- DL manuals

- Samson

- Valve Positioners

- Type 3766

- Mounting And Operating Instructions

Samson Type 3766 Mounting And Operating Instructions

Summary of Type 3766

Page 1

Pneumatic positioner type 3766 mounting and operating instructions eb 8355-1 en edition november 2011 fig. 1 · type 3766 pneumatic positioner.

Page 2

2 eb 8355-1 en safety instructions safety instructions 4 the positioner is to be mounted, started up or operated only by trained and experienced personnel familiar with the product. According to these mounting and operating instructions, trained personnel refers to individuals who are able to judge ...

Page 3

Contents page 1 design and principle of operation . . . . . . . . . . . . . . . . . . . . 4 1.1 versions (article code). . . . . . . . . . . . . . . . . . . . . . . . . . 6 1.2 technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 2 attachment to control valve . . . . . . . . . ...

Page 4: Design and Principle of

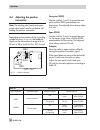

1 design and principle of operation the positioners ensure a fixed assignment between the valve stem position (controlled variable x) and the pneumatic or electric in- put signal (reference variable w). They com- pare the input signal received from the con- trol unit with the travel of the control v...

Page 5

Eb 8355-1 en 5 design and principle of operation 4 3 7 8 9 11 6.1 6.2 travel 1 pick-up lever 1.1 pin 1.2 clamp 2.1 nozzle >> 2.2 nozzle 3 diaphragm lever 4 range spring 5 measuring diaphragm 6.1 span adjuster 6.2 zero adjuster 7 turnboard 8 xp restriction 9 pressure regulator 10 booster 11 volume re...

Page 6: 1.1

Positioner with position transmitter a positioner containing a position transmit- ter cannot be equipped with integrated limit switches or an integrated solenoid valve since the position transmitter requires most of the space inside. The position transmitter is used to establish a certain relationsh...

Page 7

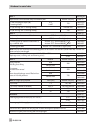

Eb 8355-1 en 7 design and principle of operation pneumatic positioner type 3766- x x x 0 1 x x x x 1 x 0 x 0 pneumatic connections ¼-18 npt 1 iso 228/1 - g ¼ 2 electrical connections without (no additional equipment or solenoid valve) 0 0 0 0 cable gland m20 x 1.5, blue (plastic) 1 0 0 m20 x 1.5, bl...

Page 8: 1.2

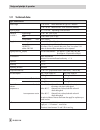

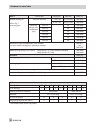

1.2 technical data 8 eb 8355-1 en design and principle of operation type 3766 positioner travel range 7.5 to 30 mm direct attachment to type 3277 actuator 7.5 to 120 mm attachment acc. To iec 60534-6 (namur) opening angle 70°, 75° or 90° depending on the cam disk reference variable w signal range 0....

Page 9

Eb 8355-1 en 9 design and principle of operation electromagnetic compatibility complying with requirements specified in en 61000-6-2, en 61000-6-3 and namur recommendation ne 21 explosion protection refer to article code or list of approvals in data sheet t 8355 en degree of protection ip 54 (specia...

Page 10: Attachment to Control Valve

2 attachment to control valve the positioner is attached either directly to samson type 3277 actuator or to valves with cast yokes or with rod-type yokes in ac- cordance with iec 60534-6-1 (namur). When combined with an intermediate piece, the device can also be attached to rotary ac- tuators as a r...

Page 11

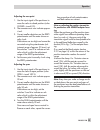

Eb 8355-1 en 11 attachment to control valve fig. 3 · mounting position and connections of type 3277 (top) and type 3277-5 120 cm 2 (bottom) actuators actuator stem extends actuator stem retracts internal signal pressure connection connection block tip of gasket (16) op. Direction >> attachment left ...

Page 12

2. Screw the associated lever d1 or d2 (for 700 cm² actuator) to the pick-up lever of the positioner. 3. Fasten the distance plate (15) with the seal pointing towards the actuator yoke. 4. Attach the positioner such that the lever d1 or d2 slides centrically over the pin (1.1) of the clamp (1.2). Sc...

Page 13

For version "actuator stem retracts" and type 3277-5 actuators with an effective di- aphragm area of 120 cm², an internal bore hole ensures that the spring chamber is filled with air. Notice when the valve is installed, the side cover of the actuator must be mounted such that the vent plug points do...

Page 14

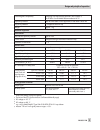

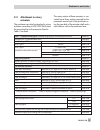

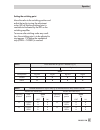

14 eb 8355-1 en attachment to control valve table 1 mounting kit required lever with associated clamp and distance plate actuator size [cm²] order no. D1 with vent plug for output (38) connecting thread g ¼ ¼ npt 120 1400-6790 1400-6791 d1 (33 mm long with 17-mm-high clamp) 240 and 350 1400-6370 d2 ...

Page 15: 2.2

2.2 attachment according to iec 60534-6 note: required mounting parts are listed in table 5. The rated travel of the valve deter- mines which lever and range spring (table 6) are required. An adapter housing (fig. 7) is required for namur attachment. The valve travel is transmitted over the lever (1...

Page 16: 2.2.1 Mounting Sequence

2.2.1 mounting sequence choose the required mounting parts and range spring from table 4 or 5 and install them as illustrated in fig. 7. Control valve with cast yoke 1. Screw the plate (20) to the stem connec- tor connecting the actuator and plug stems using countersunk screws. For 2100 and 2800 cm ...

Page 17

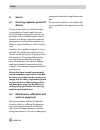

Eb 8355-1 en 17 attachment to control valve 2 1,5 1 24 25 22 32 31 20 19 19 21 20 23 18 29 30 28 26 a b 27b 27a fig. 7 · attachment according to iec 60534-6 (namur) mounting position 18 lever n1, n2 19 pin 20 plate 21 clip 22 clamping plate 23 screw 24 pointer 25 shaft 26 lever of the positioner 27a...

Page 18

18 eb 8355-1 en attachment to control valve table 5 control valve travel [mm] with lever order no. Namur mounting kit refer to fig. 7 concerning parts valve with cast yoke 7.5 to 60 n1 (125 mm) 1400-6787 22.5 to 120 n2 (212 mm) 1400-6789 valve with rod-type yoke, rod diameter [mm] 20 to 25 n1 1400-6...

Page 19: 2.3

2.3 attachment to rotary actuators the positioner can also be attached to rotary actuators according to vdi/vde 3845 when the mounting kits and accessories listed in table 7 are used. The rotary motion of these actuators is con- verted into a linear motion required by the pneumatic control unit of t...

Page 20: Lever

Notice use the correct range spring (1 or 2)! Range spring 1 is installed as standard. Double-acting springless rotary actuators re- quire the use of a reversing amplifier on the connection side of the positioner housing (see section 2.3.4). When using a reversing amplifier, the pres- sure regulator...

Page 21

Eb 8355-1 en 21 attachment to control valve 33 38 35 39 39 40 34 36 40 34 44 45 42 43 37 fig. 8 · attachment to rotary actuators attachment to samson type 3278 attachment acc. To vdi/vde 3845 vent plug or filter check valve 33 positioner 34 intermediate piece 35 lever with cam follower roll 36 adapt...

Page 22: Disk

2.3.3 default setting of the cam disk the valve model used determines the default setting of the cam disk. Notice cam disks tailored to the special character- istic of a valve cause the valve to open in a non-linear or non-equal percentage way. The visible difference between the set point (4 to 20 m...

Page 23

Eb 8355-1 en 23 attachment to control valve 90˚ 60˚ 30˚ 0˚ 90˚ 60˚ 30˚ 0˚ 90˚ 60˚ 30˚ 0˚ 90˚ 60˚ 30˚ 0˚ cam follower roll starting point i starting point n position at max. Signal pressure starting point i starting point n holes to secure the cam disk insert clip and press tongue outwards cam follow...

Page 24

24 eb 8355-1 en attachment to control valve 90˚ 60˚ 30˚ 0˚ 90˚ 60˚ 30˚ 0˚ cam follower roll starting point n starting point i insert clip and press tongue out- wards 0˚ 90˚ 60˚ 30˚ 0˚ 90˚ 60˚ 30˚ starting point i cam follower roll starting point n double-acting springless rotary actuator with revers...

Page 25

Securing the aligned cam disk to additionally prevent the cam disk from being turned, drill a hole into the adapter (36) or the coupling (44) and install a 2 mm dowel pin. Four bore holes are located centrically around the center hole on the cam disk. Se- lect a suitable hole to install the pin. Eb ...

Page 26: Double-Acting Actuators

2.3.4 reversing amplifier for double-acting actuators for the use with double-acting actuators, the positioner must be fitted with a reversing amplifier. Type 3710 refer to the mounting and operating in- structions eb 8392 en for the mounting of the samson type 3710 reversing ampli- fier. 1079-1118 ...

Page 27

Eb 8355-1 en 27 attachment to control valve 1.3 1.2 1.1 1 output 38 supply 9 a 1 1.5 1.6 z a 2 1.4 a 1 a 2 output 38 supply 9 1.3 1.2 1.1 1.6 z a 1 fig. 11 · mounting a reversing amplifier from the positioner 1 reversing amplifier 1.1 special screws 1.2 gasket 1.3 special nuts 1.4 rubber seal 1.5 se...

Page 28: Connections

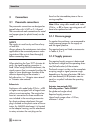

3 connections 3.1 pneumatic connections the pneumatic connections are designed as tapped holes with ¼ npt or g ¼ thread. The conventional male connections for metal and copper pipes (or plastic hoses) can be used. Notice the supply air must be dry and free of any oil and dust. Always observe the mai...

Page 29: 3.2

Actuator stem retracts (fe): fail-safe position "valve open" (for globe and angle valves) the required supply pressure for a tight-closing valve is roughly estimated from the maximum signal pressure pst max : pst max = f + d p a ² × × × p d 4 [bar] d = seat diameter [cm] d p = differential pressure ...

Page 30

The position transmitter is operated on a two-wire circuit. The usual supply voltage is 24 v dc. Considering the resistance of the supply leads, the voltage at the position transmitter terminals can be between 12 and 45 v dc. For terminal assignment, refer to fig. 12 or the label on the terminal str...

Page 31: 3.2.1 Switching Amplifier

Accessories cable gland m20 x 1.5 black plastic order no. 1400-6985 blue plastic order no. 1400-6986 nickel-plated brass order no. 1890-4875 adapter m20 x 1.5 to npt: aluminum, powder-coated 0310-2149 3.2.1 switching amplifier for operation of the limit switches, switching amplifiers must be connect...

Page 32: Operation

4 operation 4.1 setting the positioner at the valve starting point and reference variable when adjusting the positioner directly at the control valve, the travel (opening angle) must be adapted to the reference variable. With a reference variable, for example, 4 to 20 ma, the valve must pass through...

Page 33: Band Xp and Air Delivery Q

4.1.1 adjusting the proportional band xp and air delivery q 1. Close the volume restriction q (11) as far as the required positioning speed permits. To check, push the diaphragm lever (3) as far it will go. 2. Adjust the reference variable at the input to approx. 50 % of its range. 3. Turn the zero ...

Page 34: "actuator Stem Retracts"

If the upper range value is incorrect, turn the span adjuster (travel). Four turns correspond to a travel change of 10 % in standard oper- ation. In split-range operation, this value is reduced by half. Turn the adjuster clockwise to reduce the travel and counterclockwise to increase it. 2. After co...

Page 35: 4.2

If no pressure gauge is available, set the starting point to 0.97 bar instead. Notice after attaching and calibrating the positioner, make sure that the vent plug on the housing cover points downward when the valve is installed in the plant. 4.2 changing the operating direction if you want to change...

Page 36: 4.3

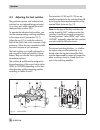

4.3 adjusting the limit switches the positioner version with inductive limit switches has two adjustable tags mounted on a rotary axis which operate the associ- ated proximity switches (50). To operate the inductive limit switches, con- nect the corresponding switching amplifiers in the output circu...

Page 37

Setting the switching point move the valve to the switching position and adjust the tag by turning the adjustment screw (53) so that the switching point is reached and indicated by the led on the switching amplifier. To ensure safe switching under any condi- tion, the switching point is to be adjust...

Page 38: 4.4

4.4 adjusting the position transmitter note: the starting point (zero) and upper range value (span) must be set before cali- brating the position transmitter. Depending on the position of the 4-pin plug (symbol on plug: >> or ), the feedback signal can be set to either a range of 4 to 20 ma or 20 to...

Page 39

Adjusting the zero point 1. Use the input signal of the positioner to move the valve to closed position (valve closed – travel 0 %). 2. The ammeter must now indicate approx. 4 ma. 3. Correct smaller deviations on the zero potentiometer until the meter shows ex- actly 4 ma. If deviations are too high...

Page 40: Converting The Positioner

5 converting the positioner the pneumatic positioner (3766-x...X.04 and higher) can be converted to form a type 3767 electropneumatic positioner. Note: conversion of explosion-protected versions only on request. Apart from the type 6112 i/p module (see table 11), the associated conversion kit in- cl...

Page 41

Note: for details on type 3767 positioners, refer to mounting and operating instruc- tions eb 8355-2 en. Eb 8355-1 en 41 converting the positioner.

Page 42: Service

6 service 6.1 servicing explosion-protected devices if a part of the device on which the explo- sion protection is based needs to be ser- viced, the device must not be put back into operation until a qualified inspector has as- sessed it according to explosion protection requirements, has issued an ...

Page 43: Dimensions In Mm

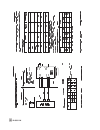

7 dimensions in mm eb 8355-1 en 43 dimensions in mm 44 19.5 35 39 164 46 76 50 36 n1=113 n2=200 58 56 68 28 14 29 150 164 19.5 37 68 185 76 Ø110 82 56 66 50 m20 x 1.5 28.5 28.5 output 1 (a1) output 2 (a2) supply (z) 50 output (38) supply (9) input signal pneumatic connections g ¼ or ¼ npt attachment...

Page 44

44 eb 8355-1 en.

Page 45

Eb 8355-1 en 45.

Page 46

46 eb 8355-1 en.

Page 47

Eb 8355-1 en 47.

Page 48

48 eb 8355-1 en.

Page 49

Eb 8355-1 en 49.

Page 50

50 eb 8355-1 en $gghqgxp3djh 5hylvlrqv&rqwuro1xpehu0d\ $ gghqgxpwr(%(1 7deoh 7khfruuhodwlrqe hw z hh qwhp shu dwxuh f odvvlilf dwlrqd qgs huplv vleo hdpel hqw whpshu dwxu hudq jh vlv vkr z qlqwk hwd eoh ehor z 7hpshudwxuhfodvv 3huplvveohdpelhqw whpshudwxuhudqjh 7 7 7 & & & & & & 7deoh )ruwkh0r...

Page 51

Eb 8355-1 en 51 $gghqgxp3djh 5hylvlrqv&rqwuro1xpehu0d\ $ gghqgxpwr(%(1 &6$fhuwlilhgirukd]dugrxvorfdwlrqv &odvv,'ly *urxsv$%& ' 7\sh(qf orvxuh &odvv,,'ly( ) *&odvv ,,, 3rvlwlrqhu zlwk srvl wlrqlqglf dwru vrohq rlgy doy h dqgolplw vzlwfk hv +$=$5'286 6$)( /2&$7,21'ly /2&$7,21 , tr a n sm itter 1rwhv 7...

Page 52

52 eb 8355-1 en $gghqgxp3djh 5hylvlrqv&rqwuro1xpehu$xjxvw $gghqgxpwr(%(1 ,qvwdoodwlrq0dqxdo irudssdudwxv dssuryhge\ )0iruxvhlqkd]dugrxvorfdwlrqv (ohfwulfdou dwlqjril qwulqvlf doo\ vdi hds sdu dwxv d qgds sdudwx virul qvwdoo dwlrqlqk d]d ugrx v orfdwlrqv 7deoh0d[lpxpydoxhv 3rvlwlrq lqglfdwru /lplwvzl...

Page 53

Eb 8355-1 en 53 $gghqgxp3djh 5hylvlrqv&rqwuro1xpehu$xjxvw $gghqgxpwr(%(1 8vhrqo \vx sso\ zlu hv vxlwd eohir u& dery hv xuu rxqglqjw hpsh udwxu h +$=$5'286 6$)( /2&$7,21 /2&$7,21 9huvlrq 0rgho zlw kvro hqrlg ydoy hdq glqgx fwly h olplwvzlw fkh v 0rgho zlwksr vlwlrqlq glfdwru 5hod \ruwu dqvl vwrurxw ...

Page 54

54 eb 8355-1 en $gghqgxp3djh 5hylvlrqv&rqwuro1xpehu$xjxvw $gghqgxpwr(%(1 ,qvwdoodwlrqgudzlqj &rqwuro5hod\+d e ²f( [ghzlwk sur[lplw\vhq vruvw\s6-e1 &rqwuro5hod\ 7hup lqdo 1r *urxsv / >p +@ & >) @ 9& >9@ ,6& >p$@ $% &( ') * +$=$5'286 /2&$7,21 6$)( /2&$7,21 fr q wd fw &odvv, ' lylvlrq *urxsv$ % & ' &o...

Page 55

Eb 8355-1 en 55.

Page 56

Samson ag · mess- und regeltechnik weismüllerstraße 3 · 60314 frankfurt am main · germany phone: +49 69 4009-0 · fax: +49 69 4009-1507 internet: http://www.Samson.De eb 8355-1 en 2011-11.