- DL manuals

- Samson

- Controller

- 3730-6

- Mounting And Operating Instructions

Samson 3730-6 Mounting And Operating Instructions - 4.7

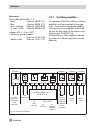

4.7

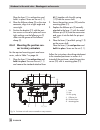

Mounting the leakage

sensor

Normally, the control valve is delivered with

positioner and leakage sensor already

mounted.

If the leakage sensor is mounted after the

valve has been installed or it is mounted

onto another control valve, proceed as de-

scribed in following.

NOTICE

Fasten the leakage sensor using a torque of

20

±

5 Nm.

The hole with M8 thread on the NAMUR rib

should preferably be used to mount the sen-

sor (Fig. 17).

Note: If the positioner was mounted directly

onto the actuator (integral attachment), the

NAMUR interfaces on either side of the

valve yoke can be used to mount the leak-

age sensor.

The start-up of the leakage sensor is descri-

bed in detail in the Operating Instructions

EB 8389-1 EN on EXPERTplus Valve Diag-

nostics.

EB 8384-6 EN

39

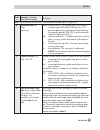

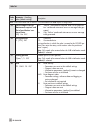

Attachment to the control valve – Mounting parts and accessories

1

2

3

Fig. 17 · Mounting the leakage sensor

1

Leakage sensor

2

Screw

3

Plug-type connection

Summary of 3730-6

Page 1

Series 3730 electropneumatic positioner type 3730-6 with hart ® communication and pressure sensors mounting and operating instructions eb 8384-6 en (1300-1623) firmware version 1.01 edition february 2012 fig. 1 · type 3730-6.

Page 2

2 eb 8384-6 en danger! Indicates a hazardous situation which, if not avoided, will result in death or serious injury. Warning! Indicates a hazardous situation which, if not avoided, could result in death or serious injury. Notice indicates a property damage message. Note: supplementary explanations,...

Page 3

Contents page 1 important safety instructions . . . . . . . . . . . . . . . . . . . . . . 6 2 article code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 3 design and principle of operation. . . . . . . . . . . . . . . . . . . . 8 3.1 safety function (sil) . . . . . . . . . . . . . . ...

Page 4

5.2.2 establishing communication . . . . . . . . . . . . . . . . . . . . . . 49 6 operator controls and readings . . . . . . . . . . . . . . . . . . . . 52 6.1 serial interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54 6.2 hart ® communication . . . . . . . . . . . . . . . . . . . ....

Page 5

15 dimensions in mm . . . . . . . . . . . . . . . . . . . . . . . . . . 109 15.1 fixing levels according to vdi/vde 3845 (september 2010) . . . . . 110 16 valve characteristic selection . . . . . . . . . . . . . . . . . . . . . 111 certificates. . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 6

1 important safety instructions for your own safety, follow these instructions concerning the mounting, start-up and opera- tion of the positioner: 4 the positioner is to be mounted, started up or operated only by trained and experienced personnel familiar with the product. According to these mounti...

Page 7: Article Code

2 article code positioner type 3730-6- x x x x x x x 0 x x 0 x 0 0 with hart ® communication and pressure sensors explosion protection atex: ii 2g ex ia iic/iib t6; ii 2d ex tb iiic t6 ip 66 110 iecex: ex ia iic/iib t6; ex d[ia] iic/iib t6; ex td a21 ip 66 t 80°c 111 gost: 1ex ia iic t6 x, dip a21 t...

Page 8: Design and Principle of

3 design and principle of operation the electropneumatic positioner is attached to pneumatic control valves. It is used to as- sign the valve stem position (controlled vari- able x) to the control signal (reference vari- able w). The input signal received from a control system is compared to the tra...

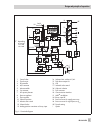

Page 9

Eb 8384-6 en 9 design and principle of operation 1 control valve 2 travel sensor 3 pd controller 4 a/d converter 5 microcontroller 6 i/p converter 7 air capacity booster 8 pressure regulator 9 flow regulator 10 volume restriction 11* inductive limit switch 12* solenoid valve 13* analog position tran...

Page 10: 3.1

3.1 safety function (sil) the safety function is based on the shutdown of the i/p converter (6). This causes the pneumatic actuator to be vented and the valve to move to its fail-safe position. Monitoring of the input signal the i/p converter is switched off when the input signal of the positioner a...

Page 11

Eb 8384-6 en 11 design and principle of operation diagnostic function control valve on/off valve diagnosis monitoring data logger • • depending on trigger condition selected valve signature • Ä – friction – supply pressure – actuator springs – pneumatic leakage on/off valve – • – breakaway time – tr...

Page 12: 3.4

3.4 type of application there are two different types of application: control valve and on/off valve. The auto- matic mode (auto) and manual mode (man) can be selected in both types of applications. Operating mode control valve on/off valve automatic the positioner follows the refer- ence variable (...

Page 13: 3.6

3.6 additional equipment inductive limit switch in the version with inductive limit switch, the rotary shaft of the positioner carries an ad- justable tag which actuates the installed proximity switch. The optional inductive limit switch (11) is connected to a1, while the re- maining software limit ...

Page 14

Mined safety set point when the positioner is in automatic mode (auto). This function is not performed in the manual mode (man) or fail-safe position mode (safe). 4 switch auto/manual the positioner changes from the auto- matic mode (auto) to the manual mode (man) or vice versa. This function is not...

Page 15: 3.7

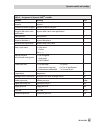

3.7 technical data eb 8384-6 en 15 design and principle of operation type 3730-6 positioner (technical data in test certificates additionally apply for explosion-protected devices) travel, adjustable direct attachment to type 3277: 3.6 to 30 mm attachment acc. To iec 60534-6: 3.6 to 200 mm rotary ac...

Page 16

16 eb 8384-6 en design and principle of operation type 3730-6 positioner (technical data in test certificates additionally apply for explosion-protected devices) electrical connections one m20 x 1.5 cable gland for 6 to 12 mm clamping range · additional second m20 x 1.5 threaded hole · screw termina...

Page 17

Eb 8384-6 en 17 design and principle of operation options for type 3730-6 positioner inductive limit switch for connection to switching amplifier acc. To en 60947-5-6. Can be used in combination with a software limit switch. Sj2-sn proximity switch namur nc contact sj2-s1n proximity switch namur no ...

Page 18

18 eb 8384-6 en design and principle of operation options for type 3730-6 positioner binary input · galvanically isolated · switching behavior configured over software active switching behavior (default setting) connection for external switch (floating contact) or relay contacts electrical data open...

Page 19

Eb 8384-6 en 19.

Page 20: Attachment to The Control

4 attachment to the control valve – mounting parts and accessories warning! Attach the positioner, keeping the following sequence: 1. Mount the positioner on the control valve 2. Connect the supply air 3. Connect the electrical power 4. Perform the start-up settings the positioner is suitable for th...

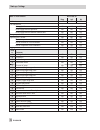

Page 21

Travel tables note: the lever m is included in the scope of delivery. Levers s, l, xl for attachment according to iec 60534-6 (namur) are available as accesso- ries (see table 4 on page 42). Direct attachment to type 3277-5 and type 3277 actuators actuator size rated travel adjustment range at posit...

Page 22: 4.1

4.1 direct attachment 4.1.1 type 3277-5 actuator refer to table 2 on page 41 for the required mounting parts and accessories. Note the travel table on page 21! Actuator with 120 cm² 1. Mount connecting plate (9) on the actu- ator. 2. Mount connecting plate (6) or pressure gauge bracket (7) with pres...

Page 23

Eb 8384-6 en 23 attachment to the control valve – mounting parts and accessories 11 9 supply 9 output 38 5 6 7 6 10 3 2 1 15 6.1 1.1 1.2 14 8 fig. 4 · direct attachment - signal pressure connection for type 3277-5 actuator with 120 cm² 1 lever 1.1 nut 1.2 disk spring 2 follower pin 3 follower clamp ...

Page 24: 4.1.2 Type 3277 Actuator

4.1.2 type 3277 actuator refer to table 3 on page 42 or the required mounting parts and the accessories. Note the travel table on page 21! Actuators with 240 to 700 cm² mount the positioner on the yoke as shown in fig. 5. The signal pressure is routed to the actuator over the connection block (12), ...

Page 25

Eb 8384-6 en 25 attachment to the control valve – mounting parts and accessories 2 10 14 15 1 2 3 11 11.1 supply 13 b c 1.1 1.2 12 12.1 12 12.2 12.1 12 16 16 16 12.2 supply ansicht a ansicht b ansicht c suppl y g g 3/8 a fig. 5 · direct attachment – signal pressure connection for type 3277 actuator ...

Page 26: 4.2

4.2 attachment according to iec 60534-6 (namur) refer to table 4 on page 42 for the required mounting parts and the accessories. Note the travel table on page 21! The positioner is attached to the control valve with a namur bracket (10). 1. Screw the two bolts (14) to the bracket (9.1) of the stem c...

Page 27

Eb 8384-6 en 27 attachment to the control valve – mounting parts and accessories 10 11 1 1 14.1 3 3.1 16 15 14 1 1.2 1.1 2 9.1 9 6.1 6 7 8 fig. 6 · attachment according to iec 60534-6 (namur) attachment to namur rib attachment to rod-type yoke rod diameter 20 to 35 mm additional bracket for actuator...

Page 28: 4.3

4.3 attachment to type 3510 micro-flow valve with type 3271-5 actuator refer to table 4 on page 42 for the required mounting parts and accessories. Note the travel table on page 21! The positioner is attached to the valve yoke using a bracket. 1. Place clamp (3) on the valve stem con- nector, align ...

Page 29

Eb 8384-6 en 29 attachment to the control valve – mounting parts and accessories 3 10 11 11 6 1 2 1.2 1.1 7 8 6.1 fig. 7 · attachment to type 3510 micro-flow valve 1 lever 1.1 nut 1.2 disk spring 2 follower pin 3 clamp 6 connecting clamp 6.1 seal rings 7 pressure gauge bracket 8 pressure gauge mount...

Page 30: 4.4

4.4 attachment to rotary actuators refer to table 5 on page 43 for the required mounting parts and accessories. Note the travel table on page 21! The positioner is mounted to the rotary actu- ator using two pairs of brackets. Prior to attaching the positioner to the samson type 3278 rotary actuator,...

Page 31

Eb 8384-6 en 31 attachment to the control valve – mounting parts and accessories 10 10.1 6 (7, 8) 1.1 2 4.3 5 6.1 4 1.2 1 130 mm 80 mm fig. 9 · attachment to rotary actuators slot slot note: always use the connecting plate (6) included in the accessories to connect supply and output. Never screw thr...

Page 32: 4.4.1 Heavy-Duty Version

4.4.1 heavy-duty version refer to table 4 on page 42 for the required mounting parts and accessories. Both mounting kits contain all the necessary mounting parts. First select correct actuator size. Prepare actuator, and mount required adapter supplied by the actuator manufac- turer, if necessary. 1...

Page 33

Eb 8384-6 en 33 attachment to the control valve – mounting parts and accessories 6 6.1 7 8 1 1.1 1.2 2 4.1 3 10.1 10 11 5 4.3 4 4.2 4.1 3 5.1 5 10.1 10 4.3 4 4.2 fig. 11 · attachment to rotary actuators (heavy-duty version) 1 lever 1.1 nut 1.2 disk spring 2 follower pin 3 adapter 4 coupling wheel 4....

Page 34: 4.5

4.5 reversing amplifier for double-acting actuators for the use with double-acting actuators, the positioner must be fitted with a reversing amplifier, e.G. The samson type 3710 re- versing amplifier (see mounting and oper- ating instructions eb 8392 en). 4.6 attaching an external position sensor re...

Page 35

Type 3277 actuator with 240 to 700 cm² the signal pressure is routed to the connec- tion at the side of the actuator yoke for the version "actuator stem extends". For the fail-safe position "actuator stem re- tracts" the connection on the top diaphragm case is used. The connection at the side of the...

Page 36: Sor With Attachment Accord-

Place the lever (1) in mid-position and hold it in place. Screw on the nut (1.1). 5. Place the follower clamp (3) on the ac- tuator stem, align and fasten it, making sure that the fastening screw rests in the groove of the actuator stem. 6. Place the mounting plate (21) together with the sensor onto...

Page 37: Sor to Type 3510 Mi-

For other actuator sizes or travels, select the lever and pin position from the travel table on page 21. Lever l and xl are included in the mounting kit. 3. Place the lever (1) and disk spring (1.2) on the sensor shaft. Place the lever (1) in mid-position and hold it in place. Screw on the nut (1.1)...

Page 38: Sor to Rotary Actuators

Place the lever (1) in mid-position and hold it in place. Screw on the nut (1.1). 4. Place the follower clamp (3) on the stem connector, align it at a right angle and screw tight. 5. Position the bracket (21) with the posi- tion sensor on the valve yoke and screw tight, making sure the follower pin ...

Page 39: 4.7

4.7 mounting the leakage sensor normally, the control valve is delivered with positioner and leakage sensor already mounted. If the leakage sensor is mounted after the valve has been installed or it is mounted onto another control valve, proceed as de- scribed in following. Notice fasten the leakage...

Page 40: 4.8

4.8 attaching positioners with stainless steel housings positioners with stainless steel housings re- quire mounting parts that are completely made of stainless steel or free of aluminum. Note: the pneumatic connecting plate, pres- sure gauge bracket and type 3710 pneu- matic reversing amplifier are...

Page 41

Notice the adapter uses one of the m20 x 1.5 con- nections in the housing which means just one cable gland can be installed. Should other valve accessories be used which vent the actuator (e.G. Solenoid valve, volume booster, quick exhaust valve), this exhaust air must also be included in the purgin...

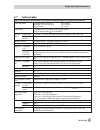

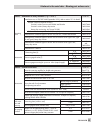

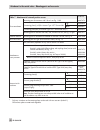

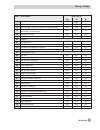

Page 42

42 eb 8384-6 en attachment to the control valve – mounting parts and accessories table 3 · direct attachment to type 3277 (fig. 5) order no. Mounting parts for actuators with 240, 350, 355 and 700 cm² 1400-7453 accessories required piping with screw fitting – for "actuator stem retracts" – with air ...

Page 43

Eb 8384-6 en 43 attachment to the control valve – mounting parts and accessories table 5 · attachment to rotary actuators (figs. 8 and 9) order no. Mounting parts attachment acc. To vdi/vde 3845 (september 2010), refer to section 15.1 for details actuator surface corresponds to level 1 size aa1 to a...

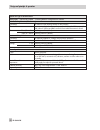

Page 44

44 eb 8384-6 en attachment to the control valve – mounting parts and accessories table 7 · attachment of external position sensor order no. Direct attachment mounting parts for actuators with 120 cm² see fig. 13 left 1400-7472 connecting plate (9, old) for actuator type 3277-5xxxxxx.00 g 1 8 1400-68...

Page 45: Connections

5 connections warning! Mount the positioner, keeping the following sequence: 1. Mount the positioner on the control valve 2. Connect the supply air 3. Connect the electrical power 4. Perform the start-up settings the connection of the electrical auxiliary power may cause the actuator stem to move, d...

Page 46: 5.2

Actuator stem extends fa (air to open) fail-safe position "valve closed" (for globe and angle valves): actuator stem retracts fe (air to close) fail-safe position "valve open" (for globe and angle valves): for tight-closing valves, the maximum signal pressure pst max is roughly estimated as fol- low...

Page 47

Nection, an additional cable gland can be installed. Seal cable entries left unused with plugs. Devices used at ambient temperatures be- low –20 °c must be fitted with metal cable glands. Equipment for use in zone 2/zone 22 in equipment operated with type of protec- tion eex na ii (non-sparking equi...

Page 48: 5.2.1 Switching Amplifiers

Accessories: plastic cable gland m20 x 1.5: – black order no. 8808-1011 – blue order no. 8808-1012 – brass, nickel-pl. Order no. 1890-4875 – st. Steel 1.4305 order no. 8808-0160 adapter m20 x 1.5 to ½ npt – aluminum, powder-coated order no. 0310-2149 – stainless steel order no. 1400-7114 5.2.1 switc...

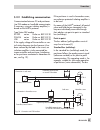

Page 49

5.2.2 establishing communication communication between pc and positioner (via fsk modem or handheld communicator, if necessary, using an isolation amplifier) is based on the hart ® protocol. Type viator fsk modem rs 232 not ex. Order no. 8812-0130 pcmcia not ex order no. 8812-0131 usb not ex order n...

Page 50

Address/polling address has to be within a range of 1 to 15. Note: communication errors may occur when the process controller/control station output is not hart-compatible. For adaptation, the z box (order no. 1170-2374) can be installed between out- put and communication interface. At the z box a v...

Page 51

Eb 8384-6 en 51.

Page 52: Operator Controls and

6 operator controls and readings rotary pushbutton the rotary pushbutton is located underneath the front protective cover. The positioner is operated on site using the rotary pushbutton: turn to select codes and values. Press to confirm setting. Slide switch air to open or air to close 4 air to open...

Page 53

Eb 8384-6 en 53 operator controls and readings air to open close init caution va lv e actua tes min side max back min back max side q serial interf ace % s mm % mm % s mm % mm fig. 21 · display and operator controls auto automatic cl clockwise ccl counterclockwise err error esc escape hi ix ³ 21.6 m...

Page 54: 6.1

6.1 serial interface the positioner must be supplied with at least 3.8 ma. The positioner can be connected directly to the pc via the local serial interface and the serial interface adapter. The operator software is trovis-view 4 with installed device module 3730-6. 6.2 hart ® communication the posi...

Page 55

Eb 8384-6 en 55 operator controls and readings table 8 · assignment of dynamic hart ® variables variable meaning unit set point set point % direction of action set point direction of action set point % set point after transit time specification set point after transit time specification % valve posi...

Page 56: Start-Up – Settings

7 start-up – settings warning! Attach the positioner, keeping the following sequence: 1. Mount the positioner on the control valve 2. Connect the supply air 3. Connect the electrical power 4. Perform the start-up settings reading on display after connecting the electrical auxiliary power: 4 the faul...

Page 57: 7.2

Note: the switch position is prompted prior to an initialization. After an initialization has been completed, changing the switch posi- tion does not have any effect on the opera- tion of the positioner. 7.2 setting the volume restriction q the volume restriction q is used to adapt the air delivery ...

Page 58: 7.5

Configuration enabled default: no turn ® code 3, display: no press , code 3 blinks turn ® yes press , display limiting the signal pressure: pressure limit default: no turn ® code 16 press , code 16 blinks turn until the required pressure limit ap- pears. Press to confirm the pressure limit setting. ...

Page 59: 7.6

Warning! To avoid personal injury or property dam- age caused by the supply air or electrical auxiliary power, disconnect the supply air and electrical auxiliary power before ex- changing the lever or changing the pin posi- tion. 7.6 initialization warning! During initialization, the control valve m...

Page 60: On Maximum Range

After the basic initialization, the reference curve for the valve signature is recorded (code 48 - h0 = yes). Reading in alternating sequence: test/d1 bar graph display indicating the progress of the initialization initialization successful, positioner in automatic operating mode the time required f...

Page 61: On Nominal Range

Adopts this travel/angle of rotation as the operating range from 0 to 100 %. Enable configuration: note: if no settings are entered within 120 seconds, the enabled configuration function becomes invalid. Default no turn ® code 3, display: no press , code 3 blinks turn ® yes press , display enter the...

Page 62: On A Manually Selected

Enable configuration: note: if no settings are entered within 120 seconds, the enabled configuration function becomes invalid. Default no turn ® code 3, display: no press , code 3 blinks turn ® yes press , display enter pin position and nominal range: pin position default no nominal range (locked wi...

Page 63

Positions and adopts it as the operating range with limits of lower travel/angle range value (code 8) and upper travel/an- gle range value (code 9). Enable configuration: note: if no settings are entered within 120 seconds, the enabled configuration function becomes invalid. Enable configuration def...

Page 64: On Manually Selected End

After initialization, the maximum travel is in- dicated in mm or the maximum angle in ° in code 5. 7.6.4 man2 – initialization based on manually selected end positions before starting initialization, move the con- trol valve manually to the end positions. The positioner calculates the travel/angle d...

Page 65

Turn ® man2 press to adopt the initialization mode man2 ® pos1 and the current angle posi- tion of the lever are indicated on the display in alternating sequence. Turn clockwise in small steps until the re- quired valve position is reached. The valve must be moved with a monotonically in- creasing s...

Page 66

Enter the pin position and nominal range: pin position default no nominal range (locked with code 4 = no) turn ® code 4 press , code 4 blinks turn ® pin position on lever (see relevant section on attachment) press turn ® code 5 press , code 5 blinks turn ® nominal travel/angle press select the initi...

Page 67

Pressure limit default no kp level default 7 tv level default turn ® code 16/17/18 press , code 16/17/18 blinks turn to set the control parameter selected press to confirm the setting. Enter closing direction and blocking posi- tion: closing direction direction of rotation causing the valve to move ...

Page 68: 7.7

Zero point calibration if the process allows it (valve move once to the closed position), perform a zero point calibration according to section 7.7. 7.6.6 tuning the kp input filter changing the kp level (code 17) affects the set point deviation. This effect can be com- pensated for by tuning the in...

Page 69: 7.8

Turn ® zp 4 press init key! Zero calibration is started, the positioner moves the control valve to the closed position and readjusts the internal electri- cal zero point. 7.8 settings for on/off valves if the valve is to be operated using the on/off valve as the type of application, the operating po...

Page 70

Triggering the partial stroke test (pst) a partial stroke test is started when the ref- erence (w ) moves from the operat- ing point into the range between 25 and 50 % travel and remains there for longer than six seconds. The valve ( ) moves from the last defined position to the lower range value (o...

Page 71: 7.9

7.9 reset to default values a reset allows the positioner to be reset to the default settings. To reset the positioner, the options diag, std and ds are available in code 36. Table 8 lists the reset functions. Note: code 36 – ds is usually selected when the valve is mounted in another posi- tion or ...

Page 72

72 eb 8384-6 en start-up – settings table 9 · reset functions reset code 36 diag std ds initialization no yes yes fail-safe behavior air supply failure no no yes power supply failure of positioner no no yes power supply failure of external solenoid valve no no yes emergency mode no no no operating h...

Page 73

Eb 8384-6 en 73 start-up – settings table 9 · reset functions reset code 36 diag std ds 26 limit a1 no yes yes 27 limit a2 no yes yes 32 error message in case of 'function check' condensed state no yes yes 33 error message in case of 'maintenance required' and 'out of specification' condensed state ...

Page 74: Operation

8 operation warning! The actuator stem moves while the positioner is being operated. Do not touch the actuator stem or obstruct it to avoid risk of injury to hands or fingers. 8.1 enabling and selecting parameters the code list in section 14 on page 83 on- wards contains all codes with their meaning...

Page 75: 8.2

8.2 operating modes 8.2.1 automatic and manual mo- des after initialization has been completed suc- cessfully, the positioner is in the automatic mode (auto). Automatic mode switch to manual operating mode turn ® code 0 press , display: auto, code 0 blinks turn ® man press to change to the manual op...

Page 76: 8.3

8.2.2 fail-safe position (safe) if you want to move the valve to fail-safe po- sition determined during start-up (see sec- tion 7.1), proceed as follows: turn ® code 0 press , display: current operating mode (auto or man), code 0 blinks turn ® safe press , display: s the valve moves to the fail-safe...

Page 77

4 out of specification the positioner is operated outside the specified operating conditions. Note: if an event is assigned to the 'no mes- sage' status, this event does not have any ef- fect on the condensed state. Condensed state the condensed state appears on the display with the following icons:...

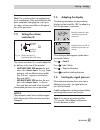

Page 78: Adjusting The Limit Switch

9 adjusting the limit switch the positioner version with inductive limit switch has one adjustable tag (1) mounted on the shaft which operates the proximity switch (3). For operation of the inductive limit switch, the corresponding switching amplifier ac- cording to en 60947-5-6 (see section 5.2.1) ...

Page 79

Setting the switching point: notice during adjustment or testing, the switching point must always be approached from mid-position (50 %). To ensure safe switching under any ambient conditions, the switching point should be ad- justed to a value of approx. 5 % before the mechanical stop (open – close...

Page 80: 9.1

9.1 retrofitting an inductive limit switch required retrofit kit: limit switch order no. 1400-7460 note: for explosion-protected devices, the requirements in section 11 need to be kept. 1. Take off the rotary pushbutton (3) and cap (1), unthread the five screws (2) and lift off the plastic cover (9)...

Page 81: Maintenance

10 maintenance the positioner does not require any mainte- nance. There are filters with a 100 µm mesh size in the pneumatic connections for supply and output which can be removed and cleaned, if required. The maintenance instructions of any up- stream supply air pressure reducing stations must be o...

Page 82: Maintenance, Calibration

B.) updates on site: updates on site are only permitted after the plant operator has presented a sig- ned hot work permit. After updating has been completed, add the current firmware to the nameplate; this can be done using labels. 13 maintenance, calibration and work on equipment the interconnectio...

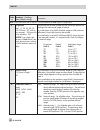

Page 83: Code List

14 code list code no. Parameter – readings, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 0 operating mode [man] manual mode auto automatic mode safe fail-safe position esc escape switchover from automatic to man...

Page 84

Code no. Parameter – readings, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 4* pin position [no] · 17, 25, 35, 50, 70, 100, 200 mm · 90° with ro- tary actuators · 300 mm with piston actuators · esc notice if you...

Page 85

Code no. Parameter – readings, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 6* initialization mode (init mode) - continued - man2: manual setting 2 · for all globe valves with unknown nominal range (open and clo...

Page 86

Code no. Parameter – readings, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 9* upper travel/angle range value (upper x-range value) 20.0 to [100.0] % of the nominal range · esc specified in mm or angle°, provide...

Page 87

Code no. Parameter – readings, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 12* set point, lower range value (w-start) [0.0] to 75.0 % · esc lower range value (0 % = 4 ma) of the valid set point range this value...

Page 88

Code no. Parameter – readings, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 17* proportional-action coefficient kp level 0 to 17 · esc, [7] notice changing the k p level influences the system deviation. This inf...

Page 89

Code no. Parameter – readings, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 21* transit time open (w ramp open) [0] to 240 s · esc notice the transit time entered in this code does not apply when the safety func...

Page 90

Code no. Parameter – readings, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 25* alarm mode 0 to 3 · esc, [2] switching mode of software limit switches alarm a1 and a2 in responding state (when positioner has bee...

Page 91

Code no. Parameter – readings, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 28* alarm test reading direction: standard turned [no] [no] run 1 1 run run 2 2 run run 3 3 run esc esc test testing the software limit...

Page 92

Code no. Parameter – readings, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 33* error message in case of 'maintenance required' and 'out of specification' con- densed states [yes] · no · esc yes: 'failure', 'mai...

Page 93

Code no. Parameter – readings, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 37 options read only indicates which option (connected to terminals 31 and 32, fig. 18) is installed: no: no option installed pos: anal...

Page 94

Code no. Parameter – readings, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 45 internal solenoid valve/ forced venting read only indicates whether a solenoid valve/forced venting is installed. If a voltage suppl...

Page 95

Code no. Parameter – readings, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. D5* zero point limit 0.0 to 100.0 % of the nom- inal range · esc, [5.0] valve position limit in relation to the nominal range when the ...

Page 96

96 eb 8384-6 en code list code no. Parameter – readings, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. H0* initialization including valve signature no · [yes] · esc initialization with [yes] or without [no] plott...

Page 97

Code no. Parameter – readings, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. A2* test auto · [man] · esc notice the write protection is active in the auto setting (local operation and operation over software lock...

Page 98

Code no. Parameter – readings, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. D3* upper range value 0.0 to 100.0 % · esc, [90.0] final value of the test d4* activate ramp function no · [yes] yes: the valve is ramp...

Page 99

Code no. Parameter – readings, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. E4 – unassigned – e5* activate pst tolerance band monitoring [no] · yes activates pst tolerance band monitoring (yes) or deactivates it...

Page 100

Code no. Parameter – readings, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. F9 canceled by control loop error the test was canceled. A control loop error has occurred. Type of application note: section 7.8 conta...

Page 101

Note: the error codes listed in following appear in the display corresponding to their status classification set over the condensed state (maintenance required/maintenance demanded: , out of specification: blinking, failure alarm: ). If 'no message' is assigned to the error code as the status classi...

Page 102

Initialization errors error codes – recommended action condensed state alarm active, when prompted, err appears. When error messages exist, they are displayed here. 50 x > range the value supplied by the measuring signal is either too high or too low, the measuring sensor is close to its mechanical ...

Page 103

Eb 8384-6 en 103 code list error codes – recommended action condensed state alarm active, when prompted, err appears. When error messages exist, they are displayed here. 53 initialization time exceeded (init time >) the initialization routine lasts too long. – the valve opens after a considerable de...

Page 104

Error codes – recommended action condensed state alarm active, when prompted, err appears. When fault alarms exist, they are displayed here. 104 eb 8384-6 en.

Page 105

Hardware errors error codes – recommended action condensed state alarm active, when prompted, err appears. When fault alarms exist, they are displayed here. 62 x signal additional indication at the fault alarm contact! – measured data recording for actuator has failed. – conductive plastic element i...

Page 106

Error appendix error codes – recommended action condensed state alarm active, when prompted, err appears. When fault alarms exist, they are displayed here. 65 hardware additional indication at the fault alarm contact! A hardware error has occurred, the positioner changes to the fail-safe position (s...

Page 107

Diagnostic errors error codes – recommended action condensed state alarm active, when prompted, err appears. When fault alarms exist, they are displayed here. 77 – unassigned – 78 – unassigned – 79 collective error messages generated by expertplus exist. The error does not have any direct effect on ...

Page 108

Error codes – recommended action condensed state alarm active, when prompted, err appears. When fault alarms exist, they are displayed here. 86 sil tests the sil operator test has failed. Refer to operating instructions eb 8389-1 en on expertplus valve diagnostics. Status classification failure (sta...

Page 109: Dimensions In Mm

15 dimensions in mm eb 8384-6 en 109 dimensions in mm 40 34 210 28 14 80 164 output (38) supply (9) 86 70 15 46 34 70 70 28 schild 58 58 fig. 23a · namur and direct attachment direct attachment attachment acc. To iec 60534-6 external position sensor lever mm s = 17 m = 50 l = 100 xl = 200 pressure g...

Page 110

15.1 fixing levels according to vdi/vde 3845 (september 2010) 110 eb 8384-6 en dimensions in mm 56 86 130 80 166 30 86 Ø 101 80 52 output y 1 output y 2 supply (9) output y 1 output y 2 fig. 23b · attachment to rotary actuators vdi/vde 3845 (sept. 2010), level 1, size aa1 to aa4 type 3710 reversing ...

Page 111

16 valve characteristic selection the characteristics that can be selected in code 20 are shown in following in graph form. Note: a characteristic can only be defined (user-defined characteristic) using the operator software (e.G. Trovis-view 4). Linear (select characteristic: 0) equal percentage (s...

Page 112

Samson butterfly valve, linear (select characteristic: 3) samson butterfly valve, equal percentage (select characteristic: 4) vetec rotary plug valve, linear (select characteristic: 5) vetec rotary plug valve, equal percentage (select characteristic: 6) segmented ball valve, linear (select character...

Page 113

Eb 8384-6 en 113.

Page 114

114 eb 8384-6 en.

Page 115

Eb 8384-6 en 115.

Page 116

116 eb 8384-6 en.

Page 117

Eb 8384-6 en 117.

Page 118

118 eb 8384-6 en.

Page 119

Eb 8384-6 en 119.

Page 120

120 eb 8384-6 en.

Page 121

Index a accessories . . . . . . . . . . . . . . 42 application, type of . . . . . . . . 12, 69 article code . . . . . . . . . . . . . . . 7 attachment acc. To iec 60534-6 (namur) . . . 26 direct attachment to type 3277 actuator . . . . . 24 to type 3277-5 actuator . . . . 22 reversing amplifier . . ...

Page 122

Substitute calibration (sub) . . . . . 65 k kp input filter . . . . . . . . . . . . . 68 l leakage sensor . . . . . . . . . . . . 13 electrical connection . . . . . . . . 48 mounting. . . . . . . . . . . . . . 39 limit switch . . . . . . . . . . . . . . 13 adjusting . . . . . . . . . . . 78 - 80 ele...

Page 123

Eb 8384-6 en 123 diagnostic functions . . . . . . . . 11 z zero calibration . . . . . . . . . . . . 68 index.

Page 124

Samson ag · mess- und regeltechnik weismüllerstraße 3 · 60314 frankfurt am main · germany phone: +49 69 4009-0 · fax: +49 69 4009-1507 internet: http://www.Samson.De eb 8384-6 en 2012-0 8.