- DL manuals

- Samson

- Control Unit

- 3241-1

- Mounting And Operating Instructions

Samson 3241-1 Mounting And Operating Instructions

Summary of 3241-1

Page 1

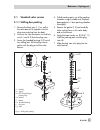

Pneumatic control valves type 3241-1 and type 3241-7 mounting and operating instructions eb 8015 en edition september 2009 fig. 1 · type 3241 valve with type 3271 actuator and with type 3277 actuator type 3241-7 type 3241-1.

Page 2

Contents page 1 design and principle of operation. . . . . . . . . . . . . . . . . . . . 4 2 assembling valve and actuator. . . . . . . . . . . . . . . . . . . . . . 4 2.1 assembly and adjustment . . . . . . . . . . . . . . . . . . . . . . . . 4 2.2 pretensioning springs in actuator version “actuato...

Page 3

Eb 8015 en 3 safety instructions general safety instructions 4 the control valve may only be mounted, started up or serviced by fully trained and qualified personnel, observing the accepted industry codes and practices. Make sure employees or third persons are not exposed to any danger. All safety i...

Page 4: Tion

1 design and principle of opera- tion the type 3241-1 and type 3241-7 pneu- matic control valves consist of a type 3241 single-seated globe valve and either a type 3271 or type 3277 pneumatic actua- tor. Thanks to the modular design, the actuators can be exchanged, and the standard version of the va...

Page 5

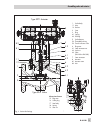

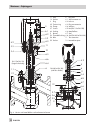

Eb 8015 en 5 assembling valve and actuator fig, 2 · sectional drawings 1. Valve body 1.1 nuts 1.2 gasket 2 seat 3 plug 4.1 spring 4.2 packing 5 valve bonnet 5.2 threaded bushing 5.3 travel indicator scale 6 plug stem 6.1 stem connector nut 6.2 lock nut 6.3 yoke (dn 200 to dn 300) 7 stem connector 8 ...

Page 6

6 eb 8015 en assembling valve and actuator fig. 3 · sectional drawings of type 3241-7 and valve body dn 200 to dn 300 8 8.1 8.2 7 6.1 1.1 4.1 1.2 5 3 2 1 4.2 6 5.2 6.2 5.3 6.3 1 valve body 1.1 nuts 1.2 gasket 2 seat 3 plug 4.1 spring 4.2 packing 5 valve bonnet 5.2 threaded bushing 5.3 travel indicat...

Page 7: Actuator Version “Actuator

2. Remove the stem connector clamps (7) and the ring nut (8.2) from the actuator (8). Slide the ring nut over the plug stem. 3. Place actuator onto the valve bonnet (5) and secure with the ring nut (8.2). 4. Read bench range (or bench range with pre-loaded springs) and fail-safe action from the actu...

Page 8: 2.3 Valve and Actuator With

2.3 valve and actuator with different rated travels actuator version "actuator stem extends" note! Valves that have a travel smaller than the rated travel of the actuator always need to use preloaded springs. Example: valve dn 100 with 30 mm rated travel and 1400 cm² actuator with 60 mm rated travel...

Page 9: Installation

3 installation 3.1 mounting position the valve can be mounted in any desired position. However, vertical installation with the actuator pointing upwards is preferable for valves in nominal size dn 100 or larger to facilitate maintenance. For valves with extension bonnet or metal bellows seal, or for...

Page 10

5 maintenance – replacing parts the control valve is subject to natural wear, especially at the seat, plug and packing. Depending on the application, the valve needs to be checked regularly to prevent against possible failures. If leakage occurs, this could be caused by a damaged packing or a defect...

Page 11: 5.1 Standard Valve Version

5.1 standard valve version 5.1.1 stuffing box packing 1. Remove the body nuts (1.1) as well as the valve bonnet (5) together with the plug stem and plug from the body. 2. Unscrew the stem connector nut and lock nut (6.1 and 6.2) from the plug stem. 3. Screw the threaded bushing (5.2) out of the stuf...

Page 12: 5.1.2 Seat And/or Plug

8. Insert new flat gasket (1.2) into the body. Carefully place the valve bonnet onto the valve body, making sure that the large v-shaped port of the v-port plug faces towards the valve outlet. Secure with nuts (1.1). 9. Carefully slide the packing parts over the plug stem into the packing chamber. K...

Page 13: Or Metal Bellows Seal

5.2 valve with extension bonnet or metal bellows seal 5.2.1 stuffing box packing 1. Remove the stem connector nut and lock nut (6.1 and 6.2) from the plug stem ex- tension (6.3). Unscrew the threaded bushing (5.2) out of the stuffing box. 2. Remove nuts (5.4) and carefully lift the bonnet (5) over t...

Page 14

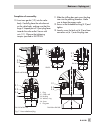

14 eb 8015 en maintenance – replacing parts fig. 6 · versions with metal bellows seal and extension bonnet 5 6.1 6.2 5.2 6.3 11 12 6.5 6.6 6.4 6 4.2 5.5 5.4 1.1 1.2 1.1 nuts 1.2 gasket 3 plug 3.5 tension ring 3.6 flange 3.7 screws 4.2 packing 5 bonnet 5.2 threaded bushing 5.4 bolts 5.5 gasket 6 plug...

Page 15: 5.2.3 Seat

Check whether the two washers (6.4) are still in the plug stem extension (6.3). Screw the plug stem firmly into the plug stem extension (6.3); tightening torque is 50 nm for Ø 10 mm and 80 nm for Ø 16 mm. 4 to complete assembly, refer to section 5.2.5. Nominal sizes dn 200 to dn 300: 1. Remove the n...

Page 16: 5.2.5 Reassembly

Nominal sizes dn 200 to dn 300: 1. Unscrew the plug (3) from the plug stem as described in section 5.2.2. Pull the plug stem (6) together with the metal bellows (6.6) upwards, out of the intermediate piece (12). 2. Replace the seal (6.7) and insert a new plug stem with metal bellows (6.6). 3. Screw ...

Page 17

Completion of reassembly: 10. Insert new gasket (1.2) into the valve body. Carefully place the valve bonnet on the valve body, making sure that the large v-shaped port of v-port plug faces towards the valve outlet. Secure with nuts (1.1). Observe the tightening torques specified in eb 029 en. 11. Sl...

Page 18: Material Identification

14. Mount the actuator and adjust the upper and lower range values as described in section 2.1. Nominal sizes dn 50 to dn 150 5. Remove screw (3.4) with its locking de- vice and washer (3.3). Replace collar (3.1). 6. Insert washer (3.3). Thread down the screw (3.4) with its locking device. 7. Apply ...

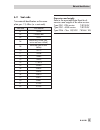

Page 19: 6.2 Seat Code

6.2 seat code trim material identification on the name- plate, pos. 13, mexx (xx = seat code). Seat code trim material 01 1.4006 02 crnimo steel 03 1.4301 04 stellite 6b (crnimo steel, entire seat bore stellited) 05 stellite 6b (seat of solid stellite) 10 1.4112 11 1.4306 12 1.4462 13 1.4539 14 1.73...

Page 20: Description of Nameplates

7 description of nameplates 20 eb 8015 en description of nameplates 3 4 5 9 10 7 8 11 12 13 14 15 2 1 6 samson made in germany - samson 1 6 5 7 v f h 2 3 4 samson model - no. Serial - no. Pneum. Stellantrieb pneum. Actuator servo - monteur pneum. Cm² hub stroke course mm bar bar bar federbereich spr...

Page 21: Customer Inquiries

8 customer inquiries if you encounter any problems, please sub- mit the following details: 4 order number 4 type, product number, nominal size and version of the valve 4 pressure and temperature of the process medium 4 flow rate in m³/h 4 bench range of the actuator (e.G. 0.2 to 1 bar) 4 has a strai...

Page 22

22 eb 8015 en.

Page 23

Eb 8015 en 23.

Page 24

Samson ag · mess- und regeltechnik weismüllerstraße 3 · 60314 frankfurt am main · germany phone: +49 69 4009-0 · fax: +49 69 4009-1507 internet: http://www.Samson.De eb 8015 en s/ z 2012-03.