- DL manuals

- Samson

- Controller

- 3374

- Mounting And Operating Instructions

Samson 3374 Mounting And Operating Instructions

Summary of 3374

Page 1

Mounting and operating instructions eb 8331-3 en tr anslat ion of original instruct ions edition december 2012 type 3374 electric actuator three-step version.

Page 2

2 eb 8331-3 en note on these mounting and operating instructions these mounting and operating instructions assist you in mounting and operating the device safely. The instructions are binding for handling samson devices. Î for the safe and proper use of these instructions, read them carefully and ke...

Page 3

Contents eb 8331-3 en 3 1 safety instructions and measures ...................................................................5 1.1 notes on possible severe personal injury .........................................................7 1.2 notes on possible personal injury .................................

Page 4

4 eb 8331-3 en contents 7 servicing.....................................................................................................32 7.1 preparation for return shipment .....................................................................32 8 malfunctions .........................................

Page 5

Eb 8331-3 en 5 safety instructions and measures 1 safety instructions and measures thetype 3374electricactuatorisdesignedtooperateamountedglobevalveusedin industrial applications as well as in heating, ventilation and air-conditioning systems. The actuatorisdesignedtooperateunderexactlydefinedcondit...

Page 6

6 eb 8331-3 en safety instructions and measures revisions and other modifications revisions,conversionsorothermodificationstotheproductarenotauthorizedbysamson. Theyareperformedattheuser'sownriskandmayleadtosafetyhazards,forexample. Furthermore, the product may no longer meet the requirements for it...

Page 7

Eb 8331-3 en 7 safety instructions and measures referenced documentation the following documents apply in addition to these mounting and operating instructions: − mounting and operating instructions of the valve on which the electric actuator is mounted, e.G. For samson valves: u eb 5861fortype 3260...

Page 8

8 eb 8331-3 en safety instructions and measures 1.2 notes on possible personal injury warning ! Crush hazard arising from moving parts. The electric actuator contains moving parts (actuator and plug stems), which can injure handsorfingersifinsertedintotheactuator. Î donotinserthandsorfingersintothey...

Page 9: 2 Markings On The Device

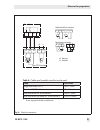

Eb 8331-3 en 9 markings on the device 2 markings on the device 2.1 nameplate samson 3374- 1 13 3 2 4 5 6 7 8 9 11 12 10 electric actuator var.-id serial no. Samson ag, germany u: p max : s: v: f f 0062 made in germany 1 type designation 2 configurationid 3 serial number 4 powersupply;powerlinefreque...

Page 10: Ration

10 eb 8331-3 en design and principle of operation 3 design and principle of ope- ration thetype 3374electricactuatorisusedin industrial plants as well as in heating, venti- lation and air-conditioning systems. Theactuatorissuitableforform-fitattach- ment to various samson valve series, de- pending o...

Page 11: 3.2 Additional Equipment

Eb 8331-3 en 11 design and principle of operation 3.2 additional equipment the actuator can be equipped with mechani- cal limit contacts or with resistance transmit- terstoinfluencethetasksofcontrolequip- ment. 3.2.1 mechanical limit cont- acts the two mechanical limit contacts can be ad- justed ind...

Page 12: 3.4 Technical Data

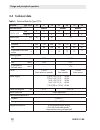

12 eb 8331-3 en design and principle of operation 3.4 technical data table 1: technical data for type 3374 actuator type 3374 -10 -11 -15 -21 -26 -31 -36 fail-safe action without extends retracts version with yoke • • • • ring nut • • • rated travel mm 30 15 30 15 transit time for rated travel stand...

Page 13

Eb 8331-3 en 13 design and principle of operation actuator type 3374 -10 -11 -15 -21 -26 -31 -36 overvoltage category iiaccordingtoen 60664 design and testing en 61010 class of protection iiaccordingtoen 61140 noise immunity en 61000-6-2,en 61326 noise emission en 61000-6-3,en 61326 compliance · man...

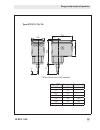

Page 14: 3.5 Dimensions In Mm

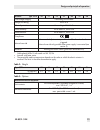

14 eb 8331-3 en design and principle of operation 3.5 dimensions in mm type 3374-10/-11/-21/-31 * ) when actuator stem is fully extended type 3374 dimension h -10 30 -11 15 -21 15 -31 15 -15 30 -26 15 -36 15 57 194 50* ) h 298 120 120 h 1 * ) 220 h 57 193 146 146.

Page 15

Eb 8331-3 en 15 design and principle of operation types 3374-15/-26/-36 * ) when actuator stem is fully extended type 3374 dimension h dimension h 1 -10 30 – -11 15 – -21 15 – -31 15 – -15 30 90 -26 15 75 -36 15 75 57 194 50* ) h 298 120 120 h 1 * ) 220 h 57 193 146 146.

Page 16: 4.1 Unpacking

16 eb 8331-3 en measures for preparation 4 measures for preparation after receiving the shipment, proceed as fol- lows: 1. Check the scope of delivery. Compare the shipment received against the delivery note. 2. Check the shipment for transportation damage. Report any damage to samson and the forwar...

Page 17: 5 Mounting and Start-Up

Eb 8331-3 en 17 mounting and start-up 5 mounting and start-up risk of malfunction due to incorrectly performed start-up. Perform start-up following the described sequence. 1. Mount the actuator onto the valve. Î seesection 5.1. 2. Connect power supply. Î seesection 5.2. 5.1 mounting the actuator ont...

Page 18: Rated Yoke

18 eb 8331-3 en measures for preparation 5.1.2 construction with integ- rated yoke attachment − seriesv2001valves(dn 15to80) − type3260(dn 65to150) − type 3214(dn 65to100) Î refertofig. 5 1. Remove protective covers and unscrew nut (6) from the valve. 2. Retract actuator stem (3) as described in sec...

Page 19

Eb 8331-3 en 19 measures for preparation 3. Retract actuator stem (3) as described in section 3.3. 4. Place actuator onto the valve bonnet (2.3) and secure using the ring nut (7). 5. When the stem connector nut (8) rests on the actuator stem, attach both stem connector clamps (4) and fasten with scr...

Page 20: Supply

20 eb 8331-3 en measures for preparation 5.2 electrical connections risk of electric shock. − upon installation of the electric cables, you are required to observe the regulations concerning low-voltage installations accor- ding to din vde 0100 as well as the regu- lations of your local power suppli...

Page 21

Eb 8331-3 en 21 measures for preparation table 4: cables and stranded wires that can be used cable cross section single-wireh05(07)v-u 1) 0.2to1.5 mm² fine-wireh05(07)v-k 1) 0.2to1.5 mm² withwireferruleacc.Todin 46228-1 0.25to1.5 mm² withwireferruleandsleeveacc.Todin 46228-4 0.25to0.75 mm² 1) 8 mmst...

Page 22: 6 Additional Functions

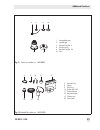

22 eb 8331-3 en additional functions 6 additional functions 6.1 mechanical limit contacts toinstallthelimitcontacts,thefollowingretrofitkitsarerequired: − basicunit:orderno.1400-8829(seefig. 9) − retrofitkit:orderno.1402-0898(seefig. 10) Î whenorderingthelimitcontacts,statetheconfigurationidandthety...

Page 23: 6 Additional Functions

Eb 8331-3 en 23 additional functions 6 additional functions 6.1 mechanical limit contacts toinstallthelimitcontacts,thefollowingretrofitkitsarerequired: − basicunit:orderno.1400-8829(seefig. 9) − retrofitkit:orderno.1402-0898(seefig. 10) Î whenorderingthelimitcontacts,statetheconfigurationidandthety...

Page 24

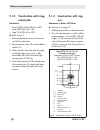

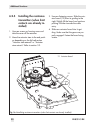

24 eb 8331-3 en additional functions Î refertofig. 11 1. Unscrew screws on housing cover and take the cover off the actuator. 2. Move the actuator stem to the end position depending on the fail-safe action "actua- tor stem extends" or "actuator stem re- tracts”(seesection 3.3). 3. Unscrew fastening ...

Page 25

Eb 8331-3 en 25 additional functions 1 2 3 4 8 12 13 17 20 11.1 19 11.2 18 1 intermediate gear 2 spindle gear 3 serrated ring 4 tension spring 8 spacer 11.1 spindle 1 11.2 spindle 2 12 actuator board 13 bearingsleeve 17 terminal board 18 adjustment gear 19 contact cams 20 cam holder fig. 11: install...

Page 26: Sistance Transmitters Are

26 eb 8331-3 en additional functions 6.1.2 retrofitting (when re- sistance transmitters are already installed) 1. Unscrew screws on housing cover and take the cover off the actuator. 2. Move the actuator stem to the end positi- on depending on the fail-safe action "actuator stem extends" or "actuato...

Page 27

Eb 8331-3 en 27 additional functions b 18 21 1 b 18 21 1 when actuator stem retracted when actuator stem extended 11.2 12 10 6 fig. 12: retrofitting limit contacts (when resistance transmitters are already installed) actuator stem retracted actuator stem extended 19 19 20 fig. 13: alignment of conta...

Page 28: Transmitters

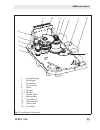

28 eb 8331-3 en additional functions 6.2 resistance transmitters 6.2.1 installing the resistance transmitters an actuator board with the corresponding resistance transmitters and gear wheels is re- quiredforaresistancetransmitterretrofit. Which actuator board is to be used depends on the actuator ty...

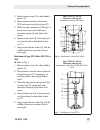

Page 29

Eb 8331-3 en 29 additional functions 1 intermediate gear 2 spindle gear 3 serrated ring 4 tension spring 6 serrated ring 10 shim 11.1 spindle 1 11.2 spindle 2 11.3 spindle 3 11.4 spindle 4 12 actuator board 13 bearingsleeve 22 gearforpotentiometer1 23 gearforpotentiometer2 11.2 6 4 10 3 1 12 2 13 11...

Page 30: Transmitters (When Limit

30 eb 8331-3 en additional functions 6.2.3 installing the resistance transmitters (when limit contacts are already in- stalled) 1. Unscrew screws on housing cover and take the cover off the actuator. 2. Move the actuator stem to the end positi- on depending on the fail-safe action "actuator stem ext...

Page 31: Transmitters

Eb 8331-3 en 31 additional functions 6.2.4 adjusting the resistance transmitters the gears of the resistance transmitters (22) and (23) must be put onto their shafts to cor- respond with the rated travel of the valve. The rated travel inscription 'a' 30 mm for ra- tedtravelor'b'for15 mmratedtravelmu...

Page 32: 7 Servicing

32 eb 8331-3 en servicing 7 servicing the electric actuator was checked by samson before it left the factory. − the product warranty becomes void if ser- vice or repair work not described in these instructions is performed without prior agreement by samson's after-sales ser- vice department. − only ...

Page 33: 8 Malfunctions

Eb 8331-3 en 33 malfunctions 8 malfunctions Î troubleshooting(seetable 5). Contact samson's after-sales service department for malfunctions not listed in the table. Table 5: troubleshooting error possible reasons recommended action actuator stem does not move. Actuator is blocked. Î check attachment...

Page 34: 9 Decommissioning and

34 eb 8331-3 en decommissioning and disassembly 9 decommissioning and disassembly risk of electric shock. Before disconnecting live wires, switch off the power supply at the actuator and protect it against unintentional reconnection. Risk of personal injury due to residual pro- cess medium in the va...

Page 35: 9.3 Disposal

Eb 8331-3 en 35 decommissioning and disassembly 9.3 disposal Î observe local, national and internatio- nal refuse regulations. Î do not dispose of components, lubricants andhazardoussubstancestogetherwith your other household waste..

Page 36: 10 Annex

36 eb 8331-3 en annex 10 annex 10.1 after-sales service contact samson's after-sales service de- partment for support concerning service or repair work or when malfunctions or defects arise. E-mail you can reach the after-sales service de- partment at aftersalesservice@samson. Addresses of samson ag...

Page 37

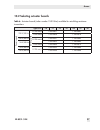

Eb 8331-3 en 37 annex 10.2 selecting actuator boards table 6: actuator boards (order number 1180-96xx) available for retrofitting resistance transmitters type 3374 -10 -11 -15 -21 -26 -31 -36 power supply 230 v/50 hz str oking speed 0.125 mm/s 1180-9601 1180-9607 0.25 mm/s 1180-9604 1180-9610 230 v/...

Page 38

38 eb 8331-3 en.

Page 39

Eb 8331-3 en 39.

Page 40: Eb 8331-3 En

Samson ag · mess- und regeltechnik weismüllerstraße 3 · 60314 frankfurt am main, germany phone: +49 69 4009-0 · fax: +49 69 4009-1507 samson@samson.De · www.Samson.De eb 8331-3 en 2017-11-20 · engl ish.