- DL manuals

- Samson

- Controller

- 3374-10

- Mounting And Operating Instructions

Samson 3374-10 Mounting And Operating Instructions - 8.2 Adapting The Display

EB 8331-4 EN

43

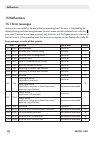

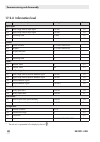

Operating level

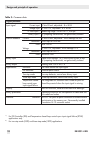

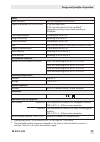

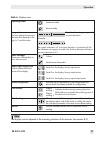

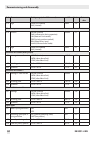

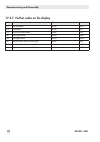

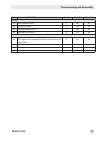

8.2 Adapting the display

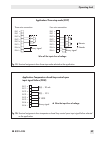

8.2.1 Reading direction

To adapt the reading on the display to the mounting situation of the actuator, the display con-

tents can be turned by 180° in Code 4.

Code

Description

WE

Adjustment range

4

Reading direction

DISP

DISP,

DISP

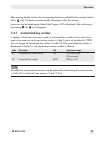

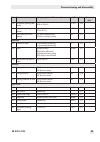

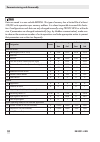

On changing the reading direction, the position of the icons and bar graph reading remains

unchanged, while the segments for numbers, text as well as binary input and output are

turned by 180°:

%

mm

%

mm

S

%

S

mm

%

mm

Default reading direction

Reading direction turned by 180°

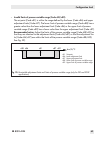

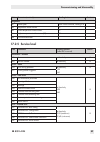

8.2.2 Backlight

The display backlight can be changed to be always switched on in Code c93.

Code

Description

WE

Adjustment range

c93

Backlight always on

NO

NO

YES

−

Regardless of the setting in Code c93, the backlight starts to blink whenever an error oc

-

curs (section 15).

−

The display backlight can also be switched on and off by the binary input (section 9.6).

Note

Summary of 3374-10

Page 1

Mounting and operating instructions eb 8331-4 en firmware version 3.11 tr anslat ion of original instruct ions edition august 2016 type 3374 electric actuator version with positioner, revision 3.

Page 2

2 eb 8331-4 en note on these mounting and operating instructions these mounting and operating instructions assist you in mounting and operating the device safely. The instructions are binding for handling samson devices. Î for the safe and proper use of these instructions, read them carefully and ke...

Page 3

Contents eb 8331-4 en 3 1 safety instructions and measures ...................................................................6 1.1 notes on possible severe personal injury .........................................................9 1.2 notes on possible personal injury .................................

Page 4

4 eb 8331-4 en contents 6.3 setting up modbus-rtu communication .........................................................34 6.3.1 protocol .......................................................................................................34 7 operation ..............................................

Page 5

Contents eb 8331-4 en 5 11 service level ................................................................................................67 11.1 activating and setting parameters .................................................................67 11.2 starting zero calibration .........................

Page 6

6 eb 8331-4 en safety instructions and measures 1 safety instructions and measures the type 3374 electric actuator is designed to operate a mounted globe valve used in industrial applications as well as in heating, ventilation and air-conditioning systems. The digital positioner ensures a predetermi...

Page 7

Eb 8331-4 en 7 safety instructions and measures personal protective equipment no personal protective equipment is required for the direct handling of the electric actuator. Work on the control valve may be necessary when mounting or removing the electric actua- tor. Î observe the requirements for pe...

Page 8

8 eb 8331-4 en safety instructions and measures responsibilities of operating personnel operating personnel must read and understand these mounting and operating instructions as well as the specified hazard statements, warning and caution notes. Furthermore, the operat - ing personnel must be famili...

Page 9

Eb 8331-4 en 9 safety instructions and measures 1.1 notes on possible severe personal injury danger ! Risk of electric shock. Î before connecting wiring, performing any work on the device or opening the de- vice, disconnect the power supply and protect it against unintentional reconnection. Î only u...

Page 10

10 eb 8331-4 en safety instructions and measures 1.3 notes on possible property damage notice ! Risk of damage to the electric actuator due to the power supply exceeding the permissible tolerances. The type 3374 electric actuator is designed for use according to regulations for low-voltage installat...

Page 11: 2 Markings On The Device

Eb 8331-4 en 11 markings on the device 2 markings on the device 2.1 nameplate 1 type designation 2 configuration id 3 serial number 4 power supply; power line frequency 5 power consumption 6 nominal transit time 7 stroking speed 8 thrust (stem retracts) 9 thrust (stem extends) 10 fail-safe action re...

Page 12: Ation

12 eb 8331-4 en design and principle of operation 3 design and principle of oper- ation the type 3374 electric actuator is used in industrial plants as well as in heating, venti- lation and air-conditioning systems. The actuator is suitable for form-fit attach - ment to various samson valve series, ...

Page 13: 3.2 Limit Contacts

Eb 8331-4 en 13 design and principle of operation 3.2 limit contacts the actuator can be equipped with either mechanical or electronic limit contacts to in- fluence the tasks of control equipment. 3.2.1 mechanical limit con- tacts the two mechanical limit contacts can be ad- justed independently fro...

Page 14: 3.4 Communication

14 eb 8331-4 en design and principle of operation 3.4 communication the type 3374 electric actuator has two communication interfaces: − internal serial rs-232 interface for ssp protocol for configuration using trovis- view. Î see section 7.3 − rs-485 interface (rs-485 module re- quired) for modbus-r...

Page 15

Eb 8331-4 en 15 design and principle of operation 4 1 3 2 6 5 1 rotary pushbutton 2 display 3 serial interface 4 terminals 5 actuating shaft for mechanical manual override 6 terminal board for limit contacts fig. 3: operating controls (with housing cover removed).

Page 16: 3.6 Technical Data

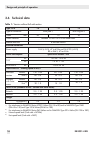

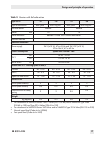

16 eb 8331-4 en design and principle of operation 3.6 technical data table 1: version without fail-safe action type 3374 -10 -11 -15 type of connection with yoke 1) with ring nut 2) travel mm 30 15 30 travel limitation between 10 and 100 % of the rated travel manual override 4 mm hex wrench electric...

Page 17

Eb 8331-4 en 17 design and principle of operation table 2: version with fail-safe action type 3374 -21 -26 -31 -36 type of connection with yoke 1) with ring nut 2) with yoke 1) with ring nut 2) fail-safe action extends retracts travel mm 15 15 travel limitation between 10 and 100 % of the rated trav...

Page 18

18 eb 8331-4 en design and principle of operation table 3: common data digital positioner input signal current input 0/4 to 20 ma, adjustable · r i = 50 Ω voltage input 0/2 to 10 v, adjustable · r i = 20 kΩ pt 1000 input 1) measuring range: –50 to 150 °c, 300 µa binary input 2) by jumpering the term...

Page 19

Eb 8331-4 en 19 design and principle of operation safety motor switch-off by torque-dependent limit contacts degree of protection acc. To en 60529 ip 54 with cable ducts ip 65 with cable glands (can be retrofitted) 1) suspended mounting not permitted according to en 60664 overvoltage category ii acc...

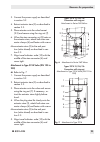

Page 20: 3.7 Dimensions In Mm

20 eb 8331-4 en design and principle of operation 3.7 dimensions in mm type 3374-10/-11/-21/-31 * ) when actuator stem is fully extended type 3374 dimension h -10 30 -11 15 -21 15 -31 15 -15 30 -26 15 -36 15 57 194 50* ) h 298 120 120 h 1 * ) 220 h 57 193 146 146.

Page 21

Eb 8331-4 en 21 design and principle of operation types 3374-15/-26/-36 * ) when actuator stem is fully extended type 3374 dimension h dimension h 1 -10 30 – -11 15 – -21 15 – -31 15 – -15 30 90 -26 15 75 -36 15 75 57 194 50* ) h 298 120 120 h 1 * ) 220 h 57 193 146 146.

Page 22: 4.1 Unpacking

22 eb 8331-4 en measures for preparation 4 measures for preparation after receiving the shipment, proceed as fol- lows: 1. Check the scope of delivery. Compare the shipment received against the deliv- ery note. 2. Check the shipment for transportation damage. Report any damage to samson and the forw...

Page 23: 5 Mounting And Start-Up

Eb 8331-4 en 23 mounting and start-up 5 mounting and start-up risk of malfunction due to incorrectly performed start-up. Perform start-up following the described sequence. 1. Mount the actuator onto the valve. Î see section 5.1. 2. Connect power supply. Î see section 5.2. 3. Initialize the actuator....

Page 24: Grated Yoke

24 eb 8331-4 en measures for preparation 5.1.2 construction with inte- grated yoke attachment − series v2001 valves (dn 15 to 80) − type 3260 (dn 65 to 150) − type 3214 (dn 65 to 100) Î refer to fig. 5 4. Remove protective covers and unscrew nut (6) from the valve. 5. Connect the power supply to the...

Page 25

Eb 8331-4 en 25 measures for preparation 3. Connect the power supply as described in section 5.2. 4. Retract actuator stem (3) as described in section 3.3. 5. Place actuator onto the valve bonnet (2.3) and secure using the ring nut (7). 6. When the stem connector nut (8) rests on the actuator stem, ...

Page 26: Supply

26 eb 8331-4 en measures for preparation 5.2 electrical connections risk of electric shock. − upon installation of the electric cables, you are required to observe the regulations concerning low-voltage installations ac- cording to din vde 0100 as well as the regulations of your local power supplier...

Page 27

Eb 8331-4 en 27 measures for preparation + out i – out b + l n – out u/i + out u + 1 in – 1 in + 2 in – 2 in + 3 in – 3 in + 4 in out b – 4 in binary output inputs 1 to 4 (see section 8.4.2 for assignment) 0/4 to 20 ma 0/2 to 10 v position feedback power supply (depending on version 24 v ac and dc; ...

Page 28: 6 Additional Functions

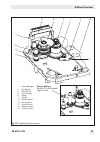

28 eb 8331-4 en additional functions 6 additional functions 6.1 mechanical limit contacts 6.1.1 installing the limit contacts Î when ordering the limit contacts, state the configuration id and the type designation of the actuator. Both specifications are written on the nameplate (see section 2.1). Î...

Page 29: 6 Additional Functions

Eb 8331-4 en 29 additional functions 6 additional functions 6.1 mechanical limit contacts 6.1.1 installing the limit contacts Î when ordering the limit contacts, state the configuration id and the type designation of the actuator. Both specifications are written on the nameplate (see section 2.1). Î...

Page 30

30 eb 8331-4 en additional functions 1. Undo screws on housing cover and take the cover off the actuator. 2. Move the actuator stem to the end position depending on the fail-safe action "actua- tor stem extends" or "actuator stem re- tracts” (see section 3.3). 3. Remove serrated ring and shim from s...

Page 31

Eb 8331-4 en 31 additional functions 1. Undo screws on housing cover and take the cover off the actuator. 2. Move the actuator stem to the end position depending on the fail-safe action "actua- tor stem extends" or "actuator stem re- tracts” (see section 3.3). 3. Remove serrated ring and shim from s...

Page 32: Tacts

32 eb 8331-4 en additional functions 11. Replace cover. Briefly turn the fastening screws counterclockwise with a screw- driver to center them. Then fasten down the cover by tightening the screws. 6.1.2 adjusting the limit con- tacts to undo the screws on the housing cover, use a pozidriv pz2 screwd...

Page 33: Tacts

Eb 8331-4 en 33 additional functions driver to center them. Then fasten down the cover by tightening the screws. 6.2.2 adjusting the limit con- tacts the electronic limit contacts are adjusted at the operating controls of the actuator (see section 3.5). See section 9.8 on how to ad- just them..

Page 34: 6.3 Setting Up Modbus-Rtu

34 eb 8331-4 en additional functions 6.3 setting up modbus-rtu communication the electric actuator can be connected to a control station over modbus and can be con- figured using trovis-view. For this pur - pose, the actuator with firmware version 3.10 and higher can be fitted with an rs- 485 module...

Page 35

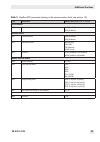

Eb 8331-4 en 35 additional functions table 5: modbus-rtu parameter (setting in the communication level, see section 12) code parameters display/select (select esc to cancel) serial interface a51 communication enab (enabled) disa (disabled) interface module a61 communication enab (enabled) disa (disa...

Page 36: 7 Operation

36 eb 8331-4 en operation 7 operation 7.1 display after switching on the power supply, the current firmware is displayed for two seconds. Af - terwards, the start screen appears. % on starting up the actuator for the first time, the start screen and the error reading e00 (no initialization performed...

Page 37

Eb 8331-4 en 37 operation table 6: display icons operating modes automatic mode manual mode bar graph the bars indicate the set point deviation that depends on the sign (+/–) and the value. One bar element appears per 1 % set point deviation. Example: bar graph indicates a +3 % set point deviation. ...

Page 38: 7.2 Rotary Pushbutton

38 eb 8331-4 en operation 7.2 rotary pushbutton the rotary pushbutton is used for on-site operation of the actuator. Turn : select/change codes and values press : confirm setting/change changed parameters are immediately effective! The process is directly affected by these changes. First check any c...

Page 39: 7.3 Serial Interface

Eb 8331-4 en 39 operation 7.3 serial interface the actuator can be configured with the trovis-view software. In this case, the seri- al interface on the actuator is used to con- nect the actuator to the computer. The trovis-view software enables the user to easily configure the positioner as well as...

Page 40

40 eb 8331-4 en operation 7.4 optional key number protection to change parameters in the configuration level, a key number can be activated in the actua - tor over code c94. When the key number function is activated, the key number must be en - tered before the parameter setting can be changed. If a...

Page 41

Eb 8331-4 en 41 operation after entering the key number, the corresponding levels are enabled for five minutes (indicat - ed by icon). The levels are automatically locked again after five minutes. Levels can also be locked again: select code 9 again. Off is displayed. After confirming it by pressing...

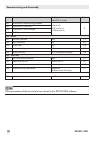

Page 42: 8 Operating Level

42 eb 8331-4 en operating level 8 operating level the operating level is active while the actuator is in the automatic mode. In this level, import- ant information on the operation is shown, the operating mode is selected and the initializa- tion started. The other levels are accessible from the ope...

Page 43: 8.2 Adapting The Display

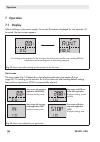

Eb 8331-4 en 43 operating level 8.2 adapting the display 8.2.1 reading direction to adapt the reading on the display to the mounting situation of the actuator, the display con- tents can be turned by 180° in code 4. Code description we adjustment range 4 reading direction disp disp, disp on changing...

Page 44

44 eb 8331-4 en operating level 8.3 initializing the actuator risk of injury due to the actuator stem extending or retracting. Do not touch or block the actuator stem. The process is disturbed by the movement of the actuator stem. Do not perform the initialization while the process is running. First...

Page 45: 8.4 Applications

Eb 8331-4 en 45 operating level 8.4 applications the actuator's application can be selected from one of the following applications: − positioner (posi) − pid controller (pid) − two-step mode (2stp) − three-step mode (3stp) − temperature closed-loop control upon input signal failure (posf) − dependin...

Page 46

46 eb 8331-4 en operating level pid controller application the set point adjustable at the actuator is used to position the valve using a pid algorithm. The input signal is used as the process variable. The pid controller is adjusted using the pa- rameters: proportional-action coefficient kp, reset ...

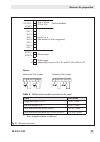

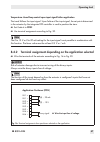

Page 47

Eb 8331-4 en 47 operating level temperature closed-loop control upon input signal failure application the travel follows the input signal. Upon failure of the input signal, the set point determined in the actuator by the integrated pid controller is used to position the stem. Î set code 6 to posf . ...

Page 48

48 eb 8331-4 en operating level application: pid controller (pid) – + 1 in – 1 in + 2 in – 2 in + 3 in – 3 in + 4 in 4 in 0(4) ... 20 ma 0(2) ... 10 v pt 1000 binary signal Î wire the input free of voltage. Fig. 17: terminal assignment when pid controller selected as the application wire all the inp...

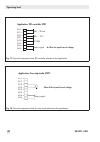

Page 49

Eb 8331-4 en 49 operating level application: three-step mode (3stp) – + 1 in – 1 in + 2 in – 2 in + 3 in – 3 in + 4 in 4 in + – binary signal three-wire connection: four-wire connection: – + 1 in – 1 in + 2 in – 2 in + 3 in – 3 in + 4 in 4 in binary signal retracts : extends : wire all the inputs fr...

Page 50: Configuration Level

50 eb 8331-4 en configuration level 9 configuration level the actuator is adapted to its control task in the configuration level. The codes in this level have a 'c' prefix to identify them. All the parameters of the configuration level are listed in section 17.2.2 on page 83. 9.1 activating and sett...

Page 51: 9.2 Input Signal

Eb 8331-4 en 51 configuration level 9.2 input signal the input signal determines the actuator stem position. Either a current or voltage signal can be applied to the input depending on the configuration in code c01. The default lower and upper range values of the input signal are 2 to 10 v or 4 to 2...

Page 52: 9.3 Operating Direction

52 eb 8331-4 en configuration level − internal positioning value (c32 = int): the actuator stem moves to the position specified in code c33 upon failure of the input signal. − last position (c32 = last): the actuator stem remains in the last position that the valve moved to before failure of the inp...

Page 53: 9.4 End Position Guiding

Eb 8331-4 en 53 configuration level a b ab ab a b a ab b ab a b mixing valve for mixing service diverting valve for mixing service for diverting service for diverting service flow pipe flow pipe flow pipe flow pipe return flow pipe return flow pipe return flow pipe return flow pipe fig. 21: operatin...

Page 54: 9.4.2

54 eb 8331-4 en configuration level 9.4.2 operating direction increasing/decreasing − end position guiding (stem retracts) (c35): the actuator stem moves the valve to the low- er end position if the input signal reaches the value entered in this code. Setting c35 = 100.0 % causes this function with ...

Page 55: 9.6 Binary Input

Eb 8331-4 en 55 configuration level 9.6 binary input the function of the binary input can be configured as required. Code c12 is used to deter - mine the switching state for the active function. C12 = ninv: the binary input is active when the input terminals in 4 +/in 4 – are connected with each oth...

Page 56: 9.7 Binary Output

56 eb 8331-4 en configuration level 9.7 binary output the binary output is a floating contact. The function and switching state of the binary input can be configured as required. − inactive (c15 = none): no function is assigned to the binary output. − error indication (c15 = fail): when an error ( i...

Page 57: 9.9 Restart

Eb 8331-4 en 57 configuration level 9.8 electronic limit contacts the electronic limit contact can be triggered by the actuator stem position exceeding or fall- ing below an adjustable switching point. − triggered when the position exceeds the switching point: the limit contact is activated when the...

Page 58: 9.10 Blockage

58 eb 8331-4 en configuration level − fixed positioning value (c43 = fix): the actuator switches to the manual mode and moves the actuator stem to the fixed positioning value for restart . − stop in manual level (c43 = stop): the actuator switches to the manual mode and sets the last positioning val...

Page 59: 9.11 Travel

Eb 8331-4 en 59 configuration level 9.11 travel limited travel range (c63) the limited travel range parameter determines in % how far the actuator stem can move at the maximum. The rated travel (c61) acts as the reference. When c63 = 100.0 %, the travel range is not limited. Code description we adju...

Page 60: 9.12 Characteristic

60 eb 8331-4 en configuration level 9.12 characteristic the characteristic expresses the relation between the input signal and the actuator stem's po- sition. − linear (c71 = lin): the travel is proportional to the input signal. Travel y [%] 0 50 100 0 50 100 input signal x [%] − equal percentage (c...

Page 61

Eb 8331-4 en 61 configuration level code description we adjustment range c71 characteristic type lin lin (linear) equa (equal percentage) inv (reverse equal percentage) user (user-defined) when c71 = user: c72 = use user-defined characteristic h0, y0 input signal x0, travel value y0 0.0 % 0.0 to 100...

Page 62: 9.13

62 eb 8331-4 en configuration level 9.13 fast configuration level code 8 opens the fast configuration level, which allows the selection of several parameter configurations. Code description display adjustment range 8 fast configuration fco in, out, dir (see table below) the settings for the followin...

Page 63

Eb 8331-4 en 63 configuration level open fast configuration level 1. Turn (when the start screen appears) to select code 8 (dis- play: fco). 2. Press . First setting that can be selected appears. Selectable setting Î code in, input signal 0 to 20 ma select setting 3. Press to select setting (indicat...

Page 64: 9.14 Plausibility Error

64 eb 8331-4 en configuration level 9.14 plausibility error due to an invalid combination of interacting parameters in the configuration level, a plausi - bility error arises which is indicated by plau blinking on the display. A correction of the in- teracting parameters resets the error message. Ca...

Page 65

Eb 8331-4 en 65 configuration level − invalid limits of process variable range (code c88/c89): the set point (code c81) is within the range defined by the lower (code c86) and upper adjustment limits (code c87). The lower limit of process variable range (code c88) has a greater value than the lower ...

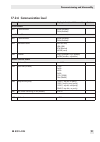

Page 66: 10 Information Level

66 eb 8331-4 en information level 10 information level in the information level, all the actuator data important for closed-loop operation are dis- played. Codes of the information level have an 'i' prefix to identify them. All the parameters of the information level are listed in section 17.2.4 on ...

Page 67: 11 Service Level

Eb 8331-4 en 67 service level 11 service level the service level contains detailed information on the actuator and its operating state. Addi- tionally, various test functions can be performed in this level. Codes in the diagnostic level have a 'd' prefix to identify them. All the parameters of the s...

Page 68

68 eb 8331-4 en service level 11.2 starting zero calibration risk of injury due to the actuator stem extending or retracting. Do not touch or block the actuator stem. The actuator stem moves to the 0 % end position. Following this, the actuator changes to closed-loop operation and moves the actuator...

Page 69: 11.6 Testing The Display

Eb 8331-4 en 69 service level 11.5 loading default settings all the parameters of the configuration level can be reset to their default settings (we). Code description adjustment range d54 load default settings in actuator def 11.6 testing the display all the segments of the display are shown during...

Page 70: 12 Communication Level

70 eb 8331-4 en communication level 11.7 measuring the transit time risk of injury due to the actuator stem extending or retracting. Do not touch or block the actuator stem. The process is disturbed by the movement of the actuator stem. Do not perform the initialization while the process is running....

Page 71

Eb 8331-4 en 71 communication level 12.1 activating and setting parameters activate the communication level 1. Turn (when the start screen appears) to select code 23. Î code a51 is displayed. Activating parameters Î turn to select the required code. Setting parameters 1. Press . The reading blinks o...

Page 72: 13 Memory Pen

72 eb 8331-4 en memory pen 13 memory pen the memory pen is optional (accessories) and is used to store and transfer data: − memory pen-64 (order no. 1400-9753) the memory pen can be configured in trovis-view. The following functions for the actuator can be selected: − read data from the memory pen −...

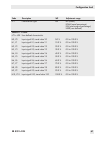

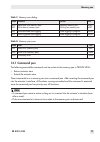

Page 73: 13.1 Command Pen

Eb 8331-4 en 73 memory pen table 7: memory pen dialog code function action text s02/ s03 read data from memory pen/ write data to memory pen reading memory pen/ writing on memory pen read writ s10 time-controlled data logging data logging in progress tlog s11 event-triggered data logging data loggin...

Page 74

74 eb 8331-4 en memory pen using the command pen 1. Open the actuator cover. 2. Insert the command pen into the serial interface of the actuator. Î the actuator automatically recognizes the command pen. The dialog for the command pen is displayed. The function (command) selected in trovis-view is re...

Page 75: 14 Servicing

Eb 8331-4 en 75 servicing 14 servicing the electric actuator was checked by samson before it left the factory. − the product warranty becomes void if service or repair work not described in these instructions is performed without prior agreement by samson's after-sales service department. − only use...

Page 76: 15 Malfunctions

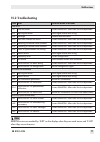

76 eb 8331-4 en malfunctions 15 malfunctions 15.1 error messages active errors are added at the end of the top operating level. An error is indicated by the display blinking and alternating between the start screen and the indicated error with the error icon. If several errors have occurred, only th...

Page 77: 15.2 Troubleshooting

Eb 8331-4 en 77 malfunctions 15.2 troubleshooting code error corrective action to be taken fatal error ef final test failed contact samson's after-sales service department. E01 input signal failure check signal source and wiring e02 blockage unblock stem and valve. E03 both limit contacts are active...

Page 78: 15.3 Emergency Action

78 eb 8331-4 en malfunctions 15.3 emergency action the valve, on which the electric actuator with fail-safe action is mounted, is moved to its fail-safe position upon power supply failure (see section 3.1). The plant operator is responsible for emer- gency action to be taken in the plant. Emergency ...

Page 79: 16 Decommissioning and

Eb 8331-4 en 79 decommissioning and disassembly 16 decommissioning and disassembly risk of electric shock. Before disconnecting live wires, switch off the power supply at the actuator and protect it against unintentional reconnection. Risk of personal injury due to residual pro - cess medium in the ...

Page 80: 16.3 Disposal

80 eb 8331-4 en decommissioning and disassembly 16.3 disposal Î observe local, national and internation- al refuse regulations. Î do not dispose of components, lubricants and hazardous substances together with your other household waste..

Page 81: 17 Annex

Eb 8331-4 en 81 annex 17 annex 17.1 after-sales service contact samson's after-sales service de- partment for support concerning service or repair work or when malfunctions or defects arise. E-mail you can reach the after-sales service de- partment at aftersalesservice@samson. Addresses of samson ag...

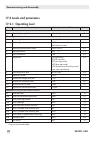

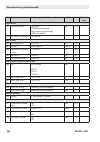

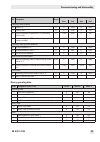

Page 82: 17.2 Levels And Parameters

82 eb 8331-4 en decommissioning and disassembly 17.2 levels and parameters 17.2.1 operating level code parameters display/select (select esc to cancel) section start screen 0/1 depending on application u read only 7 operating level 1 positioning value u read only 2 operating mode auto (automatic mod...

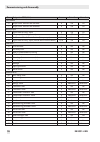

Page 83: 17.2.2

Eb 8331-4 en 83 decommissioning and disassembly code parameters display/select (select esc to cancel) section eeprom error (can only be seen when error exists) e11 error: no basic setting ntrv 15 e12 error: no configuration nco 15 e13 error: no calibration ncal 15 e14 error: no potentiometer calibra...

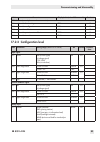

Page 84

84 eb 8331-4 en decommissioning and disassembly code parameters setting range (select esc to cancel) we section customer data c12 logic ninv (not inverted) inv (inverted) ninv 9.6 binary output c15 function none (inactive) fail (indicate error during operation) lim (electronic limit contact) prio (p...

Page 85

Eb 8331-4 en 85 decommissioning and disassembly code parameters setting range (select esc to cancel) we section customer data c35 end position guiding (stem retracts) 50.0 to 100.0 % 97.0 % 9.4 c36 end position guiding (stem extends) 0.0 to 49.9 % 1.0 % 9.4 c37 superimposing an error message yes (er...

Page 86

86 eb 8331-4 en decommissioning and disassembly code parameters setting range (select esc to cancel) we section customer data characteristic c71 characteristic type lin (linear) equa (equal percentage) inv (reverse equal percentage) user (user-defined) lin 9.12 c72 user-defined characteristic user-d...

Page 87

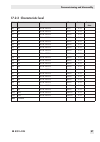

Eb 8331-4 en 87 decommissioning and disassembly 17.2.3 characteristic level code parameters selection we section customer data h0 x0 0.0 to 100.0 % 0.0 % 9.12 y0 y0 0.0 to 100.0 % 0.0 % 9.12 h1 x1 0.0 to 100.0 % 10.0 % 9.12 y1 y1 0.0 to 100.0 % 10.0 % 9.12 h2 x2 0.0 to 100.0 % 20.0 % 9.12 y2 y2 0.0 ...

Page 88: 17.2.4 Information Level

88 eb 8331-4 en decommissioning and disassembly 17.2.4 information level code parameters (read only) reading/unit section input signal i01 lower range value of input signal v or ma 1) 9.2 i02 upper range value of input signal v or ma 1) 9.2 i03 positioning value %/state 9.2 i04 unit v or ma 1) 9.2 c...

Page 89: 17.2.5 Service Level

Eb 8331-4 en 89 decommissioning and disassembly code parameters (read only) reading/unit section diagnostics i61 travel cycles from 10000 onwards, reading in k i62 temperature inside actuator °c i63 lowest temperature inside actuator °c i64 highest temperature inside actuator [°c] °c i00 exit inform...

Page 90

90 eb 8331-4 en decommissioning and disassembly code parameters display/selection (select esc to cancel) section d42 eeprom error: manufacturing parameters u read only e rd (read error) e wr (write error) 15 d43 eeprom error: transit time d44 eeprom error: status messages d45 eeprom error: statistic...

Page 91

Eb 8331-4 en 91 decommissioning and disassembly 17.2.6 communication level code parameters display/select (select esc to cancel) section serial interface a51 communication enab (enabled) disa (disabled) interface module a61 communication enab (enabled) disa (disabled) a62 interface module 485 (rs-48...

Page 92

92 eb 8331-4 en decommissioning and disassembly 17.2.7 further codes on the display code function state text f11 zero calibration active zero f12 initialization active init f13 transit time measurement active run f41 blocking protection active bpro f42 blockage removal active brem f61 retract actuat...

Page 93

Eb 8331-4 en 93 decommissioning and disassembly 17.2.8 excerpt from modbus list the electric actuator in firmware version 3.10 and higher can be fitted with an rs-485 mod - ule to use the modbus-rtu protocol. This protocol is a master/slave protocol. In this case, a control station is the master and...

Page 94

94 eb 8331-4 en decommissioning and disassembly data are saved in a non-volatile eeprom. This type of memory has a limited life of at least 100,000 write operations per memory address. It is almost impossible to exceed this limita - tion if configurations and data are only changed manually using tro...

Page 95

Eb 8331-4 en 95 decommissioning and disassembly hr designation access transmission range indicating range start end start end operating values (outputs) 18 travel in % r 0 1000 0 100.0 19 travel in mm r 0 1000 0 100 20 set point deviation of positioner in % (positioning value/travel) r –1000 1000 0 ...

Page 96

96 eb 8331-4 en decommissioning and disassembly class designation coils (1-bit) access status 0 status 1 limit contact 10 torque switch: actuator stem retracted r off on 11 torque switch: actuator stem extended r off on binary output 12 logical state of binary output r off on 13 binary output (switc...

Page 97

Eb 8331-4 en 97 decommissioning and disassembly class designation coils (1-bit) access status 0 status 1 functions 43 zero calibration active r no yes 44 initialization active r no yes 45 blocking protection active r no yes 46 blockage removal active r no yes states 48 active controller (only applic...

Page 98

Index 98 eb 8331-4 en index a accessories .......................................... 39 actuator attachment to the valve ................... 23 design and principle of operation .... 12 initialize ......................................... 44 restart ........................................... 68 thr...

Page 99

Index eb 8331-4 en 99 n nameplate .......................................... 11 o operating controls display .......................................... 36 menu control .................................. 38 rotary pushbutton ........................... 38 serial interface ...............................

Page 100

100 eb 8331-4 en.

Page 101

Eb 8331-4 en 101 service key number 1732 customized key number.

Page 104: Eb 8331-4 En

Samson ag · mess- und regeltechnik weismüllerstraße 3 · 60314 frankfurt am main, germany phone: +49 69 4009-0 · fax: +49 69 4009-1507 samson@samson.De · www.Samson.De eb 8331-4 en 2017-11-08 · engl ish.