- DL manuals

- Samson

- Valve Positioners

- 3725 series

- Mounting And Operating Instructions

Samson 3725 series Mounting And Operating Instructions - 4.3 Direct Attachment

14

EB 8394 EN

Mounting the positioner

4.3 Direct attachment

4.3.1 Type 3277-5 and

Type 2780-2 Actuators

Î

Requiredmountingpartsandaccesso-

ries:Table 2onpage 29.

Î

Observetraveltablesonpage 13.

Actuator with 120 cm² diaphragm area

Dependingonthetypeofpositionerattach-

ment,thesignalpressureisroutedeitherleft

orrightoftheyokethroughaholetotheac-

tuator diaphragm.

Î

Dependingonthefail-safeactionofthe

actuator "actuator stem extends" or "ac-

tuatorstemretracts",firstattachtheswi-

tchoverplate(9)totheactuatoryoke

(whilealigningitwiththecorresponding

symbolforleftorrightattachmentac-

cordingtothemarking,seeFig. 4).

1. Mountconnectingplate(6)orpressure

gaugebracket(7)withpressuregauges

onthepositioner,makingsurethetwo

seals(6.1)areseatedproperly.

2. Screwthescrewplug(4)onthebackof

thepositionerintotheholebelowit(park

position)(seeFig. 6)andsealthesignal

pressure output on the connecting plate

(6)oronthepressuregaugebracket(7)

withthestopper(5)includedintheac-

cessories.

3. Placefollowerclamp(3)ontheactuator

stem,alignitandscrewtightsothatthe

mounting screw is located in the groove

oftheactuatorstem.

4. 15 mm travel:Keepthefollowerpin(2)

ontheMlever(1)onthebackofthepo-

sitionerinthepinposition35(delivered

state).7.5 mm travel:Removethefol-

lowerpin(2)fromthepinposition35,

repositionitintheholeforpinposition

25 and screw tight.

5. Insertformedseal(15)intothegrooveof

the positioner housing.

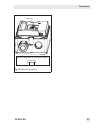

6. Place positioner on the actuator in such a

mannerthatthefollowerpin(2)restson

topofthefollowerclamp(3).Whiledo-

ingthis,pressontheribbedareashown

inFig. 3tolockthepick-upleverinthe

topposition.Thelever(1)mustreston

thefollowerclampwithspringforce.

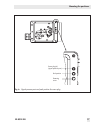

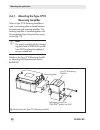

Fig. 3: Locking the pick-up lever in position

7. Mount the positioner on the actuator us-

ingthetwofixingscrews.

8. Mountcover(11)ontheotherside.

Makesurethattheventplugislocatedat

the bottom when the control valve is in-

stalled to allow any condensed water

thatcollectstodrainoff(Fig. 4).

Summary of 3725 series

Page 1

Mounting and operating instructions eb 8394 en firmware version 1.12 edition june 2014 series 3725 type 3725 electropneumatic positioner.

Page 2

Definition of signal words danger! Hazardous situations which, if not avoided, will result in death or seri- ous injury warning! Hazardous situations which, if not avoided, could result in death or seri- ous injury notice property damage message or mal- function note: additional information tip: rec...

Page 3

Contents eb 8394 en 3 1 general safety instructions .............................................................................6 2 article code ...................................................................................................7 3 design and principle of operation ....................

Page 4

4 eb 8394 en contents 8 settings .......................................................................................................39 8.1 adaptingthedisplay ....................................................................................39 8.2 enablingconfigurationtochangeparameters...........

Page 5

Eb 8394 en 5 contents firmware revisions 1.02(old) 1.03(new) internalrevisions 1.03(old) 1.10(new) settingofthetravelinstepsof0.5 mm(p4parametercode) monitoringoftheendstopsonlyduringinitializationandinman- ual mode tosuppresscommon-modeinterferenceonthesignallines,thed componentofthepositionerisswi...

Page 6

6 eb 8394 en general safety instructions 1 general safety instructions foryourownsafety,followtheseinstructionsconcerningthemounting,startupandopera- tionofthepositioner: − thedeviceistobemounted,starteduporoperatedonlybytrainedandexperienced personnelfamiliarwiththeproduct.Accordingtothesemountinga...

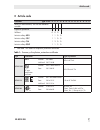

Page 7: 2 Article Code

Eb 8394 en 7 article code 2 article code positioner type 3725- x x x 0 0 0 0 0 0 0 9 9 9 9 withlcdandautotune,4to20 mareference variable explosionprotection 1) without 0 0 0 intrinsicsafety:atex 1 1 0 0 intrinsicsafety:stcc 1 1 0 0 intrinsicsafety:csa 1 3 0 0 intrinsicsafety:gost 1 1 3 0 1) seetable...

Page 8: Ation

8 eb 8394 en design and principle of operation 3 design and principle of oper- ation thetype 3725electropneumaticpositioneris mounted on pneumatic control valves and is usedtoassignthevalveposition(controlled variable x)tothecontrolsignal(reference variable w).Thepositionercomparesthe electriccontro...

Page 9

Eb 8394 en 9 design and principle of operation % s mm % mm q 3 4 11 6 7 8 10 1 w 9 x y 2 5 1 valve 7 aircapacitybooster 2 sensor 8 pressure regulators 3 a/dconverter 9 fixed restriction 4 microcontroller 10 volumerestriction 5 d/aconverter 11 display 6 i/pconverter fig. 1: circuit diagram.

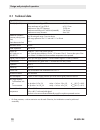

Page 10: 3.1 Technical Data

10 eb 8394 en design and principle of operation 3.1 technical data type 3725 positioner travel(adjustable) directattachmenttotype3277: 5 to 30 mm directattachmenttotype2780-2: 6/12/15mm attachmenttotype 3372actuator: 15/30mm attachmentaccordingtoiec 60534-6(namur): 5 to 50 mm attachmenttorotaryactua...

Page 11

Eb 8394 en 11 design and principle of operation safety influences temperature: ≤0.15%/10k effectofvibration: ≤0.25%upto2000hzand4gaccordingtoiec 770 supplyair: none electromagnetic compatibility complyingwithen 61000-6-2,en 61000-6-3andnamurrecommendationne 21 explosionprotection 1) intrinsicsafety:...

Page 12: 4 Mounting The Positioner

12 eb 8394 en mounting the positioner 4 mounting the positioner thetype 3725positionerissuitableforthe followingtypesofattachment: − directattachmenttosamson type 3277andtype 2780-2actuators − attachmenttoactuatorsaccordingto iec 60534-6(namur) − attachmenttotype 3372actuator (seriesv2001valves) − a...

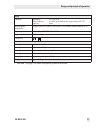

Page 13

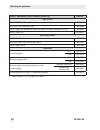

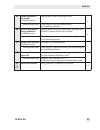

Eb 8394 en 13 mounting the positioner travel tables note: the m lever is included in the scope of delivery. Direct attachment to type 3277-5 and type 3277 actuators actuator size rated travel adjustment range at positioner required lever assigned pin position [cm²] [mm] min. Travel max. 120 7.5 5.0 ...

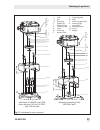

Page 14: 4.3 Direct Attachment

14 eb 8394 en mounting the positioner 4.3 direct attachment 4.3.1 type 3277-5 and type 2780-2 actuators Î requiredmountingpartsandaccesso- ries:table 2onpage 29. Î observetraveltablesonpage 13. Actuator with 120 cm² diaphragm area dependingonthetypeofpositionerattach- ment,thesignalpressureisroutede...

Page 15

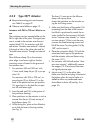

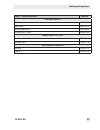

Eb 8394 en 15 mounting the positioner 9 11 supply 9 output 38 5 6 7 3 2 1 15 6.1 1.1 1.2 8 4 16 1 lever 1.1 nut 1.2 diskspring 2 follower pin 3 follower clamp 4 screw plug 5 sealing plug 6 connectingplate 6.1 seals 7 pressure gauge bracket 8 pressure gauge mountingkit 9 switchover plate (actuator) 1...

Page 16

16 eb 8394 en mounting the positioner additional solenoid valve ifasolenoidvalveisadditionallymounted ontotheactuator,thesignalpressureportat thebackofthepositionermustbesealed (seefig. 6).Todothis,unscrewthescrew pluglocatedinthemiddlehole(screwplug inparkposition)andscrewitintothesignal pressure p...

Page 17

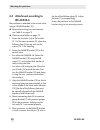

Eb 8394 en 17 mounting the positioner screwplug(4) (signalpressureport) parkposition fastening screw fig. 6: signal pressure port and park position for screw plug.

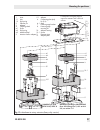

Page 18: 4.3.2 Type 3277 Actuator

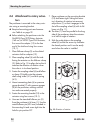

18 eb 8394 en mounting the positioner 4.3.2 type 3277 actuator Î requiredmountingpartsandaccesso- ries:table 3onpage 29. Î observetraveltablesonpage 13. Actuators with 240 to 700 cm² effective ar- eas the positioner can be mounted either on the leftorrightsideoftheyoke.Thesignalpres- sure is routed ...

Page 19

Eb 8394 en 19 mounting the positioner 2 10 15 1 2 3 11 1.1 1.2 12.1 12 16 16 12.2 supply a ansicht a 1 2 10 15 1 2 3 11 1.1 1.2 12.1 12 16 16 12.2 supply a ansicht a 1 1 m lever 1.1 nut 1.2 diskspring 2 follower pin 3 follower clamp 11 cover 12 connectionblock 12.1 screw 12.2 stopperorconnectionfor ...

Page 20: Iec 60534-6

20 eb 8394 en mounting the positioner 4.4 attachment according to iec 60534-6 the positioner is attached to the control valve usinganamurbracket(10). Î requiredmountingpartsandaccesso- ries:table 5onpage 31. Î observetraveltablesonpage 13. 1. Screwthetwobolts(14)tothebracket (9.1)ofthestemconnector(...

Page 21

Eb 8394 en 21 mounting the positioner 1 lever 1.1 nut 1.2 diskspring 2 follower pin 3 follower plate 6 connectingplate 6.1 seals 7 pressure gauge bracket 8 pressure gauge 9 stem connector 9.1 bracket 10 namurbracket 11 screw 14 bolt 14.1 screws 15 travel indicator scale 16 clamp 10 11 14.1 3 14 1 1....

Page 22: Attachment to Type 3372

22 eb 8394 en mounting the positioner 4.5 attachment to type 3372 actuator (v2001) thetype 3725positionerisalreadyincluded inthescopeofdeliveryforseriesv2001 valves(fig. 9). Theattachmentisbrieflydescribedbelowto allowconversionworktobeperformed. Actuator with 120/350 cm², stem extends the signal pr...

Page 23

Eb 8394 en 23 mounting the positioner type 3372 actuator, version with 120 cm² type 3372 actuator, version with 350 cm² fig. 9: mounting on type 3372 actuator.

Page 24: Tors

24 eb 8394 en mounting the positioner 4.6 attachment to rotary actua- tors the positioner is mounted to the rotary actu- atorusingamountingbracket. Î requiredmountingpartsandaccesso- ries:table 6onpage 32. Î beforeattachingthepositionerontothe samsontype 3278rotaryactuator (160 cm²)orvetectype s160a...

Page 25

Eb 8394 en 25 mounting the positioner 1 lever 1.1 nut 1.2 diskspring 2 follower pin 3 follower clamp 4 couplingwheel 4.1 screw 4.2 diskspring 5 actuatorshaft 6 connectingplate 6.1 seals 7 pressuregaugebracket 8 pressure gauge mountingkit 10 mountingbracket 10.1screws 13 adapter 80 50 60 30 6 6.1 7 8...

Page 26: 4.6.1 Heavy-Duty Version

26 eb 8394 en mounting the positioner 4.6.1 heavy-duty version Î requiredmountingpartsandaccesso- ries:table 6onpage 32. Prepare actuator and mount possibly re- quired adapter supplied by the actuator manufacturer. 1. Mountthehousing(10)ontotherotary actuator.Incaseofvdi/vdeattachment, placespacers(...

Page 27

Eb 8394 en 27 mounting the positioner 6 6.1 7 8 1 1.1 1.2 2 12 4.1 3 10.1 10 11 5 4.3 4 4.2 4.1 3 5.1 5 10.1 10 4.3 4 4.2 1 lever 1.1 nut 1.2 diskspring 2 follower pin 3 adapter 4 couplingwheel 4.1 screw 4.2 diskspring 4.3 adhesivelabel 5 actuatorshaftoradapter 5.1 adapter 6 connectingplate(only for...

Page 28: Reversing Amplifier

28 eb 8394 en mounting the positioner 4.6.1 mounting the type 3710 reversing amplifier whenatype 3710reversingamplifieris used,aconnectingplateisplacedbetween thepositionerandreversingamplifier.The reversingamplifierisfastenedtogetherwith the connecting plate to the positioner using screws(fig. 14)....

Page 29

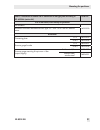

Eb 8394 en 29 mounting the positioner 4.7 accessories and mounting parts table 2: direct attachment to type 3277-5 and type 2780-2 actuators (see section 4.3) order no. Mounting parts foractuatorsupto120 cm² 1402-0239 accessories for actuator switchoverplatefortype3277-5xxxxxx.01actuator 1400-6822 c...

Page 30

30 eb 8394 en mounting the positioner table 4: pipe connections for type 3277 (direct attachment) pipe connection actuator size material connection order no. Pipingwithscrewfittings –forfail-safeaction"actuatorstemretracts" –withairpurgingofthetopdiaphragmchamber 175 cm² steel g ¼ /g 3 / 8 1402-0930...

Page 31

Eb 8394 en 31 mounting the positioner table 5: attachment to namur rib or attachment to rod-type yokes according to iec 60534-6 (section 4.4) order no. 5 to 50 mm travel, lever already on positioner for actuators 1402-0330 actuatorsfromothermanufacturersandtype 3271with120to700cm²effective areas acc...

Page 32

32 eb 8394 en mounting the positioner table 6: attachment to rotary actuators (section 4.6) order no. Light version vdi/vde 3845,aa1size,level1 1) 1402-0243 vdi/vde 3845,aa2size,level1 1) 1402-0244 vetectype s160actuatororsamsontype3278rotaryactuator(160 cm²) 1402-0294 vetectypes320 1402-0295 heavy-...

Page 33

Eb 8394 en 33 mounting the positioner table 7: general accessories order no. Cable gland m20x1.5 blackplastic 8808-1011 blue plastic 8808-1012 nickel-platedbrass 1890-4875 stainless steel 1.4305 8808-0160 adapter m20x1.5 to ½ npt powder-coated aluminum 0310-2149 stainless steel 1400-7114 brief instr...

Page 34: 5 Connections

34 eb 8394 en connections 5 connections 5.1 pneumatic connections the pneumatic connections are optionally designedasaborewith¼nptorg¼ thread.Thecustomaryfittingsformetaland copper pipes or plastic hoses can be used. Points that apply concerning the pneumatic connections: Î onlyscrewthescrewfittings...

Page 35

Eb 8394 en 35 connections supply pressure for fail-open valves (for globe and angle valves): Î fortight-closingvalves,themaximum signal pressure pst max is roughly estimat- edasfollows: pst max = f + d²·π·∆p [bar] 4·a d = seat diameter [cm] ∆p = differentialpressureacrossthe valve [bar] a = actuator...

Page 36: Wires

36 eb 8394 en connections 5.2.1 electric power supply Î onlyuseacurrentsourceandnevera voltage source! Î keepthereferencevariablewithinthe staticdestructionlimitof±33 v. 5.2.2 selecting cables and wires Î observeen 60079-14andparticularly clause12initwheninstallingintrinsical- lysafecircuits. The su...

Page 37

Eb 8394 en 37 connections plastic part terminalassignmentformacontrolsignal: +11 -12 fig. 15: electrical connections.

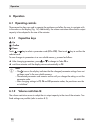

Page 38: 6 Operation

38 eb 8394 en operation 6 operation 6.1 operating controls threecapacitivekeysareusedtooperatethepositionerandallowtheusertonavigatewith- inthemenuonthedisplay(fig. 16).Additionally,thevolumerestrictionallowstheairoutput capacitytobeadaptedtothesizeoftheactuator. 6.1.1 capacitive keys :up : confirm ...

Page 39: 6.1.3 Display

Eb 8394 en 39 operation 6.1.3 display iconswhichareassignedtocertaincodesandfunctionsareindicatedonthedisplay (fig. 16).Thebarelementsindicatethesystemdeviationthatdependsonthesign(+/–)and thevalue.Onebarelementappearsper1 %systemdeviation. Ifthepositionerhasnotyetbeeninitialized,theleverpositionind...

Page 40: 7 Start-Up

40 eb 8394 en start-up 7 start-up beforestart-up,mountthepositionerfollowingthesequencedescribedinsection 4.1.Apply theelectricreferencevariabletostartupthepositioner.Refertosection 5.2. Note: − low on the display indicates that the reference variable is lower than 3.8 ma. − the positioner is ready ...

Page 41: 8 Settings

Eb 8394 en 41 settings 8 settings 8.1 adapting the display thedisplayreadingdirectioncanberotatedby180°.Ifthedisplayeddataappearupside down,proceedasfollows: 1. Touch or until code p1 appears. 2. Press to confirm the selected code. P1 blinks. 3. Touch or until the display is set in the desired direc...

Page 42

42 eb 8394 en settings 8.3 adjusting the volume restriction q thevolumerestrictionq(seefig. 17)servestoadapttheairoutputcapacitytothesizeof theactuator: actuatorswithatransit time ,e.G.Linearactuatorswithaneffectiveareasmallerthan 240 cm²,requirearestrictedairflowrate. Settingtomin actuatorswithatra...

Page 43

Eb 8394 en 43 settings 8.4 entering the direction of action − ato(airtoopen)appliestoavalveopeningasthesignalpressureincreases. − atc(airtoclose)appliestoavalveclosingasthesignalpressureincreases. Thesignalpressureisthepneumaticpressureattheoutputofthepositionerappliedtothe actuator. Default directi...

Page 44

44 eb 8394 en settings thefollowingcorrelationapplies: valve closed open reading 0% 100% directionofactionincreasing/increasing (>>) 4ma 20ma directionofactionincreasing/decreasing () 20ma 4ma 8.6 limiting the signal pressure ifthemaximumactuatorforceistoohighforthevalveused,thesignalpressurelimitca...

Page 45: 8.8 Initialization

Eb 8394 en 45 settings parameter codes[defaultsettings] p7 w/xdirectionofaction[>>] p18 rstreset p8 1) gainkp[50] p19 enableconfiguration p9 pressurelimitation2.3bar[off] p20 firmware version p10 endpositionw 1) positionerneedstobere-initializedafterchangingtheparametersetting 8.8 initialization dur...

Page 46

46 eb 8394 en settings 9. Touch or until code p15 appears. 10. Press and hold for six seconds. 6...5...4...3...2...1 is counted down on the display. The initialization starts and init blinks. The time required for the ini- tialization procedure depends on the actuator transit time and can take a few...

Page 47: 8.9 Zero Calibration

Eb 8394 en 47 settings 8.9 zero calibration incaseofinconsistenciesintheclosingpositionofthevalve,e.G.Withsoft-seatedplugs,it mightbenecessarytorecalibratezeroovercodep16(enableconfigurationasdescribedin section 8.2). Startthezerocalibrationbyactivatingcodep16asfollows: 11. Touch or until code p16 a...

Page 48

48 eb 8394 en settings % enable configuration as described in section 8.2. 13. Touch or until code p17 appears. 14. Press and hold for six seconds. 6-5-4-3-2-1- is counted down on the display and p17 blinks. The manual set point is indicated on the display of an initialized positioner. The lever pos...

Page 49: 8.11 Reset

Eb 8394 en 49 settings 8.11 reset aresetcausesaninitializationtobeundoneandallparameterssettingsareresettothede- faultsettings(seecodelistinsection 9). Enable configuration as described in section 8.2. 16. Touch or until code p18 appears. 17. Press and hold for six seconds. 6...5...4...3...2...1 is ...

Page 50

50 eb 8394 en settings s e6 error code: rated travel not achieved thenominalrange(codep4)mustbechangedandthepositionerre-initializedtoremedy this problem. 8.12.1 resetting error codes thee0ande8errorcodescanberesetasfollows: 18. Touch or to select the error code. 19. Touch to confirm the error code....

Page 51: 9 Code List

Eb 8394 en 51 code list 9 code list 9.1 parameter codes code display, values [default setting] description note:codesmarkedbyanasterisk(*)indicatethatthepositionerneedstobere-initializedafter- wards p0 status reading with basic information thereadingindicatesthevalvepositionorangleofrotationin% when...

Page 52

52 eb 8394 en code list p5 characteristic 0to8 [0] selectcharacteristic: 0,1,2forglobevalves,0to8withrotaryactuators(p3=90°) 0 linear 1 equalpercentage 2 reverseequalpercentage 3 samsonbutterflyvalve,linear 4 samsonbutterflyvalve,equalpercentage 5 vetecrotaryplugvalve,linear 6 vetecrotaryplugvalve,e...

Page 53

Eb 8394 en 53 code list p15 start initialization press buttontocanceltheinitializationprocess.Asaresult,the valvemovestothefail-safeposition.Afterapowersupplyfailure duringinitialization,thepositionerstartswiththevaluesofthelast initialization(ifavailable). P16 start zero calibration thezerocalibrat...

Page 54: 9.2 Error Codes

54 eb 8394 en code list 9.2 error codes incaseofafault,thefaultindicationicon is displayed. Theerrorslistedinthefollowingtableareassignedtoerrorclasses: error class 1: no operation possible error class 2: manual operation only possible error class 3: manual operation and closed-loop control possible...

Page 55

Eb 8394 en 55 code list e5 standstill detection is not possible (initializationerror) supply pressure varies. Mounting incorrect. 2 recommendedaction checksupplyairandpositionermounting. Re-initializethepositioner. E6 travel is not achieved during initialization (initializationerror) supplypressurei...

Page 56: 10 Maintenance

56 eb 8394 en maintenance 10 maintenance the positioner does not require any maintenance. Therearefilterswitha100 µmmeshsizeinthepneumaticconnectionsforsupplyandoutput whichcanberemovedandcleaned,ifrequired. Î observethemaintenanceinstructionsofanyupstreamsupplyairpressurereducingsta- tions. 11 serv...

Page 57: 12 Dimensions In Mm

Eb 8394 en 57 dimensions in mm 12 dimensions in mm 14 22 m20 x 1.5 157.5 108 87 42 21 62.50 25 14 22 m20 x 1,5 157,5 108 87 42 21 62,50 25 fig. 18: dimensional drawings for type 3725 positioner.

Page 58

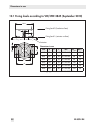

58 eb 8394 en dimensions in mm 12.1 fixing levels according to vdi/vde 3845 (september 2010) a m6 c b 25 m min Ød Ød fixinglevel2(bracketsurface) fixinglevel1(actuatorsurface) actuator dimensions in mm size a b c Ød m min Ød 1) aa0 50 25 15 5.5form5 66 50 aa1 80 30 20 5.5form5 96 50 aa2 80 30 30 5.5...

Page 59

Eb 8394 en 59.

Page 60

60 eb 8394 en.

Page 61

Eb 8394 en 61.

Page 62

62 eb 8394 en.

Page 63

Eb 8394 en 63.

Page 64

64 eb 8394 en.

Page 65

Eb 8394 en 65.

Page 66

66 eb 8394 en.

Page 67

Eb 8394 en 67.

Page 68: Eb 8394 En

Samson ag · mess- und regeltechnik weismüllerstraße 3 · 60314 frankfurt am main, germany phone: +49 69 4009-0 · fax: +49 69 4009-1507 samson@samson.De · www.Samson.De eb 8394 en 2016-10-27 · engl ish.