- DL manuals

- Samson

- Valve Positioners

- 3785 series

- Mounting And Operating Instructions

Samson 3785 series Mounting And Operating Instructions

Summary of 3785 series

Page 1

Profibus positioner type 3785 pa device profile version 3.0 mounting and operating instructions eb 8382-2 en firmware version r 1.42/k 2.12 edition may 2007 fig. 1 · type 3785.

Page 2

Contents page 1 design and principle of operation . . . . . . . . . . . . . . . . . . . 8 1.1 options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 1.2 communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 1.3 technical data . . . . . . . . . . . . . . . . . . ....

Page 3

7.3 parameter description . . . . . . . . . . . . . . . . . . . . . . . . . 42 7.4 codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45 7.4.1 measured value status . . . . . . . . . . . . . . . . . . . . . . . . . 45 7.4.2 set point status . . . . . . . . . . . . . . . . . . . . ...

Page 4

4 eb 8382-2 en safety instructions general safety instructions 4 the positioner may only be assembled, started up or operated by trained and experienced personnel familiar with the product. According to these mounting and operating instructions, trained personnel is referred to as individuals who ar...

Page 5

Modifications in the positioner firmware compared to earlier version old new control r 1.23 r 1.31 firmware adaption for new hardware version hardware version device index .01 control r 1.31 r 1.4 actuator type when the actuator type is set from "linear actuator" to "rotary ac- tuator", the followin...

Page 6

Initialization during initialization, the minimum control signals from 20 % to 80 % of the range of the manipulated variable are determined and saved in the eeprom. Proportional-action coefficients kp_y1 and kp_y2 the coefficients are adapted to the selected actuator type and the measured transit ti...

Page 7

Communication k 1.60 k 2.00 this firmware version implements the profibus pa profile 3.0, class b for control valves according to profibus pa profile for process control devices version 3.0-actuator. The positioner can be connected to the trovis-view configura- tion and operator interface via the se...

Page 8: Design and Principle of

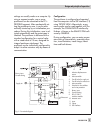

1 design and principle of operation the digital profibus pa positioner is at- tached to pneumatic control valves. It as- signs the valve position (controlled variable) to the control signal (reference variable). The positioner compares the digital control signal transmitted from the control equip- m...

Page 9

Settings are usually made on a computer. By using a segment coupler, one or more positioners can be connected to the pc's profibus segment. After mechanically set- ting the positioner to zero, it can be auto- matically started up by an initialization pro- cedure. During this initialization, zero is ...

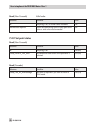

Page 10: 1.3

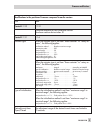

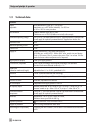

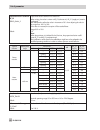

1.3 technical data positioner travel, adjustable direct attachment to type 3277: 5 to 30 mm attachment acc. To iec 60534 (namur): 5 to 255 mm or 30° to 120° for rotary actuators bus connection fieldbus interface as per iec 61158-2 field device acc. To fisco (fieldbus intrinsically safe concept) perm...

Page 11

Binary input internal supply 5 v dc, ri = 100 kw for alarm function e.G. Connection to a pressure switch forced venting, activated over internal switch input: 6 to 24 v dc, static destruction limit 45 v, ri approx. 6 k Ω with 24 v dc (voltage dependent, switching point “1” signal at ≥ 3 v, “0” signa...

Page 12: Attaching The Positioner

2 attaching the positioner the positioner can be attached either di- rectly to the samson type 3277 actuator, or according to iec 60534-6 (namur) to control valves with cast or rod-type yokes. In combination with an intermediate piece, the device can also be attached to rotary ac- tuators as rotary ...

Page 13

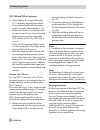

Eb 8382-2 en 13 attaching the positioner actuator stem extends actuator stem retracts internal signal pressure connection connection block signal pressure connection over external piping with seal (new) with switch plate (old) venting actuator stem extends actuator stem extends symbol switchover pla...

Page 14

240, 350 and 700 cm² actuators 6. Check whether the tongue of the seal (17) is properly aligned at the side of the connection block with the actuator symbol "actuator stem extends" or "ac- tuator stem retracts" to match the actua- tor version used. If not, remove the three fastening screws and the c...

Page 15

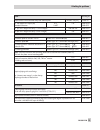

Eb 8382-2 en 15 attaching the positioner table 1 mounting kit required lever with associated clamp and distance plate actuator size [cm 2 ] order no. D1 with stopper for output (38) threaded connection g ¼ ¼ npt 120 1400-6790 1400-6791 d1 (33 mm in length with clamp 17 mm in height) 240 and 350 1400...

Page 16: 2.2

2.2 attachment according to iec 60534-6 refer to tables 4 and 5 on page 19 for re- quired accessories. For positioner attachment according to namur as shown in fig. 4, an adapter housing is required. The valve travel is transmitted via the lever (18) and the shaft (25) to the bracket (28) of the ada...

Page 17

Eb 8382-2 en 17 attaching the positioner fig. 4 · attachment according to iec 60534-6 (namur) 18 lever n1, n2 19 pin 20 plate 21 clamp 22 clamping plate 23 screw 24 pointer 25 shaft 26 lever of positioner 27a transmission pin 27b counter nut 28 bracket 29 studs 30 plate 31 nuts 32 mounting bracket m...

Page 18

Intermediate values must be calculated. 5. Measure the distance between the center of the shaft (25) and the center of the pin (19). You will be prompted for this value later during the configuration of the positioner. 2.2.2 presetting the valve travel 1. Adjust the shaft (25) in the adapter housing...

Page 19

Eb 8382-2 en 19 attaching the positioner table 4 namur attachment valve travel [mm] with lever order no. Namur mounting kit, see fig. 4 for parts valve with cast yoke 7.5 to 60 n1 (125 mm) 1400-6787 30 to 120 n2 (212 mm) 1400-6789 valve with rod-type yoke, rod diameter [mm] 20 to 25 n1 1400-6436 20 ...

Page 20: 2.3

2.3 attachment to rotary actuators refer to table 6 on page 23 for required accessories. The positioner can also be attached to ro- tary actuators according to vdi/vde 3845 by using the mounting parts and accessories in table 6. In this arrangement, the actua- tor's rotary motion is converted via th...

Page 21

Eb 8382-2 en 21 attaching the positioner 33 38 35 39 39 40 34 36 40 34 44 45 42 43 37 fig. 5 · attachment to rotary actuators attachment acc. To vdi/vde 3845 vent plug or filter check valve 33 positioner 34 intermediate piece 35 lever with cam follower roll 36 adapter 37 transmission lever 38 screws...

Page 22: Cam Disk

2.3.3 aligning and mounting the cam disk in rotary actuators with spring-return mech- anism, the built-in actuator springs deter- mine the fail-safe position and the direction of rotation of the control valve. In dou- ble-acting, springless rotary actuators, the direction of rotation depends on both...

Page 23

Eb 8382-2 en 23 attaching the positioner fig. 6 · aligning the cam disk view onto the actuator shaft from positioner control valve opens counterclockwise control valve opens clockwise cam follower roll starting point holes to secure cam disk insert the clip and press tongues outwards table 6 rotary ...

Page 24: Double-Acting Actuators

2.3.4 reversing amplifier for double-acting actuators for use with double-acting actuators, the positioner must be fitted with a reversing amplifier. The reversing amplifier is listed as an accessory in table 6 on page 23. The output signal pressure of the positioner is supplied at output a1 of the ...

Page 25

Eb 8382-2 en 25 attaching the positioner fig. 7 · attaching a reversing amplifier 1 reversing amplifier 1.1 special screws 1.2 flat gasket 1.3 special nuts 1.4 rubber seal 1.5 plug 1.6 filter from the positioner control signals to the actuator.

Page 26: Connections

3 connections 3.1 pneumatic connections the air connections are either ¼ npt or g ¼ tapped holes. The customary fittings for metal and copper tubes or plastic hoses can be used. Note! The supply air must be dry and free of oil and dust. The maintenance instructions for upstream pressure reducing sta...

Page 27: 3.1.2 Supply Air Pressure

3.1.2 supply air pressure the required supply pressure depends on the bench range and the operating direction (fail-safe action) of the actuator. The bench range is indicated on the nameplate as spring range or signal pressure range. Actuator stem extends: required supply pressure = upper bench rang...

Page 28

Caution! The terminal assignment specified in the cer- tificate must be adhered to. Reversing the assignment of the electrical terminals may cause the explosion protection to become in- effective! Do not tamper with enameled screws inside or on the housing note on the selection of cables and wires: ...

Page 29: 3.2.1 Forced Venting

At the binary input, a passive floating con- tact can be used. The positioner signals the circuit status via the bus protocol. Note! The connection of limit switches, bi- nary input and forced venting function re- quires an additional cable gland which must replace the cap fitted on the housing. Acc...

Page 30: 3.2.2 Limit Switches

3.2.2 limit switches for operation of the limit switches, switching amplifiers have to be connected in the out- put circuit. Their function is to control the limit values of the control circuit according to namur, thus ensuring operational reli- ability of the positioner. If the positioner is instal...

Page 31

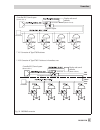

Eb 8382-2 en 31 connections fig. 10 · profibus connection display and control elements ( master class 2) controller/plc/control system ( master class 1) segment coupler termination termination ex segment coupler controller/plc/control system ( master class 1) display and control elements ( master cl...

Page 32: Operation

4 operation warning! Before putting the positioner into op- eration, carefully move the valve to its final position by covering the hole (manual operation) on the cover plate (fig. 11). Check whether the lever mechanism functions properly. If the maximum angle of rotation is exceeded by selecting th...

Page 33: 4.2

4.2 write protection a microswitch marked "write protection" is located to the right of the seven bus address selector switches inside the hinged cover. When activated (position on), the positioner settings are write protected, so that they cannot be overwritten by the profibus communication protoco...

Page 34: 4.4.2 Initialization

4.4.1 adjusting mechanical zero note! Zero must be adjusted with the valve closed (for three-way valves with the actuator stem extended). 4 firmly push the zero point lever, which is located in the cover plate of the positioner, once in the direction indi- cated by the arrow as far as it will go. Th...

Page 35

Final position at a reference variable less than –2.5% (function deactivated), final position at a reference variable larger than 99 % (tight closing). 4 set delay time to at least 30 seconds. 4 enter tag identification. 4 if necessary, additional configuration, e.G. Special characteristics for rota...

Page 36: 4.5

4.5 adjusting the inductive limit switches the positioner version with inductive limit switches has two adjustable tags which are mounted on the shaft of the positioner lever and operate the associated proximity switches. For operation of the inductive limit switches, the corresponding switching amp...

Page 37: Maintenance

5 maintenance the positioner is maintenance free. The pneumatic connection 9/supply contains a filter with a mesh size of 100 μ m. If neces- sary, the filter can be unscrewed and cleaned. If applicable, observe the maintenance in- structions for upstream pressure reducing stations for supply air. 6 ...

Page 38: 7.1

7 how to implement the profibus master class 1 7.1 device database files (gsd) the device database files are provided as text files: sams0688.Gsd for profile 3.0 or sams3785.Gsd for profile 2.0. The files are available from samson ag under product no. 1400-7417 on a 1.44 mb disc (3½"). Alternatively...

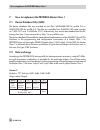

Page 39

Variant 2: module = “rcas_out, rcas_in“ 0xb4 or 0xc2, 0x84, 0x84, 0x82, 0x8c input value (input) byte 0 1 2 3 4 octet 1 sign, exponent octet 2 exponent, fraction octet 3 fraction octet 4 fraction octet 5 rcas_out, value (floating point, ieee) status output value (output) byte 0 1 2 3 4 octet 1 sign,...

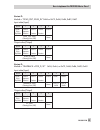

Page 40

Variant 4: module = “checkback, sp“ 0x92, 0xa4, or 0xc2, 0x84, 0x82, 0x82, 0x92 input value (input) byte 0 1 2 octet 1 octet 2 octet 3 check_ back[0] check_ back[1] check_ back[2] output value (output) byte 0 1 2 3 4 octet 1 sign, exponent octet 2 exponent, fraction octet 3 fraction octet 4 fraction...

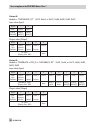

Page 41

Variant 6: module = “rcas_out + checkback, rcas_in“ 0x97, 0xa4, or 0xc2, 0x84, 0x87, 0x82, 0x9c input value (input) byte 0 1 2 3 4 5 6 7 octet 1 sign, exponent octet 2 exponent, fraction octet 3 fraction octet 4 fraction octet 5 octet 1 octet 2 octet 3 rcas_out, value (floating point, ieee) status c...

Page 42: 7.3

Output value (output) byte 0 1 2 3 4 5 6 7 8 9 octet 1 sign, exponent octet 2 exponent, fraction octet 3 fraction octet 4 fraction octet 5 octet 1 sign, exponent octet 2 exponent, fraction octet 3 fraction octet 4 fraction octet 5 sp, value (floating point, ieee) status rcas_in, value (floating poin...

Page 43

The message value is encoded as follows: 0 = not initialized 1 = closed (x 2 = open (x > 99.5 %) 3 = intermediate position checkback – device status: detailed device information, bit-wise encoded each bit can be hidden by the class 2 master for cyclic communication. This allows a specific selection ...

Page 44

Device diagnosis messages "slave diagnostic information" each bit can be hidden by the class 2 master for cyclic communication. This allows a specific selection to be made from the existing messages. In addition to the standard diagnosis messages, the positioner can provide other messages as "ext_di...

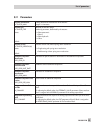

Page 45: 7.4

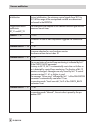

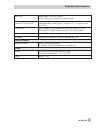

7.4 codes 7.4.1 measured value status the following status codes are used by the type 3785 positioner: bad : valid value substatus condition value (decimal) configuration error error in device configuration, value cannot be measured 4 device failure device error: memory, electronics 12 sensor failur...

Page 46: 7.4.2 Set Point Status

Good (non-cascade) valid value substatus condition value ok everything is ok, no further status available 128 maintenance required transit time monitoring active or zero point error active or total valve travel exceeded 164 7.4.2 set point status good (non-cascade) substatus condition value ok every...

Page 47: 7.5

7.5 operating modes operating modes of the ao (analog output) 4 out of service (os) 4 local override (lo) 4 manual (man) 4 automatic (auto) 4 remote cascade (rcas) out of service (os) the ao algorithm of the component is not executed. The control valve is moved to fail-safe posi- tion. Local overrid...

Page 48: 7.5.1 Start-Up (Warm Start)

Operating modes of the transducer block out of service (os) in this operating mode, the correction value received from the ao function block is not used. The control valve is moved to the fail-safe position determined via act_fail_action. The positioner also switches to operating mode os when the fo...

Page 49

Mode auto if the status of the reference variable (sp) is bad, the action determined via fsafe_type is exe- cuted after the fail-safe time (fsafe_time) has elapsed. Mode rcas in rcas mode, the positioner switches to automatic mode after the fail-safe time (fsafe_time) has elapsed, unless the status ...

Page 50

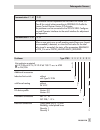

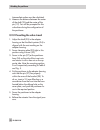

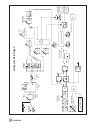

50 eb 8382-2 en configuration block diagram direction of action travel limitation lower, upper start end reference variable range correction value final position function end pos. >a t end pos. T travel range rated travel travel range relation control characteristic fail-safe position fail-safe acti...

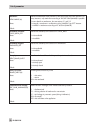

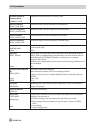

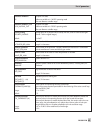

Page 51: List of Parameters

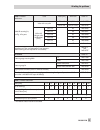

8 list of parameters the detailed overview below lists the parameters by their fields of application. The list of parameters following the overview is in alphabetical order and describes all parame- ters of the positioner which can be displayed or modified via profibus communication, e.G. On a pc. M...

Page 52

Additional component serial number . . . . . . . . . Add_gear_ser_num additional component manufacturer . . . . . . . . . Add_gear_man additional component identification . . . . . . . . . Add_gear_id additional component installation date . . . . . . . . Add_gear_inst_datetag_desc start-up security...

Page 53

Device settings configuration write protection . . . . . . . . . . . . . . . . . . . Hw_write_protection reference variable range . . . . . . . . . . . . . . Pv_scale fail-safe value reference variable . . . . . . . . . . Fsafe_value fail-safe action . . . . . . . . . . . . . . . . . . . Fsafe_type ...

Page 54

Valve position feedback, discrete . . . . . . . . . . Pos_d set point deviation e . . . . . . . . . . . . . . . . . Setp_deviation correction value . . . . . . . . . . . . . . . . . . Out transducer state . . . . . . . . . . . . . . . . . . . Transducer_state (m) correction value transducer block . ...

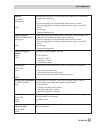

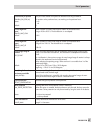

Page 55: 8.2

8.2 parameters actuator manufacturer actuator_man clearly identifies the manufacturer of the actuator. Length: 16 characters actuator type actuator_type states: default: identifies the actuator design. Read-only parameter, determined by the actuator. 0 = electropneumatic 1 = electric 2 = electrohydr...

Page 56

Attachment attachment (m) states: default: defines the attachment of the positioner to the control valve with linear actuators. For rotary actuators, only attachment according to vdi/vde 3845 (namur) is possible. For more details on attachments, also see sections 2.1 and 2.2. 0 = integral > attachme...

Page 57

Calibration command self_calib_cmd states: command to start manufacturer-specific calibration procedures in the field device. 0 = no test, standard control operation 1 = zero calibration 2 = initialization 7 = reset total valve travel 10 = reset "control loop fault" 255 = abort process in action cal...

Page 58

Controlled variable of transducer block feedback_value indicates current valve position in unit out_scale date last calibration device_calib_date indicates the date of the last calibration of the field device. Date last configuration device_config_date indicates the date of the last configuration of...

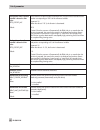

Page 59

Diagnosis diagnosis message type: states: detailed device information, bit-wise encoded which enables several simultaneous messages, also see section 9. D a: dynamic messages; they are automatically reset when they are read. R: static messages; they are retained as long as the event is present in th...

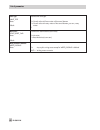

Page 60

Final position when reference variable is above the limit value setp_cutoff_inc default: if the reference variable exceeds the entered limit, the valve moves towards the end position corresponding to 100 % of the reference variable. Hysteresis 1%. When the value is 125 %, the function is deactivated...

Page 61

Initialization method init_method (m) states: default: method of initialization related to the nominal or maximum range. For initialization in the nominal range, only the range of the manipulated variable entered under rated travel/nominal angle is considered (e.G. Globe valve with me- chanical stop...

Page 62

Operating mode, target operating mode, current mode_blk/ target_mode positioner operating mode firmware version k 1.20 and lower: os, auto firmware version k 1.30 and higher: os, lo, man, auto positioner operating modes: automatic (auto): in this operating mode, the positioner follows the cyclic or ...

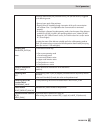

Page 63

The action determined by the parameter fsafe_type (fail-safe action) is triggered by the following events: • start-up (warm start) of the positioner • elapsing of the dp watchdog through interruption of the cyclic communication with a master class 1 (not applicable when communication is terminated p...

Page 64

Proportional-action coefficient kp_y2 servo_gain_2 default: proportional-action coefficient for exhaust air. When writing, the value is written to kp_y2 (exhaust air). Kp_y1 (supply air) remains unchanged. We recommend to adjust the value in increments of 0.1 when adjusting the value in the range fr...

Page 65

Reference variable w sp set point with status reference variable w in "auto" operating mode also see reference variable range. Reference variable w_rcas rcas_in/rcas_out set point with status reference variable w in "rcas" operating mode also see reference variable range. Security locking security_l...

Page 66

Total valve travel total_valve_travel total valve travel, sum of nominal duty cycles (double up-and-down travels) maximum value: 16 500000 total valve travel limit value total_valve_travel_lim default: total valve travel limit value. Range 0 to 16 500 000 1 000 000 transit time - minimum open act_st...

Page 67

Transmission pin position transm_pin_pos (m) states: default: only for linear actuator with positioner attached according to namur. Pin position on the positioner lever, see marking on the positioner lever. 0 = a 1 = b 0 travel/angle limit lower travel_limit_low default: lower limitation of valve tr...

Page 68

Valve type valve_type states: default: describes the valve type. 0 = control valve with linear motion of the control element 1 = control valve with rotary motion of the control element, part turn, rotary motion 0 warm start device_reset_cmd states: default: command to reset the device (warm start). ...

Page 69: Messages and Diagnosis

9 messages and diagnosis the type 3785 profibus pa positioner provides the best possibilities for diagnosis during the initialization process. In automatic mode, detailed tests are carried out to check and evaluate the attachment situation and the positioner's reaction, taking into account the prese...

Page 70

10 dia_conf_inval incorrect configuration – invalid bus address set when the address switch is adjusted to the invalid address 127. Device starts with default address 126. R 11 dia_warmstart reset (warm start) completed displayed when the device was reset via warm start. This reset is triggered foll...

Page 71: 9.2

9.2 check_back messages bit no. Name description r = static message, remains valid while the error is present in the field device a = dynamic message, automatically reset when read 0 cb_fail_save fail-safe position the fail-safe position was activated by the device, either by se- lecting operating m...

Page 72

13 cb_contr_err internal control loop error displayed when the positioner is unable to control the adjusted range of tolerance for error messages within the preset delay time. Possible sources of error: > oscillation caused by actuator operated too rapidly (small travel volume) > remedy: reduce supp...

Page 73: 9.3

9.3 initialization messages description not defined the device has not been initialized or a cold start was performed. Automatically reset after confirmation. Aborted the initialization routine was canceled by the user. Automatically reset after confirmation. If the device has already been successfu...

Page 74

Air leakage in pneumatic system the actuator must stall for a few seconds when the duty cycle is being determined initially. This time is used to check the pneumatic system for leaks. If the control valve moves more than 9.3 % from its resting position in 7 seconds, the relevant message is issued an...

Page 75

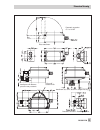

Dimensional drawing eb 8382-2 en 75 pneumatic connection g ¼ or ¼ npt direct attachment attachment acc. To iec 60534 w. Adapter housing pneumatic connection reversing amplifier attachment with distance piece for rotary actuators fulcrum of actuator shaft.

Page 76

76 eb 8382-2 en.

Page 77

Eb 8382-2 en 77.

Page 78

78 eb 8382-2 en.

Page 79

Eb 8382-2 en 79.

Page 80

80 eb 8382-2 en messages and diagnosis.

Page 81

Eb 8382-2 en 81.

Page 82

Samson ag · mess- und regeltechnik weismüllerstraße 3 · 60314 frankfurt am main · germany phone: +49 69 4009-0 · fax: +49 69 4009-1507 internet: http://www.Samson.De eb 8382-2 en s/z 2017-07.