Pneumatic actuator type 3277 mounting and operating instructions eb 8311 en edition july 2006 fig. 1 · type 3277 pneumatic actuator fig. 2 · type 3277-5 pneumatic actuator.

1 design and principle of operation the type 3277 pneumatic actuators with an effective diaphragm area of 240, 350 or 700 cm² are primarily mounted to control valves from the series 240, 250 and 280. Type 3277-5 with a die-cast aluminum case and an effective diaphragm area of 120 cm², is mounted to ...

Fail-safe action when the signal pressure fails, the fail-safe action of the actuator depends on whether the springs are installed in the top or bottom diaphragm chamber. Actuator stem extends when the signal pressure is reduced or the air supply fails, the springs move the actua- tor stem downwards...

Loading pressure connection type 3277 actuator (fig. 3) in the type 3277 actuator with fail-safe ac- tion "actuator stem extends", the loading pressure is connected to the loading pres- sure connection (11) at the side of the yoke to fill the bottom diaphragm chamber which causes the actuator stem (...

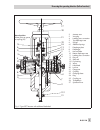

Eb 8311 en 5 design and principle of operation fig. 4 · type 3277-5 actuators with 120 cm 2 effective diaphragm area connecting plate actuator stem extends left attachment right attachment 1 nut 1.1 nut 2.1 bushing 5 diaphragm case 6 springs 7 diaphragm plate 7.1 metal plate 8 diaphragm 9 nuts and b...

2 operation note! It is important for a trouble-free operation of the type 3277 actuator that the vent plug (3) is not blocked. Make sure in versions with a handwheel that the plug stem can move freely when the valve is being positioned by the pneumatic actuator by moving the handwheel into a neutra...

Caution! Do not loosen the nut (1.1) on the actuator stem. It is painted over to protect it. If, however, it has been loosened, it is essen- tial that the dimension a (figs. 3 and 4) measured from the top of the nut to the bot- tom of the actuator stem is kept. 5. Apply lubricant/sealant (order no. ...

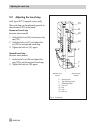

Tor stem only starts to retract when the signal pressure overcomes the force of the springs. 9. Record the changed fail-safe action on the nameplate! 2.1.2 actuator with handwheel type 3277 (fig. 5) only 1. Undo lock nut (20) and relieve the springs (6) by turning the handwheel (17). 2. Loosen threa...

Eb 8311 en 9 reversing the operating direction (fail-safe action) 17 20 21 22 24 15 13 3 4 6 9 6.1 7 11 12.1 13 23 26 25 12 5 27 8 10 12 fig. 5 · type 3277 actuator with additional handwheel 2 actuator stem 3 vent plug 4 loading press. Connection 5 top diaphragm case 6 springs 6.1 additional springs...

2.2 adjusting the travel stop (with type 3277 in special version only) the travel stop can be adjusted upwards or downwards to 50% of the travel. Downward travel stop (actuator stem extends) 1. Undo the lock nut (34) and unscrew the cap (33). 2. Undo the lock nut (31) and adjust the nut (32) to set ...

3 replacing the diaphragm and stem seal 3.1 diaphragm (fig. 3) 1. Remove the diaphragm plate (7) to- gether with diaphragm (8) and actuator stem (2) from the diaphragm case as de- scribed in section 2.1.1. 2. Remove the hose clamp and pull it to- gether with the diaphragm (8) off the di- aphragm pla...

Samson ag · mess- und regeltechnik weismüllerstraße 3 · 60314 frankfurt am main · germany phone: +49 69 4009-0 · fax: +49 69 4009-1507 internet: http://www.Samson.De eb 8311 en s/z 2006-08.