Summary of AC***MXSCCC

Page 2

Air conditioner installation manual imagine the possibilities thank you for purchasing this samsung product. En pt es fr db68-07241a-00 ac777mxsccc.

Page 3: Contents

English-2 contents preparation safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 preparation for outdoor unit installa...

Page 4: Safety Precautions

0 1 prep ar a tion english-3 safety precautions warning state of california proposition 65 warning (us only) this product contains chemicals known to the state of california to cause cancer and birth defects or other reproductive harm. Carefully follow the precautions listed below because they are e...

Page 5: Safety Precautions

English-4 installing the unit f important: when installing the unit, always remember to connect first the refrigerant tubes, then the electrical lines. Always disassemble the electric lines before the refrigerant tubes. F upon receipt, inspect the product to verify that it has not been damaged durin...

Page 6

0 1 prep ar a tion english-5 preparation for outdoor unit installation the air conditioner uses r-410a refrigerant. A type: ac018mxsccc cooling only (unit : inch) 25.98 0.47 14.33 12.20 25.12 34.65 2.13 0.91 b type: ac024mxsccc cooling only (unit : inch) 25.98 0.47 14.33 12.20 31.42 34.65 2.09 0.71 ...

Page 7

English-6 deciding on where to install the outdoor unit outdoor unit f the outdoor unit must not be placed on its side or upside down, as the compressor lubrication oil will run into the cooling circuit and seriously damage the unit. F choose a location that is dry and sunny, but not exposed to dire...

Page 8

0 1 prep ar a tion english-7 - install the outdoor unit in a place (such as near buildings etc.) where it can be prevented from sea breeze which can damage the outdoor unit. Outdoor unit outdoor unit sea breeze sea breeze sea sea - if you cannot avoid installing the outdoor unit by the seashore, con...

Page 9

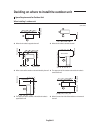

English-8 space requirements for outdoor unit when installing 1 outdoor unit (unit : inch) 11.81 or mor e 59.06 or mor e ❋ when the air outlet is opposite the wall ❋ when the air outlet is towards the wall 11.81 or mor e 5.91 or more 23.62 or more 59.06 or mor e 78.74 or more ❋ when 3 sides of the o...

Page 10

0 1 prep ar a tion english-9 when installing 1 outdoor unit (with wind baffle) (unit : inch) 11.81 or mor e 59.06 or mor e ❋ when the air outlet is opposite the wall ❋ when the air outlet is towards the wall 11.81 or mor e 5.91 or more 23.62 or more 59.06 or mor e 78.74 or more ❋ when 3 sides of the...

Page 11

English-10 deciding on where to install the outdoor unit 11.81 or mor e 11.81 or more 23.62 or more 23.62 or more 23.62 or more ❋ when 3 sides of the outdoor unit are blocked by the wall 11.81 or mor e 59.06 or mor e 23.62 or more 23.62 or more ❋ when front and rear side of the outdoor unit is towar...

Page 12

0 1 prep ar a tion english-11 11.81 or mor e 11.81 or more 23.62 or more 23.62 or more 23.62 or more ❋ when 3 sides of the outdoor unit are blocked by the wall 11.81 or mor e 59.06 or mor e 23.62 or more 23.62 or more ❋ when front and rear side of the outdoor unit is towards the wall 59.06 or more 2...

Page 13: Outdoor Unit Installation

English-12 outdoor unit installation the outdoor unit must be installed on a rigid and stable base to avoid any increase in the noise level and vibration, particularly if the outdoor unit is to be installed in a location exposed to strong winds or at a height, the unit must be fixed to an appropriat...

Page 14: Connecting The Cable

0 1 prep ar a tion english-13 connecting the cable two electronic cables must be connected to the outdoor unit. F the connection cord between indoor unit and outdoor unit. F the power cable between outdoor unit and auxiliary circuit breaker. F be sure to run the power supply cable and the communicat...

Page 15: Connecting The Cable

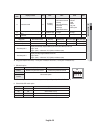

1. Rla is based on ahri 210/240 colling standard condition [indoor temp. : 26.7 °c / 80 °f(db) / 19.46 °c / 67 °f(wb), outdoor temp. : 35 °c / 95 °f(db)] 2. Voltage tolerance is ± 10 %. 3. Maximum allowable voltage between phases is 2 %. Symbols t rla : rated load ampere t fla : full load ampere t m...

Page 16

Wiring diagram of power cable when using elb for 1 phase elb mccb mccb 1(l) 2(n) n l l1 l2 l1 l2 power supply electrical component box indoor unit indoor power communication cable main power cable cable clamp cable tie ❋ the appearance of the unit may be different from the picture depending on the m...

Page 17: Connecting The Cable

Wiring diagram of connection cord 1 phase outdoor unit 1(l) 2(n) n l l1 l2 l1 l2 l(l1) n(l2) indoor unit main power cable cable clamp indoor power communication cable cable tie l f2 v1 v2 f3 f4 f1 n t lay the electrical wiring so that the front cover does not rise up when doing wiring work and attac...

Page 18

Connecting the power terminal f connect the cables to the terminal board using the compressed ring terminal. F cover a solderless ring terminal and a connector part of the power cable and then connect it. Silver solder nominal dimensions for cable [mm 2 (inch 2 )] nominal dimensions for screw [mm(in...

Page 19

Connecting the refrigerant pipe refrigerant piping system l1 l0 h refrigerant piping system table pipe length or height ac018mxsccc ac024mxsccc max. Allowable length actual pipe length l0 + h + l1 98.4 ft (30 m) or less 164.0 ft (50 m) or less allowable height length actual pipe length h 65.6 ft (20...

Page 20: Adding Refrigerant

Adding refrigerant (r-410a) the outdoor unit is loaded with sufficient refrigerant for the standard piping. Thus, refrigerant must be added if the piping is lengthened. This operation can only be performed by a qualified refrigeration specialist. For quantity of adding refrigerant, refer to page 19....

Page 21

Connecting up and removing air in the circuit t when installing, make sure there is no leakage. When recovering the refrigerant, ground the compressor first before removing the connection pipe. If the refrigerant pipe is not properly connected and the compressor works with the service valve open, th...

Page 22

5. Purge the air from the system using vacuum pump for about 10 minutes. F close the valve of the low pressure side of manifold gauge clockwise. F make sure that pressure gauge shows -0.1 mpa(-76cmhg) after about 10 minutes. This procedure is very important to avoid a gas leak. F turn off the vacuum...

Page 23: Cutting/flaring The Pipes

Cutting/flaring the pipes 1. Make sure that you have the required tools available. (pipe cutter, reamer, flaring tool and pipe holder) 2. If you wish to shorten the pipes, cut it with a pipe cutter, taking care to ensure that the cut edge remains at a 90° angle with the side of the pipe. Refer to th...

Page 24: Performing Leak Tests

Performing leak tests leak test with nitrogen (before opening valves) in order to detect basic refrigerant leaks, before recreating the vacuum and recirculating the r-410a, it’s responsible of installer to pressurize the whole system with nitrogen (using a cylinder with pressure reducer) at a pressu...

Page 25: Insulation

Insulation once you have checked that there are no leaks in the system, you can insulate the piping and hose. 1. To avoid condensation problems, place an insulator around each refrigerant pipe. T when insulate the pipe, be sure to overlap the insulation. T the insulation has to be produced in full c...

Page 26: Using Stop Valve

Using stop valve to open the stop valve 1. Open the cap and turn the stop valve counterclockwise by using a hexagonal wrench. 2. Turn it until the axis is stopped. T do not apply excessive force to the stop valve and always use special instruments. Otherwise, the stopping box can be damaged and the ...

Page 27: Pump Down Procedure

Pump down procedure pump down will be carried out when an evaporator is replaced or when the unit is relocated in another area. 1. Let the compressor run for more than 5 minutes. 2. Release the valve caps on high and low pressure side. 3. Use l-wrench to close the valve on the high pressure side. 4....

Page 28: Checking Correct Grounding

Checking correct grounding if the power distribution circuit does not have a grounding or the grounding does not comply with specifications, an grounding electrode must be installed. The corresponding accessories are not supplied with the air conditioner. 1. Select an grounding electrode that compli...

Page 29: Testing Operations

Testing operations 1. Check the power supply between the outdoor unit and the auxiliary circuit breaker. F 1 phase power supply : l1, l2 2. Check the indoor unit. 1) check that you have connected the power and communication cables correctly. (if the power cable and communication cables one mixed up ...

Page 30

Short push display contents seg1 seg2 seg3 seg4 unit 13 protective control d 0: cooling 1: heating protective control 0: no protective control 1: freezing 2: non-stop defrosting 3: over-load 4: discharge 5: total electric current frequency status 0: normal 1: hold 2: down 3: up_limit 4: down_limit -...

Page 31: Installing The Wind Baffle

Installing the wind baffle if you operate the cooling operation of air conditioner in the condition where ambient temperature is lower than 23 °f db(dry bulb), or the outdoor unit might be faced with strong wind directly, the wind baffle should be installed to prevent the outdoor unit fan from opera...

Page 32: Troubleshooting

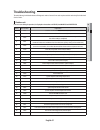

Troubleshooting the table below give indication about self diagnostic routine. Some of error code requires activities exclusively for authorized service center. Outdoor unit if an error occurs during the operation, it is displayed on the outdoor unit pcb led, both main pcb and inverter pcb. Priority...

Page 33: Troubleshooting

Priority error number explanation 30 e500 ipm over heat error on inverter 1 31 e484 pfc overload (over current) error 32 e466 dc-link voltage under/over error 33 e403 compressor down due to freeze protection control 34 e440 heating operation restricted at outdoor temperature over theat_high value (d...

Page 34: Extending The Power Cable

1. Prepare the following tools. Tools crimping pliers connection sleeve insulation tape contraction tube spec mh-14 20xØ0.26 inch(6.5 mm) (hxod) width 0.75 inch(19 mm) 70xØ0.31 inch(8.0 mm) (lxod) shape 2. As shown in the figure, peel off the shields from the rubber and wire of the power cable. - pe...

Page 35: Extending The Power Cable

5. Wrap it with the insulation tape twice or more and position your contraction tube in the middle of the insulation tape. Three or more layers of insulation are required. F method 1 1.57 inch (40 mm) insulation tape f method 2 insulation tape 1.38 inch (35 mm) 6. Apply heat to the contraction tube ...

Page 36: Memo

Memo 0 3 o thers english-35.