- DL manuals

- Samson

- Valve Positioners

- 3730-3

- Mounting And Operating Instructions

Samson 3730-3 Mounting And Operating Instructions - 3.2 Communication

EB 8384-5

13

Design and principle of operation

Note:

The binary inputs are configured in

the DI Function Blocks. Refer to

Configuration Manual

u

KH 8384-5.

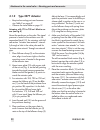

3.2 Communication

The positioner is controlled completely by

digital signal transmission according to

F

OUNDATION

™ fieldbus specification.

Data are transmitted over the bus using digi-

tal, bit-synchronous Manchester coding at a

baud rate of 31.25 kbit/s over twisted-pair

wires according to IEC 61158-2.

Note:

If complex functions are started in the

positioner, which require a long cal-

culation time or lead to a large quan-

tity of data being saved in the vola-

tile memory of the positioner, the

alert 'busy' is issued over the DD.

This alert is not an error message

and can be simply confirmed.

Configuration and operation of the posi-

tioner over F

OUNDATION

™

fieldbus are de-

scribed in the Configuration Manual

u

KH 8384-5.

3.2.1 Configuration using the

TROVIS-VIEW software

The positioner can be configured with

SAMSON's TROVIS-VIEW Configuration

and Operator Interface.

The positioner has for this purpose a serial

interface to allow the RS-232 or USB port of

a computer to be connected to it over an

adapter cable.

The TROVIS-VIEW software enables the user

to easily configure the positioner as well as

view process parameters online.

Note:

TROVIS-VIEW provides a uniform us-

er interface that allows users to con-

figure and parameterize various

SAMSON devices using device-spe-

cific database modules. The 3730-5

device module can be downloaded

free of charge from our website

(www. samson.de) at Services > Soft-

ware > TROVIS-VIEW. Further infor-

mation on TROVIS-VIEW (e.g. system

requirements) is available on our

website and in the Data Sheet

u

T 6661.

3.2.2 Configuration using the

NI-FBUS™ configurator

The positioner can also be configured over

the NI-FBUS™ configurator from National

Instruments. For this purpose, an interface

card must be installed in a computer to con-

nect it to the F

OUNDATION

™ fieldbus.

The integrated function blocks are linked us-

ing the NI-FBUS™ configurator.

Summary of 3730-3

Page 1

Mounting and operating instructions eb 8384-5 en (1300-1619) firmware version 1.56 edition april 2016 series 3730 type 3730-5 electropneumatic positioner with f oundation ™ fieldbus communication ff device rev. 2 eb + cd.

Page 2

Definition of signal words danger! Hazardous situations which, if not avoided, will result in death or seri- ous injury warning! Hazardous situations which, if not avoided, could result in death or seri- ous injury notice property damage message or mal- function note: additional information tip: rec...

Page 3

Contents eb 8384-5 en 3 1 important safety instructions ..........................................................................9 2 article code .................................................................................................10 3 design and principle of operation ....................

Page 4

4 eb 8384-5 en contents 5.2 electrical connections ...................................................................................54 5.2.1 establishing communication ..........................................................................58 6 operating controls and readings ......................

Page 5

Eb 8384-5 en 5 contents 14.2 decimal values of the states in the foundation™ fieldbus blocks (code 48) ...................................................................................................98 15 dimensions in mm ..............................................................................

Page 6

6 eb 8384-5 en firmware revisions (control r) control r 1.43 r 1.44 to 1.46 internal revisions r 1.52 diagnostics all expertplus diagnostic functions are available without having to acti- vate them in the positioner ( u eb 8389 on expertplus valve diagnos- tics). Additional function blocks • 2x do (...

Page 7

Eb 8384-5 en 7 firmware revisions (communication k) further details can be found in u kh 8384-5. Kh 8384-5 is included on the enclosed cd-rom and is available on our website. K 1.21 leakage sensor at binary input 2 the connection of a leakage sensor at binary input 2 (by selecting leakage sensor in ...

Page 8

8 eb 8384-5 en firmware revisions (communication k) further details can be found in u kh 8384-5. Kh 8384-5 is included on the enclosed cd-rom and is available on our website. K 1.24 bus_address parameter the bus address has the default setting of 248. Device type in the delivered state, the device i...

Page 9

Eb 8384-5 9 important safety instructions 1 important safety instructions for your own safety, follow these instructions concerning the mounting, start-up and opera- tion of the positioner: − the positioner is to be mounted, started up or operated only by trained and experienced personnel familiar w...

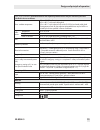

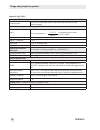

Page 10: 2 Article Code

10 eb 8384-5 article code 2 article code positioner type 3730-5 x x x 0 x x x x 0 x 0 0 x 0 x x with lcd and autotune, f oundation ™ fieldbus explosion protection without 0 atex ii 2g ex ia iic t6; ii 2d ex tb iiic t80°c ip66 1 csa ex ia iic t6; class i, ii, div.1, groups a-g; ex na ii t6; ex nl iic...

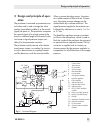

Page 11: Ation

Eb 8384-5 11 design and principle of operation 3 design and principle of oper- ation the positioner is mounted on pneumatic con- trol valves and is used to assign the valve position (controlled variable x) to the control signal (set point w). The positioner compares the control signal of a control s...

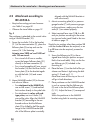

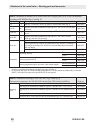

Page 12: 3.1 Additional Equipment

12 eb 8384-5 design and principle of operation the positioner communicates and is powered using iec 61158-2 transmission technology conforming to f oundation ™ fieldbus specifi- cation. As a standard feature, the positioner comes with a binary input used to signalize process information over the f o...

Page 13: 3.2 Communication

Eb 8384-5 13 design and principle of operation note: the binary inputs are configured in the di function blocks. Refer to configuration manual u kh 8384-5. 3.2 communication the positioner is controlled completely by digital signal transmission according to f oundation ™ fieldbus specification. Data...

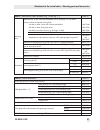

Page 14: 3.3 Technical Data

14 eb 8384-5 design and principle of operation 3.3 technical data type 3730-5 positioner: the technical data for the explosion-protected devices may be restricted by the limits specified in the test certificates. Rated travel, adjustable direct attachment to type 3277 actuator: 3.6 to 30 mm attachme...

Page 15

Eb 8384-5 15 design and principle of operation type 3730-5 positioner: the technical data for the explosion-protected devices may be restricted by the limits specified in the test certificates. Perm. Ambient temperature –20 to +80 °c for all versions –45 to +80 °c with metal cable gland –25 to +80 °...

Page 16

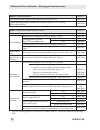

16 eb 8384-5 design and principle of operation options for type 3730-5 binary input bi2 for floating contact switching input r galvanic isolation solenoid valve · approval according to iec 61508/sil input 24 v dc · reverse polarity protection · static destruction limit 40 v current consumption i = u...

Page 17

Eb 8384-5 17 design and principle of operation summary of explosion protection approvals type certification type of protection/comments 3730-5 ccoe no. A p hq mh 104 1343 ex ia iic t6 date 2013-04-19 valid until 2018-04-18 stcc no. 972 0ex ia iic t6x; 2ex s ii t6 x valid until 2017-10-01 3730-51 1) ...

Page 18: Valve – Mounting Parts and

18 eb 8384-5 en attachment to the control valve – mounting parts and accessories 4 attachment to the control valve – mounting parts and accessories notice risk of malfunction due to incorrect sequence of mounting, installation and start-up! Keep the following sequence. 1. Remove the protective film ...

Page 19: Valve – Mounting Parts and

Eb 8384-5 en 19 attachment to the control valve – mounting parts and accessories 4 attachment to the control valve – mounting parts and accessories notice risk of malfunction due to incorrect sequence of mounting, installation and start-up! Keep the following sequence. 1. Remove the protective film ...

Page 20: 4.1 Direct Attachment

20 eb 8384-5 en attachment to the control valve – mounting parts and accessories 4.1 direct attachment 4.1.1 type 3277-5 actuator − required mounting parts and accesso- ries: table 1 on page 48 − observe the travel table on page 19. Actuator with 120 cm² (see fig. 3) depending on the type of positio...

Page 21: 4.1 Direct Attachment

Eb 8384-5 en 21 attachment to the control valve – mounting parts and accessories 4.1 direct attachment 4.1.1 type 3277-5 actuator − required mounting parts and accesso- ries: table 1 on page 48 − observe the travel table on page 19. Actuator with 120 cm² (see fig. 3) depending on the type of positio...

Page 22: 4.1.2 Type 3277 Actuator

22 eb 8384-5 en attachment to the control valve – mounting parts and accessories 4.1.2 type 3277 actuator − required mounting parts and accesso- ries: table 2 on page 49 − observe the travel table on page 19. Actuators with 175 to 750 cm² effective ar- eas (see fig. 4) mount the positioner on the yo...

Page 23: 4.1.2 Type 3277 Actuator

Eb 8384-5 en 23 attachment to the control valve – mounting parts and accessories 4.1.2 type 3277 actuator − required mounting parts and accesso- ries: table 2 on page 49 − observe the travel table on page 19. Actuators with 175 to 750 cm² effective ar- eas (see fig. 4) mount the positioner on the yo...

Page 24: Iec 60534-6

24 eb 8384-5 en attachment to the control valve – mounting parts and accessories 4.2 attachment according to iec 60534-6 − required mounting parts and accesso- ries: table 3 on page 50 − observe the travel table on page 19. Fig. 5 the positioner is attached to the control valve using a namur bracket...

Page 25: Iec 60534-6

Eb 8384-5 en 25 attachment to the control valve – mounting parts and accessories 4.2 attachment according to iec 60534-6 − required mounting parts and accesso- ries: table 3 on page 50 − observe the travel table on page 19. Fig. 5 the positioner is attached to the control valve using a namur bracket...

Page 26: Vdi/vde 3847

26 eb 8384-5 en attachment to the control valve – mounting parts and accessories 4.3 attachment according to vdi/vde 3847 type 3730-5xxx0xxxx0x0060xx and type 3730-5xxx0xxxx0x0070xx positioners with air purging of the actuator's spring chamber can be attached according to vdi/ vde 3847. Type 3730-5x...

Page 27: Vdi/vde 3847

Eb 8384-5 en 27 attachment to the control valve – mounting parts and accessories 4.3 attachment according to vdi/vde 3847 type 3730-5xxx0xxxx0x0060xx and type 3730-5xxx0xxxx0x0070xx positioners with air purging of the actuator's spring chamber can be attached according to vdi/ vde 3847. Type 3730-5x...

Page 28

28 eb 8384-5 en attachment to the control valve – mounting parts and accessories 7. Insert the screws (13.1) through the mid- dle holes of the adapter block (13). 8. Place the connecting plate (12) together with the seal (12.1) onto the screws (13.1) corresponding to the fail-safe ac- tion "actuator...

Page 29

Eb 8384-5 en 29 attachment to the control valve – mounting parts and accessories attachment to namur rib (see fig. 8) − required mounting parts and accesso- ries: table 4 on page 50 − observe the travel table on page 19. 1. Series 240 valves, actuator size up to 1400-60 cm²: screw the two bolts (14)...

Page 30

30 eb 8384-5 en attachment to the control valve – mounting parts and accessories 5. Insert the formed seal (6.2) in the groove of the adapter bracket. 6. Insert the formed seal (17.1) into the turnboard (17) and mount the turnboard to the adapter block (13) using the screws (17.2). 7. Mount the blan...

Page 31

Eb 8384-5 en 31 attachment to the control valve – mounting parts and accessories 5. Insert the formed seal (6.2) in the groove of the adapter bracket. 6. Insert the formed seal (17.1) into the turnboard (17) and mount the turnboard to the adapter block (13) using the screws (17.2). 7. Mount the blan...

Page 32: Micro-Flow Valve

32 eb 8384-5 en attachment to the control valve – mounting parts and accessories 4.4 attachment to type 3510 micro-flow valve fig. 9 − required mounting parts and accesso- ries: table 3 on page 50 − observe the travel table on page 19. The positioner is attached to the valve yoke using a bracket. 1....

Page 33: Micro-Flow Valve

Eb 8384-5 en 33 attachment to the control valve – mounting parts and accessories 4.4 attachment to type 3510 micro-flow valve fig. 9 − required mounting parts and accesso- ries: table 3 on page 50 − observe the travel table on page 19. The positioner is attached to the valve yoke using a bracket. 1....

Page 34: 4.5.1 Heavy-Duty Version

34 eb 8384-5 en attachment to the control valve – mounting parts and accessories 2. Place coupling wheel (4) with flat side facing the actuator on the follower clamp (3). Refer to fig. 11 to align slot so that it matches the direction of rotation when the valve is in its closed position. 3. Fasten t...

Page 35

Eb 8384-5 en 35 attachment to the control valve – mounting parts and accessories 2. Place coupling wheel (4) with flat side facing the actuator on the follower clamp (3). Refer to fig. 11 to align slot so that it matches the direction of rotation when the valve is in its closed position. 3. Fasten t...

Page 36: Double-Acting Actuators

36 eb 8384-5 en attachment to the control valve – mounting parts and accessories place spacers (11) underneath, if neces- sary. 2. For samson type 3278 and vetec s160 rotary actuators, screw the adapt- er (5) onto the free end of the shaft or place adapter (5.1) onto the shaft of the vetec r actuato...

Page 37

Eb 8384-5 en 37 attachment to the control valve – mounting parts and accessories place spacers (11) underneath, if neces- sary. 2. For samson type 3278 and vetec s160 rotary actuators, screw the adapt- er (5) onto the free end of the shaft or place adapter (5.1) onto the shaft of the vetec r actuato...

Page 38: 4.6.1 Reversing Amplifier

38 eb 8384-5 en attachment to the control valve – mounting parts and accessories the following applies to all reversing am- plifiers: the signal pressure of the positioner is sup- plied at the output 1 of the reversing amplifi- er. An opposing pressure, which equals the required supply pressure (z) ...

Page 39: 4.6.1 Reversing Amplifier

Eb 8384-5 en 39 attachment to the control valve – mounting parts and accessories the following applies to all reversing am- plifiers: the signal pressure of the positioner is sup- plied at the output 1 of the reversing amplifi- er. An opposing pressure, which equals the required supply pressure (z) ...

Page 40: Sition Sensor

40 eb 8384-5 en attachment to the control valve – mounting parts and accessories 4.7 attachment of external po- sition sensor positioner unit with sensor mounted on a mi- cro-flow valve − required mounting parts and accesso- ries: table 7 on page 52 in the positioner version with an external po- sit...

Page 41: Sensor With Direct Attach-

Eb 8384-5 en 41 attachment to the control valve – mounting parts and accessories 4.7.1 mounting the position sensor with direct attach- ment type 3277-5 actuator with 120 cm² (fig. 15) the signal pressure from the positioner is routed over the signal pressure connection of the connecting plate (9, f...

Page 42

42 eb 8384-5 en attachment to the control valve – mounting parts and accessories action. For the fail-safe action "actuator stem retracts" the connection on the top dia- phragm case is used. The connection at the side of the yoke must be fitted with a venting plug (accessories). Mounting the positio...

Page 43: Sensor With Attachment

Eb 8384-5 en 43 attachment to the control valve – mounting parts and accessories 4.7.2 mounting the position sensor with attachment according to iec 60534-6 − required mounting parts and accesso- ries: table 7 on page 52 fig. 16 1. Place the lever (1) on the position sensor in mid-position and hold ...

Page 44: Sensor to Type 3510 Mi-

44 eb 8384-5 en attachment to the control valve – mounting parts and accessories 4.7.3 mounting the position sensor to type 3510 mi- cro-flow valve − required mounting parts and accesso- ries: table 7 on page 52 fig. 17 1. Place the lever (1) on the position sen- sor in mid-position and hold it in p...

Page 45: Tuators

Eb 8384-5 en 45 attachment to the control valve – mounting parts and accessories 4.7.4 mounting on rotary ac- tuators − required mounting parts and accesso- ries: table 7 on page 52 fig. 18 1. Place the lever (1) on the position sensor in mid-position and hold it in place. Un- thread the nut (1.1) a...

Page 46: 4.8 Mounting The Leakage

46 eb 8384-5 en attachment to the control valve – mounting parts and accessories 4.8 mounting the leakage sensor fig. 19 normally, the control valve is delivered with positioner and leakage sensor already mounted. If the leakage sensor is mounted after the valve has been installed or it is mounted o...

Page 47: Stainless Steel Housings

Eb 8384-5 en 47 attachment to the control valve – mounting parts and accessories 4.9 attaching positioners with stainless steel housings positioners with stainless steel housings re- quire mounting parts that are completely made of stainless steel or free of aluminum. Note: the pneumatic connecting ...

Page 48

48 eb 8384-5 en attachment to the control valve – mounting parts and accessories attachment according to iec 60534-6 (namur rib or attachment to rod-type yokes) and to rotary actuators the positioner requires an additional port for the exhaust air that can be connected over piping. An adapter availa...

Page 49

Eb 8384-5 en 49 attachment to the control valve – mounting parts and accessories table 2: direct attachment to type 3277 actuator (fig. 4) order no. Mounting parts standard version for actuators 175, 240, 350, 355, 700, 750 cm² 1400-7453 version compatible with paint for actuators 175, 240, 350, 355...

Page 50

50 eb 8384-5 en attachment to the control valve – mounting parts and accessories table 3: attachment to namur ribs or control valves with rod-type yokes (20 to 35 mm rod diameter) according to iec 60534-6 (fig. 5 and fig. 9) travel in mm lever for actuator order no. 7.5 s type 3271-5 with 60/120 cm²...

Page 51

Eb 8384-5 en 51 attachment to the control valve – mounting parts and accessories table 5: attachment to rotary actuators (fig. 10 and fig. 11) order no. Mounting parts attachment acc. To vdi/vde 3845 (september 2010), see section 15.1 for details actuator surface corresponds to fixing level 1 size a...

Page 52

52 eb 8384-5 en attachment to the control valve – mounting parts and accessories table 6: general accessories order no. Serial interface adapter (samson ssp interface to rs-232 port on a pc) 1400-7700 isolated usb interface adapter (samson ssp interface to usb port on a pc) including trovis-view cd-...

Page 53: 5 Connections

Eb 8384-5 en 53 connections 5 connections warning! Risk of injury due to the actuator stem extending or retracting. Do not touch or block the actuator stem. Notice risk of malfunction due to incorrect sequence of mounting, installation and start-up. Keep the following sequence. 1. Remove the protect...

Page 54

54 eb 8384-5 en connections the bench range is written on the nameplate ei- ther as the spring range or signal pressure range depending on the actuator. The direction of action is marked fa or fe, or by a symbol. Actuator stem extends fa (air to open) fail-close (for globe and angle valves): require...

Page 55

Eb 8384-5 en 55 connections selecting cables and wires observe clause 12 of en 60079-14: 2008 (vde 0165, part 1) for installation of the intrinsically safe circuits. Clause 12.2.2.7 applies when running multi- core cables and wires with more than one intrinsically safe circuit. The radial thickness ...

Page 56

56 eb 8384-5 en connections there is a second m20 x 1.5 threaded hole in the housing that can be used for addition- al connection, when required. The screw terminals are designed for wire cross-sections of 0.2 to 2.5 mm². Tighten screws by 0.5 to 0.6 nm. Note: the power supply for the positioner can...

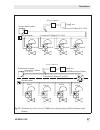

Page 57

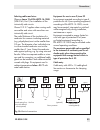

Eb 8384-5 en 57 connections f oundation ™ fieldbus iec 61158-2 f oundation ™ fieldbus iec 61158-2 3730-50 3730-50 3730-50 power conditioner 3730-50 process control system bus termination supply unit f oundation ™ fieldbus f oundation ™ fieldbus iec 61158-2 power conditioner 3730-51 3730-51 3730-51 3...

Page 58: Tion

58 eb 8384-5 en connections solenoid valve (forced venting function) for positioners fitted with the optional sole- noid valve for the forced venting function, a voltage of 24 v dc must be connected to the relevant terminals +81 and –82. If there is no voltage connected for the sole- noid valve at t...

Page 59: 6 Operating Controls and

Eb 8384-5 en 59 operating controls and readings 6 operating controls and readings rotary pushbutton the rotary pushbutton is located underneath the front protective cover. The positioner is operated on site using the rotary pushbutton: turn : select codes and values press : confirm setting air to op...

Page 60

60 eb 8384-5 en operating controls and readings readings icons assigned to certain codes, parameters and functions are indicated on the display. Operating modes: − manual mode (see section 8.2.1) the positioner follows the manual set point (code 1) instead of the set point of the analog output block...

Page 61

Eb 8384-5 en 61 operating controls and readings % mm air to open close init caution va lv e actua tes min side max back min back max side q % s mm % s mm serial interf ace % mm malfunction/fault manual mode closed-loop operation code bar graph for set point deviation or lever posi- tion units binary...

Page 62: 7 Start-Up and Settings

62 eb 8384-5 en start-up and settings 7 start-up and settings notice risk of malfunction due to incorrect sequence of mounting, installation and start-up. Keep the following sequence. 1. Remove the protective film from the pneumatic connections. 2.Mount the positioner on the control valve. 3. Connec...

Page 63: Striction Q

Eb 8384-5 en 63 start-up and settings slide switch position and re-initialize the po- sitioner. Note: the switch position is prompted prior to an initialization. After an initial- ization has been completed, chang- ing the switch position does not have any effect on the operation of the po- sitioner...

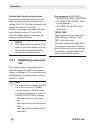

Page 64: Range of The Positioner

64 eb 8384-5 en start-up and settings reading direction for right attachment of pneumatic connections reading direction for left attachment of pneumatic connections if the displayed data appear upside down, proceed as follows: turn code 2 press , code 2 blinks. Turn required reading direction pr...

Page 65: 7.6 Initialization

Eb 8384-5 en 65 start-up and settings press . The positioner changes to the man- ual mode ( ). Check the operating range: manual set point w (current angle of rotation is indicated) turn code 1 press , code 1 and blink. Turn until the pressure in the positioner builds up, and the control valve mov...

Page 66

66 eb 8384-5 en start-up and settings the signal pressure required by the control valve. The type and extent of auto tuning de- pends on the initialization mode selected: − maximum range (max) (standard range) initialization mode for simple start-up of valves with two clearly defined mechani- cal en...

Page 67: Based On Maximum

Eb 8384-5 en 67 start-up and settings closed position air to close if the slide switch is set to air to close, the positioner automatically switches to the di- rection of action increasing/decreasing (äæ) after initialization has been completed. This results in the following assignment between set p...

Page 68: Based On Nominal Range

68 eb 8384-5 en start-up and settings press to confirm the max as the initial- ization mode. Start initialization: Î press init key. The nominal travel/angle of rotation is indi- cated in % after initialization. Code 5 (nomi- nal range) remains locked. The parameters for travel/angle range start (co...

Page 69: Based On A Manually

Eb 8384-5 en 69 start-up and settings enter the pin position and nominal range: mm pin position default: no mm nominal range (locked when code 4 = no) turn code 4 press , code 4 blinks. Turn pin position on lever (see relevant section on attachment) press . Turn code 5 press , code 5 blinks. T...

Page 70: Tion

70 eb 8384-5 en start-up and settings enter the pin position: mm pin position default: no turn code 4 press , code 4 blinks. Turn pin position on lever (see relevant section on attachment) press . Select the initialization mode: init mode default max turn code 6 press , code 6 blinks. Turn m...

Page 71

Eb 8384-5 en 71 start-up and settings notice perform a reset before re-initializing the positioner if the substitute posi- tioner has already been initialized. Refer to section 7.8. Enable configuration: note: if no settings are entered within 120 seconds, the enabled configuration function becomes ...

Page 72

72 eb 8384-5 en start-up and settings deactivate travel limit: travel limit default: no turn code 11 press , code 11 blinks. Turn g no press . Change pressure limit and control parame- ters: note: do not change the pressure limit (code 16). Only change the control parameters k p (code 17) and t v ...

Page 73: 7.7 Zero Calibration

Eb 8384-5 en 73 start-up and settings the positioner switches to man mode. The blocking position is indicated. Note: since initialization has not been com- pleted, the error code 76 (no emer- gency mode) and possibly also error code 57 (control loop) may appear on the display. These alarms do not in...

Page 74

74 eb 8384-5 en start-up and settings perform zero calibration: init mode default max turn code 6 press , code 6 blinks. Turn zp Î press init key. Zero calibration starts. The positioner moves the valve to the closed position and recalibrates the internal electrical zero point. 7.8 reset to defa...

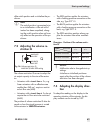

Page 75: 8 Operation

Eb 8384-5 en 75 operation 8 operation warning! Risk of injury due to the actuator stem extending or retracting. Do not touch or block the actuator stem. 8.1 enabling and selecting pa- rameters all codes and their meaning and default set- tings are listed in the code list in section 14. Codes which a...

Page 76

76 eb 8384-5 en operation % automatic mode switching to manual mode (man) turn code 0 press , display: auto, code 0 blinks. Turn man press . The positioner changes to the man- ual mode ( ). The manual mode starts using the last set point of the automatic mode, ensuring a bumpless changeover. The...

Page 77: 8.3 Fault/malfunction

Eb 8384-5 en 77 operation exit the fail-safe position turn code 0 press , code 0 blinks. Turn and select the required operating mode (auto or man). Press . The positioner switches to the operating mode selected. 8.3 fault/malfunction a status classification is assigned to all status and fault alar...

Page 78: Sages

78 eb 8384-5 en operation condensed state positioner display maintenance alarm function check text e.G. Testing, tune or test maintenance required/ maintenance demand- ed out of specification blinking if the positioner has not been initialized, the maintenance alarm icon ( ) appears on the display a...

Page 79

Eb 8384-5 en 79 adjusting the limit switch 9 adjusting the limit switch the positioner version with an inductive limit switch has an adjustable tag (1) mounted on the axis of rotation, which operates the prox- imity switch (3). For operation of the inductive limit switch, the corresponding switching...

Page 80: Limit Switch

80 eb 8384-5 en adjusting the limit switch the required switching function, i.E. Whether the output relay is to be picked up or re- leased when the tag enters the field, must be selected at the switching amplifier, if re- quired. Adjusting the switching point: note: during adjustment or testing, the...

Page 81

Eb 8384-5 en 81 adjusting the limit switch age the ribbon cable (between pcb and display). 2. Use a knife to cut an opening at the marked location (4). 3. Push the connector (11) with cable through the opening and secure the prox- imity switch (7) on the cover with a dot of glue. 4. Insert the cable...

Page 82: 10 Maintenance

82 eb 8384-5 en maintenance 10 maintenance the positioner does not require any mainte- nance. There are filters with a 100 µm mesh size in the pneumatic connections for supply and output which can be removed and cleaned, if required. The maintenance instructions of any up- stream supply air pressure...

Page 83: Work On Equipment

Eb 8384-5 en 83 maintenance, calibration and work on equipment a) updates outside the hazardous area: remove the positioners from the plant. Update them outside the haz- ardous area. B) updates on site: updates on site are only permitted after the plant operator presented a signed hot work permit. A...

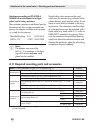

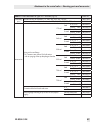

Page 84: 14 Code List

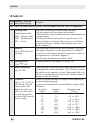

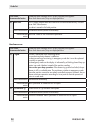

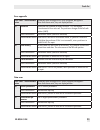

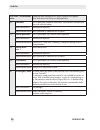

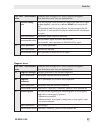

84 eb 8384-5 en code list 14 code list code no. Parameter – readings/ values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 0 operating mode [man] manual mode auto automatic mode safe fail-safe position esc cancel switch...

Page 85

Eb 8384-5 en 85 code list code no. Parameter – readings/ values [default setting] description 5* nominal range mm or angle °, esc nominal valve travel or opening angle must be entered for nominal (nom) or substitute (sub) initialization. The possible adjustment range depends on the pin position from...

Page 86

86 eb 8384-5 en code list code no. Parameter – readings/ values [default setting] description 9* travel/angle range end (upper x-range value) 20.0 to [100.0 %] of the nominal range, esc note: specified in mm or angle ° provided code 4 is activated. Upper range value for travel/angle in nominal or op...

Page 87

Eb 8384-5 en 87 code list code no. Parameter – readings/ values [default setting] description 15* reference variable range end (w-end) 50.0 to 100.0 % of the span adjusted in code 12/13, [no], esc if the set point w reaches up to the entered percentage at the final value that causes the valve to ope...

Page 88

88 eb 8384-5 en code list code no. Parameter – readings/ values [default setting] description 20* characteristic [0] to 9, esc select characteristic 0 linear 1 equal percentage 2 reverse equal percentage 3 samson butterfly valve, linear 4 samson butterfly valve, equal percentage 5 vetec rotary plug ...

Page 89

Eb 8384-5 en 89 code list code no. Parameter – readings/ values [default setting] description 24* lv total valve travel 1000 to 99 · 10 7 [1.000000], esc exponential reading from 9999 travel cycles on- wards limit value of total valve travel. If the limit is exceeded, the error mes- sage and the ico...

Page 90

90 eb 8384-5 en code list code no. Parameter – readings/ values [default setting] description 43 firmware info control read only indicates the positioner type and current firmware version in alter- nating sequence. 44 y info [0] to 100 %, 0p, max, – – – read only indicates the control signal y in % ...

Page 91

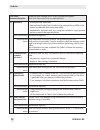

Eb 8384-5 en 91 code list note: the error codes listed in following appear in the display corresponding to their status classification set over the condensed state (maintenance required/maintenance de- manded: , out of specification: blinking, maintenance alarm: ). If “no mes- sage” is assigned to t...

Page 92

92 eb 8384-5 en code list error codes – recommended action condensed state message active. When prompted, err appears. When fault alarms exist, they are displayed here. 52 attachment • invalid positioner attachment. • nominal travel/angle (code 5) could not be achieved during nom initial- ization (n...

Page 93

Eb 8384-5 en 93 code list error codes – recommended action condensed state message active. When prompted, err appears. When fault alarms exist, they are displayed here. 56 pin position initialization canceled because selected nom and sub initialization modes require the pin position to be entered. S...

Page 94

94 eb 8384-5 en code list error codes – recommended action condensed state message active. When prompted, err appears. When fault alarms exist, they are displayed here. 60 fatal error error in safety-relevant data that cannot be corrected automatically. Possible cause: emc disturbances. The valve is...

Page 95

Eb 8384-5 en 95 code list error appendix error codes – recommended action condensed state message active, when prompted, err appears. When fault alarms exist, they are displayed here. 65 hardware initialization key jammed (firmware version r 1.51 and higher) a hardware error has occurred. The positi...

Page 96

96 eb 8384-5 en code list error codes – recommended action condensed state message active. When prompted, err appears. When fault alarms exist, they are displayed here. 70 calibration error in data from production calibration. The positioner continues oper- ation with cold start values. Status class...

Page 97

Eb 8384-5 en 97 code list error codes – recommended action condensed state message active. When prompted, err appears. When fault alarms exist, they are displayed here. 77 software loading error when the positioner starts operation for the first time after the ff signal has been applied, it carries ...

Page 98: Blocks (Code 48)

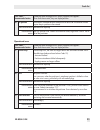

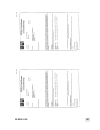

98 eb 8384-5 en code list 14.1 decimal values of the modes in the foundation™ fieldbus blocks (code 48) mode decimal val- ue auto 8 auto/cas 12 auto/rcas 134 o/s 128 man 16 14.2 decimal values of the states in the foundation™ fieldbus blocks (code 48) status decimal value good (nc) – non-specific 12...

Page 99

Eb 8384-5 en 99 code list status decimal value good (c) – not invited 204 good (c) – not selected 208 good (c) – local override 216 good (c) – fault state active 220 bad – non-specific 0 bad – configuration error 4 bad – not connected 8 bad – device failure 12 bad – sensor failure 16 bad – no comm.,...

Page 100: 15 Dimensions In Mm

100 eb 8384-5 en dimensions in mm 15 dimensions in mm 40 34 210 28 14 80 164 output (38) supply (9) 86 70 15 46 34 70 70 28 schild 58 58 pressure gauge bracket or connecting plate attachment according to iec 60534-6 lever mm s = 17 m = 50 l = 100 xl = 200 external position sensor direct attachment m...

Page 101

Eb 8384-5 en 101 dimensions in mm attachment according to vdi/vde 3847 to type 3277 attachment according to vdi/vde 3847 to a namur rib 62 164 38 200 16 4 164 13 62 24 lever mm m = 50 l = 100 xl = 200 fig. 28: attachment according to vdi/vde 3847.

Page 102

102 eb 8384-5 en dimensions in mm 56 86 130 80 166 30 86 Ø 101 80 52 output y 1 output y 2 supply (9) output y 1 output y 2 reversing amplifier (optional)* heavy-duty version a 1 z a 2 output a1 output a2 supply (9) 50 80 58 130 49 59 79 76 50 150 reversing amplifier (optional)* connecting plate g ¼...

Page 103

Eb 8384-5 en 103 dimensions in mm x z y 16 10...17 lever x y z s 17 mm 25 mm 33 mm m 25 mm 50 mm 66 mm l 70 mm 100 mm 116 mm xl 100 mm 200 mm 216 mm fig. 30: lever 15.1 fixing levels according to vdi/vde 3845 (september 2010) a m6 c b 25 m min Ød Ød fixing level 2 (bracket surface) fixing level 1 (a...

Page 104

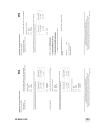

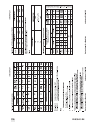

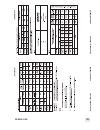

104 eb 8384-5 en valve characteristic selection linear (select characteristic: 0) 0 50 100 0 50 100 travel/ angle of rotation [%] reference variable [%] equal percentage (select characteristic: 1) reverse equal percentage (select characteristic: 2) 0 50 100 0 50 100 travel/ angle of rotation [%] ref...

Page 105

Samson butterfly valve linear (select characteristic: 3) samson butterfly valve equal percentage (select characteristic: 4) 0 50 100 0 50 100 travel/ angle of rotation [%] reference variable [%] 0 50 100 0 50 100 travel/ angle of rotation [%] reference variable [%] vetec rotary plug valve linear (se...

Page 106

106 eb 8384-5 en.

Page 107

Eb 8384-5 en 107.

Page 108

108 eb 8384-5 en.

Page 109

Eb 8384-5 en 109.

Page 110

110 eb 8384-5 en.

Page 111

Eb 8384-5 en 111.

Page 112

112 eb 8384-5 en.

Page 113

Eb 8384-5 en 113.

Page 114

114 eb 8384-5 en.

Page 115

Eb 8384-5 en 115.

Page 116

116 eb 8384-5 en.

Page 117

Eb 8384-5 en 117.

Page 118

118 eb 8384-5 en.

Page 119

Eb 8384-5 en 119.

Page 120

120 eb 8384-5 en.

Page 121

Eb 8384-5 en 121.

Page 122

122 eb 8384-5 en.

Page 123

Eb 8384-5 en 123.

Page 124

124 eb 8384-5 en.

Page 125

Eb 8384-5 en 125.

Page 126

126 eb 8384-5 en.

Page 127

Eb 8384-5 en 127.

Page 128

128 eb 8384-5 en.

Page 129

Eb 8384-5 en 129.

Page 130

130 eb 8384-5 en.

Page 131

Eb 8384-5 en 131.

Page 132: Eb 8384-5 En

Samson ag · mess- und regeltechnik weismüllerstraße 3 · 60314 frankfurt am main, germany phone: +49 69 4009-0 · fax: +49 69 4009-1507 samson@samson.De · www.Samson.De eb 8384-5 en 2016-04-20 · engl ish.