- DL manuals

- Samson

- Control Unit

- 3525

- Mounting And Operating Instructions

Samson 3525 Mounting And Operating Instructions

Summary of 3525

Page 1

Mounting and operating instructions eb 8823 en original instruct ions edition march 2017 type 3525 globe valve in combination with an actuator such as samson type 3571 pneumatic actuator ansi version.

Page 2

2 eb 8823 en note on these mounting and operating instructions these mounting and operating instructions assist you in mounting and operating the device safely. The instructions are binding for handling samson devices. Î for the safe and proper use of these instructions, read them carefully and keep...

Page 3

Contents eb 8823 en 3 1 safety instructions and safety measures .........................................................5 1.1 notes on possible severe personal injury .........................................................7 1.2 notes on possible personal injury ......................................

Page 4

4 eb 8823 en contents 7.2 compact version ..........................................................................................40 7.2.1 replacing the o-rings ..................................................................................40 7.2.2 replacing the packing ...........................

Page 5

Eb 8823 en 5 safety instructions and safety measures 1 safety instructions and safety measures intended use the samson type 3525 globe valve in combination with an actuator (e.G. Type 3571 pneumatic actuator) is designed to regulate the flow rate, pressure or temperature of liquids, gases or vapors....

Page 6

6 eb 8823 en safety instructions and safety measures personal protective equipment we recommend wearing the following protective equipment depending on the process medi- um: − protective clothing, gloves and eyewear in applications with hot, cold and/or corrosive media when working near or on the va...

Page 7

Eb 8823 en 7 safety instructions and safety measures referenced standards and regulations the samson type 3525 globe valve complies with the requirements of asme b16.34. 1.1 notes on possible severe personal injury danger ! Risk of bursting in pressure equipment. Control valves and pipelines are pre...

Page 8

8 eb 8823 en safety instructions and safety measures warning ! Risk of personal injury due to sudden escape of process medium. The valve has a safety bleed to detect damaged or worn o-rings. The process medium may escape suddenly and at high pressure. Î wear protective clothing, gloves and eyewear w...

Page 9

Eb 8823 en 9 safety instructions and safety measures 1.3 notes on possible property damage notice ! Risk of valve damage due to contamination (e.G. Solid particles) in the pipeline. The plant operator is responsible for cleaning the pipelines. Î flush the pipelines before start-up. Î observe the max...

Page 10: 2.1 Valve Nameplate

10 eb 8823 en markings on the control valve 2 markings on the control valve 2.1 valve nameplate made in usa samson 2 4 3 5 7 8 18 9 10 11 12 17 15 16 14 13 6 2 type designation 3 type version c: compact · s: standard 4 – 5 material 6 year of manufacture 7 order number with modification index 8 item ...

Page 11: 2.2 Actuator Nameplate

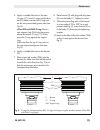

Eb 8823 en 11 markings on the control valve the valve nameplate is affixed to the rear of the body. 80 80 fig. 2: nameplate at the body 2.2 actuator nameplate see associated actuator documentation. 2.3 material number the seat and plug of the valves have an arti- cle number written on them. Specifyi...

Page 12: Ation

12 eb 8823 en design and principle of operation 3 design and principle of oper- ation the single-seated type 3525 globe valve is combined with a samson type 3571 pneumatic actuator (see fig. 4). The seat (4) and plug with plug stem (5) are assembled in the body (1). The plug stem is connected to the...

Page 13

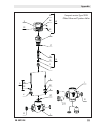

Eb 8823 en 13 design and principle of operation 17 17 244 safety bleed 82 84 1 2 4 29 16 127 224 7 36 17 83 5 60 a28 12 11 15 1 body 2 bonnet 4 seat 5 plug (29, 36) 7 guide bushing 11 spring 12 washer 15 packing (11, 12, 16) 16 v-ring packing 17 o-ring 29 plug head 36 plug stem 60 yoke assembly with...

Page 14: 3.1 Fail-Safe Positions

14 eb 8823 en design and principle of operation 3.1 fail-safe positions the fail-safe position depends on the actua- tor used. Depending on how the compression springs are arranged in the pneumatic actuator, the valve has two different fail-safe positions: actuator stem extends when the signal press...

Page 15: 3.2 Technical Data

Eb 8823 en 15 design and principle of operation 3.2 technical data the nameplates on the valve and actuator provide information on the control valve ver- sion. See section 2.1 and the actuator docu- mentation. More information is available in data sheet u t 8823. Temperature range the valve version ...

Page 16

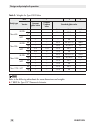

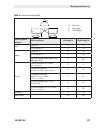

16 eb 8823 en design and principle of operation table 1: dimensions of type 3525 valve · standard version body type nps 1 2 3 version standard globe valve connection rf rjf npt rf rjf npt rf rjf l class 600 in 8.27 8.27 – 11.26 11.38 9.06 13.27 13.39 mm 210 210 – 286 289 230 337 340 class 900 in 10....

Page 17

Eb 8823 en 17 design and principle of operation table 2: dimensions of type 3525 valve · compact versions body type nps 1 version compact globe valve compact t-pattern valve connection npt npt l class 600 in – – mm class 900 in 4.69 4.69 1) mm 119 119 1) class 1500 class 1700 in – – mm h1 in 6.18 6....

Page 18

18 eb 8823 en design and principle of operation table 3: weights for type 3525 valve body type nps 1 2 3 version compact globe valve compact t-pattern valve standard globe valve class 600 rf/rtj lbs – – 34.4 60.6 83.8 kg – – 15.6 27.5 38 npt lbs – – – 44.1 – kg – – – 20 – class 900 rf/rtj lbs – – 45...

Page 19

Eb 8823 en 19.

Page 20: 4 Preparation

20 eb 8823 en preparation 4 preparation after receiving the shipment, proceed as fol- lows: 1. Check the scope of delivery. Compare the shipment received against the deliv- ery note. 2. Check the shipment for transportation damage. Report any damage to samson and the forwarding agent (re- fer to del...

Page 21: 4.2.1 Transporting

Eb 8823 en 21 preparation risk of valve damage due to incorrectly at- tached slings. The welded-on lifting eyelet on samson actuators (116 in²/750 cm²) is only intended for mounting and removing the actuator as well as lifting the actuator without valve. Do not use this lifting eyelet to lift the en...

Page 22

22 eb 8823 en preparation − prevent the control valve from tilting or tipping. − do not leave loads suspended when in- terrupting work for longer periods of time. − make sure that the axis of the pipeline is always horizontal during lifting and the axis of the plug stem is always vertical. − make su...

Page 23: 4.3 Storage

Eb 8823 en 23 preparation 4. Carefully lift the control valve. Check whether the lifting equipment and acces- sories can bear the weight. 5. Move the control valve at an even pace to the site of installation. 6. Install the valve into the pipeline (see sec- tion 5.2). 7. Version with flanges: check ...

Page 24

24 eb 8823 en preparation special storage instructions for soft parts soft parts, e.G. Actuator diaphragm − to keep soft parts in shape and to pre- vent cracking, do not bend them or hang them up. − we recommend a storage temperature of 59 °f (15 °c) for soft parts. − store soft parts away from lubr...

Page 25

Eb 8823 en 25.

Page 26: 5 Mounting and Start-Up

26 eb 8823 en mounting and start-up 5 mounting and start-up samson valves are delivered ready for use. In special cases, the valve and actuator are delivered separately and must be assem- bled on site. The procedure to mount and start up the valve are described in the follow- ing. Risk of valve dama...

Page 27

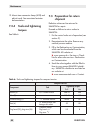

Eb 8823 en 27 mounting and start-up table 4: inlet and outlet lengths q a x nps b x nps state of process medium valve conditions inlet length a outlet length b gas ma ≤ 0.3 2 4 0.3 ≤ ma ≤ 0.7 2 10 vapor ma ≤ 0.3 1) 2 4 0.3 ≤ ma ≤ 0.7 1) 2 10 saturated steam (percentage of con- densate > 5 %) 2 20 li...

Page 28: 5.2.2 Additional Fittings

28 eb 8823 en mounting and start-up premature wear and leakage due to insuffi- cient support or suspension. Attach a suitable support or suspension on the valve, if necessary. Vent plugs vent plugs are screwed into the exhaust air ports of pneumatic, electropneumatic and electric devices. They ensur...

Page 29: 5.3 Quick Check

Eb 8823 en 29 mounting and start-up risk of valve damage due to a sudden pres- sure increase and resulting high flow veloci- ties. Slowly resume medium flow during start-up. 8. Check the valve to ensure it functions properly. Version with threaded ends 1. Proceed as described for version with flange...

Page 30: 6 Operation

30 eb 8823 en operation 6 operation immediately after completing mounting and start-up (see section 5), the valve is ready for use. Crush hazard arising from moving parts (ac- tuator and plug stem). Do not insert hands or finger into the yoke while the valve is in operation. Risk of personal injury ...

Page 31

Eb 8823 en 31.

Page 32: 7 Maintenance

32 eb 8823 en maintenance 7 maintenance the control valve is subject to normal wear, especially at the seat, plug and packing. De- pending on the operating conditions, check the valve at regular intervals to prevent pos- sible failure before it can occur. Samson’s after-sales service department can ...

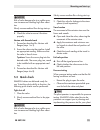

Page 33: 7.1 Standard Version

Eb 8823 en 33 maintenance risk of valve damage due to incorrect main- tenance or repair. Service and repair work must only be per- formed by trained staff. Risk of valve damage due to excessively high or low tightening torques. Excessively tightened torques lead to parts wearing out quicker. Parts t...

Page 34

34 eb 8823 en maintenance 1 body 2 bonnet 4 seat 5 plug (29, 36) 7 guide bushing 11 spring 12 washer 15 packing (11, 12, 16) 16 v-ring packing 17 o-ring 29 plug head 36 plug stem 60 yoke assembly with travel indicator (82, 83, 84) 82 screw 83 hanger 84 travel indicator scale 127 seat ring gasket 224...

Page 35

Eb 8823 en 35 maintenance 5. Apply a suitable lubricant to the new o-rings (17). Insert o-rings into the bon- net (2). Make sure that the o-rings rest on the non-pressurized groove side (see fig. 8). >class 900 with fkm o-ring: place a new support ring (244) into the groove above the bottom o-ring (...

Page 36

36 eb 8823 en maintenance 7.1.2 replacing the packing risk of valve damage due to abrasion. The plug and seat facings are very sensitive. Before unscrewing the bonnet from the body, apply a signal pressure to the actuator to slightly lift the plug off the seat. This prevents the plug and seat from b...

Page 37

Eb 8823 en 37 maintenance risk of leakage due to damaged packing chamber, packing parts and plug stem. When inserting the assembly into the bonnet make sure that the packing chamber, pack- ing parts and plug stem do not get dam- aged. Otherwise leakage may occur. 12. Thread guide bushing (7) into th...

Page 38: Plug

38 eb 8823 en maintenance 7.1.3 replacing the seat and plug risk of damage to the facing of the seat and plug due to abrasion and incorrect service or repair. The plug and seat facings are very sensitive. − before unscrewing the bonnet from the body, apply a signal pressure to the actua- tor to slig...

Page 39: Torques

Eb 8823 en 39 maintenance table 5: tools and tightening torques for standard version standard version component tool tightening torque lb-ft nm bonnet (2) – 221.27 to 346.65 300 to 470 guide bushing (7) 1¼” crowfoot wrench 66.38 90 seat (4) socket wrench nps 1: 1 7 / 16 ” nps 2 to 3: 1 7 / 8 ” nps 1...

Page 40: 7.2 Compact Version

40 eb 8823 en maintenance 7.2 compact version 7.2.1 replacing the o-rings risk of valve damage due to abrasion. The plug and seat facings are very sensitive. Before unscrewing the bonnet from the body, apply a signal pressure to the actuator to slightly lift the plug off the seat. This prevents the ...

Page 41

Eb 8823 en 41 maintenance 16 12 11 15 7 3 92 112 29 4 17 16 a7 a28 s a16 1 2 36 5 7 12 11 15 127 1 body 2 bonnet 3 yoke 4 seat 5 plug (29, 36) 7 guide bushing 11 spring 12 washer 15 packing (11, 12, 16) 16 v-ring packing 17 o-ring 29 plug head 36 plug stem 92 lock nut 112 screw plug 127 seat ring ga...

Page 42: Plug

42 eb 8823 en maintenance 9. Slide guide bushing (7) and packing parts over the plug stem. Make sure you observe the proper order (see fig. 12). 10. Carefully insert plug with plug stem, packing parts and guide bushing into the bonnet. Risk of leakage due to damaged packing chamber, packing parts an...

Page 43

Eb 8823 en 43 maintenance 4. Unscrew the seat (4) using a suitable tool. 5. Remove seat ring gasket (127) from the body (1) and carefully clean the sealing face. Insert a new seat ring gasket into the body. 6. Apply a suitable lubricant to the thread and the sealing cone of the new seat. 7. Screw in...

Page 44: Torques

44 eb 8823 en maintenance 12. Mount stem connector clamp (a28) and adjust travel. See associated actuator documentation. 7.2.4 tools and tightening torques see table 6. 7.3 preparation for return shipment defective valves can be returned to samson for repair. Proceed as follows to return valves to s...

Page 45: Operating Supplies

Eb 8823 en 45 maintenance 7.4 ordering spare parts and operating supplies spare parts see section 10.3 for details on spare parts. Lubricants details on suitable lubricants can be found in the parts list. For further information contact your nearest samson subsidiary or the samson after- sales servi...

Page 46: 8 Malfunctions

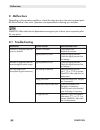

46 eb 8823 en malfunctions 8 malfunctions depending on the operating conditions, check the valve at certain intervals to prevent possi- ble failure before it can occur. Operators are responsible for drawing up a test plan. Samson’s after-sales service department can support you to draw up an inspect...

Page 47: 8.2 Emergency Action

Eb 8823 en 47 malfunctions malfunction possible reasons recommended action increased flow through closed valve (seat leakage) dirt or other foreign particles deposited between the seat and plug. Shut off the section of the pipe- line and flush the valve. Valve trim is worn out. Replace seat and plug...

Page 48: 9 Decommissioning and

48 eb 8823 en decommissioning and disassembly 9 decommissioning and disassembly risk of bursting in pressure equipment. Control valves and pipelines are pressure equipment. Improper opening can lead to valve components bursting. − before starting any work on the control valve, depressurize all plant...

Page 49: 9.3 Removing The Actuator

Eb 8823 en 49 decommissioning and disassembly version with threaded ends 1. Put the control valve out of operation (see section 9.1). 2. Unscrew the valve from the pipeline. 3. Remove the valve from the pipeline (see section 4.2). 9.3 removing the actuator from the valve see associated actuator docu...

Page 50: 10 Appendix

50 eb 8823 en appendix 10 appendix 10.1 customer inquiries contact samson’s after-sales service de- partment for support concerning mainte- nance or repair work or when malfunctions or defects arise. E-mail you can reach the after-sales service depart- ment at samson@samsongroupna.Com. Addresses of ...

Page 51

Eb 8823 en 51.

Page 52: 10.3 Spare Parts

52 eb 8823 en appendix 10.3 spare parts standard version type 3525 globe valve 1 body 2 bonnet 4 seat 5 plug (29, 36) 7 guide bushing 11 spring 12 washer 15 packing (11, 12, 16) 16 v-ring packing 17 o-ring 29 plug head 36 plug stem 60 yoke assembly with travel indicator (82, 83, 84) 82 screw 83 hang...

Page 53

Eb 8823 en 53 appendix 84 83 82 29 36 60 5 2 17 11 7 16 224 12 4 1 91 1 15 127 91 244 standard version type 3525 globe valve.

Page 54

54 eb 8823 en appendix compact version type 3525 globe valve and t-pattern valve 1 body 2 bonnet 3 yoke 4 seat 5 plug (29, 36) 7 guide bushing 11 spring 12 washer 15 packing (11, 12, 16) 16 v-ring packing 17 o-ring 29 plug head 36 plug stem 60 yoke assembly with travel indicator (82, 83, 84) 82 scre...

Page 55

Eb 8823 en 55 appendix 1 91 112 83 3 84 82 2 17 16 7 4 127 1 91 29 11 36 92 60 12 5 15 5 221 4 compact version type 3525 globe valve and t-pattern valve.

Page 56: Eb 8823 En

Samson controls inc. 4111 cedar boulevard · baytown, texas 77523-8588 phone: +1 281 383-3677 · fax: +1 281 383-3690 samson@samsongroupna.Com · www.Samsoncontrols.Com eb 8823 en 2017-03-15 · engl ish.