- DL manuals

- Samsung

- Air Conditioner

- ACMKC035EA3

- Service manual

Samsung ACMKC035EA3 Service manual

CONTENTS

AIR CONDITIONER

1

1. Precautions

1

2. Numbering system of model

1

3. Product Specification

1

4. Installation

1

5. Disassembly and Reassembly

1

6. Refrigerating Cycle Diagram

1

7. Set up the Model Option

1

8. Troubleshooting

1

9. Exploded Views and Parts List

10. Wiring Diagram

11. Schematic Diagram

SERVICE

Manual

SYSTEM AIR CONDITIONER

(DVM Series)

Summary of ACMKC035EA3

Page 1

Contents air conditioner 1 1. Precautions 1 2. Numbering system of model 1 3. Product specification 1 4. Installation 1 5. Disassembly and reassembly 1 6. Refrigerating cycle diagram 1 7. Set up the model option 1 8. Troubleshooting 1 9. Exploded views and parts list 10. Wiring diagram 11. Schematic...

Page 2: Precautions

Precautions 1 1 1. Cut off the power. ● make sure to cut off the power before repair. If not, you may be damaged by an electric shock. 1 2. Do not install an outdoor unit on the apartment outside wall(or equivalent) for safety. ● installing an outdoor unit on the apartment outside wall(or equivalent...

Page 3: Numbering System of Model

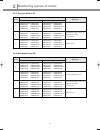

- 2 - model avm ! K @ h # 020 $ e % a ^ 0 0 0 0 @@@@@@@@e? @@@@@@@@e? @@h? @@h? @@h? @@h? @@h? @@h? @@@@@@@@e?@@@@@@@@?E@@@@@@@@e?@@@@@@@@?E@@@@@@@@e?@@@@@@@@?E@@@@@@@@e?@@@@@@@@?E@@@@@@@@e?@@@@@@@@?E@@@@@@@@e?@@@@@@@@?E@@@@@@@@e?@@@@@@@@?E@@@@@@@@e?@@@@@@@@?E@@@@@@@@e?@@@@@@@@?E@@@@@@@@e?@@@@@@@@?E...

Page 4

- 3 - - 3 - model rvm ! H @ 060 # c $ b % m ^ 0 0 0 0 @@@@@@@@e? @@@@@@@@e? @@h? @@h? @@h? @@h? @@h? @@h? @@@@@@@@e?@@@@@@@@?E@@@@@@@@e?@@@@@@@@?E@@@@@@@@e?@@@@@@@@?E@@@@@@@@e?@@@@@@@@?E@@@@@@@@e?@@@@@@@@?E@@@@@@@@e?@@@@@@@@?E@@@@@@@@e?@@@@@@@@?E@@@@@@@@e?@@@@@@@@?E@@@@@@@@e?@@@@@@@@?E@@@@@@@@e?@@@@...

Page 5: Numbering System of Model

2-2. Indoor unit version 2-2-1. 1-way cassette type (k) 2-2-2. 2-way cassette type (g) 2-2-3. 4-way cassette type (c) - 4 - numbering system of model 2 version modification indoor unit model heat pump cooling only avmkh020e(c)a0 avmkh026ea0 avmkh032ca0 avmkh035ea0 avmkh040ca0 avmkc020e(c)a0 avmkc026...

Page 6

2-2. ??? 2-2-4. Duct type (silhouette : d) 2-2-5. Duct type (high pressure : h) 2-2-6. Duct type (low pressure : l) - 5 - numbering system of model version modification indoor unit model heat pump cooling only avmdh052e(c)a0 avmdh070ea0 avmdh072ca0 avmdc052e(c)a0 avmdc070ea0 avmdc072ca0 - - auto add...

Page 7: Numbering System of Model

2-2-7. Duct type (built-in : b) 2-2-8. Wall mounted type (w) - 6 - numbering system of model 2 version modification indoor unit model heat pump cooling only - - auto address setting for indoor unit - applicable non-polarity communication 0 3 avmbh020e(c)a0 avmbh026ea0 avmbh032ca0 avmbh035ea0 avmbh04...

Page 8

2-2-9. Floor standing type (p) 2-2-10. Ceiling type (f) 2-3. Outdoor unit version - 7 - numbering system of model version modification indoor unit model heat pump cooling only - 0 avmph060e(c)a0 avmph070ea0 avmph072ca0 avmph082ea0 avmph083ca0 avmpc060e(c)a0 avmpc070ea0 avmpc072ca0 avmpc082ea0 avmpc0...

Page 9: Numbering System of Model

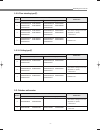

2-4. Accessories (options) - 8 - numbering system of model 2 classification model standard for model name examples mxd : distributor kit ! : eev capacity (double figures) • 14(for 2.0kw~4.0kw capa indoor) • 18(for 5.2kw~8.5kw capa indoor) @ : number of ! Capa eev # : eev capacity (double figures) • ...

Page 10

- 9 - numbering system of model classification model standard for model name examples mxj : refnet header h : one packing for gas and liquid side ! : inlet pipe diameter for gas side (mm, double figures) @ : inlet pipe diameter for liquid side (mm, double figures) # : version mxj-h !@# refnet header...

Page 11: Numbering System of Model

- 10 - numbering system of model 2 classification model standard for model name examples mrw : remote control receiver kit wire ! : length(m, double figures) @ : version mrw- !@ remote control receiver wire ● mrw-10a mwr : wired remote control ! : remote control design (a ~ present) @ : function cla...

Page 12

- 11 - numbering system of model classification model standard for model name examples ● mim-b00 : centralized controller interface module (up to 10hp outdoor unit) ● mim-b04 : centralized controller interface module (up to 34hp outdoor unit) ● mim-b01a : plc interface module ● mim-b02 : key-tag int...

Page 13: Numbering System of Model

- 12 - numbering system of model 2 2-5. Combination 2-5-1. Outdoor unit ■ cooling only power supply design model 60hz 208~230v, 1ø rvmc050cbm0 capacity(hp) 5 refrigerant r22 50hz 60hz 50hz 60hz 380~415v, 3ø 380~415v, 3ø 208~230v, 3ø rvmc060gam0 rvmc060gam1 rvmc070fam0(5) 6 6 7 r22 r22 r22 380~415v, ...

Page 14

- 13 - 2-5. Combination 2-5-1. Outdoor unit ■ heat pump ■ heat recovery numbering system of model power supply design model 50hz 60hz 380~415v, 3ø 380~415v, 3ø 208~230v, 1ø rvmh060gbm0 rvmh060gdm0(3) rvmh050cbm0 capacity(hp) 6 6 5 refrigerant r22 r407c r22 50hz 60hz 380~415v, 3ø 380~415v, 3ø 208~230...

Page 15: Numbering System of Model

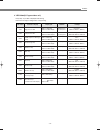

2-5-2. Indoor unit numbering system of model 2 design power supply 2.0kw (7,000btu/h) 2.6kw (9,000btu/h) 3.2kw (11,000btu/h) 3.5kw (12,000btu/h) 4.0kw (13,500btu/h) 5.2kw (18,000btu/h) 6.0kw (20,000btu/h) avmkc020ea ✳ avmkh020ea ✳ avmkc020ca ✳ avmkh020ca ✳ - - - - - - - - - - - - avmbc020ea ✳ avmbh0...

Page 16

- 15 - ✳ the design and capacity of indoor unit are subject to change without notice. Cooling only heat pump cooling only heat pump cooling only heat pump cooling only heat pump cooling only heat pump cooling only heat pump cooling only heat pump cooling only heat pump cooling only heat pump cooling...

Page 17: Product Specification

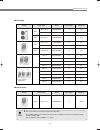

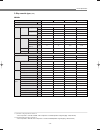

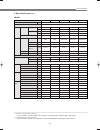

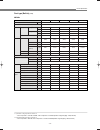

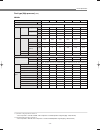

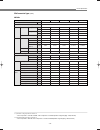

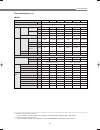

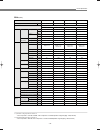

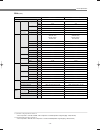

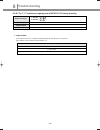

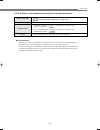

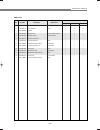

- 16 - 3-1. Indoor unit 3-1-1. 1-way cassette type ■ 50hz - 16 - model power supply remark performance power piping connections set size panel size function / option cooling ✳ 1) heating ✳ 2) model type output air flow rate (high/low) - - liquid(flare) gas(flare) drain capacity sound level fan motor...

Page 18

- 17 - 1-way cassette type (cont.) ■ 60hz - 17 - ✳ 1) nominal cooling capacities are based on: ✳ 1) - indoor temperature : 27˚c db, 19˚c wb, outdoor temperature : 35˚c db, equivalent refrigerant piping : 10m(horizontal) ✳ 2) nominal heating capacities are based on: ✳ 1) - indoor temperature : 20˚c d...

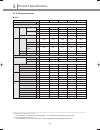

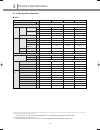

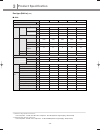

Page 19: Product Specification

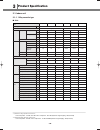

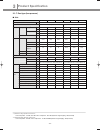

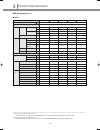

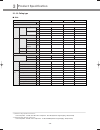

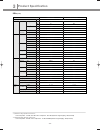

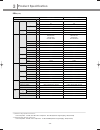

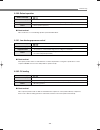

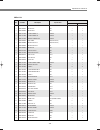

- 18 - product specification 3 3-1-2. 2-way cassette type ■ 50hz model power supply remark performance power piping connections set size panel size function / option cooling ✳ 1) heating ✳ 2) model type output air flow rate (high/low) - - liquid(flare) gas(flare) drain capacity sound level fan motor...

Page 20

- 19 - product specification 2-way cassette type (cont.) ■ 60hz model power supply remark performance power piping connections set size panel size function / option cooling ✳ 1) heating ✳ 2) model type output air flow rate (high/low) - - liquid(flare) gas(flare) drain capacity sound level fan motor ...

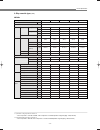

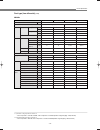

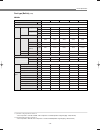

Page 21: Product Specification

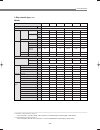

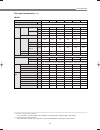

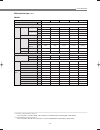

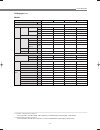

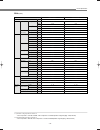

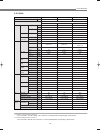

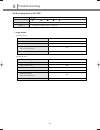

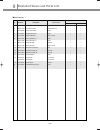

3-1-3. 4-way cassette type ■ 50hz - 20 - product specification 3 model power supply remark performance power piping connections set size panel size function / option cooling ✳ 1) heating ✳ 2) model type output air flow rate (high/low) - - liquid(flare) gas(flare) drain capacity sound level fan motor...

Page 22

4-way cassette type (cont.) ■ 50hz - 21 - product specification model power supply remark performance power piping connections set size panel size function / option cooling ✳ 1) heating ✳ 2) model type output air flow rate (high/low) - - liquid(flare) gas(flare) drain capacity sound level fan motor ...

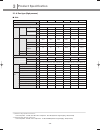

Page 23: Product Specification

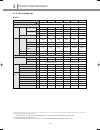

- 22 - 4-way cassette type (cont.) ■ 60hz product specification 3 ✳ 1) nominal cooling capacities are based on: ✳ 1) - indoor temperature : 27˚c db, 19˚c wb, outdoor temperature : 35˚c db, equivalent refrigerant piping : 10m(horizontal) ✳ 2) nominal heating capacities are based on: ✳ 1) - indoor tem...

Page 24

- 23 - 4-way cassette type (cont.) ■ 60hz product specification ✳ 1) nominal cooling capacities are based on: ✳ 1) - indoor temperature : 27˚c db, 19˚c wb, outdoor temperature : 35˚c db, equivalent refrigerant piping : 10m(horizontal) ✳ 2) nominal heating capacities are based on: ✳ 1) - indoor tempe...

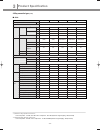

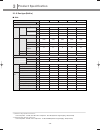

Page 25: Product Specification

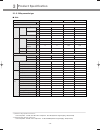

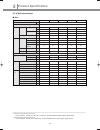

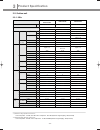

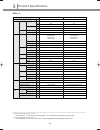

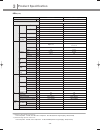

3-1-4. Duct type (low silhouette) ■ 50hz - 24 - product specification 3 model power supply remark performance power piping connections set size function / option cooling ✳ 1) heating ✳ 2) model type output air flow rate (high/low) - - liquid(flare) gas(flare) drain capacity sound level fan motor run...

Page 26

Duct type (low silhouette) (cont.) ■ 60hz - 25 - product specification model power supply remark performance power piping connections set size function / option cooling ✳ 1) heating ✳ 2) model type output air flow rate (high/low) - - liquid(flare) gas(flare) drain capacity sound level fan motor runn...

Page 27: Product Specification

3-1-5. Duct type (built-in) ■ 50hz - 26 - product specification 3 ✳ 1) nominal cooling capacities are based on: ✳ 1) - indoor temperature : 27˚c db, 19˚c wb, outdoor temperature : 35˚c db, equivalent refrigerant piping : 10m(horizontal) ✳ 2) nominal heating capacities are based on: ✳ 1) - indoor tem...

Page 28

Duct type (built-in) (cont.) ■ 50hz - 27 - product specification ✳ 1) nominal cooling capacities are based on: ✳ 1) - indoor temperature : 27˚c db, 19˚c wb, outdoor temperature : 35˚c db, equivalent refrigerant piping : 10m(horizontal) ✳ 2) nominal heating capacities are based on: ✳ 1) - indoor temp...

Page 29: Product Specification

Duct type (built-in) (cont.) ■ 60hz - 28 - product specification 3 ✳ 1) nominal cooling capacities are based on: ✳ 1) - indoor temperature : 27˚c db, 19˚c wb, outdoor temperature : 35˚c db, equivalent refrigerant piping : 10m(horizontal) ✳ 2) nominal heating capacities are based on: ✳ 1) - indoor te...

Page 30

Duct type (built-in) (cont.) ■ 60hz - 29 - product specification ✳ 1) nominal cooling capacities are based on: ✳ 1) - indoor temperature : 27˚c db, 19˚c wb, outdoor temperature : 35˚c db, equivalent refrigerant piping : 10m(horizontal) ✳ 2) nominal heating capacities are based on: ✳ 1) - indoor temp...

Page 31: Product Specification

3-1-6. Duct type (high pressure) ■ 50hz - 30 - product specification 3 ✳ 1) nominal cooling capacities are based on: ✳ 1) - indoor temperature : 27˚c db, 19˚c wb, outdoor temperature : 35˚c db, equivalent refrigerant piping : 10m(horizontal) ✳ 2) nominal heating capacities are based on: ✳ 1) - indoo...

Page 32

Duct type (high pressure) (cont.) ■ 60hz - 31 - product specification ✳ 1) nominal cooling capacities are based on: ✳ 1) - indoor temperature : 27˚c db, 19˚c wb, outdoor temperature : 35˚c db, equivalent refrigerant piping : 10m(horizontal) ✳ 2) nominal heating capacities are based on: ✳ 1) - indoor...

Page 33: Product Specification

3-1-7. Duct type (low pressure) ■ 50hz - 32 - product specification 3 ✳ 1) nominal cooling capacities are based on: ✳ 1) - indoor temperature : 27˚c db, 19˚c wb, outdoor temperature : 35˚c db, equivalent refrigerant piping : 10m(horizontal) ✳ 2) nominal heating capacities are based on: ✳ 1) - indoor...

Page 34

Duct type (low pressure) (cont.) ■ 60hz - 33 - product specification ✳ 1) nominal cooling capacities are based on: ✳ 1) - indoor temperature : 27˚c db, 19˚c wb, outdoor temperature : 35˚c db, equivalent refrigerant piping : 10m(horizontal) ✳ 2) nominal heating capacities are based on: ✳ 1) - indoor ...

Page 35: Product Specification

3-1-8. Wall-mounted type ■ 50hz - 34 - product specification 3 model power supply remark performance power piping connections set size function / option cooling ✳ 1) heating ✳ 2) model type output air flow rate (high/low) - - liquid(flare) gas(flare) drain capacity sound level fan motor running curr...

Page 36

Wall-mounted type (cont.) ■ 50hz - 35 - product specification model power supply remark performance power piping connections set size function / option cooling ✳ 1) heating ✳ 2) model type output air flow rate (high/low) - - liquid(flare) gas(flare) drain capacity sound level fan motor running curre...

Page 37: Product Specification

Wall-mounted type (cont.) ■ 60hz - 36 - product specification 3 model power supply remark performance power piping connections set size function / option cooling ✳ 1) heating ✳ 2) model type output air flow rate (high/low) - - liquid(flare) gas(flare) drain capacity sound level fan motor running cur...

Page 38

Wall-mounted type (cont.) ■ 60hz - 37 - product specification model power supply remark performance power piping connections set size function / option cooling ✳ 1) heating ✳ 2) model type output air flow rate (high/low) - - liquid(flare) gas(flare) drain capacity sound level fan motor running curre...

Page 39: Product Specification

3-1-9. Floor standing type ■ 50hz - 38 - product specification 3 ✳ 1) nominal cooling capacities are based on: ✳ 1) - indoor temperature : 27˚c db, 19˚c wb, outdoor temperature : 35˚c db, equivalent refrigerant piping : 10m(horizontal) ✳ 2) nominal heating capacities are based on: ✳ 1) - indoor temp...

Page 40

Floor standing type (cont.) ■ 60hz - 39 - product specification ✳ 1) nominal cooling capacities are based on: ✳ 1) - indoor temperature : 27˚c db, 19˚c wb, outdoor temperature : 35˚c db, equivalent refrigerant piping : 10m(horizontal) ✳ 2) nominal heating capacities are based on: ✳ 1) - indoor tempe...

Page 41: Product Specification

3-1-10. Ceiling type ■ 50hz - 40 - product specification 3 model power supply remark performance power piping connections set size function / option cooling ✳ 1) heating ✳ 2) model type output air flow rate (high/low) - - liquid(flare) gas(flare) drain capacity sound level fan motor running current ...

Page 42

Ceiling type (cont.) ■ 60hz - 41 - product specification model power supply remark performance power piping connections set size function / option cooling ✳ 1) heating ✳ 2) model type output air flow rate (high/low) - - liquid(flare) gas(flare) drain capacity sound level fan motor running current po...

Page 43: Product Specification

- 42 - 3-2. Outdoor unit 3-2-1. 50hz model power supply remark performance power others size function / option rvmc060gam0 rvmc060gam1 rvmc100gam0 3, 380~415, 50 set 55,000(7,000~55,000) 16.0(2.0~16.0) - - 54 - zrd72kc-tfd digital scroll 98.06 4.2 propeller 128 x 2 70 8.0(4.5~8.0) - 5,255(1,865~5,25...

Page 44

50hz (cont.) - 43 - model power supply remark performance power others size function / option rvmh060gdm0(3) rvmh100gam0 rvmh100gcm0 set 55,000(7000~55,000) 16.0(2.0~16.0) 61,000(7,500~61,000) 18.0(2.2~18) 57 57 zrd72kce-tfd digital scroll 98.06 4.2 propeller 128 x 2 95 9.0(6.0~9.0) 9.0(6.0~9.0) 5,6...

Page 45: Product Specification

50hz (cont.) - 44 - model power supply performance power others size function / option rvmr100gcm ✳ rmah140gam ✳ 95,500 28 107,500 31.5 59 59 zrd14mce-tfd digital scroll + fixed scroll 98.04+98.04 4.2+4.2 propeller 450 150 20 19 11,000 10,500 2.9 r407c 17 eev poe 1,890x2 12.7 low : 28.58 / high : 19...

Page 46

50hz (cont.) - 45 - model power supply performance power others size function / option rmah160gam ✳ rmah180gam ✳ 153,500 45.0 170,600 50.0 59 59 zrd72kc-tfd+zr72kc-tfd(2) digital scroll + fixed scroll(2) 98.06x3 4.2x3 propeller 450x2 150x2 26.0 26.0 14,500 14,350 2.9 r22 27 eev white oil 1,890x3 15....

Page 47: Product Specification

50hz (cont.) - 46 - product specification 3 model power supply performance power others size function / option rmah200gam ✳ rmah220gam ✳ 191,000 56.0 215,000 63.0 59 59 zrd72kc-tfd+ zr72kc-tfd+ zr144kc-tfd digital scroll + fixed scroll(2) 98.06x2+190.9 4.2x2+8.2 propeller 450x2 150x2 34.0 33.7 19,05...

Page 48

50hz (cont.) - 47 - product specification model power supply performance power others size function / option rmah240gam ✳ rmah260gam ✳ 232,000 68.0 255,900 75.0 59 59 zrd72kc-tfd+ zr72kc-tfdx2+ zr144kc-tfd digital scroll + fixed scroll(3) 98.06x3+190.9 4.2x3+8.2 propeller 450x3 150x3 39.0 38.0 21,80...

Page 49: Product Specification

50hz (cont.) - 48 - product specification 3 model power supply performance power others size function / option rmah280gam ✳ rmah300gam ✳ 267,800 78.5 300,300 88.0 59 59 zrd72kc-tfd+ zr72kc-tfd+ zr144kc-tfdx2 digital scroll + fixed scroll(3) 98.06x2+190.9x2 4.2x2+8.2x2 propeller 450x3 150x3 47.0 46.0...

Page 50

3-2-2. 60hz - 49 - product specification cooling ✳ 1) heating ✳ 2) cooling ✳ 3) cooling heating model type piston displacement output type output air flow rate cooling heating cooling heating cooling heating cooling heating name charge control name charge liquid gas drain cooling heating btu/h kw bt...

Page 51: Product Specification

60hz (cont.) - 50 - product specification 3 cooling ✳ 1) heating ✳ 2) cooling ✳ 3) cooling heating model type piston displacement output type output air flow rate cooling heating cooling heating cooling heating cooling heating name charge control name charge liquid gas drain cooling heating btu/h kw...

Page 52

60hz (cont.) - 51 - product specification ✳ 1) nominal cooling capacities are based on: ✳ 1) - indoor temperature : 27˚c db, 19˚c wb, outdoor temperature : 35˚c db, equivalent refrigerant piping : 10m(horizontal) ✳ 2) nominal heating capacities are based on: ✳ 1) - indoor temperature : 20˚c db, outd...

Page 53: Installation

4-1. Classification of outdoor unit - 52 - installation 4 type a type b type c type d type figure model name rvmc050cbm0 rvmc060gam0 rvmc070fam0(5) rvmc060gam1 rvmh050cbm0 rvmh060gbm0 rvmh060gdm0(3) heat pump cooling only db98_17816a(2)_4 11/22/04 4:20 pm page 52.

Page 54

- 53 - installation type e type f type g type figure model name heat pump cooling only rvmh100gam0 rvmh100gcm0(3) rvmh100fam0 rmah140gam ✳ rmah160gam ✳ rmah180gam ✳ rmah200gam ✳ rmah220gam ✳ rmah240gam ✳ rmah260gam ✳ rmah280gam ✳ rmah300gam ✳ rmbh100gam ✳ rvmc100gam0 rvmc100fam0(5) auxiliary outdoor...

Page 55: Installation

4-2. The setting of outdoor unit option switch and key function 4-2-1. The setting of option switch ■ the option set part of outdoor unit pcb ◗ a, c, d type outdoor unit ◗ b, e type outdoor unit - 54 - installation 4 the setting switch of indoor unit installation number the setting switch of indoor ...

Page 56

■ the setting switch of indoor unit installation number - 55 - installation 0 1 2 3 4 5 6 7 8 9 a b c d e f g h ✳ example : if three indoor units are installed, adjust the arrow of switch to "3". The display method of english characters and figures on pcb display part i j k l m n o p q r s t u v w x...

Page 57: Installation

4-2-2. The function of key on the outdoor unit pcb ■ a, c, d type outdoor unit - 56 - installation 4 k1 k2 k3 k4 function enter times 1 time refrigerant collection ( ) pump down refrigerant supplement ( ) reset cooling test operation ( ) k1 k2 k3 k4 g seg1 a f g1 g2 b c e d seg2 g seg3 a f g1 g2 b c...

Page 58

◗ view mode(b, e type outdoor unit) every temp. & cycle data is displayed at k4 entering. Refer to the following according to times of key pressing. - 57 - installation enter times contents of display high pressure data low pressure data pwm compressor discharge temp. Condensing temp. Outdoor temp. ...

Page 59: Installation

4-2-3. The setting of option switch(f, g type outdoor unit) ■ the option set part of outdoor pcb ■ the setting switch of indoor unit installation number ■ the setting of indoor unit installation number can be controlled by combination of sw01(ten) and sw02(one). ■ ● example) if 12ea indoor units are...

Page 60

4-2-4. Operation control key and display part ■ display part ■ key ■ key function ■ main operation mode and function ● refrigerant supplement( , ) : operation to inject additional refrigerant – heating refrigerant supplement : when pressing k1 a time ( ) – cooling refrigerant supplement : when press...

Page 61: Installation

■ view mode every temperature and cycle data is displayed by the pressing times when entering k4. Refer to the followings. - 60 - installation 4 enter times 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 outdoor capacity digital comp loading time high pressure low pressure discharge tem...

Page 62

■ the setting of option switch of outdoor unit make a corresponding switch default on, and switch off at corresponding mode selection. - 61 - installation # function switch on switch off sw04 sw05 sw06 sw07 sw08 sw04 sw05 sw06 sw07 sw08 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 1 2 3 4 cooling capa. + 10% com...

Page 63: Installation

- 62 - installation 4 ● refrigerant charging operation ( , ) : is applied to charge the additional refrigerant in pipe after installation of outdoor unit. ● test operation ( , ) : is applied to check out the operation of indoor/outdoor unit after installation. ● refrigerant collecting operation ( ) ...

Page 64

- 63 - 4-3. The setting of indoor address 4-3-1. Specification 1 ● the indoor unit of system air conditioner must be set address. ● set the address as follows by use of the address setup switch of indoor unit pcb. Installation k1 k2 k3 k4 k5 k6 k7 k8 k9 k10 k11 k12 sw03 sw04 sw05 sw01 rmc sw02 main ...

Page 65: Installation

- 64 - installation 4 4-3-2. Specification 2 ● spec 2 model can set max. 40 the indoor unit address. ■ main address setup 1. The main switch(sw01,sw02) is a basic address for the communication between indoor unit and outdoor unit. The products operate normally when this address is set. 2. The addres...

Page 66

- 65 - 4-3-3. The indoor unit option switch setup installation function switch no switch on switch off wired remote control k1 k2 k3 k4 k5 not used not used initial setup rpm not used not used 1,000 hours not used not used fixed to 80 0 ~ 15 group used used rpm compensation used used 2,000 hours use...

Page 67: Installation

- 66 - installation 4 4-4. Test operation 4-4-1. Pre-check for the test operation 1. Check the indoor and outdoor unit power cable, and communication wire. ● electric part f1-indoor unit f1/ electric instrument f2-indoor unit f2 2. Preheat the compressor crankcase heater by turning power breaker(3 p...

Page 68

- 67 - 4. The outdoor unit starts a tracking to check the connected indoor unit and option at power on. ● the left of outdoor unit pcb check display part checks the responded indoor unit by communication to 0~f address, and displays the responded address to the right of pcb check display part. ● che...

Page 69: Installation

- 68 - installation 4 6. Prepare to check the test operation with s-net measurement instrument. The system air conditioner can be checked with a computer. Connect s-net measurement instrument before the test operation as following figure. ● install the s-net program to the computer. ● connect a rs-4...

Page 70

- 69 - 4-4-2. Test operation 1. Perform the test operation by pressing the test operation key of outdoor unit pcb when the pre-check for the test operation is completed. ● check the compressor noise at the initial operation, and if there is a large noise, stop the test operation. ● if there is a lar...

Page 71: Installation

- 70 - installation 4 3. Check the status of a test operation through s-net. 4. Ensure s-net data after 2 hours over test operation. ● store s-net data.(use alt + print screen) ● write an important data on the report. ● judge the test operation compare with the s-net judge criteria. ● check the erro...

Page 72

- 71 - 4-4-3. The cooling test operation by s-net judge the test operation by use of the s-net data obtained from the test operation. ■ before judgment, ■ ● judge the operation status by operating all of indoor units connected with the outdoor unit, and do 30 minutes after operation. ■ ● standard fo...

Page 73: Installation

- 72 - installation 4 4. Check the electronic expansion valve(e-valve). ● it is normal if the e-valve is 100~350 step. 5. Check the inlet temperature of indoor unit (t-evap in). ● it is normal if the temp. Difference between the room temp. And the inlet temperature of indoor unit is over +10˚c. ● bu...

Page 74

- 73 - 4-4-4. The heating test operation by s-net judge the test operation by use of the s-net data obtained from the test operation. ■ before judgment, ■ ● judge the operation status by operating all of indoor units connected with the outdoor unit, and do 30 minutes after operation. ■ ● standard fo...

Page 75: Installation

7. Check t-evap in of the indoor heat exchanger(condenser) based on heating. ● it is normal if the temperature is 35˚c ~ 50˚c. ● it is normal if the temperature is 15˚c ~ 25˚c higher than that of indoor, temperature. ✳ if there is expecially low temperature of indoor unit compare with others. ✳ - th...

Page 76

- 75 - installation 4-4-5. Installation keep the air conditioner pipe outlet and inlet free from its surroundings. In case of breakdown, keep the symmetry and fix it to prevent vibration. The pipe length shall meet the standard as far as possible. 4-5. Installation of air conditioner 4-5-1. Precauti...

Page 77: Installation

- 76 - 4-5 4. Leakage check ● insert the inert gas like nitrogen into the drainpipe of outdoor unit, and check the leakage of connection part with suds or exclusive materials. In this time, there should be no leakage. 5. Connection of the drainage hose ● install drainage hose, for the drainage is na...

Page 78: Memo

- 77 - memo db98_17816a(2)_4 11/22/04 4:21 pm page 77.

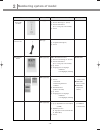

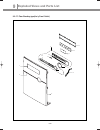

Page 79: Disassembly and Reassembly

- 78 - - 78 - disassembly and reassembly 5 stop operation of the air conditioner and remove the power cord before repairing the unit. 5-1. Indoor unit 5-1-1. 1-way cassette type parts no procedure remark 1 front grille & filter 1) open the front-grille by pushing the tabs on the grille. ✳ important ...

Page 80

- 79 - - 79 - 1-way cassette type (cont.) parts no procedure remark 2 front panel 1) disassemble the screws holding the panel as shown picture. 2) separate the front-panel pressing the 2 hooks on the both sides of the indoor unit. Disassembly and reassembly db98_17816a(2)_5 11/22/04 4:24 pm page 79.

Page 81: Disassembly and Reassembly

- 80 - disassembly and reassembly 5 1-way cassette type (cont.) parts no procedure remark 3 ass'y drain panel 1) disassemble screws for ass'y drain panel around as shown in pictures. 2) separate ass'y drain panel as shown in pictures. Disassembly and reassembly 5 db98_17816a(2)_5 11/22/04 4:24 pm pa...

Page 82

- 81 - 1-way cassette type (cont.) parts no procedure remark 4 ass'y control in 1) separate the control cover after disassembling screws as shown in pictures. 2) separate the wire connection part of the ass'y main pcb as shown in picture. Disassembly and reassembly db98_17816a(2)_5 11/22/04 4:24 pm ...

Page 83: Disassembly and Reassembly

- 82 - disassembly and reassembly 5 1-way cassette type (cont.) parts no procedure remark 3) disassemble screws of case control as shown in pictures. 4) disassemble indicating screw. 5) separate ass'y case control part pulling up. Db98_17816a(2)_5 11/22/04 4:24 pm page 82.

Page 84

- 83 - 1-way cassette type (cont.) parts no procedure remark 6) disassemble indicating screw and separate earth cable. 7) disassemble indicating screw and separate terminal cover as shown in pictures. 8) disassemble indicating screws as shown in pictures. Disassembly and reassembly db98_17816a(2)_5 ...

Page 85: Disassembly and Reassembly

- 84 - disassembly and reassembly 5 1-way cassette type (cont.) parts no procedure remark 5 ass'y drain panel sub 9) disassemble indicating screws of earth cable and indicating screw of base terminal. 10) separate base terminal as shown in picture. 1) separate ass'y drain panel sub after disassemble...

Page 86

- 85 - 1-way cassette type (cont.) parts no procedure remark 6 ass'y evap 1) disassemble the screws of ass'y evap around. 2) disassemble indicating screws as shown in picture and separate ass'y cabinet side lf b. 3) separate ass'y evap pulling up from the indoor unit as shown in picture. Disassembly...

Page 87: Disassembly and Reassembly

- 86 - disassembly and reassembly 5 1-way cassette type (cont.) parts no procedure remark 7 8 ass'y cross fan ass'y drain pump 1) disassemble the screws of cover fan motor and separate cover fan motor. 2) separate ass'y cross fan as shown in picture. 1) disassemble indicating screws as shown in pict...

Page 88

- 87 - disassembly and reassembly 5-1-2. 2-way cassette type parts no procedure remark 1 front grille _ dust-collecting filter 1) press the "push". 2) front grille disassembly (1) open the front grille and pull it up to the direction in the picture. (2) detach the safe ring. 3) filter disassembly (1...

Page 89: Disassembly and Reassembly

- 88 - disassembly and reassembly 5 2-way cassette type (cont.) parts no procedure remark 5) unscrew a mark point in the picture, and detach the cover from the panel with pushing the hook. 6) detach the connection wires of step motor and the receive part from the wire of a main body. 7) widen the bo...

Page 90

- 89 - disassembly and reassembly 2-way cassette type (cont.) parts no procedure remark 2 electronic part _ indoor & outdoor connecting cable 1) unscrew 2 fixing screws of the case control and screw of thermistor wire and holder. 2) push the hook, and pull the knob of a case. 3) detach the indoor an...

Page 91: Disassembly and Reassembly

- 90 - disassembly and reassembly 5 2-way cassette type (cont.) parts no procedure remark 3 evap ass'y 1) unsrew 3 screws connected to the main body and cover side. 2) detach the cover side if from the main body. 3) unscrew 16 screws connected to the drain pan and the main body.( mark) 4) detach the...

Page 92

- 91 - disassembly and reassembly 2-way cassette type (cont.) parts no procedure remark 4 fan & motor 6) detach the drain pump sensor from the holder, and detach the heat exchanger from the main body by pushing it to the direction of drain. 1) unscrew 4 screws of cover motor and evap guide connected...

Page 93: Disassembly and Reassembly

- 92 - disassembly and reassembly 5 2-way cassette type (cont.) parts no procedure remark 5 6 drain pump other parts 1) detach the drain hose connected to the drain pump by loosening the spring. 2) unscrew 4 screws connected to the holder pump and drain pump. 3) after connector detaching, detach the...

Page 94

- 93 - disassembly and reassembly 2-way cassette type (cont.) parts no procedure remark 7 front panel 1) unscrew 2 screws of the holder motor fixed on the panel, and detach the holder motor. The panel, and detach the holder motor. 2) unscrew 2 screws of the step-motor, and detach the step-motor from...

Page 95: Disassembly and Reassembly

- 94 - disassembly and reassembly 5 2-way cassette type (cont.) parts no procedure remark 5) when detaching the pcb from the case, unscrew the 6 screws and push the hook at the mark. 6) when detaching the blade, detach the opposite side first of step motor after turning over the guide on the panel. ...

Page 96

- 95 - 5-1-3. 4-way cassette type parts no procedure remark 1 front grille - dust-collecting filter 1) push the tap on the front grille to open it. 2) disassembly of front grille. (1) open the front grille at about 45˚ degrees and draw it forward. (2) disassemble the safety clip. 3) filter disassemb...

Page 97: Disassembly and Reassembly

- 96 - disassembly and reassembly 5 4-way cassette type (cont.) parts no procedure remark 4) loosen the bolts slowly. 5) loosen the bolt of the front net to disassemble the safety net. 6) loosen the bolt on the electronic component part cover to uncover the electronic component part cover. 7) disass...

Page 98

- 97 - 4-way cassette type (cont.) parts no procedure remark 2 3 electronic part - indoor & outdoor connecting cable fan & motor 8) hold on the hooks on both sides of the indoor unit and disassemble the front panel. 9) take away the disassembled panel out of the main body. 1) disconnect all the indo...

Page 99: Disassembly and Reassembly

- 98 - disassembly and reassembly 5 4-way cassette type (cont.) parts no procedure remark 3) disassemble the ground wire. 4) disassemble the float switch wire connected to the terminal port.(f1, f2) 5) loosen the bolts in the mark . 6) loosen a bolt in the arrow direction and inside. 7) disassemble ...

Page 100

- 99 - 4-way cassette type (cont.) parts no procedure remark 8) loosen the nut. 9) lift the fan to disassemble from the motor. 10) disassemble the motor connector wire. 11) disassemble the ground wire. Disassembly and reassembly take out the washer take out the washer take out the washer take out th...

Page 101: Disassembly and Reassembly

- 100 - disassembly and reassembly 5 4-way cassette type (cont.) parts no procedure remark 4 pump 12) loosen nuts to disassemble the motor. 1) loosen the bolts of the drain pump. 2) disassemble the hose from the drain pump. 3) disassemble the pump from the main body bracket. Db98_17816a(2)_5 11/22/0...

Page 102

- 101 - 4-way cassette type (cont.) parts no procedure remark 5 heat exchanger 1) disassemble the cover pipe beside the main body. 2) loosen the bolts fixing the heat exchanger to the indoor unit base. 3) disassemble the fixing brackets of the heat exchanger to disassemble it from the main body. Dis...

Page 103: Disassembly and Reassembly

- 102 - disassembly and reassembly 5 4-way cassette type (cont.) parts no procedure remark 6 front panel - cover front push cover front fixing screws inside the front panel and snap fixing part to separate the cover front. Db98_17816a(2)_5 11/22/04 4:24 pm page 102.

Page 104

- 103 - 4-way cassette type (cont.) parts no procedure remark 7 front panel - stepping motor 1) loosen each one of fixing screw at the corner part, (1) cushion side-a and cushion side-b inside the front panel, and then lift it up. 2) remove (1) the screw of housing motor l/r fixed at the corner part...

Page 105: Disassembly and Reassembly

- 104 - disassembly and reassembly 5 5-1-4. Duct type (low silhouette) parts no procedure remark 1 2 filter-pre blower & duct 1) disassemble screws of indication part and then assemble the direction of 2 plate-handle places by use of screw as shown in 2). 2) turn the plate handle by hand when removi...

Page 106

- 105 - duct type (low silhouette) (cont.) parts no procedure remark 2) disassemble indicating screws. 3) detach the sensor holder from the ass'y fan case. 4) detach from ass'y control in the capacitor connection wire between the motor-fan in and housing connector. 5) detach the ass'y blower and duc...

Page 107: Disassembly and Reassembly

- 106 - disassembly and reassembly 5 duct type (low silhouette) (cont.) parts no procedure remark 3 control in 1) after disassembling indicating screw, detach the cover-control. 2) detach the motor-fan in and sensor connector connected to pcb. 3) disassemble indicating screws. ( mark) 4) hold the as...

Page 108

- 107 - duct type (low silhouette) (cont.) parts no procedure remark 4 5 drain pan evap 1) disassemble indicating screws to detach ass'y drain pan. (screws each at left and right side) ✳ work is possible when disassembling the ass'y drain pan. 1) disassemble indicating screws. (each at left and righ...

Page 109: Disassembly and Reassembly

- 108 - disassembly and reassembly 5 duct type (low silhouette) (cont.) parts no procedure remark 4) after disassembling indicating screws. 5) pull the cabinet-side lf, rh by hand to disassemble. 6) separate indicating screws. (each at left and right side) 7) detach it from the set if the ass'y-evap...

Page 110

- 109 - duct type (low silhouette) (cont.) parts no procedure remark 6 holder outlet ✳ when connecting canvas to the discharge side. 1) disassemble indicating screws. (each at left and right side) 2) disassemble indicating screws. (each at upper and lower side) ✳ after connecting canvas to the disas...

Page 111: Disassembly and Reassembly

- 110 - disassembly and reassembly 5 5-1-5. Duct type (high pressure-old type) parts no procedure remark 1 disassembly of indoor unit (disassembly of the electric component box) 1) disassemble screw for fixing the electric component box cover. 2) check internal connection of the electric component b...

Page 112

- 111 - duct type (high pressure-old type) (cont.) parts no procedure remark 2 fan & motor 1) separate the screws fixed on the unit base. 2) pull the panel for fixing fan and motor as following figure. Then the fan and motor panel are separated from the unit. 3) if the motor support was removed, the...

Page 113: Disassembly and Reassembly

- 112 - disassembly and reassembly 5 duct type (high pressure-old type) (cont.) parts no procedure remark 3 4 heat exchanger drain board cleaning a filter 1) disassemble the screws on side part, then cabinet and the unit are separated. 2) it is possible to clean the surface of heat exchanger and dra...

Page 114

- 113 - duct type (high pressure-old type) (cont.) parts no procedure remark 3) after cleaning the filter, insert and fasten it with bracket for fixing. Disassembly and reassembly db98_17816a(2)_5 11/22/04 4:24 pm page 113.

Page 115: Disassembly and Reassembly

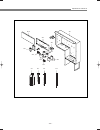

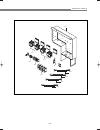

- 114 - disassembly and reassembly 5 5-1-6. Duct type (high & low pressure-new type) parts no procedure remark 1 2 disassembly of indoor unit (disassembly of the electric component box) fan & motor 1) disassemble screw for fixing the electric component box cover. 2) check internal connection of the ...

Page 116

- 115 - duct type (high & low pressure-new type) (cont.) parts no procedure remark 3 heat exchanger drain board 1) disassemble the screws on side part, then cabinet and the unit are separated. 2) it is possible to clean the surface of heat exchanger and drain board. 3) after cleaning heat exchangers...

Page 117: Disassembly and Reassembly

- 116 - disassembly and reassembly 5 duct type (high & low pressure-new type) (cont.) parts no procedure remark 4 cleaning a filter 1) remove bracket for fixing filter(screws disassembly). 2) clean the filter with removing downward. 3) after cleaning the filter, insert and fasten it with bracket for...

Page 118

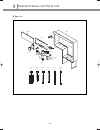

- 117 - 5-1-7. Duct type (built-in) parts no procedure remark 1 2 filter ass'y control in 1) disassemble the indicating screws. 2) remove the filter as shown in picture. 1) separate the control cover-control after disassemble the indicating screws. 2) separate the wire connection part of the ass'y c...

Page 119: Disassembly and Reassembly

- 118 - disassembly and reassembly 5 duct type (built-in) (cont.) parts no procedure remark 3 drain panel 3) disassemble the indicating screws. 4) hold the ass'y control in by hand to lift up and remove it as shown in picture. 1) disassemble the indicating screws and separate the cabinet-top. 2) dis...

Page 120

- 119 - duct type (built-in) (cont.) parts no procedure remark 4 ass'y evap 3) separate the ass'y drain panel as shown in picture. 1) disassemble the indicating screw and separate wire and cover-pipe. 2) disassemble the indicating screws. Disassembly and reassembly db98_17816a(2)_5 11/22/04 4:24 pm ...

Page 121: Disassembly and Reassembly

- 120 - disassembly and reassembly 5 duct type (built-in) (cont.) parts no procedure remark 5 ass'y blower 3) separate the ass'y evap from the set. 1) disassemble the indicating screws. 2) pull up ass'y blower and separate it from set. Db98_17816a(2)_5 11/22/04 4:24 pm page 120

Page 122

- 121 - duct type (built-in) (cont.) parts no procedure remark 6 ass'y bracket outlet 1) disassemble indicating screws. 2) separate ass'y bracket outlet from the set as shown picture. Disassembly and reassembly db98_17816a(2)_5 11/22/04 4:24 pm page 121.

Page 123: Disassembly and Reassembly

- 122 - disassembly and reassembly 5 5-1-8. Wall-mounted type parts no procedure remark 1 front grille 1) stop the air conditioner operation and block the main power. 2) separate tape of front panel upper. 3) contract the second finger to the left, and right handle and pull to open the inlet grille....

Page 124

- 123 - wall-mounted type (cont.) parts no procedure remark 2 3 4 ass'y tray drain electrical parts (main pcb) heat exchanger 1) separate the drain hose from the extension tray drain. 2) take the display pcb out. (right of indoor unit) 3) pull tray drain out from the back body. 1) take all the conne...

Page 125: Disassembly and Reassembly

- 124 - disassembly and reassembly 5 wall-mounted type (cont.) parts no procedure remark 5 fan motor & cross fan 1) loosen the fixing screws and separate the motor holder. 2) loosen the fixing screw of fan motor. (by use of m3 wrench) 3) separate the fan motor from the fan. 4) separate the fan from ...

Page 126

- 125 - 5-1-9. Floor standing type parts no procedure remark 1 indoor unit 1) package air conditioner indoor unit. 2) open the grille and detach the connection link. 3) detach the cover terminal.(screws of the front left/right) disassembly and reassembly db98_17816a(2)_5 11/22/04 4:24 pm page 125.

Page 127: Disassembly and Reassembly

- 126 - disassembly and reassembly 5 floor standing type (cont.) parts no procedure remark 4) detach the wire connected with a grille. 5) unscrew screws at the lower of panel outlet(front upper panel). 6) press the lower of panel shutter on products upper with two hands and put it in the products. 7...

Page 128

- 127 - floor standing type (cont.) parts no procedure remark 8) detach the connecter connected with panel pcb. 9) unscrew a screw on the upper of cover main pcb and detach it. Disassembly and reassembly db98_17816a(2)_5 11/22/04 4:24 pm page 127.

Page 129: Disassembly and Reassembly

- 128 - disassembly and reassembly 5 floor standing type (cont.) parts no procedure remark 10) detach the connecter connected with panel pcb. 11) unscrew a screw fixing the lf/rh of the ass'y shutter lower. 12) unscrew and detach the screws fixing duct-up. Db98_17816a(2)_5 11/22/04 4:24 pm page 128.

Page 130

- 129 - floor standing type (cont.) parts no procedure remark 2 ass'y shutter (auto shutter available model) 13) unlock the nut fixing the blower center.(wrench used.) 14) unscrew and detach the screw fixing cover evap lf/rh, ass'y evap. 1) take out the wire of the rear of ass'y shutter. Disassembly...

Page 131: Disassembly and Reassembly

- 130 - disassembly and reassembly 5 floor standing type (cont.) parts no procedure remark 2) take out sponges of the upper. 3) unscrew the screws fixing the cover outlet and holder blade. 4) this is a picture after detaching the holder blade. 5) detach the e-ring of the lower motor. Db98_17816a(2)_...

Page 132

- 131 - floor standing type (cont.) parts no procedure remark 6) detach the gear of motor. 7) take out the hinge shutter and detach the gear rack. 8) the upper and lower photo sensor can be detached and assembled. (the photo sensor can be exchanged without the panel shutter exchange.) disassembly an...

Page 133: Disassembly and Reassembly

- 132 - disassembly and reassembly 5 floor standing type (cont.) parts no procedure remark 3 ass'y grille 1) detach the filter-pre. 2) detach the electric precipitation. 3) unscrew a screw fixing the cover inlet and holder filter. 4) unscrew the upper inside screw fixing the cover inlet and panel in...

Page 134

- 133 - floor standing type (cont.) parts no procedure remark 4 ass'y panel 1) the heat insulating material on the rear of ass'y panel. 2) cut the heat insulating material with a knife far from the display pcb assembly. (a solid line) ✳ if you cut it near the pcb ass'y, the shutter operation may be ...

Page 135: Disassembly and Reassembly

- 134 - disassembly and reassembly 5 floor standing type (cont.) parts no procedure remark 5 the essential management at the assembly of ass'y panel ■ be sure to fill up the cutting place of the heat insulating material after fixing the display pcb and panel inlet with a screw. (the moisture formed ...

Page 136

- 135 - 5-1-10. Ceiling type parts no procedure remark 1 electrical part 1) open the grille by pressing 3 position. (center and both side) 2) remove the air inlet grille. 3) open the cover of electrical component box by removing the screws. (center and both side) disassembly and reassembly db98_1781...

Page 137: Disassembly and Reassembly

- 136 - disassembly and reassembly 5 ceiling type (cont.) parts no procedure remark 2 fan & motor 1) remove the screw and untie earth wire of motor. 2) disconnect of housing of motor wire. 3) disconnect the capacitor wire. Db98_17816a(2)_5 11/22/04 4:24 pm page 136.

Page 138

- 137 - ceiling type (cont.) parts no procedure remark 4) remove the guard safety by removing the screws. 5) remove the upper case of fan. (2ea) 6) remove the screws what is fix the motor. 7) remove the fan and motor assembly. Disassembly and reassembly db98_17816a(2)_5 11/22/04 4:24 pm page 137.

Page 139: Disassembly and Reassembly

- 138 - disassembly and reassembly 5 ceiling type (cont.) parts no procedure remark 3 drain pan 8) loosen the set screw using 3mm wrench. 9) remove the fan. 1) disconnect the display pcb wire as shown in picture. (white housing) 2) disconnect the step motor wire as shown in picture. (blue housing) 3...

Page 140

- 139 - ceiling type (cont.) parts no procedure remark 4) remove the screws of front side. 5) disassemble the assembly front cover part. 6) disconnect the step motor wire as shown in picture. 7) remove the wire clamp fixed in base part. 8) remove the front cover assembly completely. Disassembly and ...

Page 141: Disassembly and Reassembly

- 140 - disassembly and reassembly 5 ceiling type (cont.) parts no procedure remark 9) remove the screw what is fix with base part and drain pan. (upper side:2ea) 10) remove the screw what is fix with base part and drain pan. (lower side:2ea) 11) remove the drain pan completely. Db98_17816a(2)_5 11/...

Page 142

- 141 - ceiling type (cont.) parts no procedure remark 4 evaporator 1) disconnect the thermistor wire as shown in picture. (white housing) 2) remove the screws shown in picture. 3) remove the screws shown in picture and remove plastic part.(white) 4) remove the screws shown in picture and remove ste...

Page 143: Disassembly and Reassembly

- 142 - disassembly and reassembly 5 ceiling type (cont.) parts no procedure remark 6) remove the screws as shown in picture. 7) remove plastic cover as shown in picture. 8) remove the evaporator assembly. Db98_17816a(2)_5 11/22/04 4:24 pm page 142.

Page 144

- 143 - ceiling type (cont.) parts no procedure remark 5 6 stepping motor display pcb 1) remove the screws in rear side of front cover assembly as shown in picture. 2) remove the screws as shown in picture. 3) disassemble the blade and stepping motor assembly and remove the screws stepping motor. 1)...

Page 145: Disassembly and Reassembly

- 144 - disassembly and reassembly 5 5-2. Outdoor unit 5-2-1. B type parts no procedure remark 1 2 outdoor control box 1) outdoor unit of a package airconditioner. 2) separate a front tightening part. 3) separate the tightening part from side. 1) the connection status of control box wiring. Db98_178...

Page 146

- 145 - b type (cont.) parts no procedure remark 3 4 cabinet fan motor & propeller fan 1) remove the power cable after turn off the unit. 2) remove the top cover. 3) remove the control box cover. 4) pull out the assembly cable. 5) remove the side of cabinet. 6) remove the front side of cabinet. ✳ wh...

Page 147: Disassembly and Reassembly

- 146 - disassembly and reassembly 5 5-2-2. D type parts no procedure remark 1 electrical parts 1) remove front cabinet fasten screws as shown in the picture. 2) remove front cabinet from the unit. 3) separate control box from the unit. Db98_17816a(2)_5 11/22/04 4:24 pm page 146.

Page 148

- 147 - d type (cont.) parts no procedure remark 2 motor & fan 1) remove bellow mouth fasten screws as shown in the picture. 2) remove bellow mouth from the unit. 3) remove bolt screws from the fan. 4) separate fan from the unit. 5) reomove motor after removing screws. Disassembly and reassembly db9...

Page 149: Disassembly and Reassembly

- 148 - disassembly and reassembly 5 5-2-3. E type parts no procedure remark 1 electrical parts 1) remove front cabinet fasten screws as shown in the picture. 2) remove front cabinet from the unit. 3) remove control box cover after removing screws. Db98_17816a(2)_5 11/22/04 4:24 pm page 148.

Page 150

- 149 - e type (cont.) parts no procedure remark 2 motor & fan 4) separate control box from the unit. 1) remove bellow mouth fasten screws as shown in the picture. 2) remove bellow mouth from the unit. 3) remove bolt screws from the fan. 4) separate fan from the unit. 5) remove motor after removing ...

Page 151: Disassembly and Reassembly

- 150 - disassembly and reassembly 5 5-2-4. F type parts no procedure remark 1 electrical parts 1) remove front cabinet fasten screws as shown in the picture. 2) remove front cabinet from the unit. 3) remove contro box cover after removing screws. 4) separate control box from the unit. Db98_17816a(2...

Page 152

- 151 - f type (cont.) disassembly and reassembly parts no procedure remark 2 motor & fan 1) remove bellow mouth fasten screws as shown in the picture. 2) remove bellow mouth from the unit. 3) remove bolt screws from the fan. 4) separate fan from the unit. 5) remove motor after removing screws. Db98...

Page 153: Disassembly and Reassembly

- 152 - disassembly and reassembly 5 5-2-5. G type parts no procedure remark 1 electrical parts 1) remove front cabinet fasten screws as shown in the picture. 2) remove front cabinet from the unit. 3) remove control box cover after removing screws. 4) separate control box from the unit. Db98_17816a(...

Page 154

- 153 - g type (cont.) disassembly and reassembly parts no procedure remark 2 motor & fan 1) remove bellow mouth fasten screws as shown in the picture. 2) remove bellow mouth from the unit. 3) remove bolt screws from the fan. 4) separate fan from the unit. 5) remove motor after removing screws. Db98...

Page 155: Disassembly and Reassembly

- 154 - disassembly and reassembly 5 5-2-6. H type parts no procedure remark 1 electrical parts 1) remove front cabinet fasten screws as shown in the picture. 2) remove control box cover after removing screws. 3) separate control box from the unit. Db98_17816a(2)_5 11/22/04 4:24 pm page 154.

Page 156

- 155 - disassembly and reassembly h type(cont.) parts no procedure remark 2 motor & fan 1) remove upper cabinet fasten screws as shown in the picture. 2) remove upper cabinet from the unit. 3) remove bolt screws from the fan. 4) separate fan from the unit. 5) remove motor after removing screws. Db9...

Page 157: Refrigerating Cycle Diagram

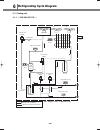

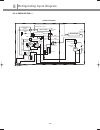

- 156 - 6-1. Cooling only 6-1-1. ✳✳ 050 / 060 / 070 / 072 ✳✳ - 156 - refrigerating cycle diagram 6 fan motor fan motor super cooler temperature sensor temperature sensor temperature sensor heat exchanger high pressure switch low pressure switch temperature sensor digital scroll compre ssor solenoid ...

Page 158

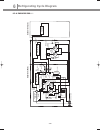

- 157 - numbering system of model - 157 - refrigerating cycle diagram 6-1-2. ✳✳ 080 / 100 ✳✳ temperature sensor tempera ture sensor fan motor temperature sensor cond out sensor heat exchanger high pressure switch high pressure sensor low pressure sensor fixed scroll compr essor digital scroll compre...

Page 159: Refrigerating Cycle Diagram

- 158 - refrigerating cycle diagram 6 6-1-3. Main parts status 1. Digital scroll compressor the variable capacity type compressor to control the capacity up to 10 ~ 100% with 19 steps. 2. Accumulator to prevent the incoming of the liquid refrigerant to the compressor (prevention of liquid back). 3. ...

Page 160

- 159 - refrigerating cycle diagram fan fan motor motor temperature sensor charging valve temperature sensor heat exchanger high pressure switch high pressure sensor 4-way valve (4-w/v) temperature sensor low pressure sensor digital scroll compre ssor solenoid valve (vbv) solenoid valve (hgbv) solen...

Page 161: Refrigerating Cycle Diagram

- 160 - refrigerating cycle diagram 6 cch cch fan motor temperature sensor cond out sensor heat exchanger high pressure switch 4-way valve (4-w/v) digital scroll compre ssor solenoid valve (vbv) solenoid valve (hgbv) solenoid valve (lbv) solenoid valve (pwm) receiver check valve (c/v) filter electro...

Page 162

- 161 - refrigerating cycle diagram 6-2-3. Rmah 140 / 160 ✳✳✳ cis(temperature sensor) cis (temperature sensor) fdts (temperature sensor) temperature sensor dts(temperature sensor) pwm valve cos (temperature sensor) cos (temperature sensor) heat exchanger heat exchanger outdoor unit (main) digital sc...

Page 163: Refrigerating Cycle Diagram

- 162 - refrigerating cycle diagram 6 6-2-4. Rmah 180 / 200 ✳✳✳ cis(temperature sensor) cis (temperature sensor) fdts (temperature sensor) oil separator temperature sensor dts(temperature sensor) pwm valve cos (temperature sensor) cos (temperature sensor) heat exchanger heat exchanger outdoor unit (...

Page 164

- 163 - refrigerating cycle diagram cis(temperature sensor) cis(temperature sensor) dts (temperature sensor) dts(temperature sensor) 10hp temperature sensor dts(temperature sensor) pwm valve cos (temperature sensor) cos (temperature sensor) heat exchanger heat exchanger heat exchanger indoor unit (m...

Page 165: Refrigerating Cycle Diagram

- 164 - refrigerating cycle diagram 6 6-2-6. Rmah 280 / 300 ✳✳✳ cis (temperature sensor) dts (temperature sensor) dts(temperature sensor) 10hp temperature sensor dts(temperature sensor) pwm valve cos (temperature sensor) cos (temperature sensor) heat exchanger heat exchanger heat exchanger indoor un...

Page 166

- 165 - refrigerating cycle diagram 6-2-7. Main parts status 1. Digital scroll compressor the variable capacity type compressor to control the capacity up to 10 ~ 100% with 19 steps 2. Accumulator to prevent the incoming of the liquid refrigerant to the compressor (prevention of liquid back). 3. Rec...

Page 167: Refrigerating Cycle Diagram

- 166 - refrigerating cycle diagram 6 13. 4-way valve (4-w/v) 13. It enables the change between cooling and heating by reversing the flow direction of refrigerant. 14. Electronic expansion valve (eev) 13. By sensing suction temperature and low pressure, controls the suction super heat and 13. Mass f...

Page 168

- 167 - 6-2-8. Rvmr100 ✳✳✳ numbering system of model outdoor unit mcu indoor unit heating main sol. Nev1204dxf main cooling sol. Nev1204dxf condenser 4-way valve ranco-vh6100 high press switch high press sencor expansion valve edm-aoypsh-6d-a eev sol valve nev603dxf nev603dxf gas-liquid sol.Valve he...

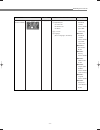

Page 169: Set Up The Model Option

- 168 - set up the model option 7 operation method applicable button indicating state ✳ step 1 ✳ method) ✳ ! Remove the battery of remote controller. ✳ @ push the temperature adjustment button simultaneously. ✳ # insert the battery. ✳ result) ✳ when the display of remote ✳ controller is indicated as...

Page 170

- 169 - set up the model option operation method applicable button indicating state ✳ step 4 ✳ method) ✳ input the third digit of option code by pressing the temperature adjustment button (down). Example) 02 1 e31142285 ✳ result) ✳ if 1 is displayed, go to the step 5. ✳ step 5 ✳ method) ✳ input the ...

Page 171: Set Up The Model Option

- 170 - set up the model option 7 operation method applicable button indicating state ✳ step 7 ✳ method) ✳ input the sixth digit by pressing the off timer button. Example) 021e3 1 142285 ✳ result) ✳ if 1 displays, go to step 8. ✳ step 8 ✳ method) ✳ after completion up to step 7, pressing mode button...

Page 172

- 171 - set up the model option operation method applicable button indicating state ✳ step 10 ✳ method) ✳ input the ninth digit by pressing the temperature adjustment button (down). Example) 021e3114 2 285 ✳ result) ✳ if 2 displays, go to step 11. ✳ step 11 ✳ method) ✳ input the tenth digit by press...

Page 173: Set Up The Model Option

- 172 - set up the model option 7 operation method applicable button indicating state ✳ step 13 ✳ method) ✳ input the 12th digit by pressing the off timer button. Example) 021e3114228 5 ✳ result) ✳ if 5 displays, go to step 14. ✳ step 14 ✳ method) ✳ turn the remote controller toward the indoor unit ...

Page 174

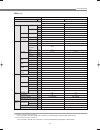

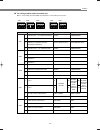

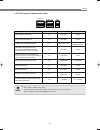

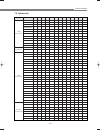

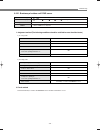

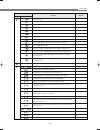

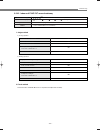

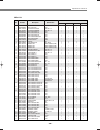

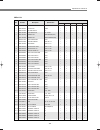

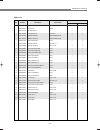

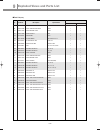

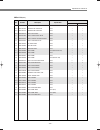

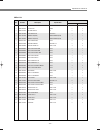

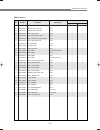

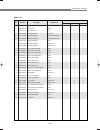

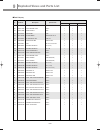

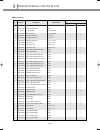

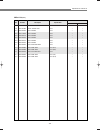

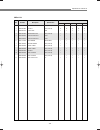

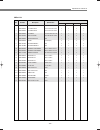

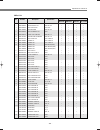

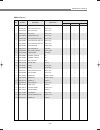

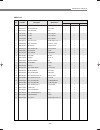

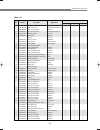

- 173 - set up the model option 7-2. Option code type model seg1 seg2 seg3 seg4 seg5 seg6 seg7 seg8 seg9 seg10 seg11 seg12 remark avmkc020ea ✳ avmkc020ca ✳ avmkc026ea ✳ avmkc032ca ✳ avmkc035ea ✳ avmkc040ca ✳ avmkh020ea ✳ avmkh020ca ✳ avmkh026ea ✳ avmkh032ca ✳ avmkh035ea ✳ avmkh040ca ✳ avmgh052ea ✳ a...

Page 175: Set Up The Model Option

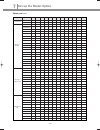

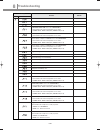

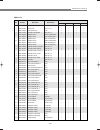

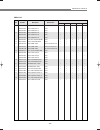

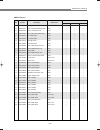

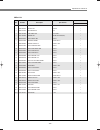

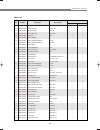

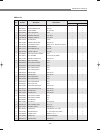

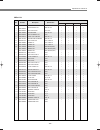

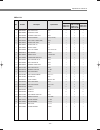

- 174 - set up the model option 7 option code (cont.) type model seg1 seg2 seg3 seg4 seg5 seg6 seg7 seg8 seg9 seg10 seg11 seg12 remark avmdh070ea ✳ avmdh072ca ✳ avmbc020ea ✳ avmbc020ca ✳ avmbc026ea ✳ avmbc032ca ✳ avmbc035ea ✳ avmbc040ca ✳ avmbc052ea ✳ avmbc070ea ✳ avmbc072ca ✳ avmbh020ea ✳ avmbh020c...

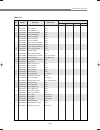

Page 176

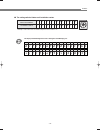

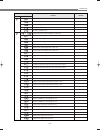

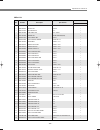

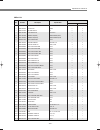

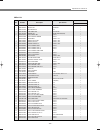

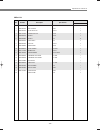

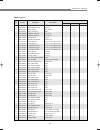

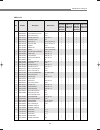

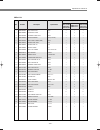

- 175 - set up the model option type model seg1 seg2 seg3 seg4 seg5 seg6 seg7 seg8 seg9 seg10 seg11 seg12 remark avmwc040ca1 avmwc052ea ✳ avmwc052ca ✳ avmwc070ea ✳ avmwc072ca ✳ avmwh020ea ✳ avmwh020ca ✳ avmwh026ea ✳ avmwh032ca ✳ avmwh035ea ✳ avmwh040ca ✳ avmwh020ea1 avmwh020ca1 avmwh026ea1 avmwh032c...

Page 177: Troubleshooting

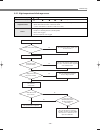

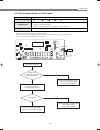

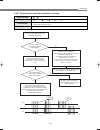

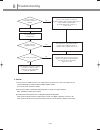

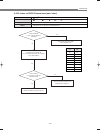

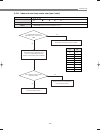

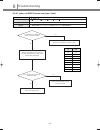

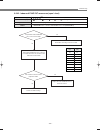

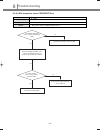

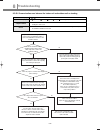

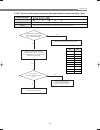

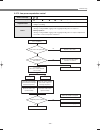

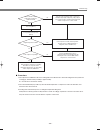

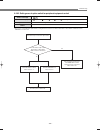

- 176 - troubleshooting 8 8-1. Operation flow of outdoor unit e2 error(tracking error) yes yes power on tracking completed? Yes no preheating cch (for 2.5 hours) yes is preheating of cch completed? No p4 error (reverse phase/ open phase error) is 3 phase power ok? No normal operation db98_17816a(2)_...

Page 178

- 177 - - 177 - 8-1-1. Initial tracking (communication check) - e2 indicated if abnormal 1. When the power is on, the micom of outdoor unit check the indoor units, wired remote controller and transmitters installed in the same system, which is called as tracking. 1) the left side display shows the a...

Page 179: Troubleshooting

2) heat pump 3) if the numbers of indoor units checked through installed indoor unit number setting switch do not match with those during tracking, the display shows er and e2 alternately. - 178 - troubleshooting 8 ■ installed indoor unit numbers setting switch ■ example) please adjust the arrow loc...

Page 180

8-1-2. Reverse phase/missing phase detection - p4 indicated if abnormal 1. To check the power to be used for 3 phase power compressor if the power is on. If there is any change of order for 3 phase l1(r)-l2(s )-l3(t) (reverse phase) or the power is not on, er and p4 are indicated alternately and the...

Page 181: Troubleshooting

8-1-3. Compressor preheating - ch indicated 1. Once the tracking is completed, check the temperature of compressor before starting the system operation. Ch is displayed at the display part at the time. 2. If it is the condition for compressor operation as the result of check, the flickering of ch di...

Page 182

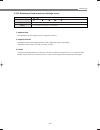

- 181 - troubleshooting ✳ priority of duplicated error display : e1 → e2 → e4 → e5 → p0 → p1 → p2 → p3 → p5 → p4 → p7 → p8 → p9 → p6 → pa → g2 → t1 → t2 → t3 → t4 → t5 → t6 → t7 → t8 → t9 → tu → to → g3 → g4 → g5 → g6 → g7 → g8 → g9 → e3 → cx → dx → bx → ax → fx → qx → rx → sx → vx → ch in case that...

Page 183: Troubleshooting

- 182 - troubleshooting 8 ✳ priority of duplicated error display : e1 → e2 → e4 → e5 → p0 → p1 → p2 → p3 → p5 → p4 → p7 → p8 → p9 → p6 → pa → g2 → t1 → t2 → t3 → t4 → t5 → t6 → t7 → t8 → t9 → tu → to → g3 → g4 → g5 → g6 → g7 → g8 → g9 → e3 → cx → dx → bx → ax → fx → qx → rx → sx → vx → ch in case th...

Page 184

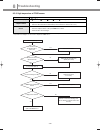

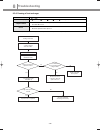

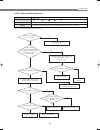

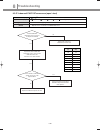

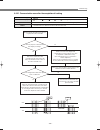

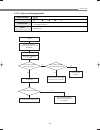

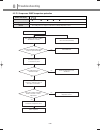

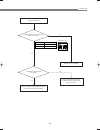

Yes yes 8-2-1. High temperature of discharge sensor - 183 - troubleshooting outdoor unit display indoor unit display judgment method causes (operation) (timer) (fan) (filter) (removing frost) - restart after operation stops when the discharge temperature exceeding 135°c is detected - system down whe...

Page 185: Troubleshooting

- 184 - troubleshooting 8 ✳ after leaving the outdoor unit for one hour before test operation compare cond sensor temperature with that of oats, and if cond sensor temperature is 10°c higher, it is sensor defect. Replace the cond sensor. 8-2-2. High temperature of cond sensor outdoor unit display in...

Page 186

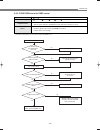

8-2-3. Cond down due to the sump control - 185 - troubleshooting error reset(key 3) test operation (key 4) is obstacles at the air inlet/outlet of outdoor air? Check the fan motor capacitor and wire fan motor running smoothly? Is cond sensor temperature normal? Is high pressure normal? Since it is t...

Page 187: Troubleshooting

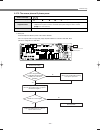

- 186 - troubleshooting 8 error reset (key 3) test operation (key4) is both service valves open? Since the service valve is clogged, open the service valve. Since it is the electronic expansion valve close error, check the electronic expansion valve and pcb related. Since it is the defect of compres...

Page 188

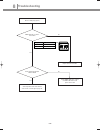

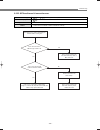

- 187 - troubleshooting check power of main parts is cn77 cable red ~ white/ white ~black/ red ~ black voltage ac380v? Exchange two wires of 3 phase incoming ones and press the reset key (k3) and then retry. P4 reappears? Since it is the trouble on the 3 phase detection circuit part, replace the pcb...

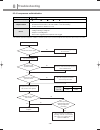

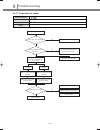

Page 189: Troubleshooting

- 188 - troubleshooting 8 check the indoor unit whose freezing is detected. Error reset (key 3) system check is completed. Test operation of all units (key 4) operate one unit of related indoor unit. Remove the obstacles around air inlet of indoor unit and clean the air filter. Is indoor unit fan mo...

Page 190

8-2-7. Momentary power failure 8-2-8. Protection of high pressure sensor 8-2-9. Protection of low pressure sensor - 189 - troubleshooting outdoor unit display indoor unit display judgment method causes (operation) (timer) (fan) (filter) (removing frost) - temporary stop of the compressor due to mome...

Page 191: Troubleshooting

- 190 - troubleshooting 8 8-2-10. In removing frost 8-2-11. Protection control of condensation ratio outdoor unit display indoor unit display judgment method causes (operation) (timer) (fan) (filter) (removing frost) - in removing frost - not a defect outdoor unit display indoor unit display judgmen...

Page 192

- 191 - troubleshooting 8-2-12. Outdoor temperature sensor error outdoor unit display indoor unit display judgment method causes (operation) (timer) (fan) (filter) (removing frost) - wire open or short of outdoor temperature sensor - wire open or current leak of related sensor is outdoor temperature...

Page 193: Troubleshooting

- 192 - troubleshooting 8 8-2-13. Outdoor unit heat exchanger temperature sensor error (open / short) outdoor unit display indoor unit display judgment method causes (operation) (timer) (fan) (filter) (removing frost) - wire open or short of outdoor heat exchanger temperature sensor - wire open or c...

Page 194

- 193 - troubleshooting 8-2-14. Discharge temperature sensor error (open / short) outdoor unit display indoor unit display judgment method causes (operation) (timer) (fan) (filter) (removing frost) - wire open or short of outdoor heat exchanger temperature sensor - wire open or current leak of relat...

Page 195: Troubleshooting

- 194 - troubleshooting 8 8-2-15. Cond out temperature sensor error (open / short) outdoor unit display indoor unit display judgment method causes (operation) (timer) (fan) (filter) (removing frost) - wire open or short of outdoor cond out sensor - wire open or current leak of related sensor is outd...

Page 196

- 195 - troubleshooting 8-2-16. Oil temperature sensor error (open / short) outdoor unit display indoor unit display judgment method causes (operation) (timer) (fan) (filter) (removing frost) - wire open or short of outdoor oil temperature sensor - wire open or current leak of related sensor is outd...

Page 197: Troubleshooting

- 196 - troubleshooting 8 8-2-17. Suction temperature sensor error (open / short) outdoor unit display indoor unit display judgment method causes (operation) (timer) (fan) (filter) (removing frost) - wire open or short of outdoor cond out sensor - wire open or current leak of related sensor is outdo...

Page 198

8-2-18. High pressure sensor error (open / short) ■ detection of high/low pressure sensor error 1. Skips the detection during the oil recovery operation and detects again from 5 minutes after completion of the operation. 2. Skips the detection during the safety start operation and detects again from...

Page 199: Troubleshooting

- 198 - troubleshooting 8 8-2-20. Fixed compressor discharge temperature sensor error (open / short) outdoor unit display indoor unit display judgment method causes (operation) (timer) (fan) (filter) (removing frost) - wire open or short of outdoor fixed compressor discharge temperature sensor - wir...

Page 200

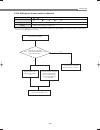

- 199 - troubleshooting +0.7v -0.7v press the reset key (k3) of outdoor unit pcb and check the display. The voltage between two lines is wave of dc±0.7v as shown in the following: is there no response of indoor unit on the display during tracking? Remove the communication cable from outdoor unit to ...

Page 201: Troubleshooting

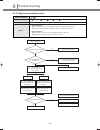

- 200 - troubleshooting 8 8-2-22. Communication error in tracking check by comparing of set values of installed numbers of indoor units on outdoor unit pcb with actual installed numbers. Press reset key (k3) on the outdoor unit pcb to check the display part and then check the indoor unit numbers wit...

Page 202

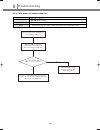

- 201 - troubleshooting 8-2-23. Indoor unit float switch error outdoor unit display indoor unit display judgment method causes (operation) (timer) (fan) (filter) (removing frost) - when the indoor unit float switch is open for longer than 1 minute - drain fan level increase due to the indoor unit dr...

Page 203: Troubleshooting

- 202 - troubleshooting 8 check of drain pump (option) replace the indoor unit pcb. Set the sw03 switch no.4 of indoor unit pcb to on and reset the power of indoor unit. Sw03 switch no.4 of indoor unit to off? Are the drain pump and float switch installed? Solve the problem in the same manner as the...

Page 204

- 203 - troubleshooting 8-2-24. Setting error of option switch in indoor unit outdoor unit display indoor unit display judgment method causes (operation) (timer) (fan) (filter) (removing frost) - switch setting error for using the wired remote controller - option switch setting error of indoor unit ...

Page 205: Troubleshooting

1. Judgment method (the following conditions should be satisfied for more than 20 minutes) 1) in cooling mode 2) in heating mode 2. Check method check the breakaway of indoor unit evap in sensor and then reassemble to correct. - 204 - troubleshooting 8 tcond, mid-tair, out > 3°c tcond, out - tair, o...

Page 206

- 205 - troubleshooting 1. Judgment method (the following conditions should be satisfied for more than 20 minutes) 1) in cooling mode 2) in heating mode 2. Check method check the breakaway of indoor unit evap out sensor and then reassemble to correct. Tcond, mid-tair, out > 3°c tcond, out - tair, ou...

Page 207: Troubleshooting

- 206 - troubleshooting 8 1. Judgment method compressor is on in cooling operation & inlet/outlet temperature of stopped indoor unit is below 0°c for 2.5 minutes. 2. Judgment time starts detecting after 5 minutes from completion of the safety start. 3. Control 4. Check method 1) check whether the el...

Page 208

- 207 - troubleshooting 1. Judgment method 1) in cooling mode (the following conditions shall be satisfied for more than 20 minutes) 2) in heating mode (all following conditions should be satisfied) 2) (1) more than 2 indoor units are operating in themo on heating mode. 2) (2) average of high pressu...

Page 209: Troubleshooting

- 208 - troubleshooting 8 1. Judgment method (the following conditions should be satisfied for more than 20 minutes) 1) in cooling mode 2) in heating mode 2. Check method check the breakaway of each sensor and then reassemble to correct. Tcond, mid-tair, out > 3°c tcond, out - tair, out > 3°c tair, ...

Page 210

- 209 - troubleshooting 1. Judgement method (the following conditions should be satisfied for more than 20 minutes) 1) in cooling mode 2) in heating mode tcond, mid-tair, out > 3°c tcond, out - tair, out > 3°c tair, in - teva, in > 4°c tair, in - teva, out > 4°c compressor operating & indoor unit op...

Page 211: Troubleshooting

- 210 - troubleshooting 8 is the resistance normal between compressor terminals? Is high pressure and low pressure normal? Is the compressor operating? Even though the compressor is operating but if there is no response on the temperature, it is the loading failure. Replace the pwm valve. If any one...

Page 212

- 211 - troubleshooting 1. Judgement method (the following conditions should be satisfied for more than 20 minutes) 1) in cooling mode 2) in heating mode 2. Check method check the breakaway of outdoor unit cond out sensor and then reassemble to correct. 8-2-31. Breakaway of outdoor unit cond sensor ...

Page 213: Troubleshooting

- 212 - troubleshooting 8 1. Judgment time during 30 minutes from starting compressor(the same as in cooling and heating operation) 2. Judgment method when sump temperature right before starting compressor is tsump, ini and present compressor sump temperature is tsump, real, in case the gap of absol...

Page 214

- 213 - troubleshooting 1. Judgment time after 30 minutes from start of digital compressor and general compressor 2. Judgment method when digital compressor discharging temperature is tdisc, digital, fixed compressor discharging temperature is tdisc, normal, in case tdisc, real - tdisc, ini > 30°c 3...

Page 215: Troubleshooting

- 214 - troubleshooting 8 8-2-35. Indoor unit room sensor error (open / short) outdoor unit display indoor unit display judgment method causes (open/short error of xth room temperature sensor) (operation) (timer) (fan) (filter) (removing frost) - refer to the following judgment method - indoor unit ...

Page 216

- 215 - troubleshooting 8-2-36. Indoor unit evap in sensor error (open / short) outdoor unit display indoor unit display judgment method causes (open/short error of xth indoor evap in sensor) (operation) (timer) (fan) (filter) (removing frost) - refer to the following judgment method - open/short er...

Page 217: Troubleshooting

- 216 - troubleshooting 8 8-2-37. Indoor unit evap out sensor error (open / short) outdoor unit display indoor unit display judgment method causes (open/short error of xth indoor evap out sensor) (operation) (timer) (fan) (filter) (removing frost) - refer to the following judgment method - open/shor...

Page 218

- 217 - troubleshooting 8-2-38. Indoor unit fan motor starting error outdoor unit display indoor unit display judgment method causes (xth indoor unit fan motor starting error) (operation) (timer) (fan) (filter) (removing frost) - refer to the following judgment method - xth indoor unit fan motor sta...

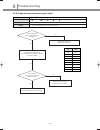

Page 219: Troubleshooting

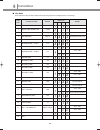

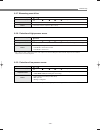

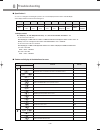

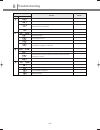

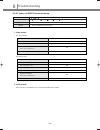

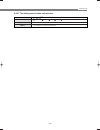

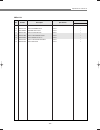

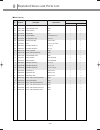

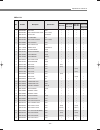

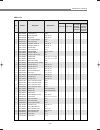

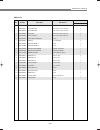

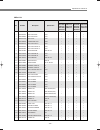

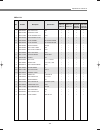

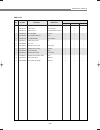

- 218 - troubleshooting 8 ■ specification 2 ■ • in case of occurring the error during the operation, error mode is displayed at the outdoor unit pcb display. ■ • error display number each means the following error. ● display method ● 101~650(error) : "e", 700~900(protection error) : "p", error occur...

Page 220

- 219 - troubleshooting error display remark contents seg 1 seg 2,3,4 number outdoor unit related error indoor fan error mixed operation error(operate heat & cool mode at same time) eeprom error option setting error electric heater discharge temperature protect error no fan error related to the elec...

Page 221: Troubleshooting

- 220 - troubleshooting 8 error display remark contents seg 1 seg 2,3,4 cond-out sub 1 temp sensor error open/short cond-mid sensor breakaway of outdoor unit cond-out 1 breakaway pwm discharge temp sensor error open/short _ detected when the outdoor temperature is over -10˚c _ error level : over 4.9...

Page 222

- 221 - troubleshooting error display remark contents seg 1 seg 2,3,4 high pressure sensor breakaway low pressure sensor breakaway suction temp. Sensor error(open/short) main cooling sol. V/v open error 4-way v/v operation error outdoor protection control/self diagnosis related error outdoor unit fr...

Page 223: Troubleshooting

- 222 - troubleshooting 8 error display remark contents seg 1 seg 2,3,4 forbid heating mode operation when outdoor temperature over 30˚c forbid cooling mode operation when outdoor temperature below -5˚c in case of refrigerant charging operation at the 15˚cover of outdoor temperature in the heating m...

Page 224

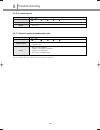

- 223 - troubleshooting 8-2-41. Indoor unit room temp. Sensor error (open / short) outdoor unit display indoor unit display judgment method causes (x x x : indoor unit address occurred error) (operation) (timer) (fan) (filter) (removing frost) - refer to the below judge method - open/short defect of...

Page 225: Troubleshooting

- 224 - troubleshooting 8 8-2-42. Indoor unit evap in sensor error (open / short) outdoor unit display indoor unit display judgment method causes (x x x : indoor unit address occurred error) (operation) (timer) (fan) (filter) (removing frost) - refer to the below judge method - open/short error of x...

Page 226

- 225 - troubleshooting 8-2-43. Indoor unit evap out sensor error (open / short) outdoor unit display indoor unit display judgment method causes (x x x : indoor unit address occurred error) (operation) (timer) (fan) (filter) (removing frost) - refer to the below judge method - open/short error of x ...

Page 227: Troubleshooting

- 226 - troubleshooting 8 1. Judge method 1) cooling operation 2) heating operation 2. Check method check if the indoor unit evap in sensor is separated, and adjust after assembly. 8-2-44. Indoor unit evap in sensor breakaway tcond, out-tair, out > 3°c tair, in - teva, in > 4°c tair, in - teva, out ...

Page 228

- 227 - troubleshooting 1. Judge method 1) cooling operation 2) heating operation 2. Check method check if the indoor unit evap out sensor is separated, and adjust after assembly. 8-2-45. Indoor unit evap out sensor breakaway tcond, out - tair, out > 3°c tair, in - teva, in > 4°c tair, in - teva, ou...

Page 229: Troubleshooting

- 228 - troubleshooting 8 8-2-46. Mcu temperature sensor open/short error outdoor unit display indoor unit display judgment method causes (operation) (timer) (fan) (filter) (removing frost) - disconnection and short of mcu temperature sensor is not the mcu temperature sensor connector separated from...

Page 230

- 229 - troubleshooting 8-2-47. The starting error of indoor unit fan motor outdoor unit display indoor unit display judgment method causes (x x x : indoor unit address occurred error) (operation) (timer) (fan) (filter) (removing frost) - the starting error of x indoor unit fan motor x x x db98_1781...

Page 231: Troubleshooting

- 230 - troubleshooting 8 8-2-48. The 1 st , 2 nd simultaneous opening error of mcu sol v/v heating & cooling indoor unit display outdoor unit display judgment method causes 1 st detection : ( ) 2 nd detection : ( ) (operation) (filter) - refer to the below judge method - the rising water level of d...

Page 232

- 231 - troubleshooting 1. Judge method 1) when error and following errors are flickering 1) 1a3- : mcu no.1 connected to indoor unit no.3 but there is no change of temperature of eva-in of indoor unit no.3 during the piping check. 1) 2b12 : mcu no.2 b connected to indoor unit no.1 but there is the ...

Page 233: Troubleshooting

- 232 - troubleshooting 8 8-2-50. Communication error between the indoor unit and outdoor unit on tracking outdoor unit display indoor unit display judgment method causes (operation) (timer) (fan) (filter) (removing frost) - when the number of indoor unit of installation switch mismatch with communi...

Page 234

- 233 - troubleshooting +0.7v -0.7v check the display part with pressing the rest key(k3) of the outdoor unit pcb. Is the voltage between both wires square wave over dc 0.7v? Is there any response of the indoor unit at the display on tracking? Remove the communication wire connecting from the outdoo...

Page 235: Troubleshooting

- 234 - troubleshooting 8 no no yes yes yes yes yes is ok the connection between the outdoor unit and communication connector? Press the reset(k3) outdoor unit pcb and check the display part. Is there any response of mcu or indoor unit from the display part on tracking? Mcu address: fb-fe is the vol...

Page 236

- 235 - troubleshooting check the error of outdoor unit display part and find a mcu occurring error. Indoor unit connected to mcu through confluence kit. Indoor unit connected with confluence kit with continuity. Reset correctly confluence kit dip switch and rotary switch of mcu and restart. Connect...

Page 237: Troubleshooting

- 236 - troubleshooting 8 check the error of outdoor unit display part and find a mcu occurring error. Check the address of indoor unit connecting with confluence kit and the address of rotary switch on mcu pcb. Is not 3 over of rotary switch of mcu set to the same address? Restart after setting cor...

Page 238

- 237 - troubleshooting find indoor unit and mcu address that occurred communication error, through outdoor unit pcb or mcu pcb. Check address set matching between indoor unit and mcu. Are not the same between indoor unit and mcu address? Restart after setting correctly between indoor unit and mcu a...

Page 239: Troubleshooting