- DL manuals

- Saito

- Engine

- FA-100T

- Instruction Manual

Saito FA-100T Instruction Manual

Summary of FA-100T

Page 1

T win -c ylinder f our -s troke e ngines instruction manual • fa-60t • fa-90ts • fa-100t • fa-130td • fa-182td • fa-300tl • fa-300ttdp.

Page 2

Very important failure to read and follow these instructions before you proceed may result in engine damage and the voiding of your warranty..

Page 3

S a f e t y i n s t r u c t i o n s 1 introduction congratulations on purchasing a saito 4-cycle engine. Cared for properly, these high-quality, finely crafted engines offer many years of modeling enjoyment. This instruction manual has been developed to ensure optimum performance from the saito engi...

Page 4

S a f e t y i n s t r u c t i o n s 2 do not use hands, fingers or any other part of the body to stop the propeller. Do not throw any object into a propeller to stop it. 10. Discard any propeller that is nicked, scratched, cracked or damaged in any way. It is highly recommended that: 1. Safety glass...

Page 5

S u p p o r t e q u i p m e n t 3 engine parts identification it is important to be able to identify the parts of your saito engines. In the back of this manual you will find an exploded view of saito twin-cylinder engines, as well as a chart which includes part numbers and descriptions. This will a...

Page 6

S t a r t i n g t h e e n g i n e 4 break-in the first run on any engine, whether 2-cycle or 4-cycle, is critical to the future of the engine itself. During this time, metal mating parts (piston and cylinder, ball bearings, etc.) wear in. Care must be taken that the engine is clean and free of any d...

Page 7

S t a r t i n g t h e e n g i n e 5 starting the engine 1. Make sure the glow plugs are installed and tightened. 2. Be sure the propeller is properly secured. The use of a “jam nut” is encouraged on 4-cycle engines. 3. Make sure the fuel tank line(s) are properly connected. The main line should be c...

Page 8

Figure 4 fa-182td aluminum stopper right carb spray bar s t a r t i n g t h e e n g i n e 6 4. Be certain the mufflers are installed properly by oiling the threads and inserting the muffler gasket (79) if applicable, and that the lines are properly connected. 5. Fill the fuel tank. 6. Prime the engi...

Page 9

S t a r t i n g t h e e n g i n e 7 • using either the “chicken stick” or electric starter, spin the propeller until the engine is running. Note: when using an electric starter, care should be taken to be sure that the engine does not become “hydro-locked.” while the electric starter will turn the e...

Page 10

E n g i n e o p e r a t i o n 8 the use of a tachometer is encouraged for setting the high-speed needle valve(s) (85) prior to flight. The peak rpm should be obtained and then reduced by approximately 200–300 rpm by turning the high speed needle valve(s) counterclockwise. Low speed carburetor adjust...

Page 11

E n g i n e o p e r a t i o n 9 fa-100t/ fa-130td/fa-182td dual carburetor adjustment upon completing the break-in and carburetor adjustment procedures mentioned previously, the following method should be utilized to balance the dual carburetor saito engines: 1. Start the engine and allow it to warm...

Page 12

E n g i n e o p e r a t i o n 10 fuel mixture by rotating the high speed needle valve counterclockwise 3 clicks. Lean the left cylinder by turning the high speed needle valve clockwise until the rpms begin to drop. This time, however, richen the fuel mixture by rotating the high speed needle valve c...

Page 13

E n g i n e o p e r a t i o n 11 normal engine operation if break in was accomplished on a test bench your engine may be mounted to the aircraft and flown. The initial flight should be performed with the engine adjusted for a rich fuel mixture. 1. Your saito engine should be securely mounted to the ...

Page 14

E n g i n e m a i n t e n a n c e 12 2. Cam gear alignment–refer to the specific section below pertaining to your saito engine. Fa-60t/90ts a. The crankshaft alignment mark should line up with the crankcase mark when the crankshaft is at the top dead center. Refer to figure 7. B. Locate the cam gear...

Page 15

E n g i n e m a i n t e n a n c e 13 position the left cam gear timing mark (etched line) at the 3 o’clock position (directly into the crankcase) and secure the left cam gear housing. See figure 11. Note: when tightening the cam gear housing bolts, apply a drop of oil to each bolt to prevent thread ...

Page 16

C a r b u r e t o r m a i n t e n a n c e 14 1. Remove the high speed needle(s) (85) and flush out the spray bar with clean fuel. Replace the high speed needle(s) and follow the instructions in the carburetor adjustment section. 2. Always use a high-quality 4-cycle glow plug. The hangar 9/mccoy mc-4...

Page 17

T r o u b l e s h o o t i n g 15 symptom cause corrective action engine fails to low voltage on replace/recharge the fire starting battery starting battery bad glow plug(s) inspect/replace bad glow plug(s) insufficient priming repeat priming procedure “flooded” due to disconnect battery, remove exce...

Page 18

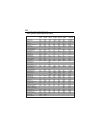

Twin cylinder cross reference chart t r o u b l e s h o o t i n g 16 part p ll aa s dd z w fa-60t fa-90ts fa-100t fa-130td fa-182td fa-300tl fa-300ttdp 01 cylinder, left 60t01 90ts01 100t01 130td01a 182td01 300t01 300ttdp01a 02 cylinder, right 60t02 90ts02 100t02 130td02a 182td02 300t02 300ttdp02a 0...

Page 19

P a r t s l i s t 17 part p ll aa s dd z w fa-60t fa-90ts fa-100t fa-130td fa-182td fa-300tl fa-300ttdp 64 air pump assembly — — 130t64c 130t64c — — — 65 air pump housing — — 100t65b 130t65b — — — 66 diaphragm & check valve rubber set — — 130t66b 130t66b — — — 67 diaphragm, pushrod, return spring — ...

Page 20

P a r t s l i s t 18 you will note a letter (a, b, c, etc.) stamped on the top of the motor mount. This letter identifies the production version of your engine. Should you ever need to order a part or have a question pertaining to your engine, specify this letter along with the engine type. This wil...

Page 21

P r o p e l l e r s e l e c t i o n 19 specifications items disp bore stroke weight k cylinder hp (cc) (mm) (mm) (g) (iso) fa-60 twin cylinder 10.0 20.0 16.0 750 m7x1 5ccx2 abc 0.9 fa-90ts twin cylinder 14-98 22.4 19.0 723 m7x1 7.4x2aac 1.4 fa-100 twin cylinder 16.4 23.4 19.0 820 m7x1 8.2ccx2 abc 1....

Page 22

89 85 92 90 70 91 90a 52 53 37 87 32 17 31 01 09 13 79 73 42 41 37 43 32 49 27 105 83 69 19 02 71 32 20 28 106 15 21 23 22 31 18 32 35 104 10 08 07 06 46 95 31 14 14 47 39 40 38 79 74 80 fa-60t e n g i n e s p e c s 20

Page 23

P a r t s l i s t 21 fa-90ts.

Page 24

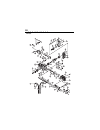

P a r t s l i s t 22 49 14 32 70 11 9 33a 79 02 32 71 14 32 91 32 08 07 06 46 09 11 15 74 35 28 27 20 26 24 19 10 31 22 31 23 69 01 80 73 40 39 38 31 36 32 34 82 92 83 87 42 43 41 47 48 37a 37a 65b 64c 66b 68a 85 fa-100t air pump assemb ly.

Page 25

P a r t s l i s t 23 14 28 27 20 15 41 31 33 46 09 06 19 11 07 08 32 36 37 74 85 47 49 32 43 48 14 42 39 38 40 35 10 73 01 32 31 02 70 32 71 82 87 33 34 69 31 83 79 32 80 22 23 11 9 32 fa-182td.

Page 26

107 83 a 85 93 a 92 a 09 a 10 b 06 a 28b 27a 11 0 95b 91a 32a 69a 91a 32a 70b 32 74b 73b 99a 32 49 14 43 37 42 41 45 14 32 47 44 14 02 39 31 35 32 40 31 36 33 38 37 46 07 13 15 08 20 21 19 34 01 44 22 71 17 45 82 a 87 a 68 82 87 85 83 93 93 101 102 103 fa-300tl p a r t s l i s t 24 fa-300ttdp t win ...

Page 27

P a r t s l i s t 25 consumer warranty and repair policy 1. Ship your engine, freight prepaid, in its original box packed inside a sturdy shipping container, to: horizon service center attn: saito service 4105 fieldstone road champaign, il 61822 phone: (217) 355-9511 include complete name and addres...

Page 28

26 3. Warranty repairs to receive warranty service you must include your original dated sales receipt to verify your proof- of-purchase date. Providing that warranty conditions have been met, your engine will be repaired without charge. 4. Non-warranty repairs should your repair cost exceed 50% of t...

Page 30

Consumer w arranty registration fill in and mail this form along with your dated sales receipt (send cop y, k eep original for your f iles) within 10 days of purchase to: horizon service center attn: saito w arranty dept. 4105 fieldstone road champaign, il 61822 engine t ype ________________________...