- DL manuals

- Samson

- Valve Positioners

- 3730-0

- Mounting and operating instructions

Samson 3730-0 Mounting and operating instructions

Summary of 3730-0

Page 1

Series 3730 electropneumatic positioner type 3730-0 mounting and operating instructions eb 8384-0 en (1300-1609) edition november 2010 fig. 1 · type 3730-0

Page 2

2 eb 8384-0 en danger! Indicates a hazardous situation which, if not avoided, will result in death or serious injury. Warning! Indicates a hazardous situation which, if not avoided, could result in death or serious injury. Notice indicates a property damage message. Note: supplementary explanations,...

Page 3

Contents page 1 important safety instructions . . . . . . . . . . . . . . . . . . . . . . 4 2 article code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 3 design and principle of operation. . . . . . . . . . . . . . . . . . . . 6 3.1 technical data . . . . . . . . . . . . . . . . . ....

Page 4

4 eb 8384-0 en 1 important safety instructions for your own safety, follow these instructions concerning the mounting, start-up and opera- tion of the positioner: 4 the positioner is to be mounted, started up or operated only by trained and experienced personnel familiar with the product. According ...

Page 5: Article Code

2 article code eb 8384-0 en 5 article code article code type 3730-0 x 0 0 0 0 0 0 0 0 x 0 0 x 0 x x explosion protection without 0 atex: ii 2g ex ia iic t6, ii 2d ex tb iiic t 80 °c ip 66 1 fm/csa: class i, zone 0 aex ia iic; class i, ii, iii, div.1, groups a–g; class i, div. 2, groups a–d; class ii...

Page 6: Design And Principle Of

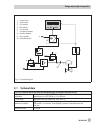

3 design and principle of operation the electropneumatic positioner is mounted to pneumatic control valves and is used to assign the valve position (controlled vari- able x) to the control signal (reference vari- able w). The dc control signal received from a control unit is compared to the travel o...

Page 7: 3.1 Technical Data

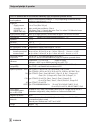

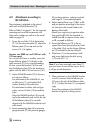

3.1 technical data eb 8384-0 en 7 design and principle of operation 2 3 6 7 8 10 1 9 4 w x q y x fig. 2 · functional diagram 1 control valve 2 travel sensor 3 pd controller 4 dip switches 6 i/p converter 7 air capacity booster 8 pressure regulator 9 flow regulator 10 volume restriction positioner (t...

Page 8

8 eb 8384-0 en design and principle of operation positioner (technical data in test certificates additionally apply for explosion-protected devices) load impedance version without explosion protection: £ 6 v (corresponding to 300 w at 20 ma), explosion-protected version: £ 6 v supply air supply pres...

Page 9: Attachment To The Control

4 attachment to the control valve – mounting parts and accessories the positioner can be attached either di- rectly to a samson type 3277 actuator or according to iec 60534-6 (namur) to con- trol valves with cast yokes or rod-type yoke. For attachment to the various actuators, cor- responding mounti...

Page 10

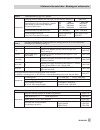

10 eb 8384-0 en attachment to the control valve – mounting parts and accessories travel table for direct attachment to type 3277 actuator type 3277-5 and 3277 actuators actuator size cm² rated travel mm adjustment range at positioner min. Travel max. Required lever assigned pin position 120 7.5 5.0 ...

Page 11

Eb 8384-0 en 11 attachment to the control valve – mounting parts and accessories table 3 attachment to namur ribs or control valves with rod-type yokes (20 to 35 mm rod diameter) according to iec 60534-6, see fig. 6 travel in mm lever for actuators order no. 7.5 s type 3271-5 actuator with 60/120 cm...

Page 12: 4.1 Direct Attachment

4.1 direct attachment 4.1.1 type 3277-5 actuator refer to table 1 on page 10 for the required mounting parts and the accessories with their order numbers as well as to the travel table on page 10! Actuator with 120 cm² depending on the type of positioner attach- ment, the signal pressure is routed e...

Page 13

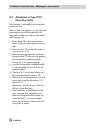

Eb 8384-0 en 13 attachment to the control valve – mounting parts and accessories 9 11 supply 9 output 38 5 6 4 7 6 10 10.1 3 2 1 15 6.1 1.1 1.2 14 8 note: always use the connecting plate (6) included in the accessories to connect supply and output. Never screw threaded parts directly into the housin...

Page 14: 4.1.2 Type 3277 Actuator

4.1.2 type 3277 actuator refer to table 2 on page 11 for the required mounting parts and the accessories with their order numbers as well as to the travel table on page 10! Actuators with 240 to 700 cm² mount the positioner on the yoke as shown in fig. 5. The signal pressure is routed to the actuato...

Page 15

Eb 8384-0 en 15 attachment to the control valve – mounting parts and accessories 2 10 14 15 1 2 3 11 11.1 supply 13 b c 1.1 1.2 12 12.1 12 12.2 12.1 12 16 16 16 12.2 supply ansicht a ansicht b ansicht c suppl y g g 3/8 a fig. 5 · direct attachment – signal pressure connection for type 3277 actuator ...

Page 16: 4.2 Attachment According to

4.2 attachment according to iec 60534-6 the positioner is attached to the control valve with a namur bracket (10). Refer to table 3 on page 11 for the required mounting parts and the accessories with their order numbers as well as to the travel table on page 10! 1. Screw the two bolts (14) to the br...

Page 17

Eb 8384-0 en 17 attachment to the control valve – mounting parts and accessories 10 11 1 1 14.1 3 3.1 16 15 14 1 1.2 1.1 2 9.1 9 6.1 6 7 8 attachment to namur rib attachment to rod-type yoke rods with 20 to 35 mm diameter 1 lever 1.1 nut 1.2 disk spring 2 follower pin 3 follower plate 3.1 follower p...

Page 18: 4.3 Reversing Amplifier For

4.3 reversing amplifier for double-acting actuators for the use with double-acting actuators, the positioner must be fitted with a reversing amplifier, e.G. The samson type 3710 re- versing amplifier (see mounting and oper- ating instructions eb 8392 en). If a different reversing amplifier (item no....

Page 19

Eb 8384-0 en 19 attachment to the control valve – mounting parts and accessories a 1 1.5 1.6 1.3 6.2 6 6.1 1.2 1.1 1 1.6 z a 2 1.4 a 1 a 2 z a 1 output 38 supply 9 output 38 supply 9 1.3 1.2 1.1 from the positioner 1 reversing amplifier 1.1 special screws 1.2 gasket 1.3 special nuts 1.4 rubber seal ...

Page 20: 4.4 Attachment to Type 3510

4.4 attachment to type 3510 micro-flow valve the positioner is attached to the valve yoke using a bracket. Refer to table 3 on page 11 for the required mounting parts and the accessories with their order numbers as well as to the travel table on page 10! 1. Place clamp (3) on the valve stem con- nec...

Page 21

Eb 8384-0 en 21 attachment to the control valve – mounting parts and accessories 3 10 11 11 6 1 2 1.2 1.1 7 8 6.1 lever s 1 lever 1.1 nut 1.2 disk spring 2 follower pin 3 clamp 6 connecting plate 6.1 seal rings 7 pressure gauge bracket 8 pressure gauge mounting kit 10 bracket 11 screw note: always u...

Page 22: Stainless Steel Housings

4.5 attaching positioners with stainless steel housings positioners with stainless steel housings re- quire mounting parts that are completely made of stainless steel or free of aluminum. Note: the pneumatic connecting plate and pres- sure gauge bracket are available in stainless steel (order number...

Page 23: Connections

Threaded bushing (m20 x 1.5): g ¼ ¼ npt 0310-2619 0310-2550 notice the adapter uses one of the m20 x 1.5 con- nections in the housing which means just one cable gland can be installed. Should other valve accessories be used which vent the actuator (e.G. Solenoid valve, volume booster, quick exhaust ...

Page 24: 5.1.2 Supply Pressure

Ally designed as a bore with ¼ npt or g ¼ thread. The customary fittings for metal and copper pipes or plastic hoses can be used. If the positioner is attached directly to the type 3277 actuator, the connection of the positioner's output pressure to the actuator is fixed. For attachment according to...

Page 25: 5.2 Electrical Connections

5.2 electrical connections danger! Risk of electric shock and/or the formation of an explosive atmosphere! – for electrical installation, observe the rel- evant electrotechnical regulations and the accident prevention regulations that apply in the country of use. – the following regulations apply to...

Page 26

Cable entries the cable entry with m20x1.5 cable gland, 6 to 12 mm clamping area. There is a second m20x1.5 threaded hole in the housing that can be used for additional connection, when required. The screw terminals are designed for wire cross-sections of 0.2 to 2.5 mm². Tighten by at least 0.5 nm. ...

Page 27: Operation

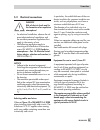

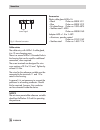

Actuator symbols for pneumatic connections on the right dip switches zero adjuster volume restriction span adjuster actuator symbols for pneumatic connections on the left fig. 10 · operator controls 6 operation 6.1 operator controls dip switches s1 to s10 the positioner is mainly operated via the di...

Page 28: Start-Up and Settings

7 start-up and settings 7.1 default switch positions after the positioner has been mounted on the valve, all switches s1 to s10 must be set to off. 7.2 fail-safe position the switch position of switch s1 depends on the fail-safe position of the valve: 4 air to open · upon air supply failure, the val...

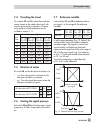

Page 29: 7.4 Presetting The Travel

7.4 presetting the travel at switches s2 and s3, select the travel that comes closest to the rated valve travel, tak- ing into account the pin position. If neces- sary, perform a final adaptation as de- scribed in section 7.11. Pin posi- tion travel when span adjuster is set to 0 s2 s3 off off s2 s3...

Page 30: 7.9 Setting Zero

7.8 connecting the positioner apply the supply air to the pneumatic con- nection (supply 9). Make sure to use the ap- propriate pressure as specified in section 5.1.2. Apply the electric reference variable (amme- ter at terminals 11 and 12). Warning! Upon connection of the electric reference variabl...

Page 31: Maintenance

8 maintenance the positioner does not require any mainte- nance. There are filters with a 100 m m mesh size in the pneumatic connections for supply and output which can be removed and cleaned, if required. The maintenance instructions of any up- stream supply air pressure reducing stations must be o...

Page 32: Dimensions In Mm

10 dimensions in mm 32 eb 8384-0 en dimensions in mm type 3710 reversing amplifier (option) 40 58 58 58 34 210 28 14 80 164 86 70 15 46 34 76 50 supply (z) output (a 2 ) supply (9) output (38) output (a 1 ) a 1 z a 2 direct attachment attachment acc. To iec 60534-5 (namur) pressure gauge bracket lev...

Page 33

Eb 8384-0 en 33 dimensions in mm 80 52 output y 1 output y 2 supply (9) output y 1 output y 2 58 type 3710 reversing amplifier (optional).

Page 34

34 eb 8384-0 en.

Page 35

Eb 8384-0 en 35.

Page 36

36 eb 8384-0 en.

Page 37

Eb 8384-0 en 37.

Page 38

38 eb 8384-0 en.

Page 39

Eb 8384-0 en 39.

Page 40

40 eb 8384-0 en.

Page 41

Eb 8384-0 en 41 $gghqgxp3djh 5hylvlrq&rqwuro1xpehu)heuxd u\ $ gghqgxpwr(%(1 +$=$5'286 6$)( /2&$7,21 /2&$7,21 &rqwu roohu&6$fhuwlilhg 6xsso\dqg hydoxd wlrqeduulhu&6$fhuwlilh g )ruwkhs huplv vleo hpd[lpxp ydox hvir uwkh lqwul qvlfdoo\ vdi hflu fxlwv hh 7deoh ru iruwkh shupl vvleo he duulh usdu dphw hu...

Page 42

42 eb 8384-0 en $gghqgxp3djh 5hylvlrq&rqwuro1xpehu)heuxd u\ $ gghqgxpwr(%(1 +$=$5'286 6$)( /2&$7,21 /2&$7,21 9huvlrq 0rgho hs3rvlwl rqhu 6xsso\d qg hydox dwlrqe duulh u)0&6$ dss ury hg )ruwkhs huplv vleo hpd[lpxp ydox hvir uwkh lqwul qvlfdoo\ vdi hflu fxlwv hh 7deoh )ruwkhs huplv vleo he duulh usdu ...

Page 43

Eb 8384-0 en 43.

Page 44

Samson ag · mess- und regeltechnik weismüllerstraße 3 · 60314 frankfurt am main · germany phone: +49 69 4009-0 · fax: +49 69 4009-1507 internet: http://www.Samson.De eb 8384-0 en s/ z 2012-07.