- DL manuals

- Samson

- Network Router

- Trovis 5475-2

- Mounting And Operating Instructions

Samson Trovis 5475-2 Mounting And Operating Instructions

Summary of Trovis 5475-2

Page 1

Automation system trovis 5400 heating and district heating controller trovis 5475-2 edition january 2001 firmware version 1.10 mounting and operating instructions eb 5475-2 en fig. 1 ⋅ trovis 5475-2 ® electronics from samson.

Page 2

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.1 notes for the user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 1.2 technical data . . . . . . . . . ....

Page 3

6. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 6.1 operating controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 6.2 selecting the operating modes . . . . . . . . . . . . . . . . . . . . . . . . . 32 6.2.1 remote controlling the heating system...

Page 4

1. General the heating and district heating controller is designed for weather-compensated flow tempera- ture control. This means it controls the flow temperature of a heating system based on a heating characteristic so that the room temperature is always maintained at the desired level regardless o...

Page 5

1.1 technical data inputs sensor inputs max. 7 ptc and pt 100 or ntc and pt 100, or pt 1000 and pt 100 sensors 2-wire circuit (heating circuit/drinking water circuit) 2 flow temperature sensors, alternatively 1 solar collector sensor 1 room temperature sensor 1 outdoor temperature sensor 1) 1 return...

Page 6

Caution safety features such as frost protection monitoring and excess temperature protection are not active in the following cases: • defective heating controller and failure of its functions • sensors are faulty, not connected or have not been deactivated • no power supply to the controller • mode...

Page 7

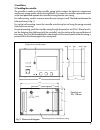

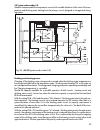

2. Installation 2.1 installing the controller the controller is made up of the controller casing which contains the electronics components and the rear casing section with the terminal blocks. To connect the controller, remove the screws on the front panel and separate the controller housing from th...

Page 8

2.2 installing the sensors 2.2.1 outdoor sensor use two screws to mount the outdoor sensor to the outside wall at an appropriate place. Make sure that the sensor is mounted away from direct heat sources (windows, vents etc.). In case of single family dwellings, preferably mount the sensor on the wal...

Page 9

Surge protection the following measures must be taken if lines are installed outside of the building or over long distances: • the shield of signal lines routed outside of buildings must have current carrying capacity and must be grounded on both sides. • surge diverters must be installed at the con...

Page 10

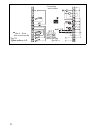

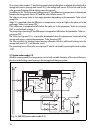

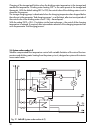

Fig. 6 system code no. 3.0 fig. 4 system code no. 2.0 fig. 5 system code no. 2.1 option type 5244 type 5257-4 stage1 stage 2 with 0 … 20 ma 50 Ω connect in parallel thermostat option type 5244 type 5257-4 with 0 … 20 ma 50 Ω connect in parallel thermostat changeover valve option type 5244 type 5257-...

Page 11

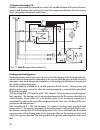

With 0 … 20 ma 50 Ω connect in parallel fig. 7 system code no. 4.0 fig. 9 system code no. 5.0 fig. 8 system code nos. 4.1, 4.2 option type 5244 type 5257-4 option type 5244 type 5257-4 thermostat with 0 … 20 ma 50 Ω connect in parallel option type 5244 type 5257-4 with 0 … 20 ma 50 Ω connect in para...

Page 12

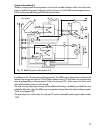

With 0 … 20 ma 50 Ω connect in parallel fig. 10 system code no. 6.0 option type 5244 type 5257-4 * fast-reacting sensor/ac tuator 12.

Page 13

4. Description of the controller functions the following function descriptions are intended to help you understand the settings required for operation. The controller functions depend on the selected system code numbers (1 to 6). See chapter 5 for details. 4.1 optimize the controller is capable of a...

Page 14

The displacement is displayed as level of the heating characteristic; this parameter cannot be accessed to adjust it manually when the flash adaptation mode (fb 2 = on) is selected. The options on the controller and remote control to correct the set point apply to the room tem- perature set point ...

Page 15

If the time-controlled summer time operation is active, heating operation will not start even at lower outdoor temperatures when the time-of-use starts. The time-controlled summer time operation is only deactivated when the daytime mean tem- perature falls below the outdoor temperature limit value o...

Page 16

Ation on the outdoor temperature sensors. An active delayed outdoor temperature adaptation is signalized in the operating level by a blinking outdoor temperature in the display. When you keep key pressed down, the calcu- lated outdoor temperature is shown in the display. If the function time-cont...

Page 17

4.9 limitation of the system deviation for open signal when using the controller for steam pressure control, we recommend that you activate this func- tion. It limits the controllers reaction to set point deviations which cause the control valve to open. This makes it much easier to start up such s...

Page 18

The drinking water circuit circulation pump zp is likewise activated, provided that storage tank charging is not taking place. Outside of rated operation times for drinking water heating, the temperature of the drinking water storage tanks is additionally kept at 5 °c, provided that a storage tank t...

Page 19

4.15 limitation of flow rate or capacity the trovis 5475-2 heating and district heating controller can be used in conjunction with heat meters to limit the flow rate or capacity. To be able to limit the flow rate based on a 0 or 4-20 ma signal issued by heat meters, the heat meters must be equipped ...

Page 20

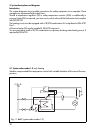

5. System descriptions and diagrams introduction the system diagrams show possible connections for safety equipment as an example. These examples are represented by dot-dash lines. Should a temperature regulator (tr) or safety temperature monitor (stm) or additionally a pressure limiter (pl) be requ...

Page 21

5.2 system code number 2.0 weather-compensated flow temperature control with variable limitation of the return flow tem- perature and drinking water heating in a storage tank system system code number 2.0 with changeover valve weather-compensated flow temperature control with variable limitation of ...

Page 22

Drinking water heating process charging of the drinking water storage tank is started when the drinking water temperature in the storage tank falls below the temperature value drinking water heating on or the value set at a storage tank thermostat. As a rule, the controller attempts to adapt the c...

Page 23

System code number 2.1 weather-compensated flow temperature control system with variable limitation of the return flow temperature and drinking water heating from the secondary circuit with differential tem- perature control for solar-powered heating of the drinking water storage tank system. Solar ...

Page 24

If, in system code number 2, the drinking water heating takes place as already described with a storage tank sensor (storage tank sensor sf1), the storage tank sensor sf2 can be used for the solar-powered heating of the drinking water storage tank. In addition to the "drinking water heating process"...

Page 25

Drinking water heating process charging of the drinking water storage tank is started when the drinking water temperature in the storage tank falls below the temperature value drinking water heating on or the value set at a storage tank thermostat. The controller attempts to reduce flow temperatur...

Page 26

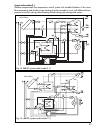

5.4 system code number 4.0 weather-compensated flow temperature control with variable limitation of the return flow tem- perature and drinking water heating with return flow temperature limitation from the primary circuit, designed as storage tank water heater drinking water heating process the drin...

Page 27

System code number 4.1 weather-compensated flow temperature control with variable limitation of the return flow tem- perature and drinking water heating from the primary circuit with differential temperature con- trol for solar-powered heating of the drinking water tank. In addition to the "drinking...

Page 28

System code number 4.2 weather-compensated flow temperature control with variable limitation of the return flow tem- perature and drinking water heating from the primary circuit with differential temperature con- trol for solar-powered heating of the drinking water tank. The difference to the system...

Page 29

5.5 system code number 5.0 weather-compensated flow temperature control with variable limitation of the return flow tem- perature and drinking water heating from the primary circuit, designed as storage tank charg- ing system drinking water heating process charging of the drinking water storage tank...

Page 30

Charging of the storage tank finishes when the drinking water temperature in the storage tank reaches the temperature drinking water heating off or the value preset at the storage tank thermostat. With the default setting fb19 = off, the control valve of the drinking water circuit is closed for th...

Page 31

Drinking water heating process the drinking water outlet temperature of the heat exchanger is controlled according to the set point in the parameter drinking water temperature. The setting of the control parameters con- cerning the achievable control quality is decisive for this. Should the capaci...

Page 32

6. Operation 6.1 operating controls to access the operator controls, open the front cover of the controller. Besides the mode switches, the following keys can be used to configure the controller. Changeover key lets you change from the operating level to the parameter level or configuration level re...

Page 33

Mode switch for the drinking water heating circuit time-controlled operation with option to deactivate drinking water heating circuit time-controlled operation, heating circuit deactivated, only frost protection active heating and drinking water heating circuits deactivated, only frost protection ac...

Page 34

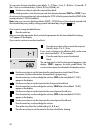

6.3 control levels upon connection to the power supply during start-up, the controller automatically switches to the operating level. To configure the controller, you must first switch over to the configuration level and then the parameter level. 6.3.1 configuration level: you can adapt the controll...

Page 35

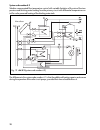

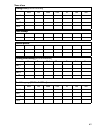

Fig. 23 ⋅ control levels configuration level operating level parameter level fast setting warmer/colder temperatures heating temperatures drinking water time schedules heating time schedules drinking water public holidays vacations time data heating time schedules heating public holidays vacations d...

Page 36

The most important symbols and their meaning: meaning when key is kept pressed down. Outdoor temperature info time-controlled summer time operation calculated outdoor temperature (only with delayed outdoor temperature adaptation ) flow temperature heating set point (blinks in case of limitation of...

Page 37

Increase/decrease heatings set point on the operating level the room temperature can be adjusted from the operating level by simply pressing a few keys. This is achieved by changing the flow temperature of the heating circuit via displacement of the heating characteristic to make it warmer or coole...

Page 38

7. Starting up and configuring the controller switch on the power supply to start up the controller. After briefly switching between displays, the controller automatically goes to the operating level and the time appears in the display. You must first configure the controller before setting it. Then...

Page 39

7.1.2 setting the system code number (anl) use a pencil (or similar item) to press the changeover key. A triangle (parameter level) starts to blink in the top left-hand corner of the display. Press the arrow keys simultaneously; two triangles (configuration level) start to blink and the currently ac...

Page 40

If you want to change the basic setting of a function block, proceed as follows: use a pencil (or similar item) to press the changeover key. A triangle (parameter level) starts to blink in the top left-hand corner of the display. Press the arrow keys simultaneously; two triangles (configuration leve...

Page 41

The number of days to activate the time-controlled sum- mer time operation appears in the display use the arrow keys if you want to change the number, following this or alternatively press the enter key to acknowledge the number. The number of days to deactivate the time-controlled summer time opera...

Page 42

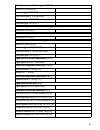

7.1.3 function block list legend: fb function block number fs factory (default) setting anl system code number fb function fs anl comment 0 optimize (chapter 4.1) off if fb 0 = on is selected, fb13 is automatically activated and cannot be deactivated 1 adaptation (chapter 4.2) off if fb 1 = on...

Page 43

8 priority for drinking water control circuit (see description of system diagrams in chapter 5) off only 4, 5, 6 fb 8 = on allows you to select priority for drinking water using set-back operation (ab) or priority for drinking water through reverse control (in). Then enter time span 2 to 10 min (def...

Page 44

13 room sensor rf off when fb 13 = on, the room temperature display does not affect the control loop; when type 5244 or type 5257-4 sensors with remote control are connected, the remote adjustment of operating modes is additionally activated 14 storage tank sensor sf1 (see chapter 5 for description ...

Page 45

You will be prompted to enter a code number when you select one of the following function blocks! 20 return flow sensor rüf (see chapter 4.8) on when fb 20 = on, the return flow sensor rüf is activated. Set the limitation factor, setting range 0.1 to 10 (default: 1). In anl2, you can select afterwar...

Page 46

7.1.4 sensor calibration the measured values of all of the connected sensors can be changed or reset. When calibrating a sensor, change the sensor value currently displayed to make it match the temperature (refer- ence value) measured directly at the point of measurement. Enter the code number 1999 ...

Page 47

7.2 parameterization only the system-specific parameters are displayed in the parameter level depending on the configuration carried out beforehand. You automatically enter the parameter level when you exit the configuration level. A blinking triangle in the top left-hand section of the display indi...

Page 48

7.2.2 entering and modifying user data the individual parameters are listed together with their symbols and default setting! Press the changeover key, the blinking triangle indicates that you are in the parameter level, a time appears in the display. Entering current time and date you are required t...

Page 49

Level of the heating characteristic parallel displacement of the heating characteristic deter- mined by the displacement value upwards (positive value) or downwards (negative value) (30 to +30 °c ) if you want to change it: press the enter key, the displacement arrows start to blink. Use the arrow ...

Page 50

Outdoor temperature limit value for deactivation in reduced operation (10 to 50 °c) outdoor temperature limit value for return to rated operation (30 to 50 °c) room set point (0 to 40 °c) reduced room set point (0 to 40 °c) see chapters 4.1 and 4.2 on optimize and adaptation modes sustained temper...

Page 51

Level of the return flow characteristic (30 to 30 °c) you must first enter the code number be- fore you can change this value. Max. Return flow temperature (20 to 90 °c) you must first enter the code number before you can change this value. If you set the max. Value = min. Value, this results in a ...

Page 52

You can enter the time schedules in time blocks 1 7 (mon sun), 1 5 (mon fri) and 6 7 (sat sun) or as individual days 1 (mon), 2 (tue), 3 (wed), etc. Use the arrow keys to select the required time block. For the rated operation, enter the time periods that alternate between start and stop...

Page 53

Public holidays vacations (max. 10 vacation periods possible) 10 11 12 13 14 15 16 17 18 19 1 2 3 4 5 6 7 8 9 20 21 22 23 24 0 default: 10 11 12 13 14 15 16 17 18 19 1 2 3 4 5 6 7 8 9 20 21 22 23 24 0 default: entering additional days: press the enter key, the first set date appears ...

Page 54

Entering parameters for drinking water circuit: drinking water heating on (20 to 90 °c) in systems 2 .0, 3 and 5 with just one storage tank sensor sf1 followed by differential gap (0 to 30 °c) in systems 2.0, 3 and 5 with just one storage tank sensor sf1 drinking water heating on (20 to 90 °c) in sy...

Page 55

Charging temperature set point (20 to 90 °c) in systems 2, 3 and 5 end charging process (20 to 90 °c) in systems 2, 3 and 5 return flow limitation temperature during drinking water heating (20 to 90 °c) you must first enter the code number before you can change this value. In systems 2, 3, 4.0 and 5...

Page 56

Time schedule for drinking water heating default rated operation 1 7 00.00 24.00 enter as described for time schedule for heating on page 51. Time schedule for circulation pump default rated operation 1 7 00.00 24.00 enter as described for time schedule for heating on page 51. 10 11 12 13 14...

Page 57

7.3 personal code numbers, locking the mode switch for manual operation, enabling the write protect function for the configuration level and masking out parameters note: you can only choose a personal code number between 100 and 1900! You must first enter the code number 1995 before you can enter a ...

Page 58

In the parameter level, all the parameters in the display are masked out except for the following parameters: time/date/year, heating characteristic gradient, heating characteristic level, set-back of flow temperature for reduced operation - alternatively room set point and sus- tained te...

Page 59

8. Data transfer using memory module to simplify configuration and parameterization of the controller, you can use the memory mo- dule 1400-7142 or 1400-7436 for data transfer between controller and module or controller and pc. The memory module 1400-7142 has a sub-d 25-pin female connector to conne...

Page 60

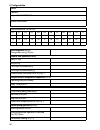

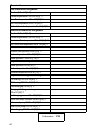

9. Configured data station operator responsible samson office system code number function blocks fb on or off 00 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23 flash adaptation (fb 02) change after every [10] min summer time operation (fb 03) start [01.06] end [30.09] 1 to 3 da...

Page 61

Control parameters for heating circuit (fb 10) gain k p 0.1 to 50.0 [2.0] reset time t n 1 to 999 [200] s valve transit time ty 15 to 240 [90] s up lag time 15 to 2400 [180] s differential gap 2 to 10 [5] °c limitation of system deviation in the heating circuit (fb 11) limit value 2 to 10 [2] °c lim...

Page 62

Characteristics flow characteristic with gradient gradient 0.2 to 3.2 [1.8] parallel displacement 30.0 to 30 [0] °c max. Flow temperature 20 to 130 [90] °c min. Flow temperature 20 to 130 [20] °c set-back for reduced operation 0 to 50 [15] °c return flow characteristic with gradient gradient 0.2 to...

Page 63

Times-of-use heating circuit [6:00 to 22:00 hrs] mon tue wed thur fri sat sun start 1 end 1 start 2 end 2 public holidays vacation periods drinking water heating [00:00 to 24:00 hrs] mon tue wed thur fri sat sun start 1 end 1 start 2 end 2 circulation pump [00:00 to 24:00 hrs] mon tue wed thur fri s...

Page 64

Samson ag ⋅ mess- und regeltechnik weismüllerstraße 3 ⋅ 60314 frankfurt am main ⋅ germany phone +49 69 4 00 9-0 ⋅ fax +49 69 4 00 9-15 07 internet: http://www.Samson.De s/ c d 2 001-1 0 eb 5475-2 en.