- DL manuals

- Saftronics

- Inverter

- VG52011

- Technical Manual

Saftronics VG52011 Technical Manual

Summary of VG52011

Page 1

Www.Saftronics.Com technical manual v g 5 rev2 (9/98) p/n 027-2040 1998.

Page 2

Preface firmware – s1043 revision: 2 (9/98) i © saftronics, inc. The vg5 series of general-purpose inverters provides v/f control and vector control as standard features along with user-friendly operation. This manual is designed to ensure correct and suitable application of the vg5 series inverters...

Page 3: Warning

Preface firmware – s1043 revision: 2 (9/98) ii © saftronics, inc. Safety information the following conventions are used to indicate precautions in this manual. Failure to follow the precautions provided in this manual can result in serious or possible even fatal injury or damage to the products or t...

Page 4: Caution

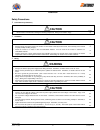

Preface firmware – s1043 revision: 2 (9/98) iii © saftronics, inc. Safety precautions § confirmations upon delivery caution page • never install an inverter that is damaged or missing components. Doing so can result in injury. 10 § installation caution page • always hold the case when carrying the i...

Page 5: Caution

Preface firmware – s1043 revision: 2 (9/98) iv © saftronics, inc. Caution page • do not connect power factor correction capacitors or lc/rc noise filters to the output circuits. The inverter can be damaged or internal parts burnt if these devices are connected. 20 • do not connect electromagnetic sw...

Page 6: Warning

Preface firmware – s1043 revision: 2 (9/98) v © saftronics, inc. § maintenance and inspection warning page • do not touch the inverter terminals. Some of the terminals carry high voltages and are extremely dangerous. Doing so can result in electric shock. 276 • always have the protective cover in pl...

Page 7

Preface firmware – s1043 revision: 2 (9/98) vi © saftronics, inc. How to change the digital operator display from japanese to english if the digital operator displays messages in japanese, change to the english mode using the following steps. (this manual provides descriptions for the english mode.).

Page 8: Table of Contents

Firmware – s1043 revision: 2 (9/98) vii © saftronics, inc. Table of contents 1 introduction .......................................................................................... 1 1.1 outline and functions .................................................................................... 2 1....

Page 9

Firmware – s1043 revision: 2 (9/98) viii © saftronics, inc. 5 trial operation....................................................................................... 85 5.1 procedure ...................................................................................................... 57 5.2 trial op...

Page 10

Firmware – s1043 revision: 2 (9/98) ix © saftronics, inc. 7.5 common functions........................................................................................ 169 7.5.1 application constants: b .....................................................................................................

Page 11

Firmware – s1043 revision: 2 (9/98) x © saftronics, inc. 12.2 motor application precautions ........................................................................ 289 12.2.1 using the inverter for an existing standard motor............................................................. 289 12.2.2 us...

Page 12: Introduction

1 introduction this chapter provides an overview of the vg5 inverter and describes its functions and components. 1.1 outline and functions .................................................... 2 1.1.1 vg5 inverter models....................................................................................

Page 13

Chapter 1: introduction firmware – s1043 revision: 2 (9/98) 2 © saftronics, inc. 1.1 outline and functions the vg5 inverter provides full-current vector control based on advanced control logic. An auto-tuning function is included for user friendly vector control. The digital operator provides a liqu...

Page 14

Chapter 1: introduction firmware – s1043 revision: 2 (9/98) 3 © saftronics, inc. 1.1.2 outline of control methods the vg5 uses four control methods: • open-loop vector control (factory setting) • flux vector control • v/f control without pg • v/f control with pg feedback note: pg stands for pulse ge...

Page 15

Chapter 1: introduction firmware – s1043 revision: 2 (9/98) 4 © saftronics, inc. Any of the above frequency references can be used by setting a constant. A maximum of nine frequency references can be registered with the inverter. With remote multi-step speed reference inputs, the inverter can operat...

Page 16

Chapter 1: introduction firmware – s1043 revision: 2 (9/98) 5 © saftronics, inc. § user constant structure and three access levels the vg5 has a number of user constants for setting various functions. These user constants are classified into a hierarchy to make them easier to use. The levels are as ...

Page 17

Chapter 1: introduction firmware – s1043 revision: 2 (9/98) 6 © saftronics, inc. 1.2 nomenclature this section provides the names of vg5 components, and the components and functions of the digital operator. 1.2.1 vg5 components the appearance of inverter and the names of its components are shown in ...

Page 18

Chapter 1: introduction firmware – s1043 revision: 2 (9/98) 7 © saftronics, inc. 1.2.2 digital operator components this section describes the component names and functions of the digital operator. The component names and functions are shown in figure 1.4 and key functions are described in table 1.4....

Page 19

Chapter 1: introduction firmware – s1043 revision: 2 (9/98) 8 © saftronics, inc. Table 1.4 key functions key name function local/remote key switches between (local) operation via the digital operator and control circuit terminal (remote) operation. This key can be enabled or disabled by setting a us...

Page 20: Handling Inverters

2 handling inverters this chapter describes the checks required upon receiving a vg5 inverter and describes installation methods. 2.1 confirmations upon delivery ......................................... 10 2.1.1 nameplate information ....................................................................

Page 21: Caution

Chapter 2: handling inverters firmware – s1043 revision: 2 (9/98) 10 © saftronics, inc. 2.1 confirmations upon delivery caution • never install an inverter that is damaged or missing components. Doing so can result in injury. Check the following items as soon as the inverter is delivered. Table 2.1 ...

Page 22

Chapter 2: handling inverters firmware – s1043 revision: 2 (9/98) 11 © saftronics, inc. § inverter specifications • open chassis type (iec ip00) protected so that parts of the human body cannot reach electrically charged parts from the front when the inverter is mounted in a control panel. • enclose...

Page 23

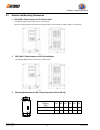

Chapter 2: handling inverters firmware – s1043 revision: 2 (9/98) 12 © saftronics, inc. 2.2 exterior and mounting dimensions § 200 v/400 v class inverters of 15 kw and lower the following diagram shows a 200 v class, 1.5 kw inverter. Remove the top and bottom covers when mounting 200 v/400 v class i...

Page 24

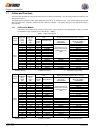

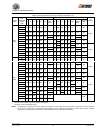

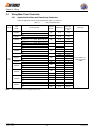

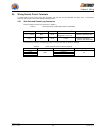

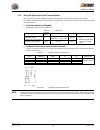

Chapter 2: handling inverters firmware – s1043 revision: 2 (9/98) 13 © saftronics, inc. Table 2.2 vg5 external dimensions (mm) and approximate masses (kg) open chassis (ip00) enclosed wall-mounted (nema 1) voltage class max. Applicable output [kw] w h d w1 h1 h2 approx. Mass w h d w1 h1 h2 approx. M...

Page 25: Caution

Chapter 2: handling inverters firmware – s1043 revision: 2 (9/98) 14 © saftronics, inc. 2.3 checking and controlling the installation site caution • always hold the case when carrying the inverter. If the inverter is held by the front cover, the main body of the inverter may fall, possibly resulting...

Page 26

Chapter 2: handling inverters firmware – s1043 revision: 2 (9/98) 15 © saftronics, inc. 2.4 installation orientation and space install the inverter on a vertical surface so as not to diminish its coding efficiency. When installing the inverter, always provide the following installation space to allo...

Page 27

Chapter 2: handling inverters firmware – s1043 revision: 2 (9/98) 16 © saftronics, inc. 2.5 removing/attaching the digital operator and front cover remove the front cover to wire the terminals. For models of 15 kw or less (both 200 v and 400 v class), do not remove or mount the front cover without f...

Page 28

Chapter 2: handling inverters firmware – s1043 revision: 2 (9/98) 17 © saftronics, inc. § mounting the digital operator 1. Hook the digital operator at a (two locations) on the front cover in the direction of arrow 1 as shown in the following illustration. 2. Press the digital operator in the direct...

Page 29: Wiring

3 wiring this chapter describes wiring terminals, main circuit terminal connections, main circuit terminal wiring specifications, control circuit terminals, and control circuit-wiring specifications. 3.1 connections to peripheral devices ............................... 21 3.2 connection diagram .......

Page 30: Warning

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 20 © saftronics, inc. Warning • always turn off the input power supply before wiring terminals. Otherwise, an electric shock or fire can occur. • wiring must be performed by an authorized person qualified in electrical work. Otherwise, an electri...

Page 31

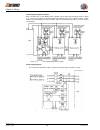

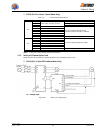

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 21 © saftronics, inc. 3.1 connections to peripheral devices examples of connections between the vg5 and typical peripheral devices are shown in figure 3.1. Use this illustration to gain an understanding of the overall equipment configuration. Fig...

Page 32

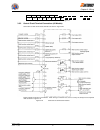

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 22 © saftronics, inc. 3.2 connection diagram the connection diagram of the vg5 is shown in figure 3.2. When using the digital operator, the motor can be operated by wiring only the main circuits. Figure 3.2 connection diagram (model vg527p5 shown...

Page 33

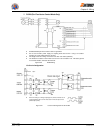

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 23 © saftronics, inc. Note: 1. Control circuit terminals 1 to 33 are not arranged in order of terminal numbers; they are arranged as shown below. Be sure to wire them correctly. 11 12(g) 13 14 15 16 17 25 26 27 33 18 19 20 1 2 3 4 5 6 7 8 21 22 2...

Page 34

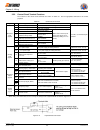

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 24 © saftronics, inc. 3.4 wiring main circuit terminals 3.4.1 applicable wire sizes and closed-loop connectors select the appropriate wires and crimp terminals from table 3.1 to table 3.3. Table 3.1 200 v class wire sizes circuit vg5 model termin...

Page 35

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 25 © saftronics, inc. Circuit vg5 model terminal symbol terminal screws awg sizes wire thickness (see note) mm 2 wire type l1, l2, l3, √ , 3, t1, t2, t3 m10 1/0 x 2p 60-100 m8 4 22 vg52045 r, s m4 20-10 0.5-5.5 l1, l2, l3, √ , 3, t1, t2, t3 m10 1...

Page 36

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 26 © saftronics, inc. Table 3.2 400 v class wire sizes circuit vg5 model terminal symbol terminal screws awg sizes wire thickness (see note) mm 2 wire type l1, l2, l3, √ , 1, 2, b1, b2, t1, t2, t3 vg540p4 m4 14-10 2-5.5 l1, l2, l3, √ , 1, 2, b1, ...

Page 37

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 27 © saftronics, inc. Circuit vg5 model terminal symbol terminal screws awg sizes wire thickness (see note) mm 2 wire type l1, l2, l3, √ , 3, t1, t2, t3 m10 1/0 x 2p 100 m8 4 22 vg54075 r, s 200, s 400 m4 20-10 0.5-5.5 l1, l2, l3, √ , 3, t1, t2, ...

Page 38

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 28 © saftronics, inc. Table 3.3 closed-loop connector sizes (jis c 2805) (for 200 v and 400 v classes) awg sizes wire thickness mm 2 terminal screws size m3.5 1.25-3.5 20 0.5 m4 1.25-4 m3.5 1.25-3.5 18 0.75 m4 1.25-4 m3.5 1.25-3.5 16 1.25 m4 1.25...

Page 39

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 29 © saftronics, inc. 3.4.2 main circuit terminal functions main circuit terminal functions are summarized according to terminal symbols in table 3.4 and table 3.5. Wire the terminals correctly for the desired purposes. Table 3.4 200 v class main...

Page 40

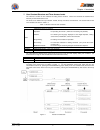

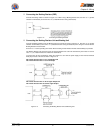

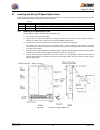

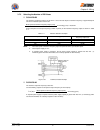

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 30 © saftronics, inc. 3.4.3 main circuit configurations the main circuit configurations are shown in figure 3.4 and figure 3.5. § 200 v class vg520p4 to 21p5 (0.4kw to 1.5kw) vg522p2 to 27p5 (0.75 kw to 5.5 kw) vg52011 to 2015 (11, 15 kw) vg52018...

Page 41

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 31 © saftronics, inc. § 400 v class vg540p4 to 41p5 (0.4 to 1.5 kw) vg542p2 to 4015 (2.2 kw to 15 kw) vg54018 to 4045 (18.5, 45 kw) vg54055 to 4160 (55 to 160 kw) vg54185 to 4300 (185 to 300 kw) * 1 prewired at the factory. * 2 remove the short-c...

Page 42

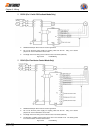

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 32 © saftronics, inc. 3.4.4 standard connection diagrams vg520p4 to 27p5, 40p4 to 4015 vg52011, 2015 be sure to remove the short-circuit bar before be sure to remove the short-circuit bar before connecting a dc reactor. Connecting a dc reactor. V...

Page 43

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 33 © saftronics, inc. 3.4.5 wiring the main circuits this section describes wiring connections for the main circuit inputs and outputs § wiring main circuit inputs installing a molded case circuit breaker always connect the power input terminals ...

Page 44

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 34 © saftronics, inc. Installing an ac reactor if the inverter is connected to a large capacity power transformer (600 kw or more) or the power factor correction capacitor is switched, an excessive peak current may flow through the input power ci...

Page 45

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 35 © saftronics, inc. § wiring on the output side of main circuit connecting the inverter and motor connect output terminals t1, t2, and t3 (u, v and w) to motor lead wires t1, t2, and t3, respectively. Check that the motor rotates forward with t...

Page 46

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 36 © saftronics, inc. Countermeasures against radio interference radio noise is generated from the inverter as well as from the input and output lines. To reduce noise, install noise filters on both input and output sides, and also install the in...

Page 47

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 37 © saftronics, inc. § connecting the braking resistor (erf) connect the braking resistor as shown in figure 3.14. When using a braking resistor unit, set l8-01 to “1” (protect selection for db resistor) and set l3-04 to “0” (no stall prevention...

Page 48

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 38 © saftronics, inc. Connecting braking units in parallel when connecting two or more braking units in parallel, use the wiring and connectors shown in figure 3.16. There are connectors for selecting whether each braking unit is to be a master o...

Page 49

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 39 © saftronics, inc. 3.5 wiring control circuit terminals a control signal line must not be longer than 50 meters (164 feet) and must be separated from power lines. The frequency reference must be input to the inverter through twisted-pair wires...

Page 50

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 40 © saftronics, inc. 3.5.2 control circuit terminal functions the functions of the control circuit terminals are shown in table 3.9. Use the appropriate terminals for the correct purposes. Table 3.9 control circuit terminals type no. Signal name...

Page 51

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 41 © saftronics, inc. 11 12(g) 13 14 15 16 17 25 26 27 33 18 19 20 1 2 3 4 5 6 7 8 21 22 23 9 10 figure 3.19 control circuit terminal arrangement 3.5.3 control circuit terminal connections (all models) connections to vg5 control circuit terminals...

Page 52

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 42 © saftronics, inc. 3.5.4 control circuit wiring precautions • separate control circuit wiring (terminals 1 to 33) from main circuit wiring (terminals l1, l2, and l3 (r, and s, and t), b1, b2 , t1, t2, and t3 (u, v, and w), √ , ⊕ 1, ⊕ 2, and ⊕ ...

Page 53

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 43 © saftronics, inc. 3.7 installing and wiring pg speed option cards pg speed option cards are used for executing speed control using a pg. There are four types of pg speed controls, as shown below. Select the type that fits the application and ...

Page 54

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 44 © saftronics, inc. 3.7.2 pg speed option card terminal blocks the terminal specifications for each pg speed option card are given in the following tables: § pg-a2 (for v/f with pg feedback mode only) table 3.10 pg-a2 terminal specifications te...

Page 55

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 45 © saftronics, inc. § pg-x2 (for flux vector control mode only) table 3.13 pg-x2 terminal specifications terminal no. Contents specifications 1 12 vdc( ± 5%), 200 ma maximum (see note) 2 0 vdc (gnd for power supply) 3 power supply for pulse gen...

Page 56

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 46 © saftronics, inc. Open collector input • shielded twisted-pair wires must be used for signal lines. • do not use the pg’s power supply for anything other than the pg. Using it for another purpose can cause malfunctions due to noise. • the len...

Page 57

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 47 © saftronics, inc. § pg-b2 (for flux vector control mode only) • shielded twisted-pair wires must be used for signal lines. • do not use the pg’s power supply for anything other than the pg. Using it for another purpose can cause malfunctions ...

Page 58

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 48 © saftronics, inc. § pg-d2 (for v/f with pg feedback mode only) • shielded twisted-pair wires must be used for signal lines. • do not use the pg’s power supply for anything other than the pg. Using it for another purpose can cause malfunctions...

Page 59

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 49 © saftronics, inc. 3.7.4 wiring pg speed option card terminal blocks use no more than 100 meters (328 feet) of wiring for pg signal lines, and keep them separate from power lines. Use shielded, twisted-pair wires for pulse inputs and pulse out...

Page 60

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 50 © saftronics, inc. § closed-loop connector sizes and tightening torque the closed-loop connectors and tightening torques for various wire sizes are shown in table 3.16. Table 3.16 closed-loop connectors and tightening torques wire thickness (m...

Page 61

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 51 © saftronics, inc. 3.7.5 selecting the number of pg pulses § pg-a2/pg-b2 the maximum response frequency is 32,767 hz. Use a pg that outputs a maximum frequency of approximately 20 khz for the rotational speed of the motor. Motor speed at maxim...

Page 62

Chapter 3: wiring firmware – s1043 revision: 2 (9/98) 52 © saftronics, inc. Figure 3.34 pg-x2 connection example.