- DL manuals

- Samson

- Valve Positioners

- 3730-3

- Mounting And Operating Instructions

Samson 3730-3 Mounting And Operating Instructions - Tion

74

EB 8384-3 EN

Start-up and settings

Enter the pin position:

mm

Pin position

Default:No

Turn Code 4

Press ,Code

4blinks.

Turn Pinpositiononlever(seerelevant

sectiononattachment)

Press .

Select the initialization mode:

Initmode

DefaultMAX

Turn Code 6

Press ,Code

6blinks.

Turn

MAN

Press toconfirmthe

MAN as the initial-

izationmode.

Enter OPEN position:

Manualsetpoint

(currentangleofrotationis

indicated)

Turn Code 0

Press ,Code

0blinks.

Turn

MAN

Press .

Turn Code 1

Press ,Code1blinks.

Turn untilthevalvereachesitsOPENpo-

sition.

Press toconfirmtheOPENposition.

Start initialization:

Î

PressINITkey.

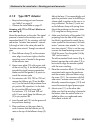

7.6.4 SUb – Substitute calibra-

tion

Acompleteinitializationproceduretakes

several minutes and requires the valve to

movethroughitsentiretravelrangeseveral

times.Thisinitializationmode,however,is

anemergencymode,inwhichthecontrol

parameters are estimated and not deter-

minedbyaninitializationprocedure.Asa

result,ahighlevelofaccuracycannotbeex-

pected.Youshouldalwaysselectadifferent

initializationmodeiftheplantallowsit.

Thesubstitutecalibrationisusedtoreplacea

positionerwhiletheprocessisrunning.For

thispurpose,thecontrolvalveisusuallyfixed

mechanicallyinacertainposition,orpneu-

maticallybymeansofapressuresignal

whichisroutedtotheactuatorexternally.

Theblockingpositionensuresthattheplant

continues to operate with this valve position.

Byenteringtheblockingposition(Code35),

closingdirection(Code34),pinposition

(Code4),nominalrange(Code5)anddi-

rectionofaction(Code7),thepositionercan

calculatethepositionerconfiguration.

Summary of 3730-3

Page 1

Mounting and operating instructions eb 8384-3 en (1300-1612) firmware version 1.56 edition april 2016 series 3730 type 3730-3 electropneumatic positioner with hart ® communication eb + cd.

Page 2

Definition of signal words danger! Hazardous situations which, if not avoided, will result in death or seri- ous injury warning! Hazardous situations which, if not avoided, could result in death or seri- ous injury notice property damage message or mal- function note: additional information tip: rec...

Page 3

Contents eb 8384-3 en 3 1 important safety instructions ..........................................................................8 2 article code ...................................................................................................9 3 design and principle of operation ...................

Page 4

4 eb 8384-3 en contents 5.2.1 switchingamplifier ......................................................................................59 5.2.1 establishingcommunication ..........................................................................59 6 operating controls and readings ......................

Page 5

Eb 8384-3 en 5 contents 14 code list .....................................................................................................88 15 dimensions in mm .....................................................................................106 15.1 fixinglevelsaccordingtovdi/vde 3845(september...

Page 6

6 eb 8384-3 en firmware revisions old new 1.01 1.10 the hart protocol as per hart ® specificationrevision5issupportedbydefault. Thesettingcanbechangedtohart ® revision6inthetrovis-viewsoftware.Hart ® toolsaswellasamsorhandheldcommunicatorsarecurrentlynotsupportedbytherevi- sion 6 version. Thefollowi...

Page 7

Eb 8384-3 en 7 firmware revisions old new 1.40 1.41 internalrevisions 1.41 1.42 internalrevisions 1.42 1.51 allexpertplusdiagnosticfunctionsareavailablewithouthavingtoactivatetheminthe positioner( u eb 8389onexpertplusvalvediagnostics). Optionalbinaryinputwithfollowingactions: • transmitswitchingsta...

Page 8

8 eb 8384-3 en important safety instructions 1 important safety instructions foryourownsafety,followtheseinstructionsconcerningthemounting,start-upandopera- tionofthedevice: − thedeviceistobemounted,starteduporoperatedonlybytrainedandexperienced personnelfamiliarwiththeproduct.Accordingtothesemounti...

Page 9: 2 Article Code

Eb 8384-3 en 9 article code 2 article code positioner type 3730-3 x x x x x x x x 0 x 0 0 x 0 x x withdisplayandautotune,hart ® communication explosion protection without 0 atex ii2gex iaiict6,ii2dextbiiict80°cip66 1 csa ex iaiict6;classi,zone0;classi,groupsa,b,c,d; classii,groupse,f,g;classi,zone2;...

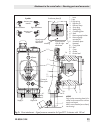

Page 10: Ation

10 eb 8384-3 en design and principle of operation 3 design and principle of oper- ation the electropneumatic positioner is mounted on pneumatic control valves and is used to assignthevalveposition(controlled vari- able x)tothecontrolsignal(setpoint w).The electricsignalfromacontrollingsystemis compa...

Page 11: 3.1 Additional Equipment

Eb 8384-3 en 11 design and principle of operation paresthisactualpositiontothe4to20 ma dccontrolsignalafterithasbeenconverted bythea/dconverter(4).Incaseofaset pointdeviation,theactivationofthei/pcon- verter(6)ischangedsothattheactuator(1) ispressurizedorventedaccordinglyoverthe downstreambooster(7)...

Page 12: 3.2 Communication

12 eb 8384-3 en design and principle of operation external position sensor inthisversion,onlythesensorismountedto the control valve. The positioner is located separatelyfromthevalve.Theconnectionof xandysignalstothevalveisestablishedby cableandpipingforair(onlywithoutinduc- tivelimitcontact). Analog...

Page 13: Trovis-View Software

Eb 8384-3 en 13 design and principle of operation note: the hart ® device revision as well as the indicating and operating modules supported by the type 3730-3 posi- tioner can be found on the samson website: 3.2.1 configuration using the trovis-view software thepositionercanbeconfiguredwith samson'...

Page 14: 3.3 Technical Data

14 eb 8384-3 en design and principle of operation 3.3 technical data type 3730-3 positioner the listed technical data may be restricted by the limits of the test certificate for explosion-protected devices. Valve travel adjustable directattachmenttotype 3277actuator 3.6to30 mm attachmentaccordingtoi...

Page 15

Eb 8384-3 en 15 design and principle of operation type 3730-3 positioner the listed technical data may be restricted by the limits of the test certificate for explosion-protected devices. Influenc- es temperature ≤0.15%/10 k supplyair none effectofvibration ≤0.25%upto2000hzand4gaccordingtoiec 770 el...

Page 16

16 eb 8384-3 en design and principle of operation type 3730-3 positioner the listed technical data may be restricted by the limits of the test certificate for explosion-protected devices. Materials housing die-castaluminumenac-alsi12(fe)(en ac-44300)acc.Todin en 1706· chromatedandpowderpaintcoated·s...

Page 17

Eb 8384-3 en 17 design and principle of operation options for type 3730-3 positioner external position sensor valvetravel sameaspositioner cable 10m·flexibleanddurable·withm12x1connector·flame-retardantacc.To vde 0472 resistanttooils,lubricantsandcoolantsaswellasotheraggressivemedia permissibleambie...

Page 18

18 eb 8384-3 en design and principle of operation summary of explosion protection certificates for type 3730-3 positioner type certification type of protection/comments 3730 -3 inmetro no. Iex13.0161 ex iaiictgb date 2013-08-28 validuntil 2016-08-27 stcc no. 972 0exiaiict6x;2exsiit6x validuntil 2017...

Page 19

Eb 8384-3 en 19 design and principle of operation type certification type of protection/comments 3730 -38 statementof conformity no. Ptb 03atex2180x ii3gexnaiit6;ii3gex iciict6; ii3dextciiict80°cip66 date 2013-07-30 no. Ruc-de08.B.00113 2exnaiict6/t5/t4gcx; 2ex iciict6/t5/t4gcx; extciiict80°cdcx dat...

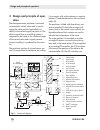

Page 20: Valve – Mounting Parts and

20 eb 8384-3 en attachment to the control valve – mounting parts and accessories 4 attachment to the control valve – mounting parts and accessories notice risk of malfunction due to incorrect sequence of mounting, installation and start-up! Keep the following sequence. 1. Remove the protective film ...

Page 21: Valve – Mounting Parts and

Eb 8384-3 en 21 attachment to the control valve – mounting parts and accessories 4 attachment to the control valve – mounting parts and accessories notice risk of malfunction due to incorrect sequence of mounting, installation and start-up! Keep the following sequence. 1. Remove the protective film ...

Page 22: 4.1 Direct Attachment

22 eb 8384-3 en attachment to the control valve – mounting parts and accessories 4.1 direct attachment 4.1.1 type 3277-5 actuator − required mounting parts and accesso- ries: table 1 on page 50 − observe the travel table on page 21. Actuator with 120 cm² (seefig. 3) dependingonthetypeofpositioneratt...

Page 23: 4.1 Direct Attachment

Eb 8384-3 en 23 attachment to the control valve – mounting parts and accessories 4.1 direct attachment 4.1.1 type 3277-5 actuator − required mounting parts and accesso- ries: table 1 on page 50 − observe the travel table on page 21. Actuator with 120 cm² (seefig. 3) dependingonthetypeofpositioneratt...

Page 24: 4.1.2 Type 3277 Actuator

24 eb 8384-3 en attachment to the control valve – mounting parts and accessories 4.1.2 type 3277 actuator − required mounting parts and accesso- ries: table 2 on page 51 − observe the travel table on page 21. Actuators with 175 to 750 cm² effective ar- eas (see fig. 4) mountthepositionerontheyoke.Th...

Page 25: 4.1.2 Type 3277 Actuator

Eb 8384-3 en 25 attachment to the control valve – mounting parts and accessories 4.1.2 type 3277 actuator − required mounting parts and accesso- ries: table 2 on page 51 − observe the travel table on page 21. Actuators with 175 to 750 cm² effective ar- eas (see fig. 4) mountthepositionerontheyoke.Th...

Page 26: Iec 60534-6

26 eb 8384-3 en attachment to the control valve – mounting parts and accessories 4.2 attachment according to iec 60534-6 − required mounting parts and accesso- ries: table 3 on page 52 − observe the travel table on page 21. Fig. 5 the positioner is attached to the control valve usinganamurbracket(10...

Page 27: Iec 60534-6

Eb 8384-3 en 27 attachment to the control valve – mounting parts and accessories 4.2 attachment according to iec 60534-6 − required mounting parts and accesso- ries: table 3 on page 52 − observe the travel table on page 21. Fig. 5 the positioner is attached to the control valve usinganamurbracket(10...

Page 28: Vdi/vde 3847

28 eb 8384-3 en attachment to the control valve – mounting parts and accessories 4.3 attachment according to vdi/vde 3847 type3730-3xxx0xxxx0x0060xxand type3730-3xxx0xxxx0x0070xxpositioners withairpurgingoftheactuator'sspring chambercanbeattachedaccordingtovdi/ vde 3847. Type3730-3xxx0xxxx0x0000xxpo...

Page 29: Vdi/vde 3847

Eb 8384-3 en 29 attachment to the control valve – mounting parts and accessories 4.3 attachment according to vdi/vde 3847 type3730-3xxx0xxxx0x0060xxand type3730-3xxx0xxxx0x0070xxpositioners withairpurgingoftheactuator'sspring chambercanbeattachedaccordingtovdi/ vde 3847. Type3730-3xxx0xxxx0x0000xxpo...

Page 30

30 eb 8384-3 en attachment to the control valve – mounting parts and accessories 7. Insertthescrews(13.1)throughthemid- dleholesoftheadapterblock(13). 8. Placetheconnectingplate(12)together withtheseal(12.1)ontothescrews (13.1)correspondingtothefail-safeac- tion"actuatorstemextends"or"actuator stemr...

Page 31

Eb 8384-3 en 31 attachment to the control valve – mounting parts and accessories attachment to namur rib (see fig. 8) − requiredmountingpartsandaccesso- ries:table 4onpage 52 − observethetraveltableonpage 21. 1. Series 240 valves, actuator size up to 1400-60 cm²:screwthetwobolts(14) tothebracketofth...

Page 32

32 eb 8384-3 en attachment to the control valve – mounting parts and accessories 5. Inserttheformedseal(6.2)inthegroove oftheadapterbracket. 6. Inserttheformedseal(17.1)intothe turnboard(17)andmounttheturnboard totheadapterblock(13)usingthe screws(17.2). 7. Mounttheblankplate(18)totheturn- boardusin...

Page 33

Eb 8384-3 en 33 attachment to the control valve – mounting parts and accessories 5. Inserttheformedseal(6.2)inthegroove oftheadapterbracket. 6. Inserttheformedseal(17.1)intothe turnboard(17)andmounttheturnboard totheadapterblock(13)usingthe screws(17.2). 7. Mounttheblankplate(18)totheturn- boardusin...

Page 34: Micro-Flow Valve

34 eb 8384-3 en attachment to the control valve – mounting parts and accessories 4.4 attachment to type 3510 micro-flow valve fig. 9 − required mounting parts and accesso- ries: table 3 on page 52 − observe the travel table on page 21. Thepositionerisattachedtothevalveyoke usingabracket. 1. Fastenth...

Page 35: Micro-Flow Valve

Eb 8384-3 en 35 attachment to the control valve – mounting parts and accessories 4.4 attachment to type 3510 micro-flow valve fig. 9 − required mounting parts and accesso- ries: table 3 on page 52 − observe the travel table on page 21. Thepositionerisattachedtothevalveyoke usingabracket. 1. Fastenth...

Page 36: 4.5.1 Heavy-Duty Version

36 eb 8384-3 en attachment to the control valve – mounting parts and accessories 2. Placecouplingwheel(4)withflatside facingtheactuatoronthefollowerclamp (3).Refertofig. 11toalignslotsothatit matchesthedirectionofrotationwhenthe valve is in its closed position. 3. Fastenthecouplingwheel(4)andfollow-...

Page 37

Eb 8384-3 en 37 attachment to the control valve – mounting parts and accessories 2. Placecouplingwheel(4)withflatside facingtheactuatoronthefollowerclamp (3).Refertofig. 11toalignslotsothatit matchesthedirectionofrotationwhenthe valve is in its closed position. 3. Fastenthecouplingwheel(4)andfollow-...

Page 38: Double-Acting Actuators

38 eb 8384-3 en attachment to the control valve – mounting parts and accessories placespacers(11)underneath,ifneces- sary. 2. For samson type 3278 and vetec s160 rotary actuators,screwtheadapt- er(5)ontothefreeendoftheshaftor placeadapter(5.1)ontotheshaftofthe vetec r actuator.Placeadapter(3)on- to ...

Page 39

Eb 8384-3 en 39 attachment to the control valve – mounting parts and accessories placespacers(11)underneath,ifneces- sary. 2. For samson type 3278 and vetec s160 rotary actuators,screwtheadapt- er(5)ontothefreeendoftheshaftor placeadapter(5.1)ontotheshaftofthe vetec r actuator.Placeadapter(3)on- to ...

Page 40: 4.6.1 Reversing Amplifier

40 eb 8384-3 en attachment to the control valve – mounting parts and accessories the following applies to all reversing am- plifiers: thesignalpressureofthepositionerissup- pliedattheoutput1ofthereversingamplifi- er.Anopposingpressure,whichequalsthe requiredsupplypressure(z)whenaddedto thepressureat...

Page 41: 4.6.1 Reversing Amplifier

Eb 8384-3 en 41 attachment to the control valve – mounting parts and accessories the following applies to all reversing am- plifiers: thesignalpressureofthepositionerissup- pliedattheoutput1ofthereversingamplifi- er.Anopposingpressure,whichequalsthe requiredsupplypressure(z)whenaddedto thepressureat...

Page 42: Sition Sensor

42 eb 8384-3 en attachment to the control valve – mounting parts and accessories 4.7 attachment of external po- sition sensor positioner unit with sensor mounted on a mi- cro-flow valve − required mounting parts and accesso- ries: table 7 on page 54 inthepositionerversionwithanexternalpo- sitionsens...

Page 43: Sensor With Direct At-

Eb 8384-3 en 43 attachment to the control valve – mounting parts and accessories 4.7.1 mounting the position sensor with direct at- tachment type 3277-5 actuator with 120 cm² (fig. 15) thesignalpressurefromthepositioneris routedoverthesignalpressureconnectionof theconnectingplate(9,fig. 15left)tothe...

Page 44

44 eb 8384-3 en attachment to the control valve – mounting parts and accessories action.Forthefail-safeaction"actuatorstem retracts"theconnectiononthetopdia- phragmcaseisused.Theconnectionatthe sideoftheyokemustbefittedwithaventing plug(accessories). Mounting the position sensor 1. Placethelever(1)o...

Page 45: Sensor With Attachment

Eb 8384-3 en 45 attachment to the control valve – mounting parts and accessories 4.7.2 mounting the position sensor with attachment according to iec 60534-6 − required mounting parts and accesso- ries: table 7 on page 54 fig. 16 1. Placethelever(1)onthepositionsensor in mid-position and hold it in p...

Page 46: Sensor to Type 3510 Mi-

46 eb 8384-3 en attachment to the control valve – mounting parts and accessories 4.7.3 mounting the position sensor to type 3510 mi- cro-flow valve − required mounting parts and accesso- ries: table 7 on page 54 fig. 17 1. Placethelever(1)onthepositionsen- sor in mid-position and hold it in place. U...

Page 47: Tuators

Eb 8384-3 en 47 attachment to the control valve – mounting parts and accessories 4.7.4 mounting on rotary ac- tuators − required mounting parts and accesso- ries: table 7 on page 54 fig. 18 1. Placethelever(1)onthepositionsensor in mid-position and hold it in place.Un- threadthenut(1.1)andremovethel...

Page 48: 4.8 Mounting The Leakage

48 eb 8384-3 en attachment to the control valve – mounting parts and accessories 4.8 mounting the leakage sensor fig. 19 normally,thecontrolvalveisdeliveredwith positionerandleakagesensoralready mounted. Iftheleakagesensorismountedafterthe valvehasbeeninstalledoritismountedon- toanothercontrolvalve,...

Page 49: Stainless Steel Housings

Eb 8384-3 en 49 attachment to the control valve – mounting parts and accessories 4.9 attaching positioners with stainless steel housings positionerswithstainlesssteelhousingsre- quiremountingpartsthatarecompletely madeofstainlesssteelorfreeofaluminum. Note: the pneumatic connecting plate and pressur...

Page 50

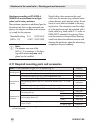

50 eb 8384-3 en attachment to the control valve – mounting parts and accessories attachment according to iec 60534-6 (namur rib or attachment to rod-type yokes) and to rotary actuators thepositionerrequiresanadditionalportfor theexhaustairthatcanbeconnectedover piping.Anadapteravailableasanaccesso- ...

Page 51

Eb 8384-3 en 51 attachment to the control valve – mounting parts and accessories table 2: direct attachment to type 3277 actuator (fig. 4) orderno. Mounting parts standardversionforactuators175,240,350,355,700,750 cm² 1400-7453 versioncompatiblewithpaintforactuators175,240,350,355,700,750 cm² 1402-0...

Page 52

52 eb 8384-3 en attachment to the control valve – mounting parts and accessories table 3: attachment to namur ribs or control valves with rod-type yokes (20 to 35 mm rod diameter) according to iec 60534-6 (fig. 5 and fig. 9) travel in mm lever for actuator orderno. 7.5 s type3271-5with60/120cm²ontyp...

Page 53

Eb 8384-3 en 53 attachment to the control valve – mounting parts and accessories table 5: attachment to rotary actuators (fig. 10 and fig. 11) orderno. Mounting parts attachmentacc.Tovdi/vde3845(september2010),seesection 15.1fordetails actuatorsurfacecorrespondstofixinglevel1 sizeaa1toaa4,versionwit...

Page 54

54 eb 8384-3 en attachment to the control valve – mounting parts and accessories table 6: general accessories orderno. Serialinterfaceadapter(samsonsspinterfacetors-232portonapc) 1400-7700 isolatedusbinterfaceadapter(samsonsspinterfacetousbportonapc)including trovis-viewcd-rom 1400-9740 table 7: att...

Page 55: 5 Connections

Eb 8384-3 en 55 connections 5 connections warning! Risk of injury due to the actuator stem extending or retracting. Do not touch or block the actuator stem. Notice risk of malfunction due to incorrect sequence of mounting, installation and start-up. Keep the following sequence. 1. Remove the protect...

Page 56

56 eb 8384-3 en connections thebenchrangeiswrittenonthenameplateei- therasthespringrangeorsignalpressure rangedependingontheactuator.Thedirection ofactionismarkedfa or fe,orbyasymbol. Actuator stem extends fa (air to open) fail-close(forglobeandanglevalves): requiredsupplypressure=upperbench rangeva...

Page 57

Eb 8384-3 en 57 connections selecting cables and wires observeclause 12 of en 60079-14: 2008 (vde 0165,part 1)forinstallationofthein- trinsicallysafecircuits. Clause 12.2.2.7applieswhenrunningmulti- corecablesandwireswithmorethanone intrinsicallysafecircuit. Theradialthicknessoftheinsulationofa cond...

Page 58

58 eb 8384-3 en connections terminalscanbebetweenatleast12and 30 v dcatthemaximum. Refertofig. 20ortothelabelonthetermi- nalblock. Notice malfunction due the current falling below minimum current. Do not allow the set point to fall be- low 3.8 ma. Accessories cable glands m20 x 1.5 orderno. Blackpla...

Page 59: 5.2.1 Switching Amplifier

Eb 8384-3 en 59 connections note: in positioners for attachment accord- ing to vdi/vde 3847, the terminal designation of the limit contacts 41/42 and 51/52 as well as the open and closed wording can be changed by turning the terminal la- bel which is printed on both sides. 5.2.1 switching amplifier ...

Page 60

60 eb 8384-3 en connections modeis,forexample,suitableforsplit-range operationofpositioners(seriesconnection). Thebusaddress/pollingaddresshastobe withinarangeof1to15. Note: communication errors may occur when the process controller/control station output is not hart ® -compati- ble. For adaptation,...

Page 61: 6 Operating Controls and

Eb 8384-3 en 61 operating controls and readings 6 operating controls and readings rotary pushbutton therotarypushbuttonislocatedunderneath thefrontprotectivecover.Thepositioneris operatedonsiteusingtherotarypushbutton: turn :selectcodesandvalues press :confirmsetting air to open/air to close slide s...

Page 62

62 eb 8384-3 en operating controls and readings % mm air to open close init caution va lv e actua tes min side max back min back max side q % s mm % s mm serial interf ace % mm malfunction/fault manualmode closed-loopoperation code bargraphforsetpoint deviation or lever position units limitcontact a...

Page 63: 6.1 Serial Interface

Eb 8384-3 en 63 operating controls and readings readings iconsassignedtocertaincodes,parameters andfunctionsareindicatedonthedisplay. Operating modes: − (manual mode) thepositionerfollowsthemanualset point(code 1)insteadofthemasignal. Blinks:thepositionerisnotinitialized. Operationonlypossibleoverma...

Page 64: 6.2.1 Dynamic Hart

64 eb 8384-3 en operating controls and readings example,toberunwiththepactwareoper- atorinterface. Allthepositioner'sparametersareaccessi- bleoverthedtmandtheuserinterface. Forstart-upandsettings,proceedasde- scribedinsection 7.1tosection 7.4.Referto thecodelistinsection 14fortheparameters necessary...

Page 65

Eb 8384-3 en 65 operating controls and readings table 8: dynamic hart ® variables assignment variable meaning unit setpoint setpoint % directionofactionsetpoint directionofactionsetpoint % setpointaftertransittimespeci- fication setpointaftertransittimespecification % actualvalue(processvariable) ac...

Page 66: 7 Start-Up and Settings

66 eb 8384-3 en start-up and settings 7 start-up and settings notice risk of malfunction due to incorrect sequence of mounting, installation and start-up. Keep the following sequence. 1. Remove the protective film from the pneumatic connections. 2.Mount the positioner on the control valve. 3. Connec...

Page 67: Striction Q

Eb 8384-3 en 67 start-up and settings note: the switch position is prompted prior to an initialization. After an initial- ization has been completed, chang- ing the switch position does not have any effect on the operation of the po- sitioner. 7.2 adjusting the volume re- striction q max back min si...

Page 68: Range of The Positioner

68 eb 8384-3 en start-up and settings readingdirectionforleftat- tachmentofpneumaticcon- nections ifthedisplayeddataappearupsidedown, proceedasfollows: turn code 2 press ,code 2blinks. Turn requiredreadingdirection press toconfirmreadingdirection. 7.4 limiting the signal pressure ifthemaximumactu...

Page 69: 7.6 Initialization

Eb 8384-3 en 69 start-up and settings check the operating range: manualsetpointw (currentangleofrotationis indicated) turn code 1 press ,code1 and iconblink. Turn until the pressure in the positioner buildsup,andthecontrolvalvemovestoits finalpositionssothatthetravel/anglecan bechecked. Theangleof...

Page 70

70 eb 8384-3 en start-up and settings − maximum range (max) (standardrange) initializationmodeforsimplestart-upof valveswithtwoclearlydefinedmechani- calendpositions,e.G.Three-wayvalves (seesection 7.6.1) − nominal range (nom) initializationmodeforallglobevalves (seesection 7.6.2) − manually selecte...

Page 71: Based On Maximum

Eb 8384-3 en 71 start-up and settings fail-safe position air to close iftheslideswitchissettoairtoclose,the positioner automatically switches to the direc- tionofactionincreasing/decreasing(äæ) afterinitializationhasbeencompleted. This resultsinthefollowingassignmentbetween setpointandvalveposition:...

Page 72: Based On Nominal Range

72 eb 8384-3 en start-up and settings press toconfirmthemaxastheinitial- izationmode. Start initialization: Î pressinitkey. Thenominaltravel/angleofrotationisindi- catedin%afterinitialization.Code 5(nomi- nalrange)remainslocked.Theparameters fortravel/anglerangestart(code8)and travel/anglerangeend(c...

Page 73: Based On A Manually

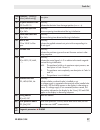

Eb 8384-3 en 73 start-up and settings enter the pin position and nominal range: mm pin position default:no mm nominalrange (lockedwhencode 4=no) turn code 4 press ,code 4blinks. Turn pinpositiononlever(seerelevant sectiononattachment) press . Turn code 5 press ,code 5blinks. Turn nominaltravel...

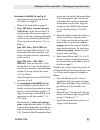

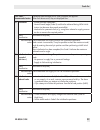

Page 74: Tion

74 eb 8384-3 en start-up and settings enter the pin position: mm pin position default:no turn code 4 press ,code 4blinks. Turn pinpositiononlever(seerelevant sectiononattachment) press . Select the initialization mode: initmode defaultmax turn code 6 press ,code 6blinks. Turn man press toconf...

Page 75

Eb 8384-3 en 75 start-up and settings notice perform a reset before re-initializing the positioner if the substitute posi- tioner has already been initialized. Refer to section 7.8. Enable configuration: note: if no settings are entered within 120 seconds, the enabled configuration function becomes ...

Page 76

76 eb 8384-3 en start-up and settings deactivate travel limit: travel limit default:no turn code 11 press ,code 11blinks. Turn g no press . Change pressure limit and control parame- ters: note: do not change the pressure limit (code 16). Only change the control parameters k p (code 17) and t v (co...

Page 77: 7.7 Zero Calibration

Eb 8384-3 en 77 start-up and settings the positioner switches to man mode. Theblockingpositionisindicated. Note: since initialization has not been com- pleted, the error code 76 (no emer- gency mode) and possibly also error code 57 (control loop) may appear on the display. These alarms do not influe...

Page 78

78 eb 8384-3 en start-up and settings enable configuration: turn gcode3,display: no press ,code 3blinks. Turn yes press ,display: perform zero calibration: initmode defaultmax turn code 6 press ,code 6blinks. Turn zp Î pressinitkey. Zerocalibrationstarts.Thepositioner movesthevalvetotheclosedp...

Page 79: 8 Operation

Eb 8384-3 en 79 operation 8 operation warning! Risk of injury due to the actuator stem extending or retracting. Do not touch or block the actuator stem. 8.1 enabling and selecting pa- rameters allcodesandtheirmeaninganddefaultset- tingsarelistedinthecodelistinsection 14. Codeswhicharemarkedwithanast...

Page 80

80 eb 8384-3 en operation % automatic mode switching to manual mode (man) turn code 0 press ,display: auto,code0blinks. Turn man press .Thepositionerchangestotheman- ualmode( ). Themanualmodestartsusingthelastset pointoftheautomaticmode,ensuringa bumplesschangeover.Thecurrentpositionis displayed...

Page 81: 8.3 Fault/malfunction

Eb 8384-3 en 81 operation exit the fail-safe position turn code 0 press ,code 0blinks. Turn andselecttherequiredoperating mode(auto or man). Press . Thepositionerswitchestotheoperating mode selected. 8.3 fault/malfunction astatusclassificationisassignedtoallstatus andfaultalarmsinthepositioner.The...

Page 82: Sages

82 eb 8384-3 en operation ifthepositionerhasnotbeeninitialized,the maintenancealarmicon( )isdisplayedas thepositionercannotfollowitssetpoint. Iffaultalarmsexist,thepossiblesourceof errorisdisplayedincode49onwards.In thiscase,err is displayed. S example: errorcausedbypinposition refertothecodelist(se...

Page 83

Eb 8384-3 en 83 adjusting the limit contact 9 adjusting the limit contact the positioner version with an inductive limit contacthasanadjustabletag(1)mounted ontheaxisofrotation,whichoperatesthe proximityswitch(3). Foroperationoftheinductivelimitcontact, thecorrespondingswitchingamplifier(see section...

Page 84: Limit Contact

84 eb 8384-3 en adjusting the limit contact software adaptation − code38(inductivealarmissettoyes). − the inductive limit contact is connected to theterminals+41/–42. − thedeviceissetupaccordinglyinthe delivered state. Adjusting the switching point note: during adjustment or testing, the switching p...

Page 85

Eb 8384-3 en 85 adjusting the limit contact 1. Takeofftherotarypushbutton(3)andcap (1),unthreadthefivefasteningscrews(2) andliftofftheplasticcover(9)together withthedisplay,takingcarenottodam- agetheribboncable(betweenpcband display). 2. Useaknifetocutanopeningatthe markedlocation(4). 3. Pushtheconn...

Page 86: 10 Maintenance

86 eb 8384-3 en maintenance 10 maintenance the positioner does not require any mainte- nance. Therearefilterswitha100 µmmeshsizein thepneumaticconnectionsforsupplyand outputwhichcanberemovedandcleaned, ifrequired. Themaintenanceinstructionsofanyup- streamsupplyairpressurereducingstations mustbeobser...

Page 87: Work On Equipment

Eb 8384-3 en 87 maintenance, calibration and work on equipment b) updates on site: updatesonsiteareonlypermitted aftertheplantoperatorpresenteda signedhotworkpermit. Afterupdatinghasbeencompleted,addthe currentfirmwaretothenameplate;thiscan bedoneusinglabels. 13 maintenance, calibration and work on ...

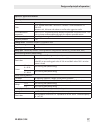

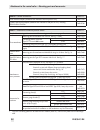

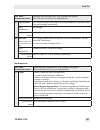

Page 88: 14 Code List

88 eb 8384-3 en code list 14 code list code no. Parameter–readings/ values[defaultsetting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 0 operating mode [man] manualmode auto automatic mode safe fail-safeposition esc cancel switchoverfr...

Page 89

Eb 8384-3 en 89 code list code no. Parameter–readings/ values[defaultsetting] description 5* nominal range mmorangle°,esc nominalvalvetraveloropeninganglemustbeenteredfornominal (nom)orsubstitute(sub)initialization. Thepossibleadjustmentrangedependsonthepinpositionfromthe tableforcode 4. Indicatesma...

Page 90

90 eb 8384-3 en code list code no. Parameter–readings/ values[defaultsetting] description 9* travel/angle range end (upper x-range value) 20.0to[100.0 %]ofthe nominalrange,esc note: specified in mm or angle ° provided code 4 is activated. Upperrangevaluefortravel/angleinnominaloroperatingrange theva...

Page 91

Eb 8384-3 en 91 code list code no. Parameter–readings/ values[defaultsetting] description 13* w-end 25.0to[100.0 %]ofthe setpointrange,esc theupperrangevalueofthesetpointrangemustbegreaterthan lowerrangevalue(w-start). 100.0 %=20 ma 14* reference variable range start (w-start) 0.0to49.9 %,[1.0 %]of ...

Page 92

92 eb 8384-3 en code list code no. Parameter–readings/ values[defaultsetting] description 18* derivative-action time t v (level) 1,[2],3,4,no,esc readorchanget v (seek p level) achangeofthet v levelhasnoeffectonthesystemdeviation. 19* tolerance band 0.1to10.0 %,[5.0 %]of theoperatingrange,esc usedfo...

Page 93

Eb 8384-3 en 93 code list code no. Parameter–readings/ values[defaultsetting] description 22* required transit time closed (w ramp closed) [0]to240s,esc timerequiredtomovethroughtheoperatingrangewhenthevalve closes. Code 22haspriorityovercode 14. Notice: the function is not activated when the fail-s...

Page 94

94 eb 8384-3 en code list code no. Parameter–readings/ values[defaultsetting] description 25* alarm mode 0to3,[2],esc switchingmodeofsoftwarelimitcontactalarmsa1anda2when activated(whenthepositionerisinitialized). 1)explosion-protectedversionaccordingtoen 60947- 5-6 0:a1≥2.2ma a2≤1.0 ma 1:a1≤1.0ma a...

Page 95

Eb 8384-3 en 95 code list code no. Parameter–readings/ values[defaultsetting] description 28* alarm test readingdirection: standard turned [no] [no] run1 1run run2 2run run3 3run esc esc testofsoftwarelimitcontactalarmsa1anda2aswellasoffault alarm contact a3. Ifthetestisactivated,thecontactisswitche...

Page 96

96 eb 8384-3 en code list code no. Parameter–readings/ values[defaultsetting] description 32* error message in case of 'function check' con- densed state [yes],no,esc yes: errormessagealsoincaseof'functioncheck'condensed state no: 'functioncheck'condensedstatedoesnotcauseanerror messagetobeissued no...

Page 97

Eb 8384-3 en 97 code list code no. Parameter–readings/ values[defaultsetting] description 39 set point deviation e info –99.9to99.9 % read only indicatesthedeviationfromthetargetposition(e=w–x). 40 transit time open info [0]to240 s read only minimumopeningtimedeterminedduringinitialization. 41 trans...

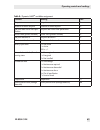

Page 98

98 eb 8384-3 en code list note: the error codes listed in the following appear in the display corresponding to their status classification set over the condensed state (maintenance required/maintenance demanded: , out of specification: blinking, maintenance alarm: ). If “no mes- sage” is assigned to...

Page 99

Eb 8384-3 en 99 code list error codes – recommended action condensedstatemessageactive,whenprompted,err appears. Whenfaultalarmsexist,theyaredisplayedhere. 52 attachment • invalidpositionerattachment. • nominaltravel/angle(code5)couldnotbeachievedduringnominitial- ization(notolerancedownwardspermiss...

Page 100

100 eb 8384-3 en code list error codes – recommended action condensedstatemessageactive,whenprompted,err appears. Whenfaultalarmsexist,theyaredisplayedhere. 55 transit time too short (transit time actuatortransittimesdetectedduringinitializationaresoshortthatoptimal positionertuningisimpossible. Sta...

Page 101

Eb 8384-3 en 101 code list error codes – recommended action condensedstatemessageactive,whenprompted,err appears. Whenfaultalarmsexist,theyaredisplayedhere. 59 auto-correction errorsinthepositioner'sdatasectionaredetecteddetectedbyautomaticmoni- toringandcorrectedautomatically. Status classification...

Page 102

102 eb 8384-3 en code list error codes – recommended action condensedstatemessageactive,whenprompted,err appears. Whenfaultalarmsexist,theyaredisplayedhere. 63 w too low thesetpointisconsiderablysmallerthan4 ma(0 %);thishappenswhenthe positioner'spowersupplydoesnotmeetthestandardrequirements. Thisst...

Page 103

Eb 8384-3 en 103 code list data error error codes – recommended action condensedstatemessageactive,whenprompted,err appears. Whenfaultalarmsexist,theyaredisplayedhere. 68 control parameters additional indication at thefaultalarmcontact! Error in control parameters. Statusclassification [maintenancer...

Page 104

104 eb 8384-3 en code list error codes – recommended action condensedstatemessageactive,whenprompted,err appears. Whenfaultalarmsexist,theyaredisplayedhere. 76 no emergency mode thetravelmeasuringsystemofthepositionerhasaself-monitoringfunc- tion(seecode 62). Anemergencymode(open-loopcontrol)isnotav...

Page 105

Eb 8384-3 en 105 code list diagnosis errors error codes – recommended action condensedstatemessageactive,whenprompted,err appears. Whenfaultalarmsexist,theyaredisplayedhere. 79 diagnostic messages messagesgeneratedbytheextendeddiagnostics statusclassification maintenancerequired(cannotbeclassified) ...

Page 106: 15 Dimensions In Mm

106 eb 8384-3 en dimensions in mm 15 dimensions in mm 40 34 210 28 14 80 164 output (38) supply (9) 86 70 15 46 34 70 70 28 schild 58 58 pressuregauge bracket orconnectingplate attachmentaccordingtoiec 60534-6 external position sensor direct attachment m20 x 1.5 fig. 28: namur and direct attachment ...

Page 107

Eb 8384-3 en 107 dimensions in mm attachmentaccordingto vdi/vde 3847totype 3277 attachmentaccordingto vdi/vde 3847toanamur rib 62 164 38 200 16 4 164 13 62 24 fig. 29: attachment according to vdi/vde 3847 lever(seefig. 31).

Page 108

108 eb 8384-3 en dimensions in mm 56 86 130 80 166 30 86 Ø 101 80 52 output y 1 output y 2 supply (9) output y 1 output y 2 reversing amplifier (optional)* heavy-duty version a 1 z a 2 output a1 output a2 supply (9) 50 80 58 130 49 59 79 76 50 150 reversing amplifier (optional)* connectingplate g ¼o...

Page 109

Eb 8384-3 en 109 dimensions in mm 15.1 fixing levels according to vdi/vde 3845 (september 2010) a m6 c b 25 m min Ød Ød fixinglevel2(bracketsurface) fixinglevel1(actuatorsurface) actuator dimensions in mm size a b c Ød m min d* aa0 50 25 15 5.5form5 66 50 aa1 80 30 20 5.5form5 96 50 aa2 80 30 30 5.5...

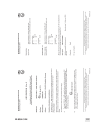

Page 110

110 eb 8384-3 en valve characteristic selection linear(selectcharacteristic:0) 0 50 100 0 50 100 travel/ angle of rotation [%] reference variable [%] equal percentage(selectcharacteristic:1) reverse equal percentage(selectcharacteristic: 2) 0 50 100 0 50 100 travel/ angle of rotation [%] reference v...

Page 111

Samson butterfly valve linear (select characteristic:3) samson butterfly valve equal percentage (selectcharacteristic:4) 0 50 100 0 50 100 travel/ angle of rotation [%] reference variable [%] 0 50 100 0 50 100 travel/ angle of rotation [%] reference variable [%] vetec rotary plug valve linear (selec...

Page 112

112 eb 8384-3 en.

Page 113

Eb 8384-3 en 113 ,( & ( [& huwlilf dw h ri &rqi ru pl w\ c er tif ic at e no .: is sue n o. : s tat us : da te o f is su e: p age of a ppl ic ant : w ei sm ue lle rst ra sse 3 d -60314 fr ank fu rt a m m ai n e le ct ric al a pp ar at us : type of p rot ec tion: m ar ki ng : d r. -i ng . U lri ch jo...

Page 114

114 eb 8384-3 en c e rt ific at e no .: da te o f is su e: is sue n o. : p age o f g e ner al de scr ipt ion : the m ode l 373 0 -31 h a r t ® capa bl e p o si tione r is a s in gl e - or dou bl e- act in g p osi tion er w ith com m uni cat ion cap abi lit y i n te n ded f or at ta chm en t t o p ne...

Page 115

Eb 8384-3 en 115.

Page 116

116 eb 8384-3 en.

Page 117

Eb 8384-3 en 117.

Page 118

118 eb 8384-3 en.

Page 119

Eb 8384-3 en 119.

Page 120

120 eb 8384-3 en.

Page 121

Eb 8384-3 en 121.

Page 122

122 eb 8384-3 en.

Page 123

Eb 8384-3 en 123.

Page 124

124 eb 8384-3 en.

Page 125

Eb 8384-3 en 125.

Page 126

126 eb 8384-3 en.

Page 127

Eb 8384-3 en 127.

Page 128

128 eb 8384-3 en.

Page 129

Eb 8384-3 en 129.

Page 130

130 eb 8384-3 en.

Page 131

Eb 8384-3 en 131.

Page 132

132 eb 8384-3 en.

Page 133

Eb 8384-3 en 133.

Page 134

134 eb 8384-3 en.

Page 135

Eb 8384-3 en 135.

Page 136

136 eb 8384-3 en.

Page 137

Eb 8384-3 en 137.

Page 138

138 eb 8384-3 en.

Page 139

Eb 8384-3 en 139.

Page 140

140 eb 8384-3 en.

Page 141

Eb 8384-3 en 141.

Page 142

142 eb 8384-3 en.

Page 143

Eb 8384-3 en 143.

Page 144

144 eb 8384-3 en.

Page 145

Eb 8384-3 en 145.

Page 146

146 eb 8384-3 en.

Page 147

Eb 8384-3 en 147.

Page 148

148 eb 8384-3 en.

Page 149

Index eb 8384-3 en 149 index a accessories .................................... 50–52 additional equipment externalpositionsensor ................... 12 leakagesensor ............................... 12 limitcontact ................................... 11 solenoidvalve ...................................

Page 150

Index 150 eb 8384-3 en l leakagesensor .................................... 12 attachment .....................................48 limitcontact electrical connection ........................ 56 setting ..................................... 83–84 m maintenance ........................................8...

Page 152: Eb 8384-3 En

Samson ag · mess- und regeltechnik weismüllerstraße 3 · 60314 frankfurt am main, germany phone: +49 69 4009-0 · fax: +49 69 4009-1507 samson@samson.De · www.Samson.De eb 8384-3 en 2016-04-19 · engl ish.