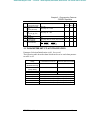

Fp5/gp5 user’s manual 41 3.1 fp5/gp5 parameters (n001~n116) no. Function name (lcd operator display) description factory default user setting ref. Page n001 parameter selection/ initialization (password) 0: n001 read and set, n002~n116 read only 1: n001~n035 read and set, n036~n116 read only 2: n001...

Page 42

42 fp5/gp5 user’s manual n014 mid. Output frequency (mid frequency) unit: 0.1hz setting range: 0.1~399.9hz 3hz 76 n015 mid. Frequency voltage (mid voltage) unit: 0.1v setting range: 0.1~255.0v (510v for 460v units) 17.2v (34.4v) 76 n016 minimum output frequency (min frequency) unit: 0.1hz setting ra...

Page 43

Fp5/gp5 user’s manual 43 n034 motor thermal protection (motor ol sel) led setting lcd setting description 0 disabled protection disabled 1 std motor/8 min general-purpose motor (time constant 8 min.) 2 std motor/5 min general-purpose motor (time constant 5 min.) 3 inv motor/8 min blower-cooled motor...

Page 44

44 fp5/gp5 user’s manual n037 multi-function input 2 (terminal s3 sel) set items are same as n036. (when n036=”fwd/rev cmd (3w), “in use by other” is displayed, and setting is prohibited) ext fault (no) 78 n038 multi-function input 3 (terminal s4 sel) set items are same as n036. Fault reset 78 n039 ...

Page 45

Fp5/gp5 user’s manual 45 n047 frequency reference level at loss of fref (fref lvl@f loss) unit: 1% setting range: 0~100% of setting fref 80% 82 n048 terminal fv gain (terminal fv gain) unit: 1% setting range: 0~200% 100% 59,96 n049 terminal fv bias (terminal fv bias) unit: 1% setting range: -100~100...

Page 46

46 fp5/gp5 user’s manual n065 elapsed timer selection (elapsed timer) led setting lcd setting description 0 time power is on accumulate time during power on 1 time running mtr accumulate time during running time running mtr - n066 elapsed timer 1 (elapsed time 1) unit: 1 hour range: 0~9999 * initial...

Page 47

Fp5/gp5user’s manual 47 n078 over/undertorque detection level ol3 (torq det level) unit: 1% setting range: 30~200% 100% = inverter rated current 160% 74 n079 over/undertorque detec- tion delay time ol3 (torq det time) unit: 0.1s setting range: 0.1~10.0s 0.1s 74 n080 on-delay timer (on-delay timer) u...

Page 48

48 fp5/gp5 user’s manual n096 energy saving selection (energy save sel) led setting lcd setting description 0 disabled energy saving is disabled. 1 enabled energy saving is enabled. Disabled 55,96 n097 energy saving gain k2 (energy save gain) unit: 0.01 setting range: 0.00~655.0 (0=no energy saving)...

Page 49

Fp5/gp5 user’s manual 49 3.2 parameter set-up & initialization parameter selection/initialization (n001, password) the following table describes data which can be set or read when parame- ter n001 is set. N112 low frequency ol start point (low freq ol2 start) unit: 0.1hz setting range: 0.0 ~ 10.0hz ...

Page 50

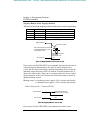

50 fp5/gp5user’s manual 3.3 fp5/gp5 operation accel/decel time adjustment when any of the multi-function input terminal selections (n036, n037, n038, n039 or n040) is set to “acc/dec switch”, accel/decel times can be selected by opening or closing the appropriate terminal (s2, s3, s4, s5 or s6). At ...

Page 51

Fp5/gp5 user’s manual 51 automatic fault retry (n060, num of restarts) after a fault occurs, the inverter can automatically restart. The number of retry attempts can be set up to 10 times via parameter n060. The inverter can be set to automatically restart after the following faults occur: · overcur...

Page 52

52 fp5/gp5 user’s manual current limit (stall prevention) this function automatically adjusts the output frequency in response to an increase in load current to continue operation without tripping the inverter. · stall prevention level during acceleration (n073, stallp accel lvl) the current limit l...

Page 53

Fp5/gp5 user’s manual 53 in the constant output area [output frequency ≥ base frequency (n013)], the current limit level during acceleration is changed by the following equation: · stall prevention level during running (n074, stallp run level) the stall prevention level during running can be set in ...

Page 54

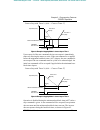

54 fp5/gp5 user’s manual · stall prevention during deceleration (n072, stallp decel sel) to prevent overvoltage during deceleration, the inverter automatically extends the deceleration time according to the value of main circuit dc voltage. When using an optional braking resistor for the fp5/gp5, se...

Page 55

Fp5/gp5 user’s manual 55 · dc injection braking time at start (n070) dc injection braking time at start can be set in increments of 0.1 sec- ond. When parameter n070 is set to “0”, dc injection braking at start- ing is disabled. Energy saving control to enable energy saving control, set energy savin...

Page 56

56 fp5/gp5 user’s manual limit, this lower limit value is output as the voltage reference value. The lower limit value is set in order to prevent stalling at light loads. Set voltage limits at 6hz and 60hz; a value obtained by linear interpolation should be used to set any limit values other than at...

Page 57

Fp5/gp5 user’s manual 57 frequency agree set point (n075, freq det level) when multi-function contact output selections n041 or n042 are set to “freq det 1” or “freq det 2”, frequency detection is enabled. This function is acti- vated when the output frequency is above or below the frequency agree s...

Page 58

58 fp5/gp5 user’s manual frequency meter or ammeter (n052, terminal am sel) this parameter selects whether the signal (on terminals am and ac) is proportional to output frequency, output current, output power, or dc bus voltage for external monitoring. Frequency meter or ammeter calibration (n053, t...

Page 59

Fp5/gp5 user’s manual 59 chapter 3 - programming features fp5/gp5 operation · terminal fv gain (n048, terminal fv gain) the analog input voltage value for the maximum output frequency (n011) can be set in units of 1%, from 0 to 200%. Factory setting: 100% · terminal fv bias (n049, terminal fv bias) ...

Page 60

60 fp5/gp5 user’s manual to operate the inverter with a frequency reference of 50% to 100% at a 0 to 10v input: gain: parameter n048 = “100” bias: parameter n049 = “50” jog operation multi-function inputs (terminals s2 to s6) can be programmed to func- tion as a jog reference selection. Operation ca...

Page 61

Fp5/gp5 user’s manual 61 chapter 3 - programming features fp5/gp5 operation modbus communication the fp5/gp5 can perform serial transmission by using a program- mable controller (plc) and modbus communication. Modbus is composed of one master plc and 1 to 31 (maximum) slave inverters. In signal tran...

Page 62

62 fp5/gp5 user’s manual chapter 3 - programming features fp5/gp5 operation · modbus frequency reference unit (n103, modbus fref unit) the frequency reference units from the plc and in the frequency refer- ence and output frequency monitors (by communication) are set with parameter n103. The output ...

Page 63

Fp5/gp5 user’s manual 63 chapter 3 - programming features fp5/gp5 operation · general-purpose and blower-cooled motors induction motors are classified as general-purpose or blower-cooled motors, based on their cooling capabilities. Hence, the motor overload detection function operates differently fo...

Page 64

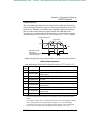

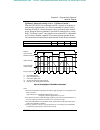

64 fp5/gp5 user’s manual chapter 3 - programming features fp5/gp5 operation multi-step speed selection this function allows the programming of up to 4 preset speeds, through multi-function contact input selections. 4-step speed selection n002 = “seq=x ref=opr”, where “x” can be trm, opr, or com n024...

Page 65

Fp5/gp5 user’s manual 65 chapter 3 - programming features fp5/gp5 operation phase loss protection · input phase loss detection (n083, in ph loss lvl) the input phase loss detection circuit monitors the dc bus current ripple and activates when one of the input phases are lost. The detection circuit c...

Page 66

66 fp5/gp5 user’s manual chapter 3 - programming features fp5/gp5 operation pid control to enable pid control, set pid selection (n084) to “enabled”, according to the description below. Then select the pid control setpoint value and detected feedback value setpoint as follows: · setpoint value selec...

Page 67

Fp5/gp5 user’s manual 67 chapter 3 - programming features fp5/gp5 operation notes: 1) value i is reset to”0” in the following cases: · when operation stops · when the integral value reset signal is input by multi-function contact input selection (any of parameters n036 to n040 are set to “pid i rese...

Page 68

68 fp5/gp5 user’s manual chapter 3 - programming features fp5/gp5 operation reverse run prohibit (n006, reverse oper) a “reverse run disabled” setting does not accept a reverse run command from the control circuit terminal or the digital operator. This setting is used in applications where a reverse...

Page 69

Fp5/gp5 user’s manual 69 chapter 3 - programming features fp5/gp5 operation the following figure shows fwd/rev run switching during deceleration to stop. Speed limit adjustment · frequency reference upper limit (n031, ref upper limit) the upper limit of the frequency reference can be set in incremen...

Page 70

70 fp5/gp5 user’s manual chapter 3 - programming features fp5/gp5 operation stopping method (n004, stopping method) this function selects the stopping method suitable for the particular application. · deceleration to stop (n004 = “ramp to stop”) upon removal of the fwd (rev) run command, the motor d...

Page 71

Fp5/gp5 user’s manual 71 chapter 3 - programming features fp5/gp5 operation · coast to stop with timer 1 (n004 = “coast w/timer 1”) upon removal of the run command, the inverter output is immediately removed, allowing the motor to coast. If the run command is re-applied before the minimum baseblock ...

Page 72

72 fp5/gp5user’s manual chapter 3 - programming features fp5/gp5 operation torque adjustment (n071, torq comp gain) motor torque can be adjusted by changing the v/f pattern (n010) or by adjusting the torque compensation gain (n071). For details on setting the v/f pattern, see “v/f pattern adjustment...

Page 73

Fp5/gp5 user’s manual 73 chapter 3 - programming features fp5/gp5 operation torque detection the over/undertorque detection circuit will activate when the motor load causes the motor current to go above or below torque detection level (n078) respectively. When the over/undertorque condition is detec...

Page 74

74 fp5/gp5 user’s manual chapter 3 - programming features fp5/gp5 operation · over/undertorque detection level (n078, torq det level) sets the torque detection current level in units of 1% inverter rated current: 100% factory default: 160% · over/undertorque detection time (n079, torq det time) the ...

Page 75

Fp5/gp5 user’s manual 75 chapter 3 - programming features fp5/gp5 operation · dc injection braking at start (n068, dcinj current; n070, dcinj time@start) this function restarts a coasting motor after first applying it with dc injection braking. Dc injection braking time at start (n070) is set in uni...

Page 76

76 fp5/gp5 user’s manual chapter 3 - programming features inputs & outputs * for 460v class units, the value is twice that of 230v class units. Increasing the voltage in the v/f pattern increases motor torque, how- ever, an excessive increase may cause: · inverter fault trips as a result of motor ov...

Page 77

Fp5/gp5 user’s manual 77 chapter 3 - programming features inputs & outputs slip compensation the slip compensation feature allows better speed regulation to be obtained by adjusting the output frequency according to the changing load. This feature compensates for the slip of the motor. Slip compensa...

Page 78

78 fp5/gp5 user’s manual chapter 3 - programming features inputs & outputs 3.4 inputs & outputs multi-function input signals (n036 to n040) multi-function contact input terminal s2 to s6 functions can be changed when necessary by setting parameters n036 to n040, respectively. None of these parameter...

Page 79

Fp5/gp5 user’s manual 79 chapter 3 - programming features inputs & outputs · local/remote selection (setting: “local/remote sel”) selects whether the run command is received from the digital operator or the control circuit terminal. Local/remote selection is available only while the inverter is stop...

Page 80

80 fp5/gp5 user’s manual chapter 3 - programming features inputs & outputs example: set n002 to “seq=trm ref=trm”. Open: frequency reference from control circuit terminals fv & fi, and run command from control circuit terminals s1 and s2. Closed: frequency reference and run command from serial commu...

Page 81

Fp5/gp5user’s manual 81 chapter 3 - programming features inputs & outputs · up/down command (setting: n040 = “up/down control”) with the fwd (rev) run command entered, a change in frequency is performed by inputting the up or down commands to control circuit terminals s5 and s6, so that operation ca...

Page 82

82 fp5/gp5user’s manual chapter 3 - programming features inputs & outputs analog input signals · master analog input selection (n043, analog input sel) to input the master frequency reference from the control circuit terminal, use terminal fv (0 to 10v) or terminal fi (4 to 20ma), by setting paramet...

Page 83

Fp5/gp5 user’s manual 83 multi-function output signals (n041, terminal ma sel; n042, terminal m1 sel) multi-function output terminal ma, mb and m1 functions can be changed when necessary by setting parameters n041 and n042. · terminal ma and mb functions: set via n041 · terminal m1 functions: set vi...

Page 84

84 fp5/gp5 user’s manual chapter 3 - programming features frequency agree (setting: “at speed”) see figure 51 below for an example of selecting the frequency agree sig- nal as the function of output terminals ma, mb or m1. Desired frequency agree (setting: “at desired speed”) see figure 52 below for...

Page 85: - Chapter 4 -

Fp5/gp5 user’s manual 85 - chapter 4 - diagnostics section description page 4 diagnostics precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86 4.1 m aintenance & i nspection . . . . . . . . . . . . . . . . . . . . . . 87 periodic inspection . . . . . . . . . . . . . ...

Page 86: Warning

86 fp5/gp5 user’s manual precautions 1) never touch high voltage terminals in the inverter. 2) replace all protective covers before powering up the inverter. When removing the cover, be sure to shut off the power supply to the inverter. 3) perform maintenance or inspection only after verifying that ...

Page 87

Fp5/gp5 user’s manual 87 4.1 maintenance & inspection this section describes basic maintenance and inspection procedures for the fp5/gp5. Periodic inspection the fp5/gp5 will function longer if it is kept clean, cool and dry, and if all precautions highlighted in this manual are observed. Periodi- c...

Page 88

88 fp5/gp5 user’s manual 4.2 alarm & fault displays this section describes the alarm and fault displays, explanations for fault condi- tions, and corrective actions to be taken if the fp5/gp5 malfunctions. Alarm display unlike faults, alarms do not activate fault contact outputs. After the cause of ...

Page 89

Fp5/gp5 user’s manual 89 fault display when the fp5/gp5 detects a fault, the fault is displayed on the digital operator and a fault contact output is activated after which the motor coasts to a stop. Check the causes listed in the table below and take the corre- sponding corrective actions. To reset...

Page 90

90 fp5/gp5 user’s manual * o h1 overheat 1 heatsink overheat (oh1) the transistor heatsink temperature exceeded the allowable value (fin temperature > oh1 detection level). Check the fan and ambient temperature. O h2 overheat 2 heatsink overheat (oh2) the transistor heatsink temperature exceeded the...

Page 91

Fp5/gp5 user’s manual 91 * stopping method selection is available for these faults. * ce modbus com err modbus transmission fault control data cannot be received nor- mally. Check the transmission devices or signals. Cpf0 com-err (op +inv) control circuit fault 1 (cpfo) digital operator transmission...

Page 92

92 fp5/gp5 user’s manual motor faults if a motor fault occurs, follow the checkpoints listed in the table below and take the corresponding corrective actions. If taking the corrective actions described does not solve the problem, contact your saftronics representative immediately. Motor faults and c...

Page 93: Appendix

Fp5/gp5 user’s manual 93 appendix section description page a appendix a-1 b raking c onnection d iagrams . . . . . . . . . . . . . . . . . . 94 a-2 d igital o perator m onitor d isplay . . . . . . . . . . . . . . 95 a-3 ce c onformance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97...

Page 94

94 fp5/gp5 user’s manual a-1 braking connection diagrams braking resistor unit 230v: 5~25hp 460v: 5~25hp p b 1 2 overload relay trip contact braking resistor unit overload relay trip contact of braking resistor unit 1 2 mc fault contact trx sa trx thrx sa sa mc mc thrx on off ma mc vs-616pc5 l1 l2 l...

Page 95

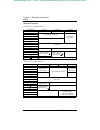

Fp5/gp5 user’s manual 95 a-2 digital operator monitor display the following table describes the contents of the digital operator monitor display. Digital operator monitor display name (lcd operator display) description frequency reference (frequency ref) · frequency reference can be monitored/set. ·...

Page 96

Fp5/gp5 user’s manual 96 monitor (monitor u-xx) u-09 last 4 faults are displayed. U-10 last 4 digits of software revision number are displayed. U-11 u-12 elapsed time is displayed as follows: u-13 pid feedback is displayed in units of 0.1hz. U-15 kilowatt-hour meter (4 least significant digits) u-16...

Page 97

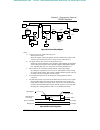

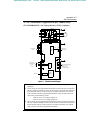

Fp5/gp5 user’s manual 97 appendix a-3 ce conformance a-3 ce conformance (applicable to 460v models only) ce conformance - low voltage directive (lvd) compliance digital rs-232 serial port analog inputs (250 Ω ) operator input fi selectable 4~20ma or 0~10v (10-pin) im ⊕ 1 ⊕ 2 b1 b2 s1 - fixed s2 s3 s...

Page 98

Fp5/gp5 user’s manual 98 ce conformance - electro-magnetic compatibility (emc) compliance in order to conform to emc standards, exclusive-use methods are required for line filter application, cable shielding and inverter installation. An outline of the methods follows. The line filter and the invert...

Page 99

Fp5/gp5 user’s manual 99 appendix a-3 ce conformance l2 l1 l3 gnd ground bonds (remove any paint) power line filter load inverter w l1l2 uv l3 ground bonds (remove any paint) im cable length: max. 40cm metal plate motor cable: max. 20m fig. 12 installation of line filter and inverter (models fp5/gp5...

Page 100

Fp5/gp5 user’s manual 100 safety warnings and operating information for inverters introduction depending on their protection rating configuration, parts of inverters can have live, unin- sulated and hot surfaces during operation. If housing components, the control unit or ter- minal covers are remov...

Page 101

Fp5/gp5 user’s manual 101 appendix a-3 ce conformance eu manufacturer’s declaration products static inverter, series fp5/gp5 scope saftronics inverters are components (bdm* , defined by iec 22g/21cdv) designed exclusively for installation in machines or systems (end products) by qualified re-users (...