- DL manuals

- Samson

- Control Unit

- 3241

- Mounting And Operating Instructions

Samson 3241 Mounting And Operating Instructions - 5.3 Quick Check

34

EB 8012 EN

Mounting and start-up

6. Depending on the field of application,

allow the valve to cool down or heat up

to reach ambient temperature before

start up.

7. Slowly open the shut-off valve in the

pipeline after the valve has been in-

stalled.

NOTICE

Risk of valve damage due to a sud-

den pressure increase and resulting

high flow velocities.

Slowly open the shut-off valve in the

pipeline during start‑up.

8. Check the valve to ensure it functions

properly.

Version with welding ends

1. Proceed as described for “Version with

flanges” (steps 1 to 3).

2. Completely retract the actuator stem to

protect the plug from sparks during weld-

ing.

3. Weld the valve free of stress into the

pipeline.

4. Proceed as described for “Version with

flanges” (steps 6 to 8).

5.3 Quick check

SAMSON valves are delivered ready for

use. To test the valve's ability to function, the

following quick checks can be performed:

Tight shut-off

1. Close the valve.

2. Slowly open the shut-off valve in the

pipeline.

NOTICE

Risk of valve damage due to a sud-

den pressure increase and resulting

high flow velocities.

Slowly open the shut-off valve in the

pipeline during start‑up.

3. Check the valve for leakage to the atmo-

sphere (visual inspection).

Travel motion

The movement of the actuator stem must be

linear and smooth.

Î

Open and close the valve, observing the

movement of the actuator stem.

Î

Apply the maximum and minimum con-

trol signals to check the end positions of

the valve.

Î

Check the travel reading at the travel in-

dicator scale.

Summary of 3241

Page 1

Mounting and operating instructions eb 8012 en tr anslat ion of original instruct ions edition march 2016 type 3241 valve with type 3271 actuator (left) and type 3277 actuator (right) type 3241 valve in combination with an actuator, e.G. A samson type 3271 or type 3277 pneumatic actuator ansi and ji...

Page 2

Definition of signal words danger! Hazardous situations which, if not avoided, will result in death or seri- ous injury warning! Hazardous situations which, if not avoided, could result in death or seri- ous injury notice property damage message or mal- function note: additional information tip: rec...

Page 3

Contents eb 8012 en 3 1 safety instructions and measures ...................................................................5 1.1 notes on possible severe personal injury .........................................................7 1.2 notes on possible personal injury ...................................

Page 4

4 eb 8012 en contents 7 maintenance ...............................................................................................38 7.1 replacing the gasket ....................................................................................39 7.1.1 standard version...................................

Page 5

Eb 8012 en 5 safety instructions and measures 1 safety instructions and measures intended use the samson type 3241 globe valve in combination with an actuator (e.G. Type 3271 or type 3277 pneumatic actuator) is designed to regulate the flow rate, pressure or temperature of liquids, gases or vapors. ...

Page 6

6 eb 8012 en safety instructions and measures personal protective equipment we recommend wearing the following protective equipment depending on the process medi- um: − protective clothing, gloves and eyewear in applications with hot, cold, and/or corrosive media − wear hearing protection when worki...

Page 7

Eb 8012 en 7 safety instructions and measures referenced standards and regulations the control valves comply with the requirements of the european pressure equipment direc- tive 97/23/ec. Valves with a ce marking have a declaration of conformity which includes information about the applied conformit...

Page 8

8 eb 8012 en safety instructions and measures 1.2 notes on possible personal injury warning! Crush hazard arising from moving parts. The control valve contains moving parts (actuator and plug stems), which can in- jure hands or fingers if inserted into the valve. Î do not insert hands or finger into...

Page 9

Eb 8012 en 9 safety instructions and measures warning! Risk of burn injuries due to hot or cold components and pipelines. Depending on the process medium, valve components, and pipelines may get very hot or cold and cause burn injuries. Î allow components and pipelines to cool down or heat up. Î wea...

Page 10

10 eb 8012 en safety instructions and measures notice risk of valve damage due to the use of unsuitable tools. Certain tools are required to work on the valve. Î only use tools approved by samson ( u ab 0100). Risk of valve damage due to the use of unsuitable lubricants. The lubricants to be used de...

Page 11

Eb 8012 en 11 safety instructions and measures.

Page 12: 2.1 Valve Nameplate

12 eb 8012 en markings on the control valve 2 markings on the control valve 2.1 valve nameplate 6 8 12 13 10 11 14 15 16 17 18 1…5 9 samson 20 21 19 fig. 1: valve nameplate 1…5 ped (pressure equipment directive), "art. 3, abs. 3" id of the notified body, fluid group, and category 6 type designation ...

Page 13: 2.2 Actuator Nameplate

Eb 8012 en 13 markings on the control valve the valve nameplate (80) in valve sizes nps ½ to 6 is affixed to the flange (fig. 2). The valve nameplate in valve sizes nps 8 and larger is located on the yoke (fig. 3). 80 80 fig. 2: nameplate on the flange fig. 3: nameplate on the yoke 2.2 actuator name...

Page 14: Ation

14 eb 8012 en design and principle of operation 3 design and principle of oper- ation the single-seated type 3241 globe valve is preferably combined with a samson type 3271 or type 3277 pneumatic actuator (see fig. 4). It can also be combined with other actuators. The seat (4) and plug with plug ste...

Page 15

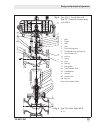

Eb 8012 en 15 design and principle of operation 1 5 4 16 11 3 84 8 9 10 14 2 17 92 a 2 84 10 a26 9 8 16 11 a8 a7 14 17 1 4 5 1 body 2 flange 3 yoke 4 seat 5 plug (with plug stem) 8 threaded bushing (packing nut) 9 stem connector nut 10 lock nut 11 spring 14 nuts 16 packing 17 body gasket 84 travel i...

Page 16: 3.1 Fail-Safe Positions

16 eb 8012 en design and principle of operation 3.1 fail-safe positions the fail-safe position depends on the actua- tor used. Depending on how the compression springs are arranged in the pneumatic actuator, the valve has two different fail-safe positions: actuator stem extends (fa) when the signal ...

Page 17: 3.3 Technical Data

Eb 8012 en 17 design and principle of operation actuators in these instructions, the preferable combina- tion with a type 3271 or type 3277 pneu- matic actuator is described. The pneumatic actuator (with or without handwheel) can be replaced by another pneumatic actuator in a different size, but wit...

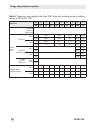

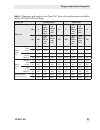

Page 18

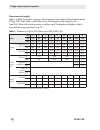

18 eb 8012 en design and principle of operation dimensions and weights table 1 to table 3 provide a summary of the dimensions and weights of the standard version of type 3241 valve. Table 4 and table 5 show the dimensions and weights for the type 3241 valve with insulating section or bellows seal. T...

Page 19

Eb 8012 en 19 design and principle of operation table 2: dimensions of type 3241 valve, nps 8 (dn 200) and larger valve nps 8 10 10 10 12 dn 200 250/cast iron 250 up to 200 mm seat bore 250 seat bore 250 mm and larg- er 300 length l 1) class 125 and 150 in 21.38 26.50 26.50 26.50 29.00 mm 543 673 67...

Page 20

20 eb 8012 en design and principle of operation table 4: dimensions and weights for the type 3241 valve with insulating section or bellows seal up to nps 6 (dn 150) valve size nps ½ ¾ 1 1½ 2 2½ 3 4 6 dn 15 20 25 40 50 65 80 100 150 insulating section or bellows seal h4 for actua- tor ≤750 cm² short ...

Page 21

Eb 8012 en 21 design and principle of operation table 5: dimensions and weights for the type 3241 valve with insulating section or bellows seal for nps 8 (dn 200) and larger version with insulating section bellows seal valve size nps 8 10 up to 200 mm seat bore 10 250 mm seat bore 12 8 10 up to 200 ...

Page 22

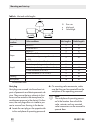

22 eb 8012 en design and principle of operation dimensional drawings h1 h2 l h8 h4 h2 l type 3241 · nps ½ to 6 (dn 15 to 150) type 3241 · nps 8 to 12 (dn 200 to 300) h4 h8 h4 type 3241 with insulating section or bel- lows seal · nps ½ to 6 (dn 15 to 150) type 3241 with insulating section or bel- low...

Page 23

Eb 8012 en 23 design and principle of operation note: refer to the following data sheets for more dimensions and weights: u t 8012 for valves with bellows seal, insulating section or heating jacket the associated actuator documentation applies to actuators, e.G. For samson pneu- matic actuators: u t...

Page 24: 4 Preparation

24 eb 8012 en preparation 4 preparation after receiving the shipment, proceed as fol- lows: 1. Check the scope of delivery. Compare the shipment received against the deliv- ery note. 2. Check the shipment for transportation damage. Report any damage to samson and the forwarding agent (re- fer to del...

Page 25: 4.2.1 Transporting

Eb 8012 en 25 preparation notice risk of valve damage due to incor- rectly attached slings. The welded-on lifting eyelet on samson actuators is only intended for mounting and removing the actu- ator as well as lifting the actuator without valve. Do not use this lifting eyelet to lift the entire cont...

Page 26

26 eb 8012 en preparation fig. 7: lifting points on the control valve: up to nps 6 (left) and with welding ends (middle) · nps 6 and larger with additional lifting eyelet on the actuator (right) − prevent the control valve from tilting or tipping. − do not leave loads suspended when in- terrupting w...

Page 27

Eb 8012 en 27 preparation version with flanges 1. Attach one sling to each flange of the body and to the rigging equipment (e.G. Hook) of the crane or forklift (see fig. 7). 2. Nps 6 and larger: attach another sling to the lifting eyelet on the actuator and to the rigging equipment. 3. Carefully lif...

Page 28: 4.3 Storage

28 eb 8012 en preparation 4.3 storage notice risk of valve damage due to im- proper storage. − observe storage instructions. − avoid long storage times. − contact samson in case of differ- ent storage conditions or longer storage times. Note: we recommend regularly checking the control valve and the...

Page 29

Eb 8012 en 29 preparation 4.4 preparation for installation proceed as follows: Î flush the pipelines. Note: the plant engineering company is re- sponsible for cleaning the pipelines in the plant. Î check the valve to make sure it is clean. Î check the valve for damage. Î check to make sure that the ...

Page 30: 5 Mounting and Start-Up

30 eb 8012 en mounting and start-up 5 mounting and start-up samson valves are delivered ready for use. In special cases, the valve and actuator are delivered separately and must be assem- bled on site. The procedure to mount and start up the valve are described in the follow- ing. Notice risk of val...

Page 31: Pipeline

Eb 8012 en 31 mounting and start-up note: − remove the mounted actuator be- fore mounting the other actuator (see associated actuator documen- tation). − preloading the actuator springs in- creases the thrust of a pneumatic actuator and reduces the travel range of the actuator (see associat- ed actu...

Page 32

32 eb 8012 en mounting and start-up vent plug vent plugs are screwed into the exhaust air ports of pneumatic and electropneumatic de- vices. They ensure that any exhaust air that forms can be vented to the atmosphere (to avoid excess pressure in the device). Further- more, the vent plugs allow air i...

Page 33: 5.2.2 Additional Fittings

Eb 8012 en 33 mounting and start-up 5.2.2 additional fittings strainers we recommend installing a samson strainer upstream of the valve. It prevents sol- id particles in the process medium from damaging the valve. Bypass and shut-off valves we recommend installing a shut-off valve both upstream of t...

Page 34: 5.3 Quick Check

34 eb 8012 en mounting and start-up 6. Depending on the field of application, allow the valve to cool down or heat up to reach ambient temperature before start up. 7. Slowly open the shut-off valve in the pipeline after the valve has been in- stalled. Notice risk of valve damage due to a sud- den pr...

Page 35

Eb 8012 en 35 mounting and start-up fail-safe position Î shut off the signal pressure line. Î check whether the valve moves to the fail-safe position. Adjustable packing tip: a label on the flange (2) or yoke (3) indicates whether an adjustable packing is installed. 1. Tighten the threaded bushing g...

Page 36: 6 Operation

36 eb 8012 en operation 6 operation immediately after completing mounting and start-up (see section 5), the valve is ready for use. Warning! Crush hazard arising from moving parts (actuator and plug stem). Do not insert hands or finger into the yoke while the valve is in operation. Warning! Risk of ...

Page 37

Eb 8012 en 37 operation.

Page 38: 7 Maintenance

38 eb 8012 en maintenance 7 maintenance the control valve is subject to normal wear, especially at the seat, plug, and packing. Depending on the operating conditions, check the valve at regular intervals to pre- vent possible failure before it can occur. Tip: samson's after‑sales service de- partmen...

Page 39: 7.1 Replacing The Gasket

Eb 8012 en 39 maintenance notice risk of valve damage due to the use of unsuitable tools. Only use tools approved by samson ( u ab 0100). Notice risk of valve damage due to the use of unsuitable lubricants. Only use lubricants approved by samson ( u ab 0100). Note: the control valve was checked by s...

Page 40

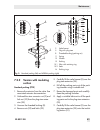

40 eb 8012 en maintenance 1 body 2 flange/valve bonnet 4 seat 5 plug (with plug stem) 8 threaded bushing (packing nut) 9 stem connector nut 10 lock nut 11 spring 14 body nut 15 packing 16 packing rings 17 body gasket 21 insulating section 23 guide bushing 25 plug stem extension 30 washers 32 screw 3...

Page 41: Section Or Bellows Seal

Eb 8012 en 41 maintenance gradually in a criss-cross pattern. Ob- serve tightening torques. 8. Mount actuator. See associated actuator documentation. 9. Adjust lower or upper signal bench range. See associated actuator docu- mentation. 7.1.2 version with insulating section or bellows seal 1. Remove ...

Page 42: 7.2.1 Standard Version

42 eb 8012 en maintenance 7.2.1 standard version standard packing (ptfe) 1. Remove the actuator from the valve. See associated actuator documentation. 2. Undo the body nuts (14) gradually in a criss-cross pattern. 3. Lift the flange (2) and plug with plug stem (5) off the body (1). 4. Unthread the s...

Page 43: Section

Eb 8012 en 43 maintenance 7.2.2 version with insulating section standard packing (ptfe) 1. Remove the actuator from the valve. See associated actuator documentation. 2. Unthread the stem connector nut (9) and lock nut (10) from the plug stem exten- sion (25). 3. Unscrew the threaded bushing (8). 4. ...

Page 44: Plug

44 eb 8012 en maintenance version with v-port plug: place the valve bonnet (2) onto the insulating section, making sure that the largest v-shaped port of the v-port plug faces toward the valve outlet. See section 5.1. 10. Carefully slide the packing parts over the plug stem extension into the packin...

Page 45: 7.3.1 Standard Version

Eb 8012 en 45 maintenance tip: when replacing the seat and plug, we also recommend replacing the packing. See section 7.2. 7.3.1 standard version 1. Remove the actuator from the valve. See associated actuator documentation. 2. Undo the body nuts (14) gradually in a criss-cross pattern. 3. Lift the f...

Page 46: Section

46 eb 8012 en maintenance 7.3.2 version with insulating section 1. Remove the actuator from the valve. See associated actuator documentation. 2. Unthread the stem connector nut (9) and lock nut (10) from the plug stem exten- sion (25). 3. Unscrew the threaded bushing (8). 4. Remove nuts (33) and bol...

Page 47: Ment

Eb 8012 en 47 maintenance 22. Fasten the valve bonnet with nuts (33) and bolts (32). Observe tightening torques. 23. Screw in the threaded bushing (8) and tighten it. Observe tightening torques. 24. Loosely screw the lock nut (10) and stem connector nut (9) onto the plug stem. 25. Mount actuator. Se...

Page 48: 8 Malfunctions

48 eb 8012 en malfunctions 8 malfunctions depending on the operating conditions, check the valve at certain intervals to prevent possi- ble failure before it can occur. Operators are responsible for drawing up a test plan. Tip: samson's after‑sales service department can support you to draw up an in...

Page 49: 8.2 Emergency Action

Eb 8012 en 49 malfunctions malfunction possible reasons recommended action increased flow through closed valve (seat leakage) dirt or other foreign particles de- posited between the seat and plug. Shut off the section of the pipe- line and flush the valve. Valve trim, particularly with soft seat, is...

Page 50: Sembly

50 eb 8012 en decommissioning and disassembly 9 decommissioning and disas- sembly danger! Risk of bursting in pressure equip- ment. Control valves and pipelines are pressure equipment. Improper open- ing can lead to bursting of the valve. − before starting any work on the control valve, depressurize...

Page 51: 9.3 Removing The Actuator

Eb 8012 en 51 decommissioning and disassembly 3. Remove the valve from the pipeline (see section 4.2). 9.3 removing the actuator from the valve see associated actuator documentation. 9.4 disposal Î observe local, national, and internation- al refuse regulations. Î do not dispose of components, lubri...

Page 52: 10 Appendix

52 eb 8012 en appendix 10 appendix 10.1 after-sales service contact samson's after-sales service de- partment for support concerning mainte- nance or repair work or when malfunctions or defects arise. E-mail you can reach the after-sales service de- partment at aftersalesservice@samson.De. Addresses...

Page 53: 10.2 Certificates

Eb 8012 en 53 appendix 10.2 certificates samson aktiengesellschaft weismüllerstraße 3 · 60314 frankfurt am main telefon: +49 69 4009-0 · telefax: +49 69 4009-1507 internet: http://www.Samson.De revision 00 ce _m od ul _a _d e_ en_ re v0 0. Doc x konformitätserklärung/declaration of conformity modul/...

Page 54

54 eb 8012 en appendix samson aktiengesellschaft weismüllerstraße 3 · 60314 frankfurt am main telefon: +49 69 4009-0 · telefax: +49 69 4009-1507 internet: http://www.Samson.De revision 00 ce _m od ul _d _d e_ en_ re v0 0. Doc x konformitätserklärung/declaration of conformity modul/module d n° ce-ped...

Page 55

Eb 8012 en 55 appendix samson aktiengesellschaft weismüllerstraße 3 · 60314 frankfurt am main telefon: +49 69 4009-0 · telefax: +49 69 4009-1507 internet: http://www.Samson.De revision 00 ce _m od ul _h_ de _e n_ re v0 0. Doc x konformitätserklärung/declaration of conformity modul/module h n° ce-ped...

Page 56: Konformitätserklärung

56 eb 8012 en appendix bearb. / created 2001-11-21 ste 15 60388 2014-08-04 lae wt gepr. / checked 2001-11-24 lae 14 59546 2013-07-19 lae wt norm / standard 2002-02-22 wt zust. / state nr. / no. Änderung modification konformitätserklärung declaration of conformity Änd.-zust. Mod. Blatt nr. Page no. _...

Page 57: Konformitätserklärung

Eb 8012 en 57 appendix bearb. / created 2001-11-21 ste 15 60388 2014-08-04 lae wt gepr. / checked 2001-11-24 lae 14 59546 2013-07-19 lae wt norm / standard 2002-02-22 wt zust. / state nr. / no. Änderung modification konformitätserklärung declaration of conformity Änd.-zust. Mod. Blatt nr. Page no. _...

Page 58

58 eb 8012 en appendix.

Page 59: 10.3 Spare Parts

Eb 8012 en 59 appendix 10.3 spare parts legend 1 body 2 flange/valve bonnet 3 yoke 4 seat 5 plug (with plug stem) 7 guide bushing (flange) 8 threaded bushing (packing nut) 9 stem connector nut 10 lock nut 11 spring 12 washer 13 stud bolt 14 body nut 15 packing (adjustable) 16 packing 17 body gasket ...

Page 60

60 eb 8012 en dn 15…150 nps ½…6 90 9 10 15 12 12 19 16 8 11 2 32 7 81 41 37 30 42 81 26 24 22 5 17 63 62 61 4 80 82 83 84 25 30 33 14 33 91 91 1 91 91 1 13 39 14 14 21 23 90 9 10 15 12 16 8 11 12 19 81 80 81 26 82 83 84 7 2 5 48 51 47 53 44 52 45 50 46 49 50 46 52 44 45 47 48 53 51.

Page 61

Eb 8012 en 61 dn 200…300 nps 8…12 (dn 250, dn 300) (10", 12") 80 81 92 83 32 84 80 81 83 84 85 82 3 42 9 10 8 16 16 12 12 12 19 11 12 19 15 3 37 39 7 101 33 14 39 22 2 21 14 81 7 5 26 7 24 27 28 29 5 64 65 63 62 61 4 13 91 1 91 17 34 31 14 26 81 92 85 82 9 10 8 16 12 19 19 12 11 15 5 102 48 51 47 53...

Page 62

62 eb 8012 en.

Page 63

Eb 8012 en 63.

Page 64: Eb 8012 En

Samson ag · mess- und regeltechnik weismüllerstraße 3 · 60314 frankfurt am main, germany phone: +49 69 4009-0 · fax: +49 69 4009-1507 samson@samson.De · www.Samson.De eb 8012 en 2016-03-16 · engl ish.