- DL manuals

- Saito

- Engine

- FA-100

- Instruction Manual

Saito FA-100 Instruction Manual

INSTRUCTION MANUAL

V

ersion

200

6

.

FA-30S (H)

.

FA-30S Golden Knight

.

FA-40a

.

FA-40a Golden Knight

.

FA-50

.

FA-50 Golden Knight

.

FA-56

.

FA-56 Golden Knight

.

FA-62a

.

FA-62a Golden Knight

.

FA-65

.

FA-65 Golden Knight

.

FA-72

.

FA-72 Golden Knight

.

FA-80

.

FA-80 Golden Knight

.

FA-82a

.

FA-82a Golden Knight

.

FA-91 Special

.

FA-91S Golden Knight

.

FA-100

.

FA-100 Golden Knight

.

FA-125a

.

FA-125a Golden Knight

Summary of FA-100

Page 1

Instruction manual v ersion 200 6 . Fa-30s (h) . Fa-30s golden knight . Fa-40a . Fa-40a golden knight . Fa-50 . Fa-50 golden knight . Fa-56 . Fa-56 golden knight . Fa-62a . Fa-62a golden knight . Fa-65 . Fa-65 golden knight . Fa-72 . Fa-72 golden knight . Fa-80 . Fa-80 golden knight . Fa-82a . Fa-82...

Page 2: Very

Very important failure to read and follow these instructions before you proceed to start your engine may result in engine damage and the voiding of your warranty..

Page 3: Introduction

1 s a f e t y i n s t r u c t i o n s introduction safety instructions you should always: congratulations on purchasing a saito 4-cycle engine. When cared for properly ,these high-quality, finely crafted engines offer many years of modeling enjoyment. This instruction manual has been developed to en...

Page 4: Beware:

2 s a f e t y i n s t r u c t i o n s do not use hands, fingers, or any other part of the body to stop the propeller. Do not throw any object into a propeller to stop it. . Safety glasses or goggles be used when starting and running your engine. . You do not run the engine in the vicinity of loose g...

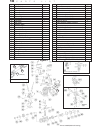

Page 5: Engine Parts

3 s u p p o r t e q u i p m e n t engine parts identification support equipment it is important to be able to identify the parts of your saito engines. Attached you will find an expioded view of a saito 4-stroke engine, as well as charts that include part numbers and descriptions. This will assist y...

Page 6: Break-In

4 s t a r t i n g t h e e n g i n e break-in the first run on any engine, whether 2-cycle or 4-cycle, is critical to the future of the engine itself. During this time, metal mating parts (piston and cylinder, ball bearings, etc.) wear in. Care must be taken that the engine is clean and free of any d...

Page 7: Starting The Engine

5 s t a r t i n g t h e e n g i n e starting the engine 1. Make sure the glow plug(s) is/are installed and tightened. 2. Be sure the propeller is properly secured. The use of an anti-loosening nut, or “jam nut,” is encouraged on 4-cycle engines. Note: saito single cylinder engines are now manufactur...

Page 8: Carburetor

6 s t a r t i n g t h e e n g i n e carburetor adjustments for two needle carburetors note: a very common error is to remove the glow plug ingiter too early. It is suggested that the igniter be left attached until after the engine has been run up and the high-speed needle valve has been properly adj...

Page 9: Carburetor

7 c a r b u r e t o r a d j u s t m e n t s carburetor adjustments for air bleed carburetors the fuel mixture may be too lean if the engine stops at the lowest idle position, or when the throttle is rapidly opened from idle. Attempt to correct this by rotating the idle needle valve counter- clockwis...

Page 10: Normal Engine

8 n o r m a l e n g i n e o p e r a t i o n normal engine operation engine maintenance if break-in was accomplished on a test bench your engine may be mounted to the aircraft and flown. The initial flight should be performed with the engine adjusted for a rich fuel mixture. If you must disassemble y...

Page 11: Valve/tappet Gap

9 e n g i n e o p e r a t i o n valve/tappet gap adjustment after approximately one hour of operation, tappet gap adjustment may be necessary. When you check the valves, lubricate the moveable parts. Also make sure the screw is in tight before making adjustments to valves. Adjust the valves to a cle...

Page 12: Carburetor

10 c a r b u r e t o r m a i n t e n a n c e carburetor maintenance should you experience difficulty with the carburetor of your engine: 1. Check that the slotted head of the idle needle valve (89) is flush with the throttle arm housing. This will put the idle needle back to the factory preadjusted ...

Page 13: Troubleshooting

11 t r o u b l e s h o o t i n g troubleshooting generally speaking, there are very few things that will keep today's modern glow engines from starting. To that end, make sure you're using good quality “fresh” fuel, there are good glow plugs installed, and the starting battery is charged and in good...

Page 14

12 t r o u b l e s h o o t i n g symptom cause corrective action in the event that none of the above procedures results in the engine running properly, contact our service department for suggestions: horizon service center 4105 fieldstone road champaign, illinois 61822 217-355-9511 (mon-fri 8:00-5:0...

Page 15: 1 3

1 3 p a r t s l i s t small single-cylinder cross-reference chart figur e 4a part nil fa-305-gk 01 cylinder, left 06 piston 07 piston pin 08 piston pin retainer(6 pc) 09 piston ring 10 connecting rod 14 cylinder screw set 15 crankcase 17 rear cover (a) 19 breather nipple 20 front ball bearing 22 rea...

Page 16: 1 4

1 4 p a r t s l i s t medium single-cylinder cross-reference chart figur e 4b part ai fa-62a 01 cylinder, left 06 piston 07 piston pin 08 piston pin retainer (6 pc) 09 piston ring 10 connecting rod 14 cylinder screw set 15 crankcase 17 rear cover (a) 19 breather nipple 20 front ball bearing 22 rear ...

Page 17: 1 5

1 5 p a r t s l i s t medium single-cylinder cross-reference chart figur e 4c part 01 cylinder, left 06 piston 07 piston pin 08 piston pin retainer (6 pc) 09 piston ring 10 connecting rod 14 cylinder screw set 15 crankcase 17 rear cover (a) 19 breather nipple 20 front ball bearing 21 main ball beari...

Page 18: 1 6

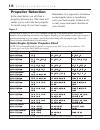

1 6 p r o p e l l e r s e l e c t i o n propeller selection saito single-cylinder propeller chart in the chart below you will find a propeller selection list. This chart will enable you to select the best propeller for initial setup of your saito engine. You will note a letter (a, b, c, etc.) stampe...

Page 19: 1 7

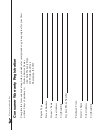

1 7 e n g i n e s p e c s figure 6 figure 7 outside dimensions (mm) items a b b1 b2 c1 ! C2 ! D ! E ! F ! G ! H ! I ! Figure 8 specifications items disp (cc) " " " " "! " " " " " " " bore (mm) " " " " "! " " " " " " " stroke (mm) " " " " "! " " " " " " " weight (g) ! K (iso) # # # # # # # # # " # " ...

Page 20

18 p a r t s l i s t no. Description qty. 01 06 07 08 09 10 14 15 17 19 20 22 23 24 25 26 27 28 29 30 31 32 33 35 36 37 38 cylinde r(left) piston piston pin piston pin retainer piston ring connecting rod cylinder screw set crankcase rear cover breather nipple front bearing rear bearing crankshaft pi...

Page 21: 1 9

. Crash damage . Modifications of any kind . Nitro content and brand of fuel . Propeller size and brand used . Type of glow plug used . Type of engine mount . Approximately how much running time the engine had before difficulty 1 9 w a r r a n t y & r e p a i r s consumer warranty and repair policy ...

Page 22: 2 0

2 0 w a r r a n t y & r e p a i r s to receive warranty service, you must include your original dated sales receipt to verify your proof-of- purchase date. Providing that warranty conditions have been met, your engine will be repaired without charge. Please advise us of the payment method you prefer...

Page 23: Consumer W

Consumer w arranty registration complete this form and mail along with your dated sales receipt (send copy , keep original for your files) within 10 days of purchase to: please cut on dotted line horizon service center attn: saito w arranty dept. 4105 fieldstone road champaign, il 61822 engine t ype...

Page 24

Exclusively distributed by horizon hobby, inc., champaign, il 61822 www.Horizonhobby.Com c.