- DL manuals

- Salicru

- Inverter

- CV10-002-S2

- User Manual

Salicru CV10-002-S2 User Manual

Summary of CV10-002-S2

Page 1

User manual inverter controlvit cv10

Page 3: Contents

Contents contents .............................................................................................................................................. 3 1 safety precautions .......................................................................................................................

Page 4: 1 Safety Precautions

4 - 104 safety precautions 1 safety precautions please read this manual carefully and follow all safety precautions before moving, installing, operating and servicing the inverter. If ignored, physical injury or death may occur, or damage may occur to the devices. If any physical injury or death or ...

Page 5

Safety precautions 5 - 104 the electrical parts and components inside the inverter are electrostatic. Take measurements to avoid electrostatic discharge during relevant operation. 1.3.1 delivery and installation please install the inverter on fire-retardant material and keep the inverter away from c...

Page 6

6 - 104 safety precautions take measures to avoid screws, cables and other conductive matters to fall into the inverter during maintenance and component replacement. Note: please select proper torque to tighten screws. Keep the inverter, parts and components away from combustible materials during ma...

Page 7: 2 Product Overview

Product overview 7 - 104 2 product overview 2.1 quick start-up 2.1.1 unpacking inspection check as followings after receiving products: 1. Check that there are no damage and humidification to the package. If not, please contact with local dealers or salicru offices. 2. Check the information on the t...

Page 8

8 - 104 product overview 2.1.4 installation confirmation check as followings after the installation: 1. Check that the load range of the input and output cables meet the need of actual load. 2. Check that the accessories of the inverter are correctly and properly installed. The installation cables s...

Page 9

Product overview 9 - 104 function specification terminal analog input resolution ≤ 20mv analog input 1 input 0~10v/0~20ma analog output 1 output 0~10v/0~20ma digital input 5 common inputs running control digital output 1 programmable digital output (y) and 1 programmable relay output communication r...

Page 10

10 - 104 product overview 2.4 type designation key the type designation contains information on the inverter. The user can find the type designation on the type designation label attached to the inverter or the simple name plate. Cv10 – 022 – s2 figure 2-2 product type key no. Detailed description d...

Page 11

Product overview 11 - 104 figure 2-3 product structure diagram no. Name illustration 1 keypad see keypad operation procedure for detailed information 2 cover protect the internal parts and components 3 power indicator power indicator 4 side cover protect the internal components 5 simple name plate s...

Page 12: 3 Installation Guidelines

12 - 104 installation guidelines 3 installation guidelines the chapter describes the mechanical installation and electric installation. Only qualified electricians are allowed to carry out what described in this chapter. Please operate as the instructions in safety precautions . Ignoring these may c...

Page 13

Installation guidelines 13 - 104 environment conditions - keep away from contaminative air, such as corrosive gas, oil mist and flammable gas - ensure foreign objects, such as metal power, dust, oil, water can not enter into the inverter (do not install the inverter on the flammable materials such a...

Page 14

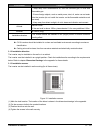

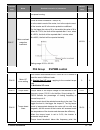

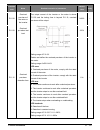

14 - 104 installation guidelines 3.1.4 installation space figure 3-2 installation space note: the minimum space of a and b is 100mm. 3.2 standard wiring 3.2.1 connection diagram of main circuit figure 3-3 connection diagram of main circuit note: the circuit breaker, braking resistor, input reactor, ...

Page 15

Installation guidelines 15 - 104 terminal sign terminal name function l power input of the main circuit single-phase ac input terminals which are generally connected with the grid. N u the inverter output 3-phase ac output terminals which are generally connected to the motor. V w pb braking resistor...

Page 16

16 - 104 installation guidelines 3.2.5 terminals of control circuit figure 3-6 wiring of control circuit description roa ro relay output contact capacity: 3a/ac250v,1a/dc30v roc +10v local power supply +10v ai 1. Input range: ai voltage and current: 0~10v/0~20ma and switch by j3 2. Input impedance: ...

Page 17

Installation guidelines 17 - 104 3.3 layout protection 3.3.1 protect the inverter and input power cable in short-circuit situations protect the inverter and input power cable in short circuit situations and against thermal overload. Arrange the protection according to the following guidelines. Figur...

Page 18

18 - 104 keypad operation procedure 4 keypad operation procedure the keypad is used to control cv10 inverters, read the state data and adjust parameters. Figure 4-1 keypad note: fix the external keypad with m3 screws or the installation bracket. The installation bracket is optional. No. Name descrip...

Page 19

Keypad operation procedure 19 - 104 no. Name description 3 code displaying zone 5-figure led display displays various monitoring data and alarm code such as set frequency and output frequency. 4 digital potentiometer corresponds to ai1. 5 buttons programming key enter or escape from the first level ...

Page 20

20 - 104 keypad operation procedure 4.2.2 displayed state of running parameters after the inverter receives valid running commands, the inverter will enter into the running state and the keypad will display the running parameters. Run/tune led on the keypad is on, while the fwd/rev is determined by ...

Page 21

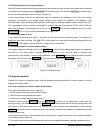

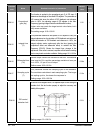

Keypad operation procedure 21 - 104 2) this function code is not modifiable in running state, but modifiable in stop state. Example: set function code p00.01 from 0 to 1. Figure 4-3 sketch map of modifying parameters 4.2.2 how to set the password of the inverter cv10 inverters provide password prote...

Page 22: 5 Function Parameters

22 - 104 function parameters 5 function parameters 5.1 function parameters description the function parameters of cv10 inverters have been divided into 30 groups (p00~p29) according to the function, of which p18~p28 are reserved. Each function group contains certain function codes applying 3-level m...

Page 23

Function parameters 23 - 104 function code name detailed instruction of parameters default value modify p00 group basic function group p00.00 speed control mode 2: svpwm control (suitable for asynchronous motor) suitable in cases where it does not need high control accuracy, such as the load of fan ...

Page 24

24 - 104 function parameters function code name detailed instruction of parameters default value modify p00.05 lower limit of the running frequency the lower limit of the running frequency is that of the output frequency of the inverter. The inverter runs at the lower limit frequency if the set freq...

Page 25

Function parameters 25 - 104 function code name detailed instruction of parameters default value modify p00.08 b frequency command reference 0: maximum output frequency , 100% of b frequency setting corresponds to the maximum output frequency (p00.03) 1: a frequency command , 100% of b frequency set...

Page 26

26 - 104 function parameters function code name detailed instruction of parameters default value modify default value, the motor’s running direction will come back to the factory default state, too. In some cases it should be used with caution after commissioning if the change of rotation direction ...

Page 27

Function parameters 27 - 104 function code name detailed instruction of parameters default value modify p00.16 avr function selection 0: invalid 1: valid during the whole prodecure the auto-adjusting function of the inverter can cancel the impact on the output voltage of the inverter because of the ...

Page 28

28 - 104 function parameters function code name detailed instruction of parameters default value modify setting range: 0.0~50.0s p01.03 the braking current before starting the inverter will carry out dc braking at the braking current set before starting and it will speed up after the dc braking time...

Page 29

Function parameters 29 - 104 function code name detailed instruction of parameters default value modify before dc braking caused by dc braking at high speed. Dc braking current : the value of p01.11 is the percentage of rated current of inverter. The bigger the dc braking current is, the greater the...

Page 30

30 - 104 function parameters function code name detailed instruction of parameters default value modify 2: switch after the speed reach p01.15 and delay for p01.24 p01.15 stopping speed 0.00~100.00hz 1.00 hz ◎ p01.18 terminal running protection selection when powering on when the running command cha...

Page 31: P02 Group Motor

Function parameters 31 - 104 function code name detailed instruction of parameters default value modify setting range: 0.0~3600.0s (valid when p01.19=2) p01.21 restart after power off this function can enable the inverter start or not after the power off and then power on. 0: disabled 1: enabled , i...

Page 32

32 - 104 function parameters function code name detailed instruction of parameters default value modify p02.02 motor rated frequency 0.01hz~p00.03(the max. Frequency) 50.00hz ◎ p02.03 motor rated speed 1~36000rpm depends on model ◎ p02.04 motor rated voltage 0~1200v depends on model ◎ p02.05 motor r...

Page 33: P04 Group Svpwm Control

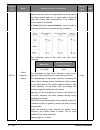

Function parameters 33 - 104 function code name detailed instruction of parameters default value modify low-speed running. P02.27 motor overload protection coefficient times of motor overload m = iout/(in*k) in is the rated current of the motor, iout is the output current of the inverter and k is th...

Page 34

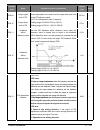

34 - 104 function parameters function code name detailed instruction of parameters default value modify torque boost is valid, but over this frequency point, the torque boost is invalid. The setting range of p04.01:0.0%:(automatic) 0.1%~10.0% the setting range of p04.02: 0.0%~50.0% p04.03 motor v/f ...

Page 35

Function parameters 35 - 104 function code name detailed instruction of parameters default value modify p04.09 motor v/f slip compensation gain this function code is used to compensate the change of the rotation speed caused by load during compensation svpwm control to improve the rigidity of the mo...

Page 36

36 - 104 function parameters function code name detailed instruction of parameters default value modify selection 5 : reverse rotation jogging 6 : coast to stop 7 : fault reset 8 : operation pause 9 : external fault input 10 : increasing frequency setting (up) 11 : decreasing frequency setting (down...

Page 37

Function parameters 37 - 104 function code name detailed instruction of parameters default value modify p05.11 switch filter time set the sample filter time of s1~s5 terminals. If the interference is strong, increase the parameter to avoid the wrong operation. 0.000~1.000s 0.010s ○ p05.12 virtual te...

Page 38

38 - 104 function parameters function code name detailed instruction of parameters default value modify the direction control is as below during operation: sln rev previous direction current direction on off → on forward reverse reverse forward on on → off reverse forward forward reverse on → off on...

Page 39

Function parameters 39 - 104 function code name detailed instruction of parameters default value modify note : for the 2-wire running mode, when fwd/rev terminal is valid, the inverter stops because of the stopping command from other sources, even the control terminal fwd/rev keeps valid; the invert...

Page 40

40 - 104 function parameters function code name detailed instruction of parameters default value modify p05.32 lower limit of ai1 the function code defines the relationship between the analog input voltage and its corresponding set value . If the analog input voltage is beyond the set minimum or max...

Page 41

Function parameters 41 - 104 function code name detailed instruction of parameters default value modify p06 group output terminals p06.01 digital output selection (y) 0 : invalid 1 : on operation 2 : forward rotation operation 3 : reverse rotation operation 4 : jogging operation 5 : inverter fault 6...

Page 42

42 - 104 function parameters function code name detailed instruction of parameters default value modify p06.10 ro switching on delay time the function code defines the corresponding delay time of the electrical level change during the programmable terminal switching on and off. The setting range :0....

Page 43

Function parameters 43 - 104 function code name detailed instruction of parameters default value modify p06.21 ao output filter time setting range of p06.18 0.00v~10.00v setting range of p06.19 p06.17~100.0% setting range of p06.20 0.00v~10.00v setting range of p06.21 0.000s~10.000s 0.000s ○ p07 gro...

Page 44

44 - 104 function parameters function code name detailed instruction of parameters default value modify 4 : clear up/down settings . Press quick/jog to clear the set value of up/down. 5 : coast to stop . Press quick/jog to coast to stop. 6 : shift the running commands source . Press quick/jog to shi...

Page 45

Function parameters 45 - 104 function code name detailed instruction of parameters default value modify bit10 : input terminals state bit11 : output terminals state bit12 : torque set value(% on) bit13 : pulse counter value bit14 : length value bit15 : current stage in multi-step speed example - def...

Page 46

46 - 104 function parameters function code name detailed instruction of parameters default value modify p07.11 reserved ● p07.12 inverter module temperature -20.0~120.0°c ● p07.13 software version 1.00~655.35 ● p07.14 local accumulative running time 0~65535h ● p07.18 the rated power of the inverter ...

Page 47

Function parameters 47 - 104 function code name detailed instruction of parameters default value modify p07.27 current fault type 0 : no fault 4 : oc1 (over-current when acceleration) 5 : oc2 (over-current when deceleration) 6 : oc3 (over-current when constant speed running) 7 : ov1 (over-voltage wh...

Page 48

48 - 104 function parameters function code name detailed instruction of parameters default value modify p07.39 input terminals state at current fault 0 ● p07.40 output terminals state at current fault 0 ● p07.41 previous fault running frequency 0.00hz ● p07.42 ramp reference frequency at previous fa...

Page 49

Function parameters 49 - 104 function code name detailed instruction of parameters default value modify p07.50 ramp reference frequency at the previous 2 faults 0.00hz ● p07.51 output voltage at the previous 2 faults 0v ● p07.52 output current at the previous 2 faults 0.0a ● p07.53 bus voltage at th...

Page 50

50 - 104 function parameters function code name detailed instruction of parameters default value modify p08.07 jogging running acc time the jogging acc time means the time needed if the inverter runs from 0hz to the max. Frequency. The jogging dec time means the time needed if the inverter goes from...

Page 51

Function parameters 51 - 104 function code name detailed instruction of parameters default value modify p08.25 setting counting value the counter works with the s1 to s5 terminals when p05.01 to p05.05 is 31 when the counter achieves a fixed number, the multi-function output terminals will output th...

Page 52

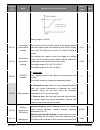

52 - 104 function parameters function code name detailed instruction of parameters default value modify p08.33 fdt retention detection value “frequency level detect fdt”. Until the output frequency decreases to a value lower than the corresponding frequency ( fdt retention detection value ), the sig...

Page 53

Function parameters 53 - 104 function code name detailed instruction of parameters default value modify p08.39 cooling fan running mode set the operation mode of the cooling fan. 0: normal mode, after the rectifier receives operation command or the detected temperature of module is above 45 , or the...

Page 54

54 - 104 function parameters function code name detailed instruction of parameters default value modify p08.44 up/down terminals control setting 0x00~0x221 led ones : frequency enabling selection 0 : up/down terminals setting valid 1 : up/down terminals setting invalid led tens : frequency control s...

Page 55

Function parameters 55 - 104 function code name detailed instruction of parameters default value modify can be used in the motor stop, as well as to change the rotation speed of the motor. Its other advantages are: brake immediately after the stop command. It does not need to wait the magnetic flux ...

Page 56

56 - 104 function parameters function code name detailed instruction of parameters default value modify p09.04 proportional gain (kp) the function is applied to the proportional gain p of pid input. P determines the strength of the whole pid adjuster. The parameter of 100 means that when the offset ...

Page 57

Function parameters 57 - 104 function code name detailed instruction of parameters default value modify p09.09 output upper limit of pid these parameters are used to set the upper and lower limit of the pid adjustor output. 100.0 % corresponds to max. Frequency setting range of p09.09: p09.10~100.0%...

Page 58

58 - 104 function parameters function code name detailed instruction of parameters default value modify p10 group multi-step speed control p10.02 multi-step speed 0 100.0% of the frequency setting corresponds to the max. Frequency p00.03. When selecting multi-step running, set p10.02~p10.33 to defin...

Page 59

Function parameters 59 - 104 function code name detailed instruction of parameters default value modify p10.26 multi-step speed 12 analog value, or communication frequency input. Select at most 16 stages speed via the combination code of s1, s2, s3, and s4. The start-up and stopping of multi-step ru...

Page 60

60 - 104 function parameters function code name detailed instruction of parameters default value modify p11.03 overvoltage stall protection 0 :disabled 1 :enabled 1 ○ p11.04 overvoltage stall point 120~150% 120% ○ p11.05 current limit action selection the actual increasing ratio is less than the rat...

Page 61

Function parameters 61 - 104 function code name detailed instruction of parameters default value modify p11.08 overload pre-alarm of the motor or the inverter the output current of the inverter or the motor is above p11.09 and the lasting time is beyond p11.10, overload pre-alarm will be output. Set...

Page 62

62 - 104 function parameters function code name detailed instruction of parameters default value modify p11.11 detection level of the underload pre-alarm if the inverter current or the output current is lower than p11.11, and its lasting time is beyond p11.12, the inverter will output underload pre-...

Page 63

Function parameters 63 - 104 function code name detailed instruction of parameters default value modify 5 : 38400bps note: the baud rate between the upper monitor and the inverter must be the same. Otherwise, the communication is not applied. The bigger the baud rate, the quicker the communication s...

Page 64

64 - 104 function parameters function code name detailed instruction of parameters default value modify p14.06 communication processing action selection 0x00~0x11 led ones : 0: operation with response . The drive will respond to all reading and writing commands of the upper monitor. 1: operation wit...

Page 65

Function parameters 65 - 104 function code name detailed instruction of parameters default value modify p17.09 output torque display the current output torque of the inverter. Range: -250.0~250.0% 0.0% ● p17.11 dc bus voltage display current dc bus voltage of the inverter range: 0.0~2000.0v 0v ● p17...

Page 66

66 - 104 function parameters function code name detailed instruction of parameters default value modify p17.26 current running time display the current running time of the inverter. Range:0~65535min 0m ● p17.27 current stage of multi-step speed display the current stage of the multi-step speed. Rang...

Page 67

Function parameters 67 - 104 5.2 diagram of quick start.

Page 68: 6 Fault Tracking

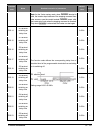

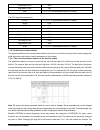

68 - 104 fault tracking 6 fault tracking 6.1 maintenance intervals if installed in an appropriate environment, the inverter requires very little maintenance. The table lists the routine maintenance intervals recommended by salicru. Checking part checking item checking method criterion ambient enviro...

Page 69

Fault tracking 69 - 104 checking part checking item checking method criterion ensure the safety valve is in the right place. Estimate the usage time according to the maintenance or measure the static capacity. Na if necessary, measure the static capacity. Measure the capacity by instruments. The sta...

Page 70

70 - 104 fault tracking 6.1.2 cooling fan the inverter’s cooling fan has a minimum life span of 25,000 operating hours. The actual life span depends on the inverter usage and ambient temperature. The operating hours can be found through p07.14 (accumulative hours of the inverter). Fan failure can be...

Page 71

Fault tracking 71 - 104 time operational principle • add 75% rated voltage for 30 minutes • add 100% rated voltage for 30 minutes storing time more than 3 years use power surge to charge for the inverter • add 25% rated voltage for 2 hours • add 50% rated voltage for 2 hours • add 75% rated voltage ...

Page 72

72 - 104 fault tracking 4 . Eliminate the fault and ask for relative help. 5. Check to eliminate the fault and carry out fault reset to run the inverter. Fault code fault type possible cause what to do oc1 over-current when acceleration 1. The acceleration or deceleration is too fast. 2. The voltage...

Page 73

Fault tracking 73 - 104 fault code fault type possible cause what to do oh1 rectifier overheat 1. Air duct jam or fan damage 2. Ambient temperature is too high. 3. The time of overload running is too long. 1. Refer to the overcurrent solution 2. Redistribute dredge the wind channel or change the fan...

Page 74: 7 Communication Protocol

74 - 104 communication protocol 7 communication protocol 7.1 brief introduction to modbus protocol modbus protocol is a software protocol and common language which is applied in the electrical controller. With this protocol, the controller can communicate with other devices via network (the channel ...

Page 75

Communication protocol 75 - 104 it is recommended to use shielded cables and make the shield layer as the grounding wires during rs485 remote communication. In the cases with less devices and shorter distance, it is recommended to use 120 Ω terminal resistor as the performance will be weakened if th...

Page 76

76 - 104 communication protocol figure 3 is the star connection. Terminal resistor should be connected to the two devices which have the longest distance. (1# and 15#device) figure 3 star connection it is recommended to use shield cables in multiple connection. The basic parameter of the devices, su...

Page 77

Communication protocol 77 - 104 the standard structure of rtu frame: start t1-t2-t3-t4 (transmission time of 3.5 bytes) addr communication address: 0~247(decimal system)(0 is the broadcast address) cmd 03h:read slave parameters 06h:write slave parameters data (n-1) … data (0) the data of 2*n bytes a...

Page 78

78 - 104 communication protocol the calculation of crc applies the international standard crc checkout principles. When the user is editing crc calculation, he can refer to the relative standard crc calculation to write the required crc calculation program. Here provided a simple function of crc cal...

Page 79

Communication protocol 79 - 104 t1-t2-t3-t4 between start and end is to provide at least the time of 3.5 bytes as the leisure time and distinguish two messages for the avoidance of taking two messages as one message. Addr = 01h means the command message is sent to the inverter with the address of 01...

Page 80

80 - 104 communication protocol start t1-t2-t3-t4 (transmission time of 3.5 bytes) addr 02h cmd 06h high bit of writing data address 00h low bit of writing data address 04h data content 13h data content 88h crc chk low bit c5h crc chk high bit 6eh end t1-t2-t3-t4 (transmission time of 3.5 bytes) rtu...

Page 81

Communication protocol 81 - 104 low byte of crc adh high byte of crc 14h end t1-t2-t3-t4 (transmission time of 3.5 bytes) the rtu response command is: start t1-t2-t3-t4 (transmission time of 3.5 bytes) addr 01h cmd 08h high byte of sub-function code 00h low byte of sub-function code 00h high byte of...

Page 82

82 - 104 communication protocol example, the function code p00.07 is not stocked into eeprom. Only by changing the value in ram can set the address to 8007h. This address can only be used in writing ram other than reading. If it is used to read, it is an invalid address. 7.3.4.2 the address instruct...

Page 83

Communication protocol 83 - 104 function instruction address definition data meaning instruction r/w characteristics bit4:=0:pre-alarm without overload =1:overload pre-alarm bit5~ bit6:=00:keypad control =01:terminal control =10:communication control fault code of the inverter 2102h see the fault ty...

Page 84

84 - 104 communication protocol r/w characteristics means the function is with read and write characteristics. For example, “communication control command” is writing chrematistics and control the inverter with writing command (06h). R characteristic can only read other than write and w characterist...

Page 85

Communication protocol 85 - 104 because the parameter data is 0032h (50) and 50 divided by 10 is 5, then the hibernation restore delay time is 5s. 7.3.6 fault message response there may be fault in the communication control. For example, some parameter can only be read. If a writing message is sent,...

Page 86

86 - 104 communication protocol 0 0 0 0 0 0 1 1 (hex 03h) for normal responses, the slave responds the same codes, while for objection responses, it will return: 1 0 0 0 0 0 1 1 (hex 83h) besides the function codes modification for the objection fault, the slave will respond a byte of abnormal code ...

Page 87

Communication protocol 87 - 104 the data content is 0003h. From the table 1, the inverter stops. Watch “the current fault type” to “the previous 5 times fault type” of the inverter through commands, the corresponding function code is p07.27~p07.32 and corresponding parameter address is 071bh~0720h(t...

Page 88

88 - 104 communication protocol set the max. Output frequency of the inverter with the address of 03h as100hz. See the figures behind the radix point, the fieldbus ratio value of the max. Output frequency (p00.03) is 100. 100hz timed by 100 is 10000 and the corresponding hex is 2710h. The command se...

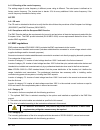

Page 89: Appendix A Technical Data

Appendix a technical data 89 - 104 appendix a technical data a.1 ratings a.1.1 capacity inverter sizing is based on the rated motor current and power. To achieve the rated motor power reference in the table, the rated current of the inverter must be higher than or equal to the rated motor current. A...

Page 90

90 - 104 appendix a technical data a.1.2.3 derating of the carrier frequency the setting range of carrier frequency in different power rating is different. The rated power is defined as its factory carrier frequency. The inverter has to derate 10% for every additional 1khz carrier frequency if the c...

Page 91

Appendix a technical data 91 - 104 1. The optional emc filter is selected according to the options and installed as specified in the emc filter manual. 2. The motor and control cables are selected as specified in this manual. 3. The drive is installed according to the instructions reference in this ...

Page 92

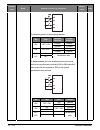

92 - 104 appendix b dimension drawings appendix b dimension drawings dimension drawings of the cv10 are shown below. The dimensions are given in millimeters. B.1 keypad structure for external mounting of the keypad, take in account that the maximum cable length between the keypad and the inverter is...

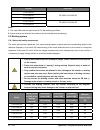

Page 93

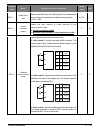

Appendix b dimension drawings 93 - 104 b.2 inverter chart wall mounting (unit: mm) model w1 w2 h1 h2 d cv10-002-s2 85.0 74.0 145.5 131.5 134.2 cv10-004-s2 85.0 74.0 145.5 131.5 134.2 cv10-008-s2 85.0 74.0 145.5 131.5 153.2 cv10-015-s2 100.0 89.0 170.5 154.0 153.2 cv10-022-s2 100.0 89.0 170.5 154.0 1...

Page 94

94 - 104 appendix c peripherial options and parts appendix c peripherial options and parts this chapter describes how to select the options and parts of cv10 inverters. C.1 peripherial wiring below is the peripherial wiring of cv10 inverters. Name descriptions circuit breaker + earth leakage protect...

Page 95: C.2 Power Supply

Appendix c peripherial options and parts 95 - 104 name descriptions output sine wave filter (lc filter) prolongues the effective transimitting distance of the inverter because controls the sudden high voltage provoqued when switchiong on/off the igbts of the inverter. Recommended when the cable dist...

Page 96

96 - 104 appendix c peripherial options and parts c.3.2 control cables all analog control cables and the cable used for the frequency input must be shielded. Use a double-shielded twisted pair cable (figure a) for analog signals. Employ one individually shielded pair for each signal. Do not use comm...

Page 97

Appendix c peripherial options and parts 97 - 104 c.4 circuit breaker and electromagnetic contactor it is necessary to use a circuit breaker (mccb) to protect the power supply and the cable system. The rated current of the circuit breaker should be 1.5-2 times of the rated input current of the inver...

Page 98

98 - 104 appendix c peripherial options and parts inverter input filter cv10-002-s2 ipf-emc-cv10-008-s2 cv10-004-s2 cv10-008-s2 cv10-015-s2 ipf-emc-cv10-022-s2 cv10-022-s2 note: 1. The input emi meet the requirement of c3 after adding input filters. 2. Above options are external, the customer should...

Page 99

Appendix c peripherial options and parts 99 - 104 note: select the resistor and power of the braking resistor according to the data salicru provided. The braking resistor may increase the braking torque of the inverter. Above table is measured at 100% braking torque, 10%, 50% and 80% braking usage r...

Page 100

.......................................................................................................... .......................................................................................................... .........................................................................................

Page 101

.......................................................................................................... .......................................................................................................... .........................................................................................

Page 102

.......................................................................................................... .......................................................................................................... .........................................................................................

Page 103

.......................................................................................................... .......................................................................................................... .........................................................................................

Page 104

Ref. El083a01 rev. A code 401* avda. De la serra 100 avda. De la serra 100 08460 palautordera barcelona tel. +34 93 848 24 00 fax +34 93 848 22 05 services@salicru.Com salicru.Com the technical service and support (t.S.S.) network, commercial network and warranty information are available in website...