- DL manuals

- Salvis

- Kitchen Appliances

- CUCINA EASY

- Installation Instructions Manual

Salvis CUCINA EASY Installation Instructions Manual

Summary of CUCINA EASY

Page 1

Salvis combi‐steamer cucina r easy cucina r pro installation instructions 623 611 1011 t 611 621 1011 1021 qt 2011 2021 qt.

Page 2

Table of contents page 2 / 24 1. User information 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.1 information about the instructions for the appliance 3 . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2 symbols in ...

Page 3

Installation instructions 3 / 24 1. User information 1.1 information about the instructions for the appliance these installation instructions contain technical data, information on transport, setup, installation and ad justment of the appliance. Hand the installation instructions to the installing ...

Page 4

Installation instructions 4 / 24 1.4 documenting the type plate data . Enter the type plate data below before setting up the appliance. . Please quote these data when you require after‐sales service for the appliance. This will speed up the response to your questions. Model: year of manufacture: ser...

Page 5

Installation instructions 5 / 24 3. Transport, setup 3.1 inspection for transport damages . Check the packaging and appliance for transport damages. . If transport damages are suspected, notify your freight carrier or the factory without delay! 3.2 transport d if the appliance must be transported ou...

Page 6

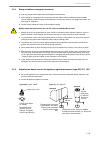

Installation instructions 6 / 24 3.3.2 choosing the setup location d set up the appliance safe against frost. The ambient temperature at the installation site may not fall below freezing. Otherwise the water in the components will freeze and damage the appliance. D no heat‐ or steam sources may be l...

Page 7

Installation instructions 7 / 24 3.3.4 setup on tables and support structures d use only support frames approved by the appliance manufacturer. D when setting up the appliance on countertops and work tables sufficient stability and load capacity must be observed. Note the weight of the appliance, in...

Page 8

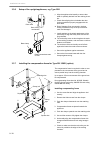

Installation instructions 8 / 24 3.3.6 setup of the upright appliances, e.G. Type 2011 . Align the appliance horizontally to ensure that water is optimally drained from the cooking cham ber. . Check after aligning the unit whether the door closing mechanism properly engages with the door catch. D r...

Page 9

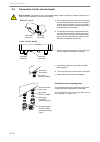

Installation instructions 9 / 24 3.3.8 apply the safety sticker ”max. Shelf level for liquid cooking products” d warning! Scald hazard! Containers with liquids or products to be boiled, becoming liquid during the cooking process, may only be pushed into the slot that can be easily viewed by the oper...

Page 10

Installation instructions 10 / 24 4.2 choice of water softening device / water filter / water treatment 4.2.1 water treatment systems d the manufacturers of water softening devices offer systems provided specifically for hot circulating‐air steamers/combi‐steamers. They may also be combined with par...

Page 11

Installation instructions 11 / 24 4.2.4 requirements on the soft‐ and cold‐water connection d the steam generation in the appliances is carried out as fresh steam, that means, the water is directly introduced into the cooking chamber. D the water must conform to the drinking water regulations. D in ...

Page 12

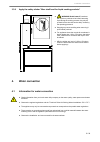

Installation instructions 12 / 24 4.3 connection of soft‐ and cold water risk of damage the appliance may not be operated without water connection! A water connection is re quired even if the appliance is only used for baking! D the connection requires using a pressure‐resist ant flexible dvgw‐tes...

Page 13

Installation instructions 13 / 24 5. Connecting water drainage – connection examples d it is preferable to use the first or second connec tion examples! D the waste water system must be designed ac cording to din 1986‐100 and din en 12056‐1. D use steam temperature‐resistant and flame‐retar dant ...

Page 14

Installation instructions 14 / 24 6. Electrical connection danger! Electrical voltage! Risk of electric shock that may result in serious injury or death! Installation, service and repair tasks may only be carried out by authorised customer service. D if the appliance was transported in a cold enviro...

Page 15

Installation instructions 15 / 24 6.1 connection to an energy optimisation unit (option) d when purchasing the "connection energy optim isation" option, the appliance is equipped by the factory with the necessary interface (abcd inter face). − a = appliance switched on − b = appliance is heating −...

Page 16

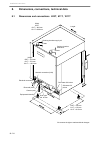

Installation instructions 16 / 24 8. Dimensions, connections, technical data 8.1 dimensions and connections 623t, 611t, 1011t 38 mm 38 mm drain pipe dia. 40 mm height: 623t = 764 mm 611t = 764 mm 1011t = 1,004 mm width: 623t 611t = 809 mm 1011t = 809 mm 623t = 435 mm 611t = 615 mm 1011t = 615 mm ele...

Page 17

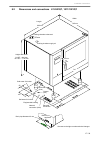

Installation instructions 17 / 24 8.2 dimensions and connections 611/621qt, 1011/1021qt 35 mm 63 mm 980 mm equipotential bonding electrical connection cleaner (red) rinse‐aid (blue) soft water 3/4 inches cold water 3/4 inches 795 mm height with bases 611qt = 840 mm 1011qt = 1,120 mm network connecti...

Page 18

Installation instructions 18 / 24 8.3 dimensions and connections 2011/2021qt soft water 3/4 inches 63 mm potential equalisation electrical connection rinse‐aid (blue) cold water 3/4 inches height with bases 1930 mm rear of device cooking chamber supply air cooking chamber exhaust air length: 1115 mm...

Page 19

Installation instructions 19 / 24 8.4 technical data: 623t, 611t, 1011t technical specifica tions 623 t 611 t 1011 t cooking chamber size 6 x gn 2/3 6 x gn 1/1 10 x gn 1/1 voltage 400v 3n 50/60hz *) 230v 1n 50/60hz / 400v 3n 50/60hz 400v 3n 50/60hz connected load *) 3.8 kw / 6.3 kw 8.6 kw 11.0 kw f...

Page 20

Installation instructions 20 / 24 8.6 technical data: 2011/2021qt technical data 2011 qt 2021 qt cooking chamber size 20 x gn 1/1 20 x gn 2/1 voltage 400v 3n 50/60hz 400v 3 / 400v 3n 50/60hz connected load 34,6 kw / 44,0 kw 51,5 kw / 67,1 kw fuse 3 x 63 a 3 x 80 a 3 x 100 a thermal output, sensitive...

Page 21

21 / 24.

Page 22

22 / 24.

Page 23

23 / 24.

Page 24

Translation of the original installation instructions 878976 / 7.11 / 12.15 salvis ag nordstrasse 15 ch‐4665 oftringen tel. +41 (0)62 788 18 18 fax. +41 (0)62 788 18 98 internet: www.Salvis.Ch e‐mail: info@salvis.Ch.