Summary of AEX060EDEHA

Page 2

2 safety precautions carefully follow the precautions listed as below because they are essential to guarantee the safety of samsung product. Warning • always disconnect a power supply of air-water heat pump before servicing it or accessing components inside the unit. • verify that installation and t...

Page 3

3 en g lis h f do not attempt to repair, move, alter or reinstall the unit by unauthorized personnel, these operations may cause product damage, electric shocks and fires. F do not place containers with liquids or other objects on the unit. F all the materials used for the manufacture and packaging ...

Page 4

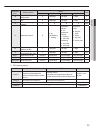

4 product specifications product line-up line-up remark heat pump units chassis - model name aex060edeha accessories f keep supplied accessories until the installation is finished. F hand the installation manual over to the customer after finishing installation. F the quantities are indicated in par...

Page 5

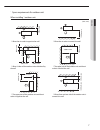

5 en g lis h main components dimensions(overall) heat pump for r-410a. 638 364 23 610 50 12 880 54.1 310 installing the unit deciding on where to install the outdoor unit decide the installation location regarding the following condition and obtain the user’s approval. F the outdoor unit must not be...

Page 6

6 f do not install the air to water heat pump in following places. • the place where there is mineral oil or arsenic acid. There is a chance that parts may get damaged due to burned resin. The capacity of the heat exchanger may reduce or the air to water heat pump may be out of order. • the place wh...

Page 7

7 en g lis h installing the unit space requirements for outdoor unit when installing 1 outdoor unit (unit : mm) 30 0 or m or e 1, 50 0 or m or e * when the air outlet is opposite the wall * when the air outlet is towards the wall 30 0 or m or e 300 or more 600 or more 1, 50 0 or m or e 2,000 or more...

Page 8

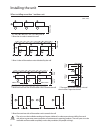

8 when installing more than 1 outdoor unit (unit : mm) 15 00 o r m or e * when the air outlet is towards the wall 30 0 or m or e 300 or more 600 or more 600 or more 600 or more * when 3 sides of the outdoor unit are blocked by the wall 30 0 or m or e 15 00 o r m or e 600 or more 600 or more 50 0 or ...

Page 9

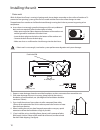

9 en g lis h outdoor unit installation the outdoor unit must be installed on a rigid and stable base to avoid any increase in the noise level and vibration, particularly if the outdoor unit is to be installed in a location exposed to strong winds or at a height, the unit must be fixed to an appropri...

Page 10

10 drain work while air-water heat pump is running in heating mode, ice can begin accumulate on the surface of condenser. To prevent ice from growing, system go into de-frost mode and then ice on the surface changes to water. Dropped water from condenser shall be eliminated through running drain hol...

Page 11

11 en g lis h selecting a location in cold climates • when operating the unit in a low outdoor ambient temperature, be sure to follow the instructions described below. F to prevent exposure to wind, install the unit with its suction side facing the wall. F never install the unit at a site where the ...

Page 12

12 electrical connections overall system configuration connection of the power cable (1 phase 2 wires) distribution board outdoor unit hydro unit 1 phase 2 wires 220- 240v~ earth communication cable elcb 1 phase 2 wires 220- 240v~ 1 phase 2 wires 220- 240v~ earth dhw tank earth mccb+ elb or • instal...

Page 13

13 en g lis h l n f 1 phase communication cable main power cable cable clamp cable tie connecting the cable between indoor unit and outdoor unit connection cable specifications(common in use) power supply communation cable power supply max/min(v) indoor power cable 1Φ, 220-240v, 50hz ±10% 0.75~1.5mm...

Page 14

14 • you should connect the power cable into the power cable terminal and fasten it with a clamp. • the unbalanced power must be maintained within 2% of supply rating. - if the power is unbalanced greatly, it may shorten the life of the condenser. If the unbalanced power is exceeded over 4% of suppl...

Page 15

15 en g lis h connecting the cable connecting the power terminal f connect the cables to the terminal board using the compressed ring terminal. F connect the rated cables only. F connect using a wrench which is able to apply the rated torque to the screws. F if the terminal is loose, fire may occur ...

Page 16

16 f install the refrigerant pipe within the maximum allowable length, difference in height and length of after the first branch pipe. F the pressure of the r-410a is high. Use only rated refrigerant pipe and follow the installation method. F use clean refrigerant pipe where there is no harmful ion,...

Page 17

17 en g lis h selecting the refrigerant pipe outdoor unit capacity (kw) liquid side (mm) gas side (mm) aex060edeha ø6.35 ø15.88 f install refrigerant pipe depending on the outdoor unit capacity. F make sure to use c1220t-1/2h (semi-hard) pipe for more than Ø19.05mm. In case of using c1220t-o (soft) ...

Page 18

18 cutting or flaring the pipes 1. Make sure that you prepared the required tools. - pipe cutter, reamer, flaring tool and pipe holder, etc. 2. If you want to shorten the pipe, cut it with a pipe cutter ensuring that the cut edge remains at 90° with the side of the pipe. - there are some examples of...

Page 19

19 en g lis h selecting the insulator of the refrigerant pipe f according to pipes size, insulate pipes on gas and liquid side by selecting appropriate insulations. F standard condition is under a temperature of 30°c and a humidity of 85%. If the units are installed in extreme weather conditions, se...

Page 20

20 insulating the refrigerant pipe f you must check if there is a gas leak before completing all the installation process. F use epdm insulation which meets the following condition. Item unit standard remarks density g/cm² 0.048~0.096 ksm 3014-01 dimension change route by heat % -5 or less water abs...

Page 21

21 en g lis h performing the refrigerant gas leak test f use a manifold gauge for r-410a to prevent the inflow of foreign substances and resist against the internal pressure. F pressure test with dry oxygen free nitrogen only. Apply pressure to the liquid side pipe and gas side pipe with nitrogen ga...

Page 22

22 vacuum drying f use a manifold gauge for r-410a to prevent the inflow of foreign substances and resist against the internal pressure. F use the vacuum pump with the check valve to prevent pump oil from flowing backward while the vacuum pump is stopped. F vacuum system to 5torr. (666.6pa, 0.0067 k...

Page 23

23 en g lis h selecting additional refrigerant charge * basic charge the basic amount of refrigerant for outdoor unit charged in factory is: outdoor unit (series) factory charge(kg) aex060edeha 1.2 * charge additional refrigerant according to the total length of the pipe. Each factory charging value...

Page 24

24 charging refrigerant f the r-410a refrigerant is blended refrigerant. Add only liquid refrigerant. F measure the quantity of the refrigerant according to the length of the liquid side pipe. Add quantity of the refrigerant using a scale. Important information regulation regarding the refrigerant u...

Page 25

25 en g lis h adding refrigerant f the r-410a refrigerant is blended refrigerant. Add only liquid refrigerant. F measure the quantity of the refrigerant depending on the length of the liquid side pipe. Add fixed quantity of the refrigerant using a scale. * adding refrigerants in cooling conditions g...

Page 26

26 to close the valve stem 1. Open the cap and turn the valve stem clockwise by using a hexagonal wrench. Cap service port sealing edge valve stem 2. Tighten the valve stem until it reached the sealing edge. • do not apply excessive force to the valve stem and always use special instruments. Otherwi...

Page 27

27 en g lis h checking correct grounding if the power distribution circuit does not have a grounding or the grounding does not comply with specifications, an grounding electrode must be installed. The corresponding accessories are not supplied with the air conditioner. 1. Select an grounding electro...

Page 28

28 testing operations 1. Check the power supply between the outdoor unit and the auxiliary circuit breaker. • 1 phase power supply : l, n 2. Check the indoor unit 1) check that you have connected the power and communication cables correctly. (if the power cable and communication cables one mixed up ...

Page 29

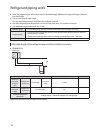

29 en g lis h number of press display contents display units segment 1 segment 2 segment 3 segment 4 10 target discharge temperature a 100s digit 10s digit 1s digit °c 11 eev b 100s digit 10s digit 1s digit step 12 not used exchanger capacity c 0 0 0 kw 13 protection control d 0 : air conditioning 1...

Page 30

30 objective of pump down for product repairs and indoor unit relocation, pump down operation must be done recover the refrigerant into the outdoor unit. Cautions when performing pump down f product limits amount of refrigerant in the outdoor unit due to slim design. F collect the majority of the re...

Page 31

31 en g lis h collecting refrigerant in refrigerant vessel before pump down operation if the amount of refrigerant in the system exceeded the maximum allowable limit, reduce the amount of the refrigerant by following the below instruction before pump down operation. 1. Prepare an exclusive rechargea...

Page 32

32 when refrigerant recovery is difficult due to the large amount of refrigerant 1. Prepare manifold gauge, scale and an empty refrigerant vessel. 2. As shown below, connect the middle hose of manifold gauge to the refrigerant vessel and then connect the both ends of manifold gauge to the outdoor un...

Page 33

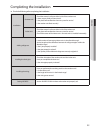

33 en g lis h completing the installation f check the following after completing the installation. Installation outdoor unit • check the external surface and the inside of the outdoor unit. • is there any possibility of short circuit? • is the place well-ventilated and ensures space for service? • i...

Page 34

34 final checks and trial operation turn on the outdoor unit 3 hours before the test operation to preheat the compressor. If the compressor is not preheated, ‘ch’ will appear on the outdoor unit pcb. Inspection before test operation 1. Check the power cable and communication cable of the indoor and ...

Page 35

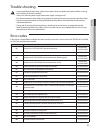

35 en g lis h trouble shooting • incorrect handling of thermostat, safety valve or other valves may lead to tank rupture. When servicing the unit follow instructions carefully: • always turn off main power supply when water supply is being shut off. • test the free operation of the safety valve regu...

Page 36

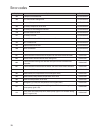

36 display explanation error source 465 compressor overload error outdoor unit 466 dc link over/low voltage error outdoor unit 467 [inverter] compressor rotation error outdoor unit 468 [inverter] compressor sensor error outdoor unit 469 [inverter] dc link voltage sensor error outdoor unit 470 eeprom...

Page 37

37 en g lis h.

Page 39

Aex060edeha air to water heat pump outdoor unit installation manual imagine the possibilities thank you for purchasing this samsung product. To receive more complete service, please register your product at www.Samsung.Com/register e s f i p d db68-03338a-1.