- DL manuals

- Samson

- Valve Positioners

- 3731-5

- Mounting and operating instructions

Samson 3731-5 Mounting and operating instructions

Summary of 3731-5

Page 1

Series 3731 type 3731-5 electropneumatic ex d positioner with f oundation ™ fieldbus communication mounting and operating instructions eb 8387-5 en firmware version r 1.4 x edition march 2016 fig. 1 · type 3731-5 eb + cd.

Page 2

2 eb 8387-5 en danger! Indicates a hazardous situation which, if not avoided, will result in death or serious injury. Warning! Indicates a hazardous situation which, if not avoided, could result in death or serious injury. Notice indicates a property damage message. Note: supplementary explanations,...

Page 3

Contents 1 important safety instructions . . . . . . . . . . . . . . . . . . . . . . 5 2 article code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 3 design and principle of operation . . . . . . . . . . . . . . . . . . . . 7 3.1 additional equipment . . . . . . . . . . . . . . . . ....

Page 4

7.5.2 initialization based on nom nominal range . . . . . . . . . . . . . . 45 7.5.3 initialization based on man manually selected range . . . . . . . . . 47 7.5.4 sub substitute calibration . . . . . . . . . . . . . . . . . . . . . . . 48 7.6 zero calibration . . . . . . . . . . . . . . . . . . . ....

Page 5

1 important safety instructions for your own safety, follow these instructions concerning the mounting, start up and opera- tion of the positioner: 4 the positioner may only be mounted, started up or operated by trained and experi- enced personnel familiar with the product. According to these mounti...

Page 6

2 article code positioner type 3731 - 5 x x x x x x 0 0 0 x 1 x 0 0 0 with lcd, autotune, f oundation ™ fieldbus explosion protection atex: ii 2g ex d iic t6,t5,t4 gb; ii 2g ex de iic t6,t5,t4 gb; ii 2d ex tb iiic t80°c db ip66 ii 2g ex d iic t6 gb; ii 2g ex de iic t6 gb; ii 2d ex tb iiic ip65 t80°c...

Page 7

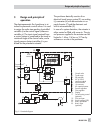

3 design and principle of operation the electropneumatic ex d positioner is at- tached to pneumatic control valves. It is used to assign the valve stem position (controlled variable x) to the control signal (reference variable w). The input signal received from a control system is compared to the tr...

Page 8

A constant air stream to the atmosphere is created by the flow regulator (9) with a fixed set point. The air stream is used to purge the inside of the housing as well as to optimize the air capacity booster (7). The i/p converter (6) is supplied with a constant upstream pressure by the pressure regu...

Page 9

3.2 communication the positioner is completely controlled over the digital signal transmission implemented according to f oundation™ fieldbus spec- ification. Data are transmitted as bit-synchronous cur- rent modulation at a rate of 31.25 kbit/s over twisted-pair cables conforming to iec 61158-2. 3....

Page 10

3.3 technical data 10 eb 8387-5 en design and principle of operation type 3731-5 ex d positioner (technical data in test certificates additionally apply for explosion-protected devices) rated travel adjustable direct attachment to type 3277: 3.6 to 30 mm attachment acc. To iec 60534-6 (namur): 3.6 t...

Page 11

Eb 8387-5 en 11 design and principle of operation type 3731-5 ex d positioner (technical data in test certificates additionally apply for explosion-protected devices) influences temperature: ≤ 0.15/10 k · supply air: none vibration: ≤ 0.25 % up to 2000 hz and 4 g acc. To iec 770 emc complying with r...

Page 12

Summary of explosion protection certificates 12 eb 8387-5 en design and principle of operation type 3731- certificate type of protection/comments 521 ec-type examination certificate number date ptb 11 atex 1014 x 2012-07-26 ii 2g ex d iic t6,t5,t4 gb; ii 2g ex de iic t6,t5,t4 gb; ii 2d ex tb iiic t8...

Page 13

4 attachment to the control valve – mounting parts and accessories warning! Attach the positioner, keeping the following sequence: 1. Mount the positioner on the control valve 2. Connect the supply air 3. Connect the electrical power 4. Perform the start-up settings the positioner is suitable for th...

Page 14

14 eb 8387-5 en attachment to the control valve – mounting parts and accessories travel tables note: the lever m is included in the scope of delivery. Levers s, l, xl for attachment according to iec 60534-6 (namur) are available as accesso- ries (see table 3 on page 30). Direct attachment to type 32...

Page 15

4.1 direct attachment 4.1.1 type 3277-5 actuator refer to table 1 on page 28 for required mounting parts and accessories. Actuator with 120 cm² notice if a solenoid valve or similar is additionally mounted to the control valve, observe the following instructions which differ from the instructions ot...

Page 16

9. Insert formed seal (15) into the groove of the positioner housing, pressing the four retaining rings over the housing screws and both fittings into the hous- ing recesses. 10. Thread the bias spring (17) through the crosspiece underneath the lever (1) and push into the hole in the housing. Push t...

Page 17

Eb 8387-5 en 17 attachment to the control valve – mounting parts and accessories 9 11 supply 9 output 38 5 6 4 17 7 6 10 10.1 3 2 1 15 6.1 1.1 1.2 14 8 11.1 a a-a a fig. 4 · direct attachment for type 3277-5 actuator with 120 cm² switchover plate (9) marking 1 lever 1.1 nut 1.2 disk spring 2 followe...

Page 18

4.1.2 type 3277 actuator refer to table 2 on page 28 for the required mounting parts and accessories. Actuators with 175 to 750 cm² mount the positioner on the yoke as shown in fig. 5. The signal pressure is routed to the actuator over the connection block (12), for actuators with fail-safe action "...

Page 19

Eb 8387-5 en 19 attachment to the control valve – mounting parts and accessories 2 17 10 14 15 1 2 3 11 supply 13 b 1.1 1.2 12 12.1 12 12.2 12.1 12 16 16 16 12.2 supply ansicht b ansicht a ansicht c suppl y g g 3/8 11.1 a c fig. 5 · direct attachment – signal pressure connection for type 3277 actuat...

Page 20

9. Mount cover (11) on the other side. Make sure that the vent plug (11.1) points to the back when the control valve is installed to allow any con- densed water that collects to drain off. 4.2 attachment according to iec 60534-6 (namur) refer to table 3 on page 30 for the required mounting parts and...

Page 21

Eb 8387-5 en 21 attachment to the control valve – mounting parts and accessories 10 11 1 1 14.1 3 3.1 16 15 14 1 1.2 1.1 2 9.1 9 6 7 8 6.1 fig. 6 · attachment according to iec 60534-6 (namur) 1 lever 1.1 nut 1.2 disk spring 3 follower plate 3.1 follower plate 6 connecting plate (only for g ¼) 6.1 se...

Page 22

Place lever (1) on the positioner shaft and screw tight using the disk spring (1.2) and nut (1.1). 6.4 move the lever once all the way as far as it will go in both directions. 7. Place positioner on the namur bracket in such a manner that the fol- lower pin (2) rests in the slot of the fol- lower pl...

Page 23

Eb 8387-5 en 23 attachment to the control valve – mounting parts and accessories 10.1 11.1 9 11 12.1 6 2 1 1.2 1.1 7 8 6.1 10 9.1 3 9.2 9.3 fig. 7 · attachment to type 3510 micro-flow valve fit screw-in restriction into output (38) 1 lever 1.1 nut 1.2 disk spring 2 follower pin 3 follower plate 6 co...

Page 24

4.4 attachment to rotary actuators refer to table 4 on page 30 for the required mounting parts and accessories. Both mounting kits contain all the necessary mounting parts. First select correct actuator size. Prepare actuator, and mount required adapter supplied by the actuator manufac- turer, if ne...

Page 25

Eb 8387-5 en 25 attachment to the control valve – mounting parts and accessories counterclockwise 6 6.1 7 8 1 1.1 1.2 2 4.1 3 10.1 10 11 5 4.3 4 4.2 4.1 3 5.1 5 10.1 10 4.3 4 4.2 fig. 9 · attachment to rotary actuators 1 lever 1.1 nut 1.2 disk spring 2 follower pin 3 adapter 4 coupling wheel 4.1 scr...

Page 26

4.5 reversing amplifier for double-acting actuators for the use with double-acting actuators, the positioner must be fitted with a reversing amplifier, e.G. The samson type 3710 re- versing amplifier (see mounting and oper- ating instructions eb 8392). If a different reversing amplifier (item no. 10...

Page 27

Eb 8387-5 en 27 attachment to the control valve – mounting parts and accessories a 1 1.5 1.6 1.3 1.2 1.1 1 1.6 z a 2 1.4 a1 a2 z a1 output 38 supply 9 output 38 supply 9 1.3 1.2 1.1 fig. 10 · mounting a reversing amplifier (1079-1118 or 1079-1119) from the positioner control signals to the actuator ...

Page 28

4.6 required mounting parts and accessories 28 eb 8387-5 en attachment to the control valve – mounting parts and accessories table 1 · direct attachment to type 3277-5 (fig. 4) order no. Mounting parts for actuators with 120 cm² effective diaphragm area 1400-7452 version compatible with paint for ac...

Page 29

Eb 8387-5 en 29 attachment to the control valve – mounting parts and accessories table 2 · direct attachment to type 3277 (fig. 5) order no. Accessories required piping with screw fitting – for "actuator stem retracts" – with air purging of the top dia- phragm chamber 355 cm² steel g 1 4 / g 3 8 140...

Page 30

Eb 8387-5 en 30 attachment to the control valve – mounting parts and accessories table 3 · attachment to namur ribs or control valves with rod-type yokes (20 to 35 mm rod diameter) according to iec 60534-6 (figs. 6 and 7) travel in mm lever for actuators order no. Accessories connecting plate g ¼ 14...

Page 31

5 connections warning! Mount the positioner, keeping the following sequence: 1. Mount the positioner on the control valve 2. Connect the supply air 3. Connect the electrical power 4. Perform the start-up settings the connection of the electrical auxilary power may cause the actuator stem to move, de...

Page 32

5.1.1 signal pressure gauges to monitor the supply air (supply) and sig- nal pressure (output), we recommend that pressure gauges be attached (see accesso- ries in tables 1 to 5). 5.1.2 supply pressure the required supply pressure (of supply air) depends on the bench range and the actua- tor's opera...

Page 33

5.2 electrical connections eb 8387-5 en 33 connections danger! Risk of electric shock and/or the formation of an explosive atmosphere! 4 for electrical installation, you are required to observe the relevant electrotechnical regulations and the accident prevention regulations that ap- ply in the coun...

Page 34

34 eb 8387-5 en connections table 6 · accessories order no. Cable gland m20 x 1.5; ex e, black plastic 8808-0178 blanking plugs; ex de; stainless steel (approvals: cenelec, csa, gost, iecex) m20 x 1.5 8323-1203 ½ npt 8323-1204 cable entry for unarmored cables; ex e, ex d, ex td a21 (approvals: cenel...

Page 35

Cable entry the threaded connections for the terminal compartment are designed with ½ npt or m20x1.5 threads. The electrical connections are screw termi- nals for wire cross-sections of 0.2 to 2.5 mm² using a tightening torque of at least 0.5 nm. Note: the positioner is powered either over the conne...

Page 36

Electrical auxiliary power supplied over the bus line 4 route the two-wire bus line to the screw terminals marked “signal”. Polarity does not have to be observed. Refer to fig. 13 or the nameplate for the terminal assignment. After connecting the electrical auxiliary power, testing runs across the d...

Page 37

Eb 8387-5 en 37 connections notice the demanded degree of protection might not be met because the terminal compart- ment is not sealed tightly. Only operate the positioner with sealed cable entries and with the lid screwed on properly. Notice loss of explosion protection due to damaged lid thread an...

Page 38

6 operator controls and readings 6.1 rotary pushbutton the rotary pushbutton ( ) is located under- neath the front protective cover. The positioner is operated on site using the rotary pushbutton: turn to select codes and values. Press to confirm setting. 6.2 serial interface the serial interface co...

Page 39

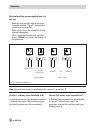

Eb 8387-5 en 39 operator controls and readings retaining screw protective cover rotary pushbutton lc display serial interface and together: ao transducer block is in man operating mode blinks emergency mode, see code 62 blinks not initialized blinks valve in mechanical fail-safe position fail-safe p...

Page 40

7 start-up – settings warning! Attach the positioner, keeping the following sequence: 1. Mount the positioner on the control valve 2. Connect the supply air 3. Connect the electrical power 4. Perform the start-up settings reading on display after connecting the electrical auxiliary power: 4 testing ...

Page 41

Notice do not activate the pressure limit function in actuators with fail-safe action air to open (ato), e.G. Double-acting actuators (off = default). Enable configuration at the positioner before activating the pressure limit function: note: if no settings are entered within 120 seconds, the enable...

Page 42

The angle of the lever on the back of the positioner is indicated on the display. A horizontal lever (mid-position) is equal to 0°. To ensure the positioner is working prop- erly, the outer bar elements may not blink while the valve is moving through the oper- ating range. The manual operating mode ...

Page 43

Turn → code 0 press , display: man code 0 blinks. Turn → init press . Turn until the required fail-safe position appears on the display. Press to confirm the fail-safe position. Turn → esc press to exit or: start initialization as described in sec- tion 7.5. For checking purposes: after the position...

Page 44

Note: the initialization procedure can be in- terrupted while running by pressing the rota- ry pushbutton ( ). Stop appears three se- conds long and the positioner then moves to the fail-safe position. The fail-safe position can be canceled again over code 0. Alternating displays: initialization run...

Page 45

Press , display: select initialization mode: init mode default: max turn → code 6 press turn → max press to confirm the max initialization mode. Start initialization: initialization fail-safe position setting progress indicated until initialization starts turn → code 0 press , code 0 blinks. Turn → ...

Page 46

Travel/angle range start (code 8) and travel/angle range end (code 9) as the op- erating range. Note: the maximum possible travel must al- ways be greater than the nominal travel en- tered. If this is not the case, initialization is interrupted (error message code 52) becau- se the nominal travel is...

Page 47

Start initialization: initialization fail-safe position setting progress indicated until initialization starts turn → code 0 press , code 0 blinks. Turn → init press . The setting of the fail-safe position ato or atc appears. Keep pressed down for 6 seconds. Initialization starts after the progress ...

Page 48

Configuration enabled default: off turn → code 3, display: off press , code 3 blinks. Turn → on press , display: enter pin position: pin position default: off turn → code 4 press , code 4 blinks. Turn → pin position on lever (see sec- tions on attachment). Press . Select initialization mode: initial...

Page 49

You should always select a different initial- ization mode if the plant allows it. The sub initialization mode is used to re- place a positioner while the process is running. For this purpose, the control valve is usually fixed mechanically in a certain po- sition, or pneumatically by means of a pre...

Page 50

Press to confirm the sub initialization mode. Enter direction of action: direction of action default: ää turn → code 7 press , code 7 blinks. Turn → direction of action (ää/äæ) press . Deactivate travel limit: travel limit default: 100.0 turn → code 11 press , code 11 blinks. Turn → off press . Chan...

Page 51

Turn → closing direction (ccl counter- clockwise/cl clockwise) press . Turn → code 35 press , code 35 blinks. Turn → blocking position, e.G. 5 mm (read off at travel indicator scale of the blocked valve or measure with a ruler) press . Start initialization: initialization fail-safe position setting ...

Page 52

Press . The positioner changes to the au- tomatic operating mode. The current valve position is indicated in % on the display. Note: if the positioner shows a tendency to hunt in automatic operating mode, the pa- rameters k p and t v must be slightly cor- rected. Proceed as follows: – set t v (code ...

Page 53

7.7 reset to default values this function resets all parameters to the fac- tory default values (see code list in section 11). Enable configuration: turn → code 3, display: off press , code 3 blinks. Turn → on press , display: reset start-up parameters: reset default: off turn → code 36, display: of...

Page 54

8 operation warning! The actuator stem moves while the positioner is being operated. Do not touch the actuator stem or obstruct it to avoid risk of injury to hands or fingers. 8.1 enabling and selecting parameters all codes with their meanings and default settings are listed in the code list in sec-...

Page 55

8.2 operating modes 8.2.1 automatic and manual operating modes after initialization has been completed suc- cessfully for the first time, the positioner is automatically in automatic operating mode. Automatic operating mode switching to manual operating mode turn → code 0 press , display: auto, code...

Page 56

8.2.2 safe – fail-safe position if you want to move the valve to fail-safe po- sition determined during start-up (see sec- tion 7.4), proceed as follows: turn → code 0 press , display: current operating mode (auto or man), code 0 blinks. Turn → safe press , display: s the valve moves to the fail-saf...

Page 57

Faster rate than expected. Maintenance is necessary in the short term. 4 function check test or calibration procedures are being performed. The positioner is temporarily unable to perform its control task until this procedure is completed note: if an event is assigned to the “no message” status, thi...

Page 58

9 maintenance the positioner does not require any mainte- nance. There are filters with a 100 µ m mesh size in the pneumatic connections for supply and output which can be removed and cleaned, if required. The maintenance instructions of any up- stream supply air pressure reducing stations must be o...

Page 59

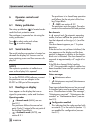

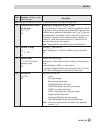

11 code list code no. Parameter – display, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 0 operating mode [man] auto · safe esc auto automatic mode man manual mode safe fail-safe position esc escape in man and au...

Page 60

Code no. Parameter – display, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 4* pin position [off] 17, 25, 35, 50, 70, 100, 200 mm 90° with rotary actuators esc note! If you select a pin position in code 4 that is...

Page 61

Code no. Parameter – display, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 7* direction of action [ää] äæ esc direction of action of the reference variable w in relation to the travel/angle of rotation x (increa...

Page 62

Code no. Parameter – display, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 11* travel/angle upper limit (upper x-limit ) 50.0 to 120.0 [100] % of the operating range off · esc limitation of the travel/angle of r...

Page 63

Code no. Parameter – display, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 17* proportional-action coeffi- cient kp (step) 0 to 17 [7] esc displaying or changing the k p and t v steps: during initialization, the...

Page 64

Code no. Parameter – display, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 21* required transit time open (w ramp open) 0 to 240 s [0] esc the time required to pass through the operating range when the valve ope...

Page 65

Code no. Parameter – display, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 39 system deviation e –99.9 to 999.9 % deviation from the target position (e = w – x) display only 40 minimum transit time open 0 to 240...

Page 66

Code no. Parameter – display, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 47* status of write protection switch [no] yes · esc when the write protection function is activated, device data can only be read, but ...

Page 67

Code no. Parameter – display, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 48* d7 start reference test [off] on · esc starting of a reference test (for the expert + functions: drive signal y steady-state (d1) an...

Page 68

Code no. Parameter – display, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 48 * process controller (pid) p0 target mode target operating mode p1 actual mode actual operating mode · display only p2 cas_in value a...

Page 69

Code no. Parameter – display, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 48* operating unit (res) s0 target mode (res) target operating mode s1 actual mode (res) actual operating mode · display only s2 block e...

Page 70

Code no. Parameter – display, values [default setting] description note: codes with marked with an asterisk (*) must be enabled with code 3 prior to configuration. 48* l3 field_val_d status and its status l4 out_d value displays the discrete output variable l5 out_d status and its status l6 block er...

Page 71

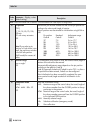

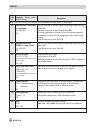

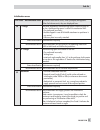

Initialization errors error codes – recommended action condensed state alarm active, when prompted, err appears. When fault alarms exist, they are displayed here. 50 x > range the value supplied by the measuring signal is either too high or too low, the measuring sensor is close to its mechanical li...

Page 72

Error codes – recommended action condensed state alarm active, when prompted, err appears. When fault alarms exist, they are displayed here. 53 initialization time exceeded (init time >) the initialization routine lasts too long. The positioner returns to its previous operating mode. • no pressure o...

Page 73

Operational errors error codes – recommended action condensed state alarm active, when prompted, err appears. When fault alarms exist, they are displayed here. 57 control loop control loop error, the control valve does not react within the to- lerable times of the controlled variable (tolerance band...

Page 74

Hardware errors error codes – recommended action condensed state alarm active, when prompted, err appears. When fault alarms exist, they are displayed here. 62 x signal determination of the measured data for the actuator has failed. Conductive plastic element is defective. The positioner continues t...

Page 75

Error codes – recommended action condensed state alarm active, when prompted, err appears. When fault alarms exist, they are displayed here. 67 test calculation the hardware controller is monitored by means of a test calculation. Status classification maintenance alarm (cannot be classified) recomme...

Page 76

Error codes – recommended action condensed state alarm active, when prompted, err appears. When fault alarms exist, they are displayed here. 73 internal device error 1 internal device error status classification [maintenance required] recommended action return the positioner to samson ag for repair....

Page 77

Diagnosis errors error codes – recommended action condensed state alarm active, when prompted, err appears. When fault alarms exist, they are displayed here. 79 extended diagnostics error messages are generated in the extended expert + diagnos- tics if expert + has been successfully activated in cod...

Page 78

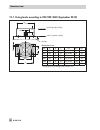

12 dimensions in mm 78 eb 8387-5 en dimensions in mm 70 15 46 34 14 122 95 34 53 28 npt ½, ¼ 58 58 236 output supply fig. 15a · attachment according to iec 60534-6 and direct attachment attachment acc. To iec 60534-6 → direct attachment → pressure gauge bracket or connecting plate (g ¼ only) electri...

Page 79

Eb 8387-5 en 79 dimensions in mm 80 52 output y 1 output y 2 supply (9) output y 1 output y 2 56 86 130 80 166 30 86 Ø 101 fig. 15b · attachment to rotary actuators vdi/vde 3845 (sept. 2010), level 1, size aa1 to aa4 type 3710 reversing amplifier (option) a 1 z a 2 56 86 130 80 166 30 86 Ø 101 76 50...

Page 80

12.1 fixing levels according to vdi/vde 3845 (september 2010) 80 eb 8387-5 en dimensions in mm a m6 c b 25 m min Ød Ød level 2 (bracket surface) level 1 (actuator surface) actuator dimensions in mm size a b c ∅ d m min ∅ d* aa0 50 25 15 5.5 for m5 66 50 aa1 80 30 20 5.5 for m5 96 50 aa2 80 30 30 5.5...

Page 81

Eb 8387-5 en 81.

Page 82

13 appendix 13.1 selecting the valve characteristic the characteristics that can be selected in code 20 are shown in following in graph form. Note: a characteristic can only be defined (user-defined characteristic) using a workstation/ operating software (e.G. Trovis-view). Linear (select characteri...

Page 83

Samson butterfly valve linear (select characteristic: 3) samson butterfly valve equal percentage (select characteristic: 4) vetec rotary plug valve linear (select characteristic: 5) vetec rotary plug valve equal percentage (select characteristic: 6) segmented valve ball linear (select characteristic...

Page 84

84 eb 8387-5 en.

Page 85

Eb 8387-5 en 85.

Page 86

86 eb 8387-5 en.

Page 87

Eb 8387-5 en 87.

Page 88

88 eb 8387-5 en.

Page 89

Eb 8387-5 en 89.

Page 90

Index a accessories . . . . . . . . . . . . . . . . . . 28 - 29 additional equipment binary input. . . . . . . . . . . . . . . . . . . . 9 electrical connection . . . . . . 36 technical data . . . . . . . . . 12 extended expert+ valve diagnostics . . 9 forced venting . . . . . . . . . . . . . . . . ...

Page 91

O operating modes . . . . . . . . . . . . . . 38, 55 operating range checking . . . . . . . . . . . . . . . . . . . . . 41 man manually selected range . . 43, 47 max maximum range. . . . . . . . 43 - 44 nom nominal range . . . . . . . . . 43, 45 operation . . . . . . . . . . . . . . . . . . . 54 - 5...

Page 92

Samson ag · mess- und regeltechnik weismüllerstraße 3 · 60314 frankfurt am main, germany phone: +49 69 4009-0 · fax: +49 69 4009-1507 internet: http://www.Samson.De eb 8387-5 en 2 0 1 6 -0 4.