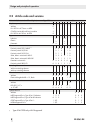

Samson 4746 Mounting And Operating Instructions - 3 Attachment to The Valve

14

EB 8365 EN

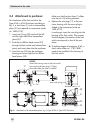

Attachment to the valve

3 Attachment to the valve

The accessories listed in section 2.4 are re-

quired for attachment.

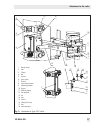

Î

The lever (I or II) must be installed before

the limit switch is attached to the control

valve. To do so, slide the lever clamping

plate (1.1) over the lever (1) and slip

them onto the shaft (2). Tighten the fas-

tening screw (1.2).

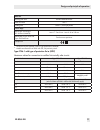

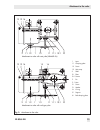

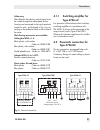

3.1 Attachment to valve with

cast yoke

1. Attach the plate (10) to the valve's stem

connector using two screws (10.1).

2. Attach the pin (11) to the plate (10) us-

ing two nuts (11.1).

3. Unscrew the cover of the limit switch. At-

tach the limit switch to the valve yoke us-

ing the mounting screw (12), washer

(13) and O-ring (14).

Make sure that the pin (11) is inserted

through the wire strap (1.3) of the lever

(1).

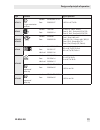

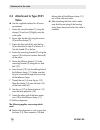

3.2 Attachment to valve with

rod-type yoke

1. Attach the plate (10) to the valve's stem

connector using two screws (10.1).

2. Attach the pin (11) to the plate (10) us-

ing two nuts (11.1).

3. Fasten the support (15) and the rod

clamping plate (16) loosely to the rod.

In the valve travel mid-position, move the

support until the center of the plate (10)

and the support (15) are aligned.

4. Fasten the rod clamping plate.

5. Attach the limit switch to the support us-

ing the mounting screw (12), washer

(13) and O-ring (14). Make sure that the

pin (11) is inserted through the wire

strap (1.3) of the lever (1).

Î

After attaching the limit switch, make

sure that the vent plug of the housing

cover faces downward when the valve is

installed