Summary of SG-FC4560

Page 1

U s e r ’ s g u i d e cutter flatbed sg-fc76106 sg-fca3+ sg-fc4560 sg-fc6090

Page 2

1 .Introduction of product 2 .Tool description 3 .Operation 4 .Software 5 .Fault and maintenance 6 .Performance parameter.

Page 3: Chapter

Chapter 1 introduction of product 1.1 type and specification 1.2 standard parts 1.3 parts names 1.4 control panel.

Page 4

1.1 type and specification model effective cutting area effective contour cutting area stand sg-fca3+ sg-fc4560p sg-fc6090 sg-fc76106 350×510mm 780×1080mm 330×488mm 760×1060mm 450×600mm 600×900mm 470×630mm 620×930mm no yes no yes 1.2 standard parts qty air pump hose software creasing blade blade bla...

Page 5

Silence device pump box 1 1 reduce noise for air pump 1.3 parts names 1 2 3 5 6 7 8 4 9 10 tool holder 1 tool holder 2 1 carriage..................Drives the cutter blade/pen/creasing tool to the forward/backward. 2 tool holder 1...........Holds the pen/creasing tool and drives it up/down 3 tool hol...

Page 6

8 1.4 control panel 1 2 3 4 5 7 6 9 11 12 13 10 1 led display......... Display various parameters. 2 fun1....................The switch for vacuum adsorption function. 3 4 5 6 7 8 9 10 11 12 13 fun2.................... Return to the main interface, when you set the parameters. Press this key to retu...

Page 7: Chapter

Chapter 2 2.1 types of cutter blades 2.2 blade holder introduction 2.3 replacing the blade 2.4 adjust the blade length tool description.

Page 8

2.1 types of cutter blade name and pic angle applications and features blade blade diameter circlip knife creasing blade pen holder 60° 45° 30° 60° 45° 0.1mm 0.1mm 0.1mm 0.1mm 0.1mm / / / / 2.2 blade holder introduction adjustment depth knobs lock pin blade when handling cutter blades, be careful to...

Page 9

2.3 replacing the blade step1 step2 step3 step1/step2/step3 1. Push the blade to the bottom of the blade holder. 2. Adjust the blade tip to suitable length by rotating “adjustment depth knobs” and then tighten the lock. 3. Press the push-pin to remove the blade from the blade holder when replacing b...

Page 10

2.4 adjust the blade length the blade length is adjusted by turning the blade adjustment knob. • to extend the cutter blade, turn the knob in the a direction. • to retract the cutter blade, turn the knob in the b direction. How to confirm the right height gradually increase the blade length to suit ...

Page 11: Chapter

Chapter 3 3.1 basic operational steps 3.2 connecting to a computer 3.3 installing tools 3.4 turning on the cutter 3.5 calibration the sensor 3.6 loading the media 3.7 running a cutting test operation.

Page 12

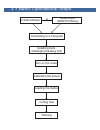

3.1 basic operational steps or install software install stand (6090/76106only) connecting to a computer installling tools (blade/pen/creasing tool) turn on the cutter calibration the sensor loading the media cutting test working.

Page 13

3.2 connecting to computer only install the software, don’t need to install any driver. Operation cannot be guaranteed in the following cases: • when connection has been made to a usb hub or an add-on usb board • when you are using a custom-built computer or one that you have modified be sure to obs...

Page 14

3.3 installing tools step1.....Loosen the tool holder screw sufficiently to enable a cutter pen to be inserted up to its flange. Step2 step3 step2.....Push the cutter pen all the way into the holder until it contacts the upper part of the tool holder. Step3..... Tighten screw. When you push the tool...

Page 15

Beam carriage the figure below shows what the plotter does when the power is turned on. The tool carriage returns to the home position. 3.5 calibration the sensor step1...... Put a blank a4 paper on the flatbed. Step2..... Move the car to the middle of the paper. step3..... Install the pen holder in...

Page 16

A4 paper a4 paper step1 step2 step3 step4 step5.

Page 17

3.6 loading the media 3.5 running a cutting test blank cutting arms cutting make sure the materical is flat. Place the paper on the platform and move the carriage to the starting point of the cutting place the paper on the platform and move the carriage to the starting point of the mark moving the c...

Page 18

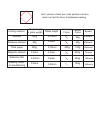

Tool1 painted a blank box, tool2 painted a red box, which can test the force of blade/pen/creasing cutting medium blade height force speed media height or gram weight creasing force blade stickers adhesive stickers thick paper masking rubber for sandblasting magnetic stickers reflective film 160g 0....

Page 19: Chapter

Chapter 4 4.1 install and activate 4.2 common parameters of software 4.3 how to use dragoncut cutting and creasing software.

Page 20

4.1 install and activate please install cd first and check your 20 bits license. Please pay attention to a few points as follows 1.Enter your license (each license can be used 3 times only) 2.Pay attention to the your machine model sg-fca3+ choice 720iip sg-fc4560 choice 720iip sg-fc6090 choice 720i...

Page 21

3.This network connection is normal and then activation software directly 4.Activation success 4.2 common parameters of software 1.Create cut contour contour lines can be generated automatically 2.Contour cut wizard automatically generate contour lines and add markers.

Page 22

3.Send to cutter direct cutting, mainly used for cutting blank materials 4.Vinyl spooler arms cutting,mainly used for file with marks. (open barcode controller after,you will find arms cutting interface) on vinyl spooler 5.Blade offset 6.Overcut blade offset blade machine default is 0.3mm, but somet...

Page 23

4.3 how to use dragoncut blank file import your file with cutting line and creasing line. Select the color of the cutting line and creasing line. Cut now use your cutting line and creasing line with different colors. Click send to cutter..

Page 24

Arms file import your label file. Press the button use left mouse. Press the button use right mouse. Select creasing line, press the button use right mouse select the cutting line, press the button use left mouse through the hand-printed, making the creasing line. Click create cut contour make outli...

Page 26: Chapter

Chapter 5 5.1 scan problem 5.2 cutting effect problem 5.5 error messages fault and maintenance.

Page 27

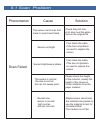

5.1 scan problem phenomenon cause solution scan failed the sensor cannt scan first mark or secnd read failed. Sensor not bright sensor brightness problem the sensor is normal, the size is normal, but can not sweep point normal size, sensor is normal, high normal, still can not scan check the print s...

Page 28

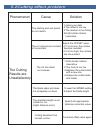

Phenomenon cause solution the starting and end points do not match. The specified length is not plotted or cut. (slight distance error) the cut corners are rounded or too pointed. The cut line starts out crooked. The blade skips and does not completely cut lines 1.Check your data 2.The offset is too...

Page 29

Phenomenon cause solution some parts of the medium cannot be cut. 1.Set the effective cutting area to a larger area. 2.Reduce the size of the data. The medium is discolored wherethe cutter blade has passed. Adjust the blade length and the cutting force setting. Reduce the blade length. Lower the cut...

Page 30: Chapter

Chapter 6 performance parameter sg-fca3+ sg-fc4560p sg-fc6090 sg-fc76106 max force max speed max cutting depth max cutting weight (paper) machincial resolution programmable resolution contorl system interface software working enviroment power supply machine size cutting media 510g(3g/step) 600mm/s 0...

Page 31

Cutter flatbed thank you for your reference, if you have any questions, please contact the local dealer. Thank you again ! From saga.