- DL manuals

- Samson

- Measuring Instruments

- 5006-0

- Mounting And Operating Instructions

Samson 5006-0 Mounting And Operating Instructions

Summary of 5006-0

Page 1

Differential pressure meter media 6 with lcd media 6 with led mounting and operating instructions eb 9527-1 en firmware a 2.11 (lcd), b 2.11 (led) edition july 2004 fig. 1 ⋅ media 6 with lcd and attached valve block, media 6 with led (right) led.

Page 2

Contents page 1 design and principle of operation . . . . . . . . . . . . . . . . . . . . . . 6 1.2 technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 2 installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 2.1 arrangement of instruments . . ...

Page 3

Safety instructions assembly, commissioning and operation of the device may only be per- formed by trained and experienced personnel familiar with this product. According to these mounting and operating instructions, trained personnel is referred to persons who are able to judge the work they are as...

Page 4

Modifications in device firmware compared to the previous version previous version new version a 2.03 / b 2.03 a 2.10 / b 2.10 limit switches the limit switches a1 and a2 are configured over software as minimum and maximum alarms. They can be adjusted separately over the keys on the device. Filling ...

Page 5

Previous version new version eb 9527-1 en 5.

Page 6

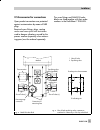

1 design and principle of operation the media 6 differential pressure meters measure and indicate the differential pres- sure or measured variables derived from the differential pressure. They are designed for gases and liquids, for example, for liq- uid level measurement in pressurized vessels. The...

Page 7

Fig. 2 ⋅ functional diagram 0 20 40 60 80 100 % m 3 # 7 6 5 3 2 1.1 1.2 9 8 10 1.5 4 1.4 1.3 1.2 1 p 2 p 1 _ + connector a u b = 12 to 36 v dc i a = 4 to 20 ma min./max. Alarm a1 connector b min./max. Alarm a2 µ p eeprom serial interface indicating unit with lcd or led 1 differential pressure cell 1...

Page 8: 1.2 Technical Data

1.2 technical data differential pressure meter nominal range mbar 0 to 100 0 to 160 0 to 250 0 to 400 0 to 600 0 to 1000 1) 0 to 1600 1) 0 to 2500 1) 0 to 3600 1) adjustable span mbar class ± 1.0 % from to ≤ 250 ≥ 125 ≤ 400 ≥ 100 ≤ 600 ≥ 150 ≤ 1000 ≥ 250 ≤ 1600 ≥ 400 ≤ 2500 ≥ 500 ≤ 3600 ≥ 720 class ...

Page 9

Version 5006-0 5006-1 output 4 to 20 ma permissible load r b = u s – 12 v 20 ma output current circuit intrinsically safe (media 6 w. Lcd/ led) see ptb 00 atex 2074 in appendix supply voltage u b two-wire transmitter 12 to 36 v dc 12 to 28 v dc only in combination with an intrinsically safe circuit ...

Page 10: 2 Installation

2 installation 2.1 arrangement of instruments 2.2 media 6 indicating unit make sure that the high-pressure line is connected to the high-pressure connec- tion and the low-pressure line to the low- pressure connection. Note! Special fittings are required to connect measuring lines. In addition, depen...

Page 11

2.5 accessories for connections open product connections are protected against contamination by means of nbr plugs. Required screw fittings, plugs, venting screws and screw joints with restrictions used to dampen vibrations caused by the process medium (especially when measur- ing gases) must be ord...

Page 12: 3 Electrical Connection

3 electrical connection as far as the electrical installation of the device is concerned, the relevant national regulations governing the installation of electrical equipment and the national accident prevention regulations of the country of destina- tion must be adhered to. In ger- many, these are ...

Page 13

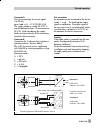

Connector a two-wire connection for current signal 4 to 20 ma, perm. Load = (u s – 12 v)/0.020 a [ Ω ]. The supply voltage is usually 24 v dc. It may be between at least 12 and maximum 36 v dc while considering the supply lead’s resistance directly at the connecting terminals of the connector. Conne...

Page 14: 4 Operation

4 operation 0 20 40 60 80 100 % m 3 x1000 – + off serial interface switches 1·2 gas selection 3 on·span 4 on·write test on off 1 234 } protection dil switches up key down key enter key test connection alarm a2 flashing ucwflashing tank capacity mcn, scn, ucw, diff. Pressure and error code unit of qu...

Page 15: For Media 6 With Lcd

4.1 display and operating elements all the necessary information and measured values stored in the instrument’s memory are shown in the display of media 6 with lcd . Although the media 6 with led ver- sion does not have such a digital display, important operating conditions are indi- cated by the le...

Page 16: 5 Start-Up

5 start-up 1. Open the equalizing valve. 2. Slowly open the high-pressure line. 3. Close the equalizing valve or the by- pass of the valve block. 4. Open the low-pressure line. Note! Carry out, if necessary, a zero point check at the dp cell as described in section 6.3, and restart the instrument. 6...

Page 17: Media 6 With Lcd

Media 6 with lcd the gas formula of the gas chosen, e.G. Ar, co2, o2, n2 , etc. Appears in the display. Select the gas type according to the table using the dil switch. The display is not activated, just the selected gas is shown! Press key to confirm the new gas type. The display is activated. Medi...

Page 18

Release key, 0 mbar appears in the display. Current signal i = 4 ma. Activate the write protection: turn switch 4 on. Correction when the tank is filled if the differential pressure lines are equipped with shut-off and equalizing valves, zero can be checked even when the plant is in operation. To ac...

Page 19: Media 6 With Led

Media 6 with led according to the test arrangement, a cur- rent signal of 4 ma must be supplied at con- nector a or at the test connection at a dif- ferential pressure of ∆ p = 0 mbar. Correction when the tank is filled 1. Close the shut-off valve in the high- pressure line. 2. Open the equalizing v...

Page 20: Media 6 With Lcd

Media 6 with lcd checking the measuring range (span) if the key is pressed five times, ∆ p100, which is the value for the maximum differen- tial pressure, appears in the display. First check zero, as described in section 6.3. Press key five times, readout: ∆ p 100 = x.Xxx ( x1000 ) mbar. Use a preci...

Page 21: 6.5 Setting Limit Switches

Turn write protection (switch 4) and span protection (switch 3) on. 6.5 setting limit switches 6.5.1 max. Limit for filling limit dur- ing operation note! The filling limit during operation set over the software can only be changed over the keys in the media 6 version with lcd. Ucw marker turn write...

Page 22: Media 6 With Led

Media 6 with led connect an ammeter to the power supply at connector a (fig. 9) or to the test terminal. Both limit switches are already set over the software as either min. Alarm or max. Alarm and are displayed to the assigned dif- ferential pressure corresponding to a cur- rent between 4 and 20 ma...

Page 23: 6.6 Ammeter Function

6.6 ammeter function in order to check the functioning of con- nected devices, an output signal of 4 to 20 or 22.8 ma can be adjusted for a short time regardless of the current liquid level in the tank. Media 6 with lcd write protection: turn switch 4 off. 4 ma ammeter press and hold down key. Press...

Page 24: Media 6 With Lcd

7 memory pen – communication 7.1 data transfer using memory pen the memory pen is a portable data carrier. Via the serial interface, it transfers standardized data which corresponds with the type of tank and the relevant gas data to media 6 instruments on site without re- quiring a pc or a notebook ...

Page 25: Media 6 With Led

Memrd = media 6 reads data from the memory pen. Memrd write protection: turn switch 4 off . Press key to activate selection. Run appears in the display, when done appears, the data is saved and the memory pen can be removed. Memrd write protection: turn switch 4 on. Data transfer from memory pen to ...

Page 26: 7.2 Communication With Pc

Data transfer from media 6 to memory pen status "write only" insert the memory pen into the serial interface connector. The led signals long flashes. Press key to start the writing process, the led is on. When the led goes out, remove the memory pen. 7.2 communication with pc media 6 can also be ope...

Page 27

Error code description corrective measure lcd: number led: flashing sequence hardware error 1 1x long/1x medium/ 9x short oscillating circuit or differential inductor defect send device to samson for repair 2 1x long/1x short/ 1x medium/8x short ram checksum error, ram is defect send device to samso...

Page 28: Versions

After acknowledging using the key, 8 seconds remain until a new error mess- age can appear. The short time interval is long enough to start the transfer of new data from the mem- ory pen. The instrument is automatically reset on re- moving the memory pen. With communication using a pc or note- book,...

Page 29: 10 Dimensions In Mm

10 dimensions in mm 30 54 158 17 30 245.5 121 114.5 145.8 5 8 60 31 194 180.5 32.5 148 25.5 43 80 117 158.5 7 2 m8 141.5 80 37 a b 0 20 40 60 80 100 % m 3 two bore holes ø 8.5 mm for attach- ment to measuring chamber rear side to fit m8 screws two bore holes ø 8.5 mm for attachment to the valve bloc...

Page 30

30 eb 9527-1 en.

Page 31

Eb 9527-1 en 31.

Page 32

32 eb 9527-1 en.

Page 33

Eb 9527-1 en 33.

Page 34

Samson ag ⋅ mess- und regeltechnik weismüllerstraße 3 ⋅ 60314 frankfurt am main ⋅ germany phone: +49 69 4009-0 ⋅ fax: +49 69 4009-1507 internet: http://www.Samson.De s/z 2 004-1 0 eb 9527-1 en.