- DL manuals

- Samsung

- Air Conditioner

- AC071MN4PKH

- Service Manual

Samsung AC071MN4PKH Service Manual

1. Precautions

2. Product Specifications

3. Disassembly and Reassembly

4. Troubleshooting

5. PCB Diagram

6. Wiring Diagram

7. Reference Sheet

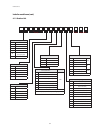

CONTENTS

SYSTEM AIR CONDITIONER

INDOOR UNIT

OUTDOOR UNIT

SYSTEM AIR CONDITIONER

CIRCULAR CASSETTE SERIES

AC071MN4PKH

AC090MN4PKH

AC100MN4PKH

AC120MN4PKH

AC140MN4PKH

AC090MXADKH

AC100MXAD*H

AC120MXAD*H

AC140MXAD*H

Summary of AC071MN4PKH

Page 1

1. Precautions 2. Product specifications 3. Disassembly and reassembly 4. Troubleshooting 5. Pcb diagram 6. Wiring diagram 7. Reference sheet contents system air conditioner indoor unit outdoor unit system air conditioner circular cassette series ac071mn4pkh ac090mn4pkh ac100mn4pkh ac120mn4pkh ac140...

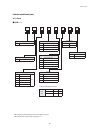

Page 2: Contents

Section 0 1 contents 1. Precautions .............................................................................................................................................................................................. 1-1 1-1. Precautions for the service .......................................

Page 3: Contents

Section 0 2 contents 4-4-11. Communication error between outdoor unit inv ׳ main micom (1 min.)(error code: e203) ... 4-39 4-4-12. Outdoor sensor error(error code : e221, e231, e251, e320) ............................................................................ 4-40 4-4-13.Reverse phase / loss p...

Page 4: 1. Precautions

1-1 1. Precautions 1-1 precautions for the service o use the standard parts when replacing the electric parts. – confirm the model name, rated voltage, rated current of the electric parts. O when repairing the equipment, connection of the harness parts must be firm and solid. – a loose connection ma...

Page 5

1-2 1-3 precautions related to product safety o do not pull the power cord and do not touch the power plug or aux power switch with wet hands. – it might cause electric shock or fire. O a damaged power line or power plug must be replaced to prevent danger. O do not bend the power cable with excessiv...

Page 6: Product Specifications

2-1 □ 360 cassette □ differentiated innovation air cooling it delivers a cool air evenly with the circular air current and provides a wide and agreeable cooling area than general ceiling air conditioners. □ refreshing and soft wind it provides a horizontal air current that form natural convection in...

Page 7

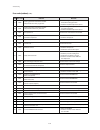

2-2 2-3 item development model ac090mn4pkh ac090mxadkh ac100mn4pkh ac100mxadkh ac100mn4pkh ac100mxadkh ac120mn4pkh ac120mxadkh ac120mn4pkh ac120mxadkh ac120mn4pkh ac120mxadnh ac071mn4pkh ac140mn4pkh ac140mxadkh ac140mn4pkh ac140mxadnh design indoor unit outdoor unit remote controller capacity coolin...

Page 8

2-4 2-5 item development model ac090mn4pkh ac090mxadkh ac100mn4pkh ac100mxadkh ac100mn4pkh ac100mxadkh ac120mn4pkh ac120mxadkh ac120mn4pkh ac120mxadkh ac120mn4pkh ac120mxadnh ac071mn4pkh ac140mn4pkh ac140mxadkh ac140mn4pkh ac140mxadnh harness spec indoor fan motor db31-00577d db31-00577d db31-00577d...

Page 9

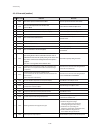

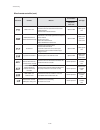

2-6 2-3 specifications of optional items 2-3-1 accessories item description code no. Q’ty remark assy drain- hose db94-02719b 1 standard / indoor unit cable tie db65-00191a 6 seal-drain ass'y db62-05810a 1 seal-drain ass'y db94-05810f 1 seal-drain ass'y db94-05810g 1 indoor unit installation manual ...

Page 10

Product specifications 2-7 item description code no. Q’ty remark wireless remote controller db93-15771c 1 optional batteries for remote controller (specification: "aaa" type) 4301-000121 2 remote controller holder db61-06607a 1 m4×16 screw 6002-000581 2 user’s manual db68-05911a 1 2-3-2 wireless rem...

Page 11

Product specifications 2-8 2-3-3 wired remote controller (mwr-we10n) item description code no. Q’ty remark wired remote controller db93-11251f 1 optional cable tie db65-10088b 2 cable clamp db65-10074e 3 m4×16 screw 6002-000474 5 user's manual db68-03732a 1 installation manual db68-03716a 1.

Page 12

Product specifications 2-9 2-3-4 filter specifications item description code no. Remark filter-air db63-03764a.

Page 13

3-1 item remark + screw driver monkey spanner (8mm, 10mm, 13mm) m6, m8 hex wrench spanner torque wrench 3. Disassembly and reassembly 3-1 necessary tools.

Page 14

3-2 3-2 indoor unit no. Parts procedure remark 1 panel ▶ ceiling type panel 1) pull up the corner 4 places of panel and separate it. 2) remove the 4 screws from the corner of panel. (use +screw driver) 3) pull the hook of panel and then separate the panel from the indoor unit. 1 panel ▶ open type pa...

Page 15

Disassembly and reassembly 3-3 no. Parts procedure remark 1 panel 2) rotate the grille to counterclockwise direction. 3) remove the safety clip of grill inside and then separate the panel from the indoor unit. 4) pull up the filter from the grill and separate it. 2 control box 1) reomove the 2 screw...

Page 16

Disassembly and reassembly 3-4 no. Parts procedure remark 2 control box 3) reomove the 1 screw which is fixed to the indoor unit upper part.(use +screw driver) 4) put finger in the "pull" marked groove and then pull up the cover 5) put finger in the "pull" marked groove and then avoids the hook and ...

Page 17

Disassembly and reassembly 3-5 no. Parts procedure remark 2 control box 6) separate the connectors from the control box. 7) remove the ground screw. (use +screw driver) 3 top cover & drain pan 1) remove the 3 screws. (use +screw driver) 2) push the hook and separate the cover. Damage can occur to pr...

Page 18

Disassembly and reassembly 3-6 no. Parts procedure remark 3 top cover & drain pan 4) pull the booster fan connector and separate the connector. 5) remove the 4 screws. (use +screw driver) 6) push the hook and separate the cover..

Page 19

Disassembly and reassembly 3-7 no. Parts procedure remark 3 top cover & drain pan 7) remove the screw and separate the display cover. (use +screw driver) 8) ) remove the 2 screws. (use +screw driver) 9) push the hook and separate the cover. 10) remove the 8 screws. (use +screw driver) 11) separate t...

Page 20

Disassembly and reassembly 3-8 no. Parts procedure remark 3 top cover & drain pan 12) remove the 3 screws. (use +screw driver) 13) pull the hook that is on the side and separate the cover. 4 drain pump & hose 1) separate the drain hose from the drain pump..

Page 21

Disassembly and reassembly 3-9 no. Parts procedure remark 4 drain pump & hose 2) remove the 2 screws and separate the drain hose that is on the side lower part of indoor unit (use +screw driver) 5 fan & motor 1) remove the hex nut which is fixed to top of fan and separate the fan from the motor. (us...

Page 22

Disassembly and reassembly 3-10 no. Parts procedure remark 4 evaporator 1) remove the screws which is fixed to indoor unit and separate the evaporator fixing bracket. (use +screw driver) 2) remove screws which is fixed to indoor unit and pull the hook and then separate the drain cover. (use +screw d...

Page 23

Disassembly and reassembly 3-11 no. Parts procedure remark 1 cabinet front rh turn off the power before disassembly necessarily. 1) remove the 2 screws from the cabinet front rh and separate it. (use +screw driver) 2 cabinet upper 1) remove the 9 screws which is fixed to each side of cabinet upper a...

Page 24

Disassembly and reassembly 3-12 no. Parts procedure remark 4 outdoor unit guard 1) pull out the sensor from the outdoor unit guard and separate it. 2) remove the 4 screws which is fixed to outdoor unit guard and separate it. (use + screw driver) 5 cabinet rear rh 1) pull out the sensor from the cabi...

Page 25

Disassembly and reassembly 3-13 no. Parts procedure remark 6 cabinet-installation rear part 1) remove the 1 screw from the cabinet- installation rear part and separate it.(use + screw driver) 7 cabinet front lf 1) remove the 10 screws from the cabinet front lf and separate it. (use +screw driver).

Page 26

Disassembly and reassembly 3-14 no. Parts procedure remark 7 cabinet front lf 8 fan 1) remove the 2 fixing nuts like the picture on the right side. (use hexagon wrench, monkey spanner, hexagon socket).

Page 27

Disassembly and reassembly 3-15 no. Parts procedure remark 9 motor 1) separate the fan propeller. 2) remove the 8 screws which is fixed to motor. (use +screw driver) 3) separate the motor wire connector from the outdoor unit control part. 10 bracket motor 1) remove the 2 screws from the bracket moto...

Page 28

Disassembly and reassembly 3-16 no. Parts procedure remark 11 control part 1) separate the 4 connectors from the outdoor unit control part. 2) remove the 1 screw which is fixed to control part. (use +screw driver) 3) separate the control part..

Page 29

Disassembly and reassembly 3-17 no. Parts procedure remark 12 4 way valve 1) first, discharge the refrigerant. 2) remove the 2 screws which is fixed to service valve and separate it. (use +screw driver) 3) separate the inlet and outlet pipes by welding torch. If you separate the compressor, heat exc...

Page 30

Disassembly and reassembly 3-18 no. Parts procedure remark 13 eev valve 1) remove the 2 screws which is fixed to service valve and separate it. (use +screw driver) 2) separate the inlet and outlet pipes by welding torch. 14 compressor 1) remove the 1 fixing nut from the end of cover and separate it....

Page 31

Disassembly and reassembly 3-19 no. Parts procedure remark 14 compressor 3) remove the 3 bolts from the bottom of compressor like the picture on the right side. (use hexagon wrench, monkey spanner, hexagon socket) 15 condenser connection part 1) remove the 3 screws which is fixed to each side of con...

Page 32

Disassembly and reassembly 3-20 ■ ac140mxad*h no. Parts procedure remark 1 cabinet front rh turn off the power before disassembly necessarily. 1) remove the 2 screws from the cabinet front rh and separate it. (use + screw driver) 2 cabinet upper 1) remove the 9 screws which is fixed to each side of ...

Page 33

Disassembly and reassembly 3-21 no. Parts procedure remark 4 outdoor unit guard 1) pull out the sensor from the outdoor unit guard and separate it. 2) remove the 4 screws which is fixed to outdoor unit guard and separate it. (use + screw driver) 5 cabinet rear rh 1) pull out the sensor from the cabi...

Page 34

Disassembly and reassembly 3-22 no. Parts procedure remark 6 cabinet-installation rear part 1) remove the 1 screw from the cabinet- installation rear part and separate it.(use +screw driver) 7 cabinet front lf 1) remove the 10 screws from the cabinet front lf and separate it. (use +screw driver).

Page 35

Disassembly and reassembly 3-23 no. Parts procedure remark 7 cabinet front lf 8 fan 1) remove the 2 fixing nuts like the picture on the right side. (use hexagon wrench, monkey spanner, hexagon socket).

Page 36

Disassembly and reassembly 3-24 no. Parts procedure remark 9 motor 1) separate the fan propeller. 2) remove the 8 screws which is fixed to motor. (use +screw driver) 3) separate the motor wire connector from the outdoor unit control part. 10 bracket motor 1) remove the 2 screws from the bracket moto...

Page 37

Disassembly and reassembly 3-25 no. Parts procedure remark 11 control part 1) separate the 4 connectors from the outdoor unit control part. 2) remove the 1 screw which is fixed to control part. (use +screw driver) 3) separate the control part..

Page 38

Disassembly and reassembly 3-26 no. Parts procedure remark 12 4 way valve 1) first, discharge the refrigerant. 2) remove the 2 screw which is fixed to service valve. (use +screw driver) 3) separate the inlet and outlet pipes by welding torch. If you separate the compressor, heat exchanger or pipe, p...

Page 39

Disassembly and reassembly 3-27 no. Parts procedure remark 14 compressor 1) remove the 1 fixing nut from the end of cover and separate it. (use hexagon wrench, monkey spanner, hexagon socket) 2) separate the felt compressor. 3) remove the 3 bolts from the bottom of compressor like the picture on the...

Page 40

Disassembly and reassembly 3-28 no. Parts procedure remark 15 condenser connection part 1) remove the 3 screws which is fixed to each side of condenser connection part and separate it. (use + screw driver).

Page 41: 4. Troubleshooting

4-1 ▶ indoor address set-up and installation options, set the remote control option.. Address setting and indoor settings option haohni setting is not possible at the same time, set each of the options. If necessary, set up the indoor address setting installation options, you must enter twice. 4-1-1...

Page 42

Troubleshooting 4-2 steps remote control display 1 set the seg2 and seg3 values: a set the seg2 value by pressing the (low fan) button repeatedly until the value you want to set appears on the remote control display. B set the seg3 value by pressing the (high fan) button repeatedly until the value y...

Page 43

Troubleshooting 4-3 the procedure of setting option(cont.) steps remote control display 7 set the seg9 and seg10 values: a set the seg9 value by pressing the (low fan) button repeatedly until the value you want to set appears on the remote control display. B set the seg10 value by pressing the (high...

Page 44

Troubleshooting 4-4 the procedure of setting option(cont.) steps remote control display 12 press the (mode) button. Cool and off appear on the remote control display. 13 set the seg16 and seg17 values: a set the seg16 value by pressing the (low fan) button repeatedly until the value you want to set ...

Page 45

Troubleshooting 4-5 the procedure of setting option(cont.) steps remote control display 18 press the (mode) button. Heat and off appear on the remote control display. 19 set the seg23 and seg24 values: a set the seg23 value by pressing the (low fan) button repeatedly until the value you want to set ...

Page 46

Troubleshooting 4-6 step 4 save the option values into the indoor unit point the remote control to the remote control sensoron the indoor unit and then press the (power)button on the remote control. Make sure that this command is received by the indoor unit; if it is notreceived, press the (power) b...

Page 47

Troubleshooting 4-7 ̻gthe total number of available options are 24: seg1 to seg24. ̻g gbecause seg1, seg7, seg13, and seg19 are the page options used by the previous remote control models,the modes to set values for these options are skipped automatically. ̻g gset a 2-digit value for each option pai...

Page 48

Troubleshooting 4-8 the procedure of setting option steps remote control display 1 set the seg2 and seg3 values: a set the seg2 value by rotating the wheel counterclockwise until the value you want to set appears on the remote control display. B set the seg3 value by rotating the wheel clockwise unt...

Page 49

Troubleshooting 4-9 the procedure of setting option(cont.) steps remote control display 7 set the seg9 and seg10 values: a set the seg9 value by rotating the wheel counterclockwise until the value you want to set appears on the remote control display. B set the seg10 value by rotating the wheel cloc...

Page 50

Troubleshooting 4-10 the procedure of setting option(cont.) steps remote control display 13 set the seg16 and seg17 values: a set the seg16 value by rotating the wheel counterclockwise until the value you want to set appears on the remote control display. B set the seg17 value by rotating the wheel ...

Page 51

Troubleshooting 4-11 the procedure of setting option(cont.) steps remote control display 19 set the seg23 and seg24 values: a set the seg23 value by rotating the wheel counterclockwise until the value you want to set appears on the remote control display. B set the seg24 value by rotating the wheel ...

Page 52

Troubleshooting 4-12 4-1-3. Order for setting options (wired remote controller) 1. If you want to use the various additional functions for your wired remote controller, press the set and esc buttons at the same time for more than three seconds. Ź you will enter the additional function settings, and ...

Page 53

Troubleshooting 4-13 4-1-4. Indoor address(main/rmc)setting before installing an indoor unit, be sure to set an address for the indoor unit by taking the following steps: 1. Make sure that the power is supplied to the indoor unit. If the indoor unit is not plugged in, it must include a power supply....

Page 54

Troubleshooting 4-14 option no. For an indoor unit address:02xxxx-1xxxxx-2xxxxx-3xxxxx option seg1 seg2 seg3 seg4 seg5 seg6 function page mode reserved use of external temperature sensor use of central control compensation of the fan rpm indication and details indication details indication details i...

Page 55

Troubleshooting 4-15 t&wfojgzpvtfuuif6tfpgesbjoqvnq4&(pqujpoupjujtbvupnbujdbmmztfuupuifesbjoqvnqjtvtfexjuinjovufefmbz t*gzpvtfuuif.Byjnvngjmufsvtbhfujnf4&(pqujpoupbwbmvfpuifsuiboboejujtbvupnbujdbmmztfuupipvst t*gzpvtfuuif*oejwjevbmdpouspmxjuisfnpufdpouspm4&(pqujpoupbwbmvfpuifsuiboupjujtbvupnbujdbmmz...

Page 56

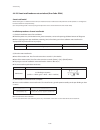

Troubleshooting 4-16 model seg1 seg2 seg3 seg4 seg5 seg6 seg7 seg8 seg9 seg10 seg11 seg12 ac071mn4pkh 0 1 1 0 7 f 1 9 5 4 a f ac090mn4pkh 0 1 0 0 7 f 1 9 5 4 7 c ac100mn4pkh 0 1 0 0 7 f 1 9 5 4 8 c ac120mn4pkh 0 1 0 0 7 f 1 9 5 4 9 d ac140mn4pkh 0 1 1 0 7 f 1 9 5 4 a f model seg13 seg14 seg15 seg16 ...

Page 57

Troubleshooting 4-17 4-3. Diagnostic checklist ago 4-3-1. Test operation mode and check mode ▒ display options key ▒ verify mode display ※ pressing the k4 switch, you can view the following information about the system status short push screen content seg1 seg2 seg3 seg4 unit 1 oder frequency 1 hund...

Page 58

Troubleshooting 4-18 4-3-2. Eco mode [power save mode] models series ac090/100/120/140mxad*h mode display eco-mode lamp seg 1 seg 2 seg 3 seg 4 red color eco mode “blank” “blank” “blank” “blank” on eco mode exit press k3 to go out from the eco mode. At the driving signal or test run (cooling/heating...

Page 59

Troubleshooting 4-19 4-3-3. Error code [indoor] ice blue yellow green blue red condition indoor unit display indications ice blue yellow green blue red power reset (blinking once every 2 seconds) x x x in the defrost operation (blinking once every 10 seconds) x x x open or short circuit error of the...

Page 60

Troubleshooting 4-20 4-3-4. Error code [outdoor] no error code remarks remarks 1 e108 error due to repeated communication address check on repeated indoor unit main address 2 e121 error on room temperature sensor of indoor unit (short or open) indoor unit room thermistor open/short 3 e122 error on e...

Page 61

Troubleshooting 4-21 no error code remarks remarks 23 e440 heating operation restricted at outdoor temperature over theat_ high value 1. Check the range of temperature limited for heating operation 2. Check the outdoor temperature sensor 24 e441 cooling operation restricted at outdoor temperature be...

Page 62

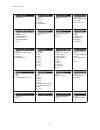

Troubleshooting 4-22 4-3-5 wired remote controller - if an error occurs, ( ) icon will be displayed on the wired remote controller. - press the test button to see the error code. Error mode contents measure product operation in error condition error type outdoor unit/ compressor/indoor unit indoor u...

Page 63

Troubleshooting 4-23 wired remote controller (cont.) error mode contents measure product operation in error condition error type outdoor unit/ compressor/ indoor unit [inverter] compressor startup error check the compressor connection status. Check the resistance between difference phases of the com...

Page 64

Troubleshooting 4-24 error mode contents measure product operation in error condition error type outdoor unit/ compressor/ indoor unit outdoor fan 2 error check the input power connection status check the connection status of the motor and the outdoor unit pcb check the indoor/outdoor unit fuse oper...

Page 65

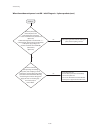

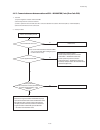

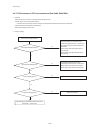

Troubleshooting 4-25 4-4. Troubleshooting by symptoms 4-4-1. When the indoor unit power is not on – initial diagnosis : 1-phase products 1. Test items 1) check the power connection of indoor/outdoor unit and check the power wire of terminal block. 2) check the connection of the power wire between th...

Page 66

Troubleshooting 4-26 4-4-2. Indoor temperature sensor error (e121) yes no no in this case, is the resistance value out of range in the temperature table on the right? Yes is indoor temperature sensor disconnected from the connector in pcb? Restart the system after replacing the pcb restart the syste...

Page 67

Troubleshooting 4-27 4-4-3. Indoor heat exchanger temperature sensor error (e122) yes no no in this case, is the resistance value out of range in the temperature table on the right? Yes is the indoor heat exchanger temperature sensor connector disconnected from the pcb? Restart the system after repl...

Page 68

Troubleshooting 4-28 4-4-4. Indoor fan error (e154) check the normal operation. No is the motor connector(cn73) disconnected from the pcb? Connect the connector to pcb yes no does the motor rotates when operating? Motor ིļུ : is voltage of dc 0v~dc 6v displayed? Check the pcb and replace it is the r...

Page 69

Troubleshooting 4-29 4-4-5. Communication error after finishing tracking (e202) no yes no yes is there a response from the indoor pcb? (led01 (red) is not on) in this case, is the voltage waveform between the lines square wave with amplitude over ±0.7v as shown in the following picture? +0.7v -0.7v ...

Page 70

Troubleshooting 4-30 4-4-6. Indoor unit float sensor error indoor unit display 360 cassette x(ice blue) ◑(yellow green) ◑(blue) x(red) judgment method refer to checking method, as shown below symptom if the increase in the drain pan water level due to failure of the indoor unit drain pump or indoor ...

Page 71

Troubleshooting 4-31 4-4-7. Eeprom circuit failure (e162) indoor unit display 360 cassette ◑(ice blue) x(yellow green) x(blue) ◑(red) judgment method refer to checking method, as shown below symptom if the eeprom component defective. (eeprom circuit parts missing / damaged / soldering failure) resta...

Page 72

Troubleshooting 4-32 4-4-8. The whistling noise from the indoor unit in low wind mode no is there abnormal noise like the whistling from the indoor unit in low wind mode? Replace a fan a motor. ĺcheck normal startupĺ end the service is there abnormal noise in the booster fan? No check normal startup...

Page 73

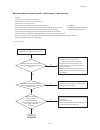

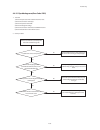

Troubleshooting 4-33 4-4-9. When the outdoor unit power is not on - initial diagnosis : 3-phase products 1. Test items 1) check the power connection of outdoor unit. 2) check the whole connection part of the power wire. 3) check the power on the indoor unit. 4) check the connection of the power wire...

Page 74

Troubleshooting 4-34 when the outdoor unit power is not on - initial diagnosis : 3-phase products (cont.) continue yes after replacing the main pcb and resetting the power, check everything is normal. Connect the power wire (first turn off the power of the terminal box!) 1. Connect the power wire. 2...

Page 75

Troubleshooting 4-35 when the outdoor unit power is not on - initial diagnosis : 1-phase products 1. Test items 1) check the power connection of outdoor unit. 2) check the whole connection part of the power wire. 3) check the power on the indoor unit. 4) check the connection of the power wire of the...

Page 76

Troubleshooting 4-36 when the outdoor unit power is not on - initial diagnosis : 1-phase products (cont.) yes after replacing the main pcb and resetting the power, check everything is normal. Connect the power wire (first turn off the power of the terminal box!) 1. Connect the power wire. 2. Turn on...

Page 77

Troubleshooting 4-37 4-4-10. Indoor/outdoor communication error (1min.) (error code : e202) 1. Test items 1) check the communication wire and power wire connection. 2) check the communication connector connection. - cn31 of outdoor unit main pcb 3) check the communication circuit on the pcb. 2. Chec...

Page 78

Troubleshooting 4-38 yes indoor/outdoor communication error (1 min.) (error code: e202) (cont.) continue check the communication circuit of the main pcb of the outdoor unit. 1. Is there a fault in communication ic? 2. Is there a fault in tvs-diode? Communication ic measuring (port) steady-state meas...

Page 79

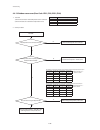

Troubleshooting 4-39 4-4-11. Communication error between outdoor unit inv ļ main micom (1 min.)(error code: e203) 1. Test items 1) is power supplied to outdoor unit inverter pcb? 2) check the power wire connection and fuse. 3) is there a problem in the communication wire connections between the outd...

Page 80

Troubleshooting 4-40 4-4-12. Outdoor sensor error(error code : e221, e231, e251, e320) 1. Test items 1) check the connection of the temperature sensor connector. 2) check the resistance value of the temperature sensor. 2. Check procedure error code description e221 outdoor temperature sensor error e...

Page 81

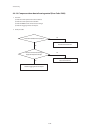

Troubleshooting 4-41 4-4-13. Reverse phase / loss phase detection (3-phase outdoor unit) (error code : e425 ) 1. When power is on, it checks the power status used for 3-phase power compressor. When the order of 3-phase l1(r) – l2(s) – l3(t) is changed (reverse phase) or there is a phase that does no...

Page 82

Troubleshooting 4-42 1. Test items 1) check the normal operation of indoor fan/motor. 2) check the normal operation of indoor eev. 3) check the in/out sensor of indoor heat exchanger. 3) check the clogging of indoor air inlet part. 2. Check procedure 4-4-14. Compressor down due to freezing control (...

Page 83

Troubleshooting 4-43 4-4-15. Outdoor unit fan error (error code : e458, e475) 1. Test items 1) check the connection of fan connectors (cn90, cn91) 2) check the voltage of the fan motor connector in the inverter pba of the outdoor unit. 3) check the power connection of the outdoor unit inverter pcb. ...

Page 84

Troubleshooting 4-44 4-4-16. Compressor starting error / rotation error (error code : e461, e467) 1. Test items 1) check the power connection. / check the restart after power reset. 2) check the compressor and the state of the compressor wire assembling. 3) check the defective for compressor wire si...

Page 85

Troubleshooting 4-45 compressor starting error / rotation error (error code : e461, e467) (cont.) 1. Replace the compressor wire. ĺ power on. ĺ check normal startup. ĺ end the service. 2. Replace the compressor wire. ĺ power on. ĺcheck normal startup. ĺ end the service. 3. Replace the compressor wir...

Page 86

Troubleshooting 4-46 4-4-17. Full current error / pfc over-current error (error code : e462, e484) 1. Test items 1) check the power connection. / check the restart after power reset. 2) install outdoor unit and check environment. ĺ check for wire disconnection related to outdoor unit inverter pcb an...

Page 87

Troubleshooting 4-47 4-4-18. Ipm ipm (over current) error (error code : e464) 1. Test items 11) check the power connection. / check the restart after power reset. 2) install outdoor unit and check environment. ĺ check for wire disconnection related to outdoor unit inverter pcb and check the installa...

Page 88

Troubleshooting 4-48 ipm over(over current) error (error code : e464)(cont.) yes turn off the power and change the location of the temperature sensor or replace it. No are the position and measuring value of the temperature sensor normal? Continue check the connection status of compressor. No is com...

Page 89

Troubleshooting 4-49 ipm over(over current) error (error code : e464)(cont.) yes 1. Replace the compressor wire. ĺ power on. ĺ check normal startup. ĺ end the service. 2. Replace the compressor wire. ĺ power on. ĺ check normal startup. ĺ end the service. 3. Replace the compressor wire. ĺ power on. ĺ...

Page 90

Troubleshooting 4-50 4-4-19. Dc link over-current / low-voltage error (error code : e466) h/w dc_link over voltage error (error code : e483) ac input voltage sensor error (error code : e488 1. Test items 1) check the power connection. / check the restart after power reset. ĺ is there a fault in inpu...

Page 91

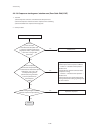

Troubleshooting 4-51 4-4-20. Gas leakage error(error code : e554) 1. Test items 1) check the power connection. / check the restart after power reset. ĺ is there a fault in input power? (single-phase : 220vac, 3-phase : 380vac) ĺ does error occur again at operation after power is reset? 2) check the ...

Page 92

Troubleshooting 4-52 gas leakage error(error code : e554) (cont.) open the valve. Yes reconnect the sensor connector. No no is the indoor eva sensor correctly connected? Yes charge the refrigerant. No is refrigerant charged? Replace the inverter pcb. Continue yes yes is service valve fully opened?.

Page 93

Troubleshooting 4-53 4-4-21. Pipe blockage error(error code : e422) 1. Test items 1) check the open state of the outdoor unit service valve. 2) check the connection of the pipe. 3) check the operation of the eev. 4) check the refrigerant leakage. 5) check the connection of the indoor unit pba eva se...

Page 94

Troubleshooting 4-54 4-4-22. Smart install mode was not carried out (error code : e508 ) smart install mode? When installing the air conditioner the first time, the installation status and fault status and performance of the product is a self-diagnostic function to determine comprehensively.. (the c...

Page 95

Troubleshooting 4-55 precautions ▶ when needing to have additional piping before entering the installation smart install mode, charge refrigerant additionally according to the manual. At this time, it is possible to run the cooling test (k2 switch once) and heating test (k1 switch once). ▶ when the ...

Page 96

Troubleshooting 4-56 4-4-22. Others 1. Eeprom option error (e163) : reset the options. 2. Temperature fuse error : e198 - if the terminal box temperature rise fuse is disconnected, replace the pcb. - check the wiring connector of temperature fuse. 3. Current sensor error : upload eeprom to the main ...

Page 97

Troubleshooting 4-57 15. Current sensor error : e468 - check the eeprom data. - check the pcb operation. 16. Ipm (igbt module) or pfcm temperature sensor error : e474 ipm overheat error for outdoor unit inverter compressor : e500 - check whether ipm is correctly assembled on the heatproof plate. - c...

Page 98

5-1 pcb diagram and parts list 5-1-1. Indoor unit main pba 5. Pcb diagram and parts list 5-1. Pcb diagram 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 20 19.

Page 99

Pcb diagram and parts list 5-2 ① cn101-earth gnd ② cn900-bldc motor ③ cn102-fuse check ④ cn950-suction fan #1 : earth gnd #1 : dc 310v #3 : gnd #4 : dc 15v #5 : fan rpm #6 : rpm feedback #1 : fuse check signal #2 : gnd #1,#5 #9 : dc12v #2 #6 #10 : fan feedback #3 #7 #11 : gnd #4 #8 #12 : fan ctrl ⑤ ...

Page 100

5-3 pcb diagram and parts list 5-1-2. Display pcb ■ 360 cassette ① cn401 – display 1 #1 : 12v #2 : visualization led_section2, layer2 #3 : visualization led_section2, layer3 #4 : visualization led_section3, layer1 #5 : visualization led_section3, layer2 #6 : visualization led_section3, layer3 ② cn50...

Page 101

Pcb diagram and parts list 5-4 5-1-3. Outdoor pcb ■ main pcb - ac090/100/120/140mxad*h 1 2 3 4 5 6 8 9 10 11 12.

Page 102

5-5 pcb diagram and parts list ① cn101 - power ② cn702 - 4way ③ cn403 - sensor ④ cn306 - download #1 : l #2 : n.C #3 : n #1 : n #2 : n.C #3 : 4way v/v signal #1 : out temp #2 : gnd #3 : cond temp #4 : gnd #5 : discharge temp #6 : gnd #7 : olp temp #8 : gnd #1 ~ #20 : download ⑤ cn802 - eev ⑥ cn806 -...

Page 103

Pcb diagram and parts list 5-6 outdoor unit pcb (cont.) ■ pf#4 inverter pcb : single-phase i - ac090/100mxadkh 4 1 2 8 3 7 6 5.

Page 104

5-7 pcb diagram and parts list ① reactor - a1/b1 ② reactor – a2/b2 ③ comp. W ④ cn551-inv-download #reactor-a1 : wht #reactor-b1 : wht #reactor-a2 : blk #reactor-b2 : blk #1 : rxd #2 : txd #3 : gnd #4 : dv5v #5 : dv12v #6 : inv, smps signal #1 : rxd_inv #2 : txd_inv #3 : boot_inv #4 : tdo_inv #5 : tc...

Page 105

Pcb diagram and parts list 5-8 outdoor unit pcb (cont.) ■ pf#6-1 inverter pcb : 3-phase i - ac100mxadnh 1 2 8 4 6 5 3 7.

Page 106

5-9 pcb diagram and parts list ① rst –ac power 3phase ② cn100 - ac power ③ cn31 – main comm ④ cn22 - downloader #r : ac 380~400v : wht #s : ac 380~400v : brn #t : ac 380~400v : blk #1~#3 : ac 220~240v #1 : rxd #2 : txd #3 : gnd #4 : dv 5v #5 : dv 12v #6 : inv, smps signal #1 : rxd_inv #2 : txd_inv #...

Page 107

Pcb diagram and parts list 5-10 outdoor unit pcb (cont.) ■ pf#4 inverter pcb : single-phase Ⅱ - ac120mxadkh 8 2 1 4 3 7 6 5 ① reactor-a1/b1 ② reactor-a2/b2 ③ cn351 - main comm ④ cn551 – downloader #reactor-a1 : wht #reactor-b1 : wht #reactor-a2 : blk #reactor-b2 : blk #1 : rxd #2 : txd #3 : gnd #4 :...

Page 108

5-11 pcb diagram and parts list outdoor unit pcb (cont.) ■ pf#5 inverter pcb : single-phase iii - ac140mxadkh 1 2 8 4 3 7 6 5 ① reactor-a1/b1 ② reactor-a2/b2 ③ cn351 - main comm ④ cn551 – downloader #reactor-a1 : wht #reactor-b1 : wht #reactor-a2 : blk #reactor-b2 : blk #1 : rxd #2 : txd #3 : gnd #4...

Page 109

Pcb diagram and parts list 5-12 outdoor unit pcb (cont.) ■ pf#6 inverter pcb : 3-phase Ⅱ - ac120/140mxadnh 1 2 8 6 4 5 3 7 ① rst - ac power 3phase ② cn100-ac power ③ cn351 - main comm ④ cn22-downloader #r : ac 380~400v : wht #s : ac 380~400v : brn #t : ac 380~400v : blk #1-#3 : ac 220~240v #1 : rxd ...

Page 110

5-13 pcb diagram and parts list outdoor unit pcb (cont.) ■ emi pcb : single-phase - ac090/120/140mxadkh ① l1 : brn ② n1 : sky-blu ③ #1-#3 : ac 220~240v l1-ac power l phase n1-ac power n phase cn01-ac power 1 1 3 2.

Page 111

Pcb diagram and parts list 5-14 outdoor unit pcb (cont.) ■pf#6 inverter pcb : 3-phase - ac100/120/140mxadnh ① #r : ac 380~400v : wht #s : ac 380~400v : brn #t : ac 380~400v : blk ② #1-#3 : ac 220~240v rst-ac power 3phase cn100-ac power 1 1 2.

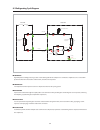

Page 112: 6. Wiring Diagram

6-1 wiring diagram this document can not be used without samsung’s authorization.. ■ circular cassette 6. Wiring diagram 6-1. Indoor unit.

Page 113

Wiring diagram 6-2 this document can not be used without samsung’s authorization. ■ single-phase pf#4 / pf#4-1 / pf#5 schematic diagram '%$ 6-2. Outdoor unit.

Page 114

6-3 wiring diagram this document can not be used without samsung’s authorization. ■ 3-phase pf#6 / pf#6-1 schematic diagram '%$.

Page 115: 7. Sw Update

7-1 sw update 7. Sw update 7-1. S-net pro download download link : http://mosaic.Sec.Samsung.Net/club/club.Menu.Bbs.List.Screen?P_club_id=1219&p_menu_id=14 note : if you do not have an authority to access the intranet, contact to your counter partner !! 7-2. Rs485 vs rs232(uart) rs485(through commun...

Page 116

Sw update 7-2 7-3. How to update the micom(rs485) t through rs485 communication. - f1,f2 terminal block on odu - f1,f2 connector on odu’s main pcb - f1,f2 terminal block on idu step 1 connect s-converter to f1,f2 line usb to rs232 cable s-converter tx+ ĺ f1 tx+ ĺ f2 outdoor unit main pcb step 2 exec...

Page 117

7-3 sw update how to update the micom(rs485) (cont.) tsw update of the hardware boards have always been critical operations.In order to reduce the time,increase usability and more on top of reliability of having the sw update successfully. Ta/c sw update enables the engineer to update the sw of indo...

Page 118

Sw update 7-4 how to update the micom(rs485) (cont.) 2. Browse and select the *.Hex file. 3. Select the device from the list of devices and select the address of the device..

Page 119

7-5 sw update how to update the micom(rs485) (cont.) 3-2 importing the address list of the device that is saved previous trial. A. To add the address list of the device, browse address list at \documents\s-net pro2\download b. On clicking the add all button will be added to the list. 3-1 manually en...

Page 120

Sw update 7-6 how to update the micom(rs485) (cont.) 4. Click the start button for initiating the sw update. A. The firmware update for the device enters download mode will be displayed. B. The progress bar at the bottom of the can check the progress of your downloads. 5. Firmware update failure a. ...

Page 121

7-7 sw update 7-4. How to update the micom(uart) t update sw through rs232(uart) communication. Step 1 power down the unit and prepare to connect download cable to the pcb * 20 pin connecter in black color(odu - 10 pin connecter) step 2 execute s-net pro 2 and go to add-on tab and click uart update ...

Page 122

Sw update 7-8 how to update the micom(uart) (cont.) 5. Select the download file and click “start button” and then turn on the s-converter 6. Pcb will be updating.

Page 123

7-9 sw update 7-5. How to write the eeprom t update eeprom through rs485 communication. Step 1 connect s-converter to f1,f2 line usb to rs232 cable s-converter tx+ ĺ f1 tx+ ĺ f2 outdoor unit main pcb step 2 execute s-net pro 2 and set environment then click connect button click connect.

Page 124

Sw update 7-10 how to write the eeprom (cont.) step 3 go to add-on tab and click eeprom writer this feature of the outdoor unit is the ability to write data to the outdoor unit eeprom settings. (eeprom firmware, the outdoor unit, fan version, dbcode to be saved, etc., in fact, write the eeprom when ...

Page 125

7-11 sw update caution - this is only for outdoor unit. - eeprom writing should be proceeded in case of eeprom ic replacement by eeprom ic defect. Because all the data in the eeprom ic will be deleted. * you need to proceed auto trial operation again. - so when you replace main pcb, keep eeprom ic a...

Page 126: 8. Reference Sheet

8-1 reference sheet h c h 0 h 7 h 1 h k h n h 4 h d h b h h h a product type am dvm aj pma ac cac (usd) / asd ae ehs an vtl ak pak (packaged system) ag chr launch year e 2012 f 2013 h 2014 j 2015 k 2016 m 2017 separator s general set (nasa) n indoor unit (nasa) x outdoor unit (nasa) a general set (n...

Page 127

Reference sheet 8-2 index for model name (cont.) h c h 0 h 7 h 1 h k h x h 4 h d h k h h h / h a product type am dvm aj pma ac cac (usd) / asd ae ehs an vtl ak pak (packaged system) ag chr launch year e 2012 f 2013 h 2014 j 2015 k 2016 m 2017 separator s general set (nasa) n indoor unit (nasa) x ind...

Page 128

8-3 reference sheet index for model name (cont.) 8-1-3. Panel ■ pc4n 666 ※ only, display the global 4 way with korean/ english k separator. ※ only, model name for the bundle packaging is “~s”. ★ ※ only, global 4 way panel version. H m h n h a h n h c h p h 4n h u product design classification p pane...

Page 129

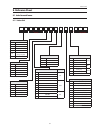

8-4 8-2 refrigerating cycle diagram ■ condenser high temperature and high pressure gas state coolant discharged from the compressor is converted to a liquid state as it is cooled down by the heat emission in the outdoor condenser unit, and sent to the evaporator. ■ compressor low temperature and low...

Page 130

This service manual is a property of samsung electronics co., ltd. Any unauthorized use of manual can be punished under applicable international and/or domestic law. © samsung electronics co., ltd. December. 2016. Printed in korea. Code no. Ac-00171e_1 gspn (global service partner network) area web ...