- DL manuals

- SAINT-GOBAIN ABRASIVES

- Saw

- CST 100 Modulo

- Operating Instructions Manual

SAINT-GOBAIN ABRASIVES CST 100 Modulo Operating Instructions Manual

Summary of CST 100 Modulo

Page 1

Cst 65 / 85 / 100 modulo operating instructions.

Page 2

2.

Page 3: Declaration Of Conformity

3 the undersigned manufacturer: saint - gobain abrasives s.A. 190, bd j.F. Kennedy l- 4930 bascharage declares that this product: masonry saws: cst 65 modulo 230v code: 70184620265 cst 85 modulo 230v 70184620266 cst 100 modulo 230v 70184620024 is in conformity with the following directives: • europe...

Page 4

4.

Page 5: Cst

5 cst operating instructions and spare parts list 1 basic safety instructions 6 1.1 symbols 6 1.2 machine plate 7 1.3 safety instructions for particular operating phases 7 2 machine description 8 2.1 short description 8 2.2 purpose of use 8 2.3 layout 8 2.4 technical data 10 3 assembly and commissio...

Page 6

6 1 basic safety instructions the cst is exclusively designed for the cutting of construction products mainly on construction sites. Uses other than the manufacturer's instructions shall be considered as contravening the regulations. The manufacturer shall not be held responsible for any resulting d...

Page 7

7 1.2 machine plate important data can be found on the following plate located on the machine: 1.3 safety instructions for particular operating phases before commencing work • before commencing work, make yourself familiar with the working environment at the place of use. The working environment inc...

Page 8

8 2 machine description any modification, which could lead to a change in the original characteristics of the machine, may be done only by saint-gobain abrasives who shall confirm that the machine is still in conformity with the safety regulations. 2.1 short description the cst block saw is designed...

Page 9

9 frame (2) built in aluminium profile, the frame is light and resistant. The welded-steel side of the machine ensure that the axles are parallel to the table. The axle assembly can also be tilted until 45º to make bevel cuts. The head axles (3) made of aluminium, guide the cutting head over the tab...

Page 10

10 2.4 technical data electric motor protection ip54 max. Blade diameter 350 mm bore 25,4 mm flange diameter 90 mm cutting depth mm 110 mm (without reversing the material) sound pressure level 73 db (a) (following iso en 11201) sound energy level 87 db (a) (following iso en 3744) cst65 code 70184620...

Page 11

11 cst100 code 70184620024 70184620270 70184620273 power 2,2 kw 2,2 kw 3 kw tension 230v 1~ 115v 1~ 400v 3~ cutting length 1000 mm rotation speed of the blade 3000 min-1 length 1680 mm width 660 mm height (with feet) 1550 mm height (without feet) 905 mm water pan capacity 35 l weight (total) 134 kg ...

Page 12

12 3 assembly and commissioning the machine is delivered fully equipped (although without diamond blade) and is ready for operation after assembly of the blade and the handles, and connection to the appropriate power supply. 3.1 tool assembly only norton blades with a maximum diameter of 350 mm can ...

Page 13

13 3.5 water cooling system fill the water pan with clean water to approximately 2cm from top (ensure that bottom of pump is fully immersed in water). Use the pump switch so you can use the pump. Open water-tap at blade guard (note that handle on water-tap should be in line with water-flow). Ensure ...

Page 14

14 4 transport and storing 4.1 securing for transport before transporting or lifting the machine, always remove the blade and empty the water pan. Also lock the cutting head on the axles. To do so, move the head so, that the screw (1) is facing the hole (2). Then tighten the screw until it enters th...

Page 15

15 5 operating the machine 5.1 site of work 5.1.1 siting the machine • remove from the site anything, which might hinder the working procedure! • make sure the site is sufficiently well lit! • observe manufacturer's conditions for connecting to power supplies! • place electric cables in such a way t...

Page 16

16 5.3 general advice for the cutting • material weighting under 30 kg and having dimensions smaller than 650x660x220mm for the cst65, 850x660x220mm for the cst85, 1000x660x220mm for the cst100 can be cut with the machine. • before commencing work make sure tools are firmly seated! • select the righ...

Page 17

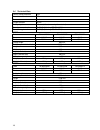

17 6 maintenance and servicing to ensure a long-term quality from the cutting with the cst, please follow the maintenance plan below: b e g in o f th e d a y d u ri n g t h e c h a n g in g o f to o l e n d o f th e d a y o r m o re o ft e n i f re q u ir e d e v e ry w e e k a ft e r a f a u lt a f...

Page 18

18 7 faults: causes and cures 7.1 fault-finding procedures should any fault occur during the use of the machine, turn it off, and isolate it from the electrical supply. Any works dealing with the electrical system or supply of the machine can only be carried out by a qualified electrician. 7.2 troub...

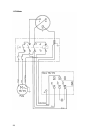

Page 19

19 circuit diagram 230v motor.

Page 20

20 115v motor.

Page 21

21 400v motor.

Page 22

22 7.3 customer service when ordering spare parts, please mention: • the serial number (7 digits). • the code of the part. • the exact denomination. • the number of parts required. • the delivery address. • please indicate clearly the means of transportation required such as "express" or "by air". W...

Page 23

23 guarantee can be claimed and technical support obtained from your local distributor where machines, spare parts and consumables can be ordered as well: benelux and france: from saint-gobain abrasives s.A. Free telephone numbers: belgium : 0 800 18951 france: 0 800 90 69 03 holland: 0 8000 22 02 7...

Page 24

24 saint-gobain abrasives 190, bd. J. F. Kennedy l-4930 bascharage luxembourg tel.: ++352 50401-1 fax: ++352 501633 e-mail: sales.Nlx@saint-gobain.Com www.Construction.Norton.Eu 29.09.2008.