- DL manuals

- Samson

- Valve Positioners

- 3725 series

- Mounting And Operating Instructions

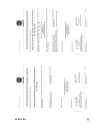

Samson 3725 series Mounting And Operating Instructions - 3.3 Travel Tables

20

EB 8394 EN

Design and principle of operation

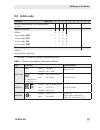

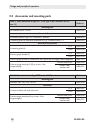

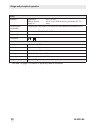

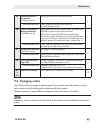

3.3 Travel tables

The M lever is included in the scope of delivery.

Direct attachment to Type 3277-5 and Type 3277 Actuators

Actuator size

Rated travel

Adjustment range at positioner

Required

lever

Assigned

pin position

[cm²]

[mm]

Min.

Travel

Max.

120

7.5

5.0 mm

to

16.0 mm

M

25

120/240/350

15

7.0 mm

to

22.0 mm

M

35

355/700

30

10.0 mm

to

32.0 mm

M

50

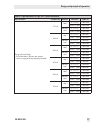

Direct attachment to Type 2780-2 Actuator

Actuator size

Rated travel

Adjustment range at positioner

Required

lever

Assigned

pin position

[cm²]

[mm]

Min.

Travel

Max.

120

6/12

5.0 mm

to

16.0 mm

M

25

120

15

7.0 mm

to

22.0 mm

M

35

Attachment according to IEC 60534-6 (NAMUR)

SAMSON Type 3271 Actuator

Travel of other valves

Required

lever

Assigned

pin position

Size [cm²]

Rated travel

[mm]

Min.

Max.

120

7.5

5.0 mm

16.0/25.0

1)

mm

M

25

120/240/350

15

7.0 mm

22.0/35.0

1)

mm

M

35

700

7.5

700/355

15/30

10.0 mm

32.0/50.0

1)

mm

M

50

1)

When 'MAX' is selected as the nominal range (P4 code, see page 68)

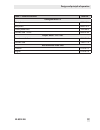

Attachment to rotary actuators according to VDI/VDE 3845

Rotary actuators

Required

lever

Assigned

pin position

Min.

Opening angle

Max.

24°

to

100°

M

90°

Note

Summary of 3725 series

Page 1

Mounting and operating instructions eb 8394 en firmware version 1.1x tr anslat ion of original instruct ions edition june 2014 series 3725 type 3725 electropneumatic positioner.

Page 2

2 eb 8394 en note on these mounting and operating instructions these mounting and operating instructions assist you in mounting and operating the device safely. The instructions are binding for handling samson devices. Î for the safe and proper use of these instructions, read them carefully and keep...

Page 3

Contents eb 8394 en 3 1 safety instructions and measures ...................................................................6 1.1 notes on possible severe personal injury .........................................................9 1.2 notes on possible personal injury ...................................

Page 4

4 eb 8394 en contents 6 operation ...................................................................................................48 6.1 operating controls .......................................................................................48 6.1.1 capacitive keys ................................

Page 5

Eb 8394 en 5 contents firmware revisions 1.02 (old) 1.03 (new) internal revisions 1.03 (old) 1.10 (new) setting of the travel in steps of 0.5 mm (p4 parameter code) monitoring of the end stops only during initialization and in manual mode to suppress common-mode interference on the signal lines, the...

Page 6

6 eb 8394 en safety instructions and measures 1 safety instructions and measures intended use the samson type 3725 positioner is mounted on pneumatic control valves and is used to assign the valve position to the control signal. The device is designed to operate under exact- ly defined conditions (e...

Page 7

Eb 8394 en 7 safety instructions and measures personal protective equipment no personal protective equipment is required for the direct handling of the positioner. Work on the control valve may be necessary when mounting or removing the positioner. Î observe the requirements for personal protective ...

Page 8

8 eb 8394 en safety instructions and measures servicing explosion-protected devices if a part of the device on which the explosion protection is based needs to be serviced, the device must not be put back into operation until a qualified inspector has assessed it accord- ing to explosion protection ...

Page 9

Eb 8394 en 9 safety instructions and measures 1.1 notes on possible severe personal injury danger ! Risk of the formation of an explosive atmosphere. Incorrect installation, operation, or maintenance of the positioner in potentially explosive atmospheres may lead to ignition of the atmosphere and ca...

Page 10

10 eb 8394 en safety instructions and measures 1.2 notes on possible personal injury warning ! Risk of personal injury due to moving parts on the valve. During initialization of the positioner and during operation, the actuator stem moves through its entire travel range. Injury to hands or fingers i...

Page 11

Eb 8394 en 11 safety instructions and measures malfunction due to initialization not yet completed. The initialization causes the positioner to be adapted to the mounting situation. After ini- tialization is completed, the positioner is ready to use. Î initialize the positioner on the first start-up...

Page 12: 2 Markings On The Device

12 eb 8394 en markings on the device 2 markings on the device 2.1 nameplate samson 3725 supply max. 10 bar / 150 psi input 4 ... 20 ma dc see technical data for ambient temperature -40 °c £ ta* £+80 °c positioner samson ag d-60314 frankfurt made in germany firmware model 3725 - 110 var.-id serial no...

Page 13: 2.2 Article Code

Eb 8394 en 13 markings on the device 2.2 article code positioner type 3725- x x x 0 0 0 0 x 0 0 with lcd and autotune, 4 to 20 ma reference variable explosion protection 1) without 0 0 0 intrinsic safety: atex 1 1 0 0 intrinsic safety: stcc 1 1 0 0 intrinsic safety: csa 1 3 0 0 intrinsic safety: gos...

Page 14: Ation

14 eb 8394 en design and principle of operation 3 design and principle of oper- ation the type 3725 electropneumatic positioner is mounted on pneumatic control valves and is used to assign the valve position (controlled variable x) to the control signal (reference variable w). The positioner compare...

Page 15

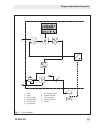

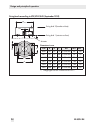

Eb 8394 en 15 design and principle of operation % s mm % mm q 3 4 11 6 7 8 10 1 w 9 x y 2 5 1 valve 7 air capacity booster 2 sensor 8 pressure regulator 3 a/d converter 9 fixed restriction 4 microcontroller 10 volume restriction 5 d/a converter 11 display 6 i/p converter fig. 1: circuit diagram.

Page 16

16 eb 8394 en design and principle of operation 3.2 accessories and mounting parts table 2: direct attachment to type 3277-5 and type 2780-2 actuators (see sec- tion 5.2) order no. Mounting parts for actuators up to 120 cm² 1402-0239 accessories for actuator switchover plate for type 3277-5xxxxxx.01...

Page 17

Eb 8394 en 17 design and principle of operation table 4: pipe connections for type 3277 (direct attachment) pipe connection actuator size material connection order no. Piping with screw fittings – for fail-safe action "actuator stem retracts" – with air purging of the top diaphragm chamber 175 cm² s...

Page 18

18 eb 8394 en design and principle of operation table 5: attachment to namur rib or attachment to rod-type yokes according to iec 60534-6 (section 5.3) order no. 5 to 50 mm travel, lever already on positioner for actuators 1402-0330 actuators from other manufacturers and type 3271 with 120 to 700 cm...

Page 19

Eb 8394 en 19 design and principle of operation table 7: general accessories order no. Cable gland m20x1.5 black plastic 8808-1011 blue plastic 8808-1012 nickel-plated brass 1890-4875 stainless steel 1.4305 8808-0160 adapter m20x1.5 to ½ npt powder-coated aluminum 0310-2149 stainless steel 1400-7114...

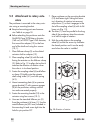

Page 20: 3.3 Travel Tables

20 eb 8394 en design and principle of operation 3.3 travel tables the m lever is included in the scope of delivery. Direct attachment to type 3277-5 and type 3277 actuators actuator size rated travel adjustment range at positioner required lever assigned pin position [cm²] [mm] min. Travel max. 120 ...

Page 21: 3.4 Technical Data

Eb 8394 en 21 design and principle of operation 3.4 technical data type 3725 positioner travel (adjustable) direct attachment to type 3277: 5 to 30 mm direct attachment to type 2780-2: 6/12/15 mm attachment to type 3372 actuator: 15/30 mm attachment according to iec 60534-6 (namur): 5 to 50 mm attac...

Page 22

22 eb 8394 en design and principle of operation safety influences temperature: ≤ 0.15 %/10 k effect of vibration: ≤ 0.25 % up to 2000 hz and 4 g according to iec 770 supply air: none electromagnetic compatibility complying with en 61000-6-2, en 61000-6-3 and namur recommendation ne 21 explosion prot...

Page 23: 3.5 Dimensions In Mm

Eb 8394 en 23 design and principle of operation 3.5 dimensions in mm 14 22 m20 x 1.5 157.5 108 87 42 21 62.50 25 14 22 m20 x 1.5 157.5 108 87 42 21 62.50 25 fig. 2: dimensional drawings for type 3725 positioner.

Page 24

24 eb 8394 en design and principle of operation fixing levels according to vdi/vde 3845 (september 2010) a m6 c b 25 m min Ød Ød fixing level 2 (bracket surface) fixing level 1 (actuator surface) actuator dimensions in mm size a b c Ød m min Ød 1) aa0 50 25 15 5.5 for m5 66 50 aa1 80 30 20 5.5 for m...

Page 25: 4.1 Unpacking

Eb 8394 en 25 measures for preparation 4 measures for preparation after receiving the shipment, proceed as fol- lows: 1. Check the scope of delivery. Compare the shipment received against the deliv- ery note. 2. Check the shipment for transportation damage. Report any transportation dam- age. 4.1 un...

Page 26: 5 Mounting and Start-Up

26 eb 8394 en mounting and start-up 5 mounting and start-up risk of malfunction due to incorrect sequence of mounting, installation, and start-up. Observe the prescribed sequence. Î sequence to be kept on mounting, install- ing, and starting up the positioner: 1. Remove the protective caps from the ...

Page 27

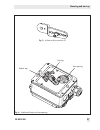

Eb 8394 en 27 mounting and start-up fig. 3: m lever with pin position 35 top stop bottom stop vent opening fig. 4: mechanical stops and vent opening.

Page 28: 5.2 Direct Attachment

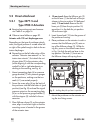

28 eb 8394 en mounting and start-up 5.2 direct attachment 5.2.1 type 3277-5 and type 2780-2 actuators Î required mounting parts and accesso- ries: table 2 on page 16. Î observe travel tables on page 20. Actuator with 120 cm² diaphragm area depending on the type of positioner attach- ment, the signal...

Page 29

Eb 8394 en 29 mounting and start-up 9 11 supply 9 output 38 5 6 7 3 2 1 15 6.1 1.1 1.2 8 4 16 1 lever 1.1 nut 1.2 disk spring 2 follower pin 3 follower clamp 4 screw plug 5 stopper 6 connecting plate 6.1 seals 7 pressure gauge bracket 8 pressure gauge mounting kit 9 switchover plate (actuator) 11 co...

Page 30

30 eb 8394 en mounting and start-up 8. Mount cover (11) on the other side. Make sure that the vent plug is located at the bottom when the control valve is in- stalled to allow any condensed water that collects to drain off (fig. 7). Additional solenoid valve if a solenoid valve is additionally mount...

Page 31

Eb 8394 en 31 mounting and start-up screw plug (4) (signal pressure port) park position fastening screw fig. 8: signal pressure port and park position for screw plug.

Page 32: 5.2.2 Type 3277 Actuator

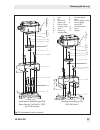

32 eb 8394 en mounting and start-up 5.2.2 type 3277 actuator Î required mounting parts and accesso- ries: table 3 on page 16. Î observe travel tables on page 20. Actuators with 240 to 700 cm² effective areas the positioner can be mounted either on the left or right side of the yoke. The signal pres-...

Page 33

Eb 8394 en 33 mounting and start-up 2 10 15 1 2 3 11 1.1 1.2 12.1 12 16 16 12.2 supply a ansicht a 1 2 10 15 1 2 3 11 1.1 1.2 12.1 12 16 16 12.2 supply a view a 1 1 m lever 1.1 nut 1.2 disk spring 2 follower pin 3 follower clamp 11 cover 12 connection block 12.1 screw 12.2 stopper or connection for ...

Page 34: Iec 60534-6

34 eb 8394 en mounting and start-up 5.3 attachment according to iec 60534-6 the positioner is attached to the control valve using a namur bracket (10). Î required mounting parts and accesso- ries: table 5 on page 18. Î observe travel tables on page 20. 1. Screw the two bolts (14) to the bracket (9.1...

Page 35

Eb 8394 en 35 mounting and start-up 1 lever 1.1 nut 1.2 disk spring 2 follower pin 3 follower plate 6 connecting plate 6.1 seals 7 pressure gauge brack- et 8 pressure gauge 9 stem connector 9.1 bracket 10 namur bracket 11 screw 14 bolt 14.1 screws 15 travel indicator scale 16 u-bolt 10 11 14.1 3 14 ...

Page 36: Attachment To Type 3372

36 eb 8394 en mounting and start-up 5.4 attachment to type 3372 actuator (v2001) the type 3725 positioner is already included in the scope of delivery for series v2001 valves (fig. 11). The attachment is briefly described below to allow conversion work to be performed. Actuator with 120/350 cm², ste...

Page 37

Eb 8394 en 37 mounting and start-up type 3372 actuator, version with 120 cm² type 3372 actuator, version with 350 cm² fig. 11: mounting on type 3372 actuator.

Page 38: Ators

38 eb 8394 en mounting and start-up 5.5 attachment to rotary actu- ators the positioner is mounted to the rotary actu- ator using a mounting bracket. Î required mounting parts and accesso- ries: table 6 on page 18. Î before attaching the positioner onto the samson type 3278 rotary actuator (160 cm²)...

Page 39

Eb 8394 en 39 mounting and start-up 1 lever 1.1 nut 1.2 disk spring 2 follower pin 3 follower clamp 4 coupling wheel 4.1 screw 4.2 disk spring 5 actuator shaft 6 connecting plate 6.1 seals 7 pressure gauge bracket 8 pressure gauge mounting kit 10 mounting bracket 10.1 screws 13 adapter 80 50 60 30 6...

Page 40: 5.5.1 Heavy-Duty Version

40 eb 8394 en mounting and start-up 5.5.1 heavy-duty version Î required mounting parts and accesso- ries: table 6 on page 18. Prepare actuator and mount possibly re- quired adapter supplied by the actuator manufacturer. 1. Mount the housing (10) onto the rotary actuator. In case of vdi/vde attachmen...

Page 41

Eb 8394 en 41 mounting and start-up 6 6.1 7 8 1 1.1 1.2 2 12 4.1 3 10.1 10 11 5 4.3 4 4.2 4.1 3 5.1 5 10.1 10 4.3 4 4.2 1 lever 1.1 nut 1.2 disk spring 2 follower pin 3 adapter 4 coupling wheel 4.1 screw 4.2 disk spring 4.3 adhesive label 5 actuator shaft or adapter 5.1 adapter 6 connecting plate (o...

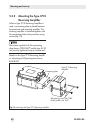

Page 42: Reversing Amplifier

42 eb 8394 en mounting and start-up 5.5.2 mounting the type 3710 reversing amplifier when a type 3710 reversing amplifier is used, a connecting plate is placed between the positioner and reversing amplifier. The reversing amplifier is fastened together with the connecting plate to the positioner usi...

Page 43: 5.6 Pneumatic Connections

Eb 8394 en 43 mounting and start-up 5.6 pneumatic connections risk of injury by possible movement of the actuator stem after connecting the signal pressure. Do not touch or block the actuator stem. Incorrect connection of the supply air will damage the positioner and will lead to mal- function. − sc...

Page 44: 5.7.2 Supply Pressure

44 eb 8394 en mounting and start-up attachment according to iec 60534-6 (namur) Î for attachment according to iec 60534- 6 (namur), the signal pressure can be routed to either the top or bottom dia- phragm chamber of the actuator, de- pending on the actuator's fail-safe action "actuator stem extends...

Page 45

Eb 8394 en 45 mounting and start-up 5.8 electrical connections risk of the formation of an explosive atmosphere. For installation in hazardous areas, observe the relevant standards that apply in the country of use. Standard applicable in germany: en 60079-14: 2008 (vde 0165, part 1) explosive atmo- ...

Page 46: 5.8.2 Cable Entry

46 eb 8394 en mounting and start-up equipment for use in zone 2/zone 22 in equipment operated according to type of protection ex na ii (non-sparking equipment) according to en 60079-15: 2003: Î circuits may be connected, interrupted, or switched while energized only during installation, maintenance,...

Page 47

Eb 8394 en 47 mounting and start-up plastic part terminal assignment for ma control signal: +11 -12 fig. 17: electrical connections.

Page 48: 6 Operation

48 eb 8394 en operation 6 operation 6.1 operating controls three capacitive keys are used to operate the positioner and allow the user to navigate with- in the menu on the display (fig. 18). Additionally, the volume restriction allows the air output capacity to be adapted to the size of the actuator...

Page 49: 6.1.3 Display

Eb 8394 en 49 operation 6.1.3 display icons which are assigned to certain codes and functions are indicated on the display (fig. 18). The bar elements indicate the system deviation that depends on the sign (+/–) and the value. One bar element appears per 1 % system deviation. If the positioner has n...

Page 50

50 eb 8394 en operating the positioner 7 operating the positioner before start-up, mount the positioner following the sequence described in section 5. Apply the electric reference variable to start up the positioner. Refer to section 5.8.3. − low on the display indicates that the reference variable ...

Page 51: 7.1 Adapting The Display

Eb 8394 en 51 operating the positioner 7.1 adapting the display the display reading direction can be rotated by 180°. If the displayed data appear upside down, proceed as follows: 1. Touch or until code p1 appears. 2. Press to confirm the selected code. P1 blinks. 3. Touch or until the display is se...

Page 52

52 eb 8394 en operating the positioner 7.3 adjusting the volume restriction q the volume restriction q (see fig. 19) serves to adapt the air output capacity to the size of the actuator: actuators with a transit time , e.G. Linear actuators with an effective area smaller than 240 cm², require a restr...

Page 53

Eb 8394 en 53 operating the positioner 7.4 entering the air action − ato (air to open) applies to a valve opening as the signal pressure increases. − atc (air to close) applies to a valve closing as the signal pressure increases. The signal pressure is the pneumatic pressure at the output of the pos...

Page 54

54 eb 8394 en operating the positioner the following correlation applies: valve closed open display 0 % 100 % direction of action increasing/increasing (>>) 4 ma 20 ma direction of action increasing/decreasing () 20 ma 4 ma 7.6 limiting the signal pressure if the maximum actuator force is too high f...

Page 55: 7.8 Initialization

Eb 8394 en 55 operating the positioner 7.7 setting other parameters the following table lists all the parameter codes and their default settings. Proceed as de- scribed previously to change parameters. More details concerning the parameter codes can be found in section 11.2. Parameter codes [default...

Page 56

56 eb 8394 en operating the positioner the type and extent of self-adaptation depends on the preset parameters. Max applies as the default setting for the nominal range (code p4). During the initialization process, the po- sitioner determines the total travel range or rotational range of the valve (...

Page 57: 7.9 Zero Calibration

Eb 8394 en 57 operating the positioner initial state 1: the positioner is not initialized. The positioner goes to the fail-safe position after the initialization process has been canceled. Initial state 2: the positioner is initialized. On canceling a new initialization process, the positioner retur...

Page 58: 7.10 Manual Mode

58 eb 8394 en operating the positioner 7.9.1 canceling zero calibration zero calibration can be canceled: 1. During zero calibration touch : esc blinks on the display. 2. Press to confirm: zero calibration is canceled. This code must be confirmed by pressing . Otherwise, the code remains active. The...

Page 59: 7.11 Reset

Eb 8394 en 59 operating the positioner positioner that has not been initialized touch or for a long time to move the valve manually. The valve is only moved in one direction uncontrolled. The bar elements on the display indi- cate the change in direction. Touch to deactivate manual mode. The manual ...

Page 60: 8 Servicing

60 eb 8394 en servicing 8 servicing the positioner was checked by samson before it left the factory. − the product warranty becomes void if ser- vice or repair work not described in these instructions is performed without prior agreement by samson's after-sales ser- vice department. − only use origi...

Page 61: 9 Malfunctions

Eb 8394 en 61 malfunctions 9 malfunctions in case of a fault, the fault indication icon is displayed. Switch past code p0 or p20 to dis- play the respective error code e0 to e15 together with err appear on the display. Refer to the error code list in section 9.2 for the cause of the errors and the r...

Page 62: 9.1 Resetting Error Codes

62 eb 8394 en malfunctions 9.1 resetting error codes the e0 and e8 error codes can be reset as follows: 1. Touch or to select the error code. 2. Touch to confirm the error code. Esc is displayed and the er- ror code blinks. 3. Touch or until rst appears. 4. Press to reset the error. The reset proced...

Page 63

Eb 8394 en 63 malfunctions.

Page 64: 9.2 Error Codes

64 eb 8394 en malfunctions 9.2 error codes the errors listed in the following table are assigned to error classes: error class 1: no operation possible error class 2: manual operation only possible error class 3: manual operation and closed-loop control possible contact samson's after-sales service ...

Page 65: 9.3 Emergency Action

Eb 8394 en 65 malfunctions e5 standstill detection is not possible (initialization error) supply pressure varies. Mounting incorrect. 2 recommended action check supply air and positioner mounting. Re-initialize the positioner. E6 travel is not achieved during initialization (initialization error) su...

Page 66: Sembly

66 eb 8394 en decommissioning and disassembly 10 decommissioning and disas- sembly risk of fatal injury due to ineffective explo- sion protection. The explosion protection becomes ineffective when the positioner cover is opened. The following regulations apply to installa- tion in hazardous areas: e...

Page 67: 11 Annex

Eb 8394 en 67 annex 11 annex 11.1 after-sales service contact samson's after-sales service de- partment for support concerning service or repair work or when malfunctions or defects arise. E-mail you can reach the after-sales service de- partment at aftersalesservice@samson. Addresses of samson ag a...

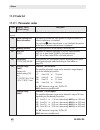

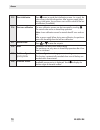

Page 68: 11.2 Code List

68 eb 8394 en annex 11.2 code list 11.2.1 parameter codes code display, values [default setting] description note: codes marked by an asterisk (*) indicate that the positioner needs to be re-initialized after- wards p0 status reading with basic information the reading indicates the valve position or...

Page 69

Eb 8394 en 69 annex p5 characteristic 0 to 8 [0] select characteristic: 0, 1, 2 for globe valves, 0 to 8 with rotary actuators (p3 = 90°) 0 linear 1 equal percentage 2 reverse equal percentage 3 samson butterfly valve, linear 4 samson butterfly valve, equal percentage 5 vetec rotary plug valve, line...

Page 70

70 eb 8394 en annex p15 start initialization press button to cancel the initialization process. As a result, the valve moves to the fail-safe position. After a power supply failure during initialization, the positioner starts with the values of the last initialization (if available). P16 start zero ...

Page 71

Eb 8394 en 71.

Page 72

72 eb 8394 en.

Page 73

Eb 8394 en 73.

Page 74

74 eb 8394 en.

Page 75

Eb 8394 en 75.

Page 76

76 eb 8394 en.

Page 77

Eb 8394 en 77.

Page 80: Eb 8394 En

Samson ag · mess- und regeltechnik weismüllerstraße 3 · 60314 frankfurt am main, germany phone: +49 69 4009-0 · fax: +49 69 4009-1507 samson@samson.De · www.Samson.De eb 8394 en 2017-08-16 · engl ish.