- DL manuals

- Samson

- Controller

- TROVIS 5433

- Mounting And Operating Instructions

Samson TROVIS 5433 Mounting And Operating Instructions

Summary of TROVIS 5433

Page 1

Firmware version 1.2x edition january 2008 mounting and operating instructions eb 5433 en automation system trovis 5400 heating and district heating controller trovis 5433 ® electronics from samson.

Page 2

Disclaimer of liability we are constantly developing our products and therefore, reserve the right to change the product or the information contained in this document at any time without notice. We do not assume any liability for the accuracy or completeness of these mounting and operating instructi...

Page 3: Contents

Contents 1 operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 1.1 operating elements. . . . . . . . . . . . . . . . . . . . . . . . . . . 6 1.1.1 rotary pushbutton . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 1.1.2 rotary switches . . . . . . . . . . . . . . . . . ....

Page 4

5.7.2 optimization with room sensor . . . . . . . . . . . . . . . . . . . . 45 5.8 flash adaptation . . . . . . . . . . . . . . . . . . . . . . . . . . . 46 5.9 room temperature dependent control . . . . . . . . . . . . . . . . . 46 6 functions of the dhw circuit. . . . . . . . . . . . . . . . . . ....

Page 5

12.1 function block lists . . . . . . . . . . . . . . . . . . . . . . . . . . 76 12.2 parameter lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83 12.3 sensor resistance tables . . . . . . . . . . . . . . . . . . . . . . . . 90 12.4 technical data . . . . . . . . . . . . . . . . . . . ...

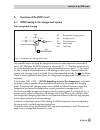

Page 6: Operation

1 operation the controller is ready for use with the temperatures and operating schedules preset by the manufacturer. On start-up, the current time and date need to be adjusted at the controller (–> section 1.5). 1.1 operating elements the operating controls are located in the front panel of the con...

Page 7: 1.2

Rotary switch for “operating modes“ – manual operation: valve closes 0 manual operation: valve stationary + manual operation: valve opens control operation deactivated, frost protection only dhw heating active, heating switched off night mode (reduced operation) day mode (rated operation) automatic ...

Page 8: 1.3

1.3 display during operation, the display indicates the current time as well as information about the op- eration of the controller. The days of the week are represented by black squares below the row of numbers at the top of the display (1 = monday, 2 = tuesday, and shown here, 7 = sunday). Icons i...

Page 9: 1.4

1.4 displaying data the time and temperature values of connected sensors and their set points can be retrieved and displayed in the info level. Proceed as follows: turn rotary switch “configuration and parameterization“ to info. Display shows: time _ _:_ _ the black squares below the row of numbers ...

Page 10: 1.5

1.5 setting the controller time the current time and date need to be set immediately after start-up or after a power failure lasting more than 24 hours. This is the case when the time blinks on the display. Proceed as follows: turn rotary switch “configuration and parameterization“ to data point “co...

Page 11: 1.6

1.6 setting the times-of-use three times-of-use can be set for each day of the week. If a time-of-use is not required, its start and stop times must be set to identical times. The times-of-use for heating and the dhw circulation pump are set using the top rotary switch: times-of-use position heating...

Page 12

Proceed as follows: turn rotary switch “configuration and parameterization“ to “times-of-use”. Display shows: 1 q select period/day for times-of-use: 1 = monday, 2 = tuesday , ..., 7 = sunday, 1-7 = daily activate editing mode for period/day. Display shows: 1*, start * the display 1 (2, 3) indicates...

Page 13

1.6.1 setting public holidays on public holidays, the times-of-use specified for sunday apply. A maximum of 20 public holidays may be entered. Parameter we level / range of values public holidays – pa-sys / 01.01 to 31.12 (1 jan to 31 dec) adopt public holidays and vacations for dhw 0 co2 -> f07 - 1...

Page 14

Note! Public holidays that are not assigned to a specific date should be deleted by the end of the year so that they are not carried on into the following year. Deleting a public holiday: q under “public holidays“, select the holiday you wish to delete. Confirm selection. Q select – –.– – (display –...

Page 15

1.6.2 setting vacation periods during vacation periods, the heating constantly remains in reduced operating mode. The dhw heating is monitored for frost protection, if necessary. A maximum of 10 vacation pe- riods can be entered. Parameter we level / range of values vacation period (start, stop) – p...

Page 16

Q select end. Exit parameter level. Display shows: co1 return rotary switch “configuration and parameterization“ to info. Display shows: time note! Vacation periods should be deleted by the end of the year so that they are not carried on into the following year. Deleting vacation periods: q under “v...

Page 17: 1.7

1.7 presetting temperature set points for the heating circuit, the desired room temperatures during the day ( day set point) and during the night ( night set point) can be preset. In the dhw circuit, the temperature you wish the domestic hot water to be heated to can be adjusted. The temperature set...

Page 18: Start-Up

2 start-up the modifications of the controller configuration and parameter settings described in this sec- tion can only be carried out after the valid key number has been entered. The valid key number for initial start-up can be found on page 96. To avoid unauthorized use of the key number, remove ...

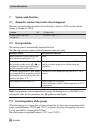

Page 19: 2.2

2.2 activating and deactivating functions a function is activated via the associated function block. The numbers 0 to 24 in the top row of the display represent the respective function block numbers. When a configuration level is opened, the activated function blocks are indicated by a black square ...

Page 20

Confirm settings. If the function block is not closed, further function block parameters can be adjusted. Proceed as follows: 1. Open data point. 2. Make desired changes and confirm. 3. If applicable, the next function block parameter is displayed. When all function block parameters have been adjust...

Page 21: 2.3

2.3 changing parameters depending on the adjusted system code number and the activated functions, not all parame- ters listed in the parameter list in the appendix (–> section 12.2) might be available. The parameters are grouped by topics: 4 pa1: heating circuit 4 pa2: dhw heating 4 pa-sys: public h...

Page 22: 2.4

2.4 calibrating sensors the connected sensors are calibrated in configuration level co-sys. The following applies: 4 co-sys -> f02 - 1: pt 1000 sensors (default) 4 co-sys -> f02 - 0: ptc sensors the resistance values of the sensors can be found on page 91. If the temperature values displayed on the ...

Page 23

Flow sensor vs1 return flow sensor rüf / flow sensor vs2/vs1 (system anl 6) storage sensor ss1 storage sensor ss2 return flow sensor rüs_tw activate editing mode for measured value. Q correct measured value. Read the actual temperature directly from the thermometer at the point of measurement and en...

Page 24: 2.5

2.5 resetting to default values all parameters as well as the function block parameters can be reset to their default settings (we). Proceed as follows: turn rotary switch “configuration and parameterization“ to copa. Display shows: 0, nr blinks. Q set valid key number. Confirm key number. Q select ...

Page 25: Manual Operation

3 manual operation switch to manual operating mode to access all outputs (see wiring diagram in section 11). When manual operation is activated using the rotary switch for “operating modes“, the ro- tary switch “configuration and parameterization“ should be in position info, otherwise the pump level...

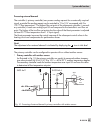

Page 26: Systems

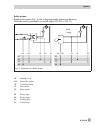

Be ba ae rk rüs vs1 up hk rs be ba ae rk vs1 up rüs hk rs 4 systems six different hydraulic schemes are available. The systems can be configured both as pri- mary and secondary systems. The fundamental hydraulic difference between a primary and a secondary system (heat exchanger in the heating/dhw c...

Page 27

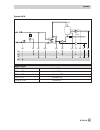

Boiler systems: based on the systems anl 1 to anl 3, one-stage boiler systems can be set up. The boiler can be controlled by an on/off output (co-sys -> f05 - 0). Eb 5433 en 27 systems be ba ae rk rüs vs1 up hk rs be ba ae rk up hk_2-pkt rs vs1 fig. 3 · schematics of a boiler system boiler 1-stage h...

Page 28

System anl 1 default values co1 -> f01 - 0 (without rs) co1 -> f07 - 1 (with as) co-sys -> f01 - 1 (with rüs) 28 eb 5433 en systems be ba ae rk as rüs vs1 up hk rs.

Page 29

System anl 2 default values co1 -> f01 - 0 (without rs) co1 -> f07 - 1 (with as) co2 -> f01 - 1 (with ss1) co2 -> f02 - 0 (without ss2) co-sys -> f01 - 1 (with rüs) eb 5433 en 29 systems hk heating circuit rüs return flow sensor up circulation pump vs flow sensor rs room sensor slp storage tank char...

Page 30

System anl 2, settings deviating from default settings settings deviating from default values co2 -> f10 - 0 (priority for dhw heating) co2 -> f06 - 1, option 2 (control of changeover valve and up) 30 eb 5433 en systems be ba ae rk ww kw as zp rüs vs1 ss1 hk rs up slp.

Page 31

System anl 3 default values co1 -> f01 - 0 (without rs) co1 -> f07 - 1 (with as) co2 -> f01 - 1 (with ss1) co2 -> f02 - 1 (with ss2) co2 -> f03 - 0 (without vs2) co-sys -> f01 - 1 (with rüs) eb 5433 en 31 systems be ba ae rk ww kw as ss2 zp rüs vs1 vs2 up ss1 hk rs slp tlp.

Page 32

System anl 4 default values co1 -> f01 - 0 (without rs) co1 -> f07 - 1 (with as) co2 -> f01 - 1 (with ss1) co2 -> f02 - 1 (with ss2) co2 -> f09 - 0 (without vs2) co-sys -> f01 - 1 (with rüs) note! The charging temperature is regulated by a self-operated regulator (roh). 32 eb 5433 en systems roh be ...

Page 33

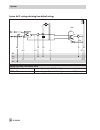

System anl 5 default values co1 -> f01 - 0 (without rs) co1 -> f07 - 1 (with as) co2 -> f11 - 1 (storage system uses three-step control) co2 -> f12 - 1 (with rüs_tw) co-sys -> f01 - 1 (with rüs) using setting co2 -> f11 - 0, a temperature valve is configured instead of the three-step control valve d...

Page 34

System anl 5, settings deviating from default settings settings deviating from default values co2 -> f14 - 1 (system with instantaneous water heater including hydraulic pressure switch) note! A pt 1000 sensor must always be used for the sensor vf2 regardless of the configuration of the other sensors...

Page 35

System anl 6 default values co2 -> f01 - 1 (with ss1) co2 -> f02 - 1 (with ss2) co2 -> f03 - 0 (without vs2) co2 -> f17 - 0 (without zs) co-sys -> f01 - 1 (with rüs) eb 5433 en 35 systems be ba ae rk ww kw ss2 zp slp vs2 zs zs tlp rÜs vs1 ss1 hk.

Page 36: 5.1

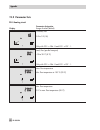

5 functions of the heating circuit which controller functions are available depends on the selected system code number. 5.1 weather-compensated control when weather-compensated control is used, the flow temperature is adjusted depending on the outdoor temperature. The heating characteristic in the c...

Page 37

5.1.1 gradient characteristic basically, the following rule applies: a decrease in the outdoor temperature causes the flow temperature to increase in order to keep the the room temperature at a constant temperature. By varying the parameters gradient and level, you can adapt the characteristic to yo...

Page 38

The level needs to be decreased and the gradient increased if the room temperature rises when it is mild outside . Outside the times-of-use, reduced set points are used for control: the reduced flow set point is calculated as the difference between the adjusted values for day set point (rated room t...

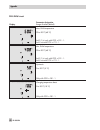

Page 39

5.1.2 4-point characteristic the 4-point characteristic allows you to define your own heating characteristic. It is defined by 4 points for the outdoor temperature, the flow temperature, the reduced flow temperature and the return flow temperature. The set-back difference at points 2 and 3 indicates...

Page 40: 5.2

Parameters we parameter level / range of values flow temperature point 1 point 2 point 3 point 4 70 °c 55 °c 40 °c 25 °c pa1 / 20 to 130 °c return flow temp. Points 1 to 4 65 °c pa1 / 20 to 90 °c set-back difference points 2, 3 15 °c pa1 / 0 to 50 °c min. Flow temperature 20 °c pa1 / 0 °c to max. Fl...

Page 41: 5.4

The digit behind start _ indicates in which operating phase the drying of jointless floors is in: 4 1 = temperature build-up phase 4 2 = temperature maintaining phase 4 3 = temperature reducing phase the drying process has been successfully completed when the additional icon in the flow temperature ...

Page 42

Temperature falls below this value (less 0.5 °c hysteresis), heating operation is restarted im- mediately. With the default settings, this means that, during the warm season, the system is switched off at an outdoor temperature of 22 °c. Parameters we parameter level / range of values ot deactivatio...

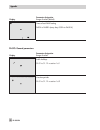

Page 43: 5.4.4 Summer Mode

5.4.4 summer mode summer mode is activated depending on the mean daytime temperature (measured between 7.00 h and 22.00 h) during the desired period. If the mean daytime temperature exceeds the ot limit value summer mode on n successive days, summer mode is activated on the following day. This means...

Page 44: 5.6

Functions we configuration delayed outdoor temperature adaptation 0 3 °c/h co1 -> f05 - 1 ( 1, 2) 1 when outdoor temperature t a decreases 2 when outdoor temp. T a decreases and increases delay / 1 to 6 °c/h outdoor temperature t a 1 co1 -> f07 - 1 5.6 remote operation 5.6.1 room panel apart from me...

Page 45: 5.6.2 Floating Switch

When the room sensor is activated and the remote room controller (room panel) is connected and activated, the measured room temperature is displayed. Nevertheless, it is not used for control unless the optimization or flash adaptation functions have been activated. Function we configuration room sen...

Page 46

5.7.2 optimization with room sensor the following two functions are only appropriate when the room containing the room sensor (reference room) has a heating characteristic similar to the rest of the building. No thermostatic valves should be mounted on the radiators in the reference room. Depending ...

Page 47: 5.8

Activation depending on outdoor temperature, deactivation depending on room temperature : optimization 0 120 min co1 -> f02 - 1, option: 2 advance heating time / 0 to 360 min outdoor temperature t a 1 co1 -> f07 - 1 activation and deactivation depending on room temperature : optimization 0 co1 -> f0...

Page 48

In rated operation, the heating is switched off when the room temperature exceeds the day set point by 2 °c. In reduced operation, the heating is switched off when the room tempera- ture exceeds the night set point by 2 °c. Note! We recommend not to select a cycle time that is too short. Cycle times...

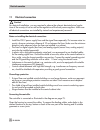

Page 49: Functions of The Dhw Circuit

6 functions of the dhw circuit 6.1 dhw heating in the storage tank system start storage tank charging the controller begins charging the storage tank when the water temperature measured at sensor ss1 falls below the dhw temperature set point by 0.1 °c. If the flow temperature in the system deviates ...

Page 50

Note! Instead of the dhw temperature parameter, the charging temperature can be set as the ab- solute value at the rotary switch if a storage tank thermostat is used. Stop storage tank charging the controller stops charging the storage tank when the water temperature measured at sen- sor ss1 has rea...

Page 51: 6.2

6.2 dhw heating in the storage tank charging system start storage tank charging the controller begins charging the storage tank when the water temperature measured at sensor ss1 falls below the dhw temperature set point by 0.1 °c. If the flow temperature in the system exceeds the desired charging te...

Page 52

If times-of-times have been set for dhw heating, the set point dhw temperature adjusted at the rotary switch is applied during these times-of-use. Outside the times-of-use, the sustained dhw temperature parameter is used. This does not apply when a storage tank thermostat is used. Stop storage tank ...

Page 53

Functions we configuration storage sensor ss1 1 co2 -> f01 - 1 storage sensor ss2 1 co2 -> f02 - 1 flow sensor vs2 0 co2 -> f03 parameter we rotary switch / range of values dhw temperature set point 55 °c min. To max. Dhw temperature parameters we parameter level / range of values min. Dhw temperatu...

Page 54: 6.3

6.3 dhw heating in the instantaneous water system dhw heating in a system with an instantaneous water heater can be configured using sys- tem anl 5. A hydraulic pressure switch signals the controller the beginning and end of dhw tapping. When the pressure switch makes contact, the exchanger charging...

Page 55: 6.4

6.4 intermediate heating operation this function is only available in systems anl 2 and 3. With the setting co2 -> f10 - 1, heat- ing operation is reactivated for 10 minutes after 20 minutes of priority (heating deactivated during dhw heating). By setting co2 -> f10 - 0, storage tank charging is giv...

Page 56: 6.7

Function we configuration operation of circulation pump during storage tank charging 0 co2 -> f04 6.7 priority operation in many district heating systems with primary dhw heating, the allotted amount of water is only intended to supply the heating system. As a result, the capacity required for dhw h...

Page 57: 6.8

Reduced operating mode stops after the time for activate priority in case of deviation has elapsed. Function we configuration priority through set-back operation 0 300 sec 40 °c co2 -> f09 - 1, option: 2 activate priority in case of deviation / 60 to 600 sec monitoring value / 20 to 90 °c 6.8 forced...

Page 58

If the disinfection temperature has not been reached in the tank and, when a circulation sen- sor zs (in anl 6 only) is used, at this sensor as well before the end of the thermal disinfection cycle, “err 3“ alarm is generated. The alarm is automatically reset when the disinfection tem- perature is p...

Page 59

6.10 vacation periods and public holidays for dhw heating with the default settings, the adjusted public holidays and vacation periods are only valid for the heating circuit. The times-of-use set for sunday for the dhw circulation pump and for dhw heating can also be applied on public holidays, prov...

Page 60: System-Wide Functions

7 system-wide functions 7.1 automatic summer time/winter time changeover the clock is automatically adjusted on the last sunday in march at 2.00 h and on the last sunday in october at 3.00 h. Function we configuration summer time/winter time changeover 1 co-sys -> f03 - 1 7.2 frost protection the he...

Page 61: 7.4

7.4 return flow temperature limitation the temperature difference between the flow and return flow in a system indicates how well the energy is used: the greater the difference, the higher the efficiency. A return flow sensor is sufficient to evaluate the temperature difference when the flow tempera...

Page 62: 7.5

Parameters we parameter level / range of values return flow temp. Points 1 to 4 65 °c pa1 / 20 to 90 °c max. Return flow temperature 65 °c pa2 / 20 to 90 °c note! To ensure that the preset return flow temperature limiting value can be met, make sure that – the heating characteristic has not been adj...

Page 63: 7.6

7.6 three-step control the flow temperature can be controlled using a pi algorithm. The valve reacts to pulses that the controller emits upon an existing system deviation. The length of the first pulse, in particu- lar, depends on the extent of the system deviation and the selected proportional gain...

Page 64: 7.8

Functions we configuration control mode dhw 1 5 °c 120 sec 120 sec co2 -> f11 - 0 hysteresis / 2 to 10 °c min. On time / 0 to 600 sec min. Off time / 0 to 600 sec 7.8 requesting/processing external demand requesting external demand in more complex heating systems, the flow temperature set points can...

Page 65

Processing external demand the controller (= primary controller) can process analog requests for an externally required signal, provided the analog request can be matched to “0 to 10 v correspond with 0 to 120 °c flow temperature“. The highest flow set point of the subsequent controller (= second- a...

Page 66

Primary controller : functions we configuration outdoor temperature t a 1 co1 -> f07 - 1 outdoor temperature 0 to 10 v at input ue 0 co1 -> f08 - 0 external demand, request 0 co-sys -> f10 - 0 external demand, processing 0 0 °c co-sys -> f11 - 1 boost / 0 to 30 °c forward outdoor temperature, 0 to 1...

Page 67

Primary controller: functions we configuration outdoor temperature t a 1 co1 -> f07 - 0 external demand, request 0 co-sys -> f10 - 0 external demand, processing 0 0 °c co-sys -> f11 - 1 boost / 0 to 30 °c forward outdoor temperature, 0 to 10 v 0 co-sys -> f12 - 0 parameter we parameter level / range...

Page 68: 7.9

7.9 locking the manual level to protect the heating system, this function can be used to lock the manual level. When this function has been activated, automatic mode is started when the rotary switch is set to man- ual operating mode (– 0 +). Function we configuration locking the manual level 0 co-s...

Page 69: Operational Faults

8 operational faults malfunctions or faults are indicated by the blinking icon on the display. In addition, the “err“ alarm is displayed immediately. Press the rotary pushbutton to open error level. It may be possible to view several alarms by turning the rotary pushbutton. As long as an error alarm...

Page 70: 8.3

4 flow sensor in the dwh circuit vs2 : when the sensor vs2 in anl 3 fails, the flow tem- perature set point for dhw heating is only controlled with vs1. In anl 4, dhw heating is no longer given priority. In anl 5, the dhw is no longer heated. 4 return flow sensor rüs_tw : when the return flow sensor...

Page 71: Memory Pen

9 memory pen a memory pen (accessories; order no. 1400-7697) is particularly useful to transfer all data from one trovis 5433 controller to several other trovis 5433 controllers. The memory pen is plugged into the connector integrated into the front panel. Once the pen has been connected, “33 sp“ is...

Page 72: Installation

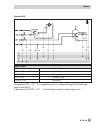

10 installation the controller consists of the housing with the electronics and the back panel with the termi- nals. It is suitable for panel, wall and top hat rail mounting (fig. 12). Panel mounting 1. Remove both screws (1). 2. Pull apart the controller housing and the back panel. 3. Make a cut-ou...

Page 73

Eb 5433 en 73 installation 41 70 14 62 5 5 4 3 57 2 2 1 fig. 12 · installation panel mounting controller housing back panel of the controller wall mounting top hat rail mounting dimensions in mm w x h x d = 144 x 97 x 130

Page 74: Electrical Connection

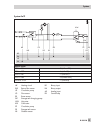

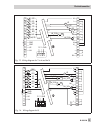

11 electrical connection caution! For electrical installation, you are required to observe the relevant electrotechnical regula- tions of the country of use as well as the regulations of the local power suppliers. Make sure all electrical connections are installed by trained and experienced personne...

Page 75

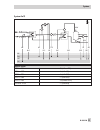

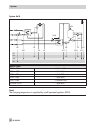

Eb 5433 en 75 electrical connection 15 14 13 12 11 10 9 8 7 6 5 4 3 3 1 2 12 11 gnd gnd 2 1 n up tlp slp zp hk_2-pkt hk_3-pkt + _ l l rk n n ba 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 ss2 ss1 vs2 fg rs rüs vs1 x1 as/zs gnd gnd pe ue ua 23 fig. 13 · wiring diagram anl 1 to 4 and anl 6 15 14 13 1...

Page 76

Connecting the sensors cables with a min. Cross-section of 0.5 mm² can be connected to the terminals at the back panel of the housing. Connecting the actuators 4 3-step or on/off outputs: connect cables with a min. Cross-section of 1.5 mm² suitable for damp locations to the terminals of the controll...

Page 77: Appendix

12 appendix 12.1 function block lists co1: heating circuit (not system anl 6)* f function we anl comment function block parameters / range of values (default) 01 room sensor rs 0 all* co1 -> f01 - 1: temperature display and input fg1 active; options: 1 types 5244 or 5257-5 room panels 2 standard sen...

Page 78

F function we anl comment function block parameters / range of values (default) 06 summer mode 0 all* co1 -> f06 - 1: time-controlled summer mode, only with co1 -> f07 - 1 function block parameters: start summer mode / 01.01 to 31.12 (01.06) no. Of days until activation/ 1 to 3 (2) stop summer mode ...

Page 79

Co2: dhw circuit f function we anl comment function block parameters / range of values (default) 01 storage sensor ss1 1 2, 3, 4, 6 co2 -> f01 - 1: sensor ss1 on co2 -> f01 - 0: storage tank thermostat, only with co2 -> f02 - 0 function block cannot be selected if: co2 -> f02 - 1, co2 -> f05 - 1, co...

Page 80

F function we anl comment function block parameters / range of values (default) 08 slp on depending on return flow temperature 0 2, 4*, 6 co2 -> f08 - 1 only with co2 -> f01 - 1 and co-sys -> f01 - 1 * in system anl 4 only applicable when implemented as a secondary system. To do so, mount return flo...

Page 81

F function we anl comment function block parameters / range of values (default) 14 instantaneous system with hydraulic pressure switch 0 5 co2 -> f14 - 1: instantaneous system w. Hydraulic pressure switch function block parameters: k p (proportional gain) / 0.1 to 50.0 (2.0) t n (reset time) / 0 to ...

Page 82

Co-sys: general functions (all systems) f function we anl comment function block parameters / range of values (default) 01 return flow sensor rüs 1 all co-sys -> f01 - 1: return flow temperature limitation active; function block parameter: limiting factor / 0.1 to 10.0 (1.0) function block cannot be...

Page 83

F function we anl comment function block parameters / range of values (default) 10 external demand, request 0 1, 4, 5*, 6 co-sys -> f10 - 1: secondary controller, only with co-sys -> f11 - 0 and co-sys -> f12 - 0 function block parameters transmission lower range value / 0 to 130 °c (0 °c) transmiss...

Page 84: 12.2 Parameter Lists

12.2 parameter lists pa1: heating circuit display parameter designation range of values (default) gradient, flow 0.2 to 3.2 (1.8) only with co1 -> f04 - 0 and co1 -> f07 - 1. Level, flow (parallel transport) –30 to 30 °c (0 °c) only with co1 -> f04 - 0 and co1 -> f07 - 1. Max. Flow temperature min. ...

Page 85

Display parameter designation range of values (default) gradient, return flow 0.2 to 3.2 (1.2) only with co1 -> f04 - 0 and co1 -> f07 - 1 and co-sys -> f01 - 1. Level, return flow –30 to 30 °c (0 °c) only with co1 -> f04 - 0 and co1 -> f07 - 1 and co-sys -> f01 - 1. Max. Return flow temperature 20 ...

Page 86

Display parameter designation range of values (default) 4-point characteristic point 1: outdoor temperature outdoor temperatures of the points 2, 3, 4 are marked by squares below the numbers 2, 3, 4. –30 to 50 °c (point 1: –15 °c, point 2: –5 °c, point 3: 5 °c, point 4: 15 °c) only with co1 -> f04 -...

Page 87

Display parameter designation range of values (default) ot activation value rated operation –30 °c to ot deactivation value reduced operation (–15 °c) only with co1 -> f07 - 1. Ot deactivation value reduced operation ot activation value rated operation to 50 °c (15 °c) only with co1 -> f07 - 1. Ot d...

Page 88

Pa2: dhw circuit display parameter designation range of values (default) max. Dhw temperature 20 to 90 °c (60 °c) anl 2, 3, 4: only with co2 -> f01 - 1. Anl 5: not with co2 -> f13 - 1. Min. Dhw temperature 20 to 90 °c (40 °c) anl 2, 3, 4: only with co2 -> f01 - 1. Anl 5: not with co2 -> f13 - 1. Hys...

Page 89

Display parameter designation range of values (default) stop charging 20 to 90 °c (53 °c) storage tank charging pump off 20 to 90 °c (53 °c) only anl 3 with co2 -> f03 - 1 max. Charging temperature 20 to 120 °c (80 °c) only anl 3 with co2 -> f03 - 1 sustained dhw temperature 20 to 90 °c (40 °c) anl ...

Page 90

Display parameter designation range of values (default) times-of-use dhw heating 0:00 h to 24:00 h (every day: 0:00 h to 24:00 h) pa-sys: general parameters display parameter designation range of values public holidays 01.01 to 31.12 –> section 1.6.1 vacation periods 01.01 to 31.12 –> section 1.6.2 ...

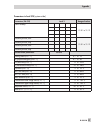

Page 91

12.3 sensor resistance tables resistance values with ptc measuring element type 5224 outdoor temperature sensor, type 5264 and type 5265 flow and return flow temperature sensor, type 5264 storage tank temperature sensor °c –20 –10 0 10 20 25 30 40 50 60 70 80 90 100 110 120 w 694 757 825 896 971 101...

Page 92: 12.4 Technical Data

12.4 technical data inputs 7 inputs for pt 1000 or ptc temperature sensors in 2-wire connection input at terminal 14 alternatively for storage tank thermostat 1 input for room panel/potentiometer 1 input for demand/outdoor temperature 0 to 10 v, ri = 20 k w (demand: 0 to 10 v correspond with 0 to 12...

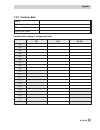

Page 93: 12.5 Customer Data

12.5 customer data station operator relevant samson office system code number function block settings in configuration levels co1 co2 co-sys f01 f02 f03 f04 f05 f06 f07 f08 f09 f10 f11 f12 f13 f14 f15 f16 f17 f18 f19 f20 eb 5433 en 93 appendix.

Page 94

Parameters in level 1 (heating circuit) parameters level 1 range of values gradient, flow 0.2 to 3.2 level, flow –30 to 30 °c max. Flow temperature min. Vt to 130 °c min. Flow temperature 0 °c to max. Vt gradient, return flow 0.2 to 3.2 level, return flow –30 to 30 °c max. Return flow temperature 20...

Page 95

Function block parameters co1 range of values maintaining time of max. Temp. (f09 1) 1 to 10 days temperature reduction (f09 - 1) 0.0 to 10.0 °c/24 h parameters in level 2 (dhw circuit) parameters level 2 range of values max. Dhw temperature 20 to 90 °c min. Dhw temperature 20 to 90 °c hysteresis 0 ...

Page 96

Function block parameters co2 range of values k p (proportional gain) (f11 - 1) 0.1 to 50.0 t n (reset time) (f11 - 1) 0 to 999 s t y (valve transit time) (f11 - 1) 10 to 240 s hysteresis (f11 - 0) 2 to 10 °c min. On time (f11 - 0) 0 to 600 s min. Off time (f11 - 0) 0 to 600 s limiting factor (f12 -...

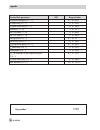

Page 97

Parameters in level sys (system-wide) parameters (pa-sys) level 3 range of values public holidays 01.01 to 31.12 vacation periods, start 01.01 to 31.12 vacation periods, stop vacation periods, start vacation periods, stop function block parameters co-sys limiting factor (f01 - 1) 0.1 to 10 k p (prop...

Page 98

Index a automatic operation. . . . . . . . . . . . . . . . . 7 b boiler systems . . . . . . . . . . . . . . . . . . . . 27 c characteristic 4-point characteristic . . . . . . . . . . . . 38 gradient characteristic . . . . . . . . . . . 37 condensate accumulation control . . . . . . 61 configuration ...

Page 99

Priority through reverse control . . . . . . . . . . . . . . . . . 55 set-back operation . . . . . . . . . . . . . . 55 public holidays. . . . . . . . . . . . . . . . . . . . 13 r rated operation . . . . . . . . . . . . . . . . . . . . 7 reduced operation . . . . . . . . . . . . . . . . . . 7 return...

Page 100

100 eb 5433 en frequently used abbreviations as outdoor sensor anl system ba binary output be binary input co configuration level eb mounting and operating instructions f function block fds hydraulic pressure switch hk heating circuit glt building control station kl terminal kw cold water ot outdoor...

Page 101

Eb 5433 en 101.

Page 102

102 eb 5433 en.

Page 103

Eb 5433 en 103.

Page 104

Samson ag · mess- und regeltechnik weismüllerstraße 3 · 60314 frankfurt am main · germany phone: +49 69 4009-0 · fax: +49 69 4009-1507 internet: http://www.Samson.De eb 5433 en 2009-02.