- DL manuals

- Samsung

- Air Conditioner

- AM***FN*D series

- User Manual

Samsung AM***FN*D series User Manual

Summary of AM***FN*D series

Page 1

Air conditioner user manual am777fn7d77 / am777jnm77 / am777mn7d77 ŷ thank you for purchasing this samsung air conditioner. ŷ before operating this unit, please read this user manual carefully and retain it for future reference..

Page 3

2 a contents safety precautions ......................................................................................................................................................3 accessories ...........................................................................................................

Page 4: Warning

3 a english safety precautions (carefully follow the precautions listed below because they are essential to guarantee the safety of the equipment.) warning xalways disconnect the air conditioner from the power supply before servicing it or accessing its internal components. Xverify that installation...

Page 5

4 a x our units must be installed in compliance with the spaces indicated in the installation manual to ensure either accessibility from both sides or ability to perform routine maintenance and repairs. The units’ components must be accessible and that can be disassembled in conditions of complete s...

Page 6

5 a english accessories the following accessories are supplied with the indoor unit. The type and quantity may differ depending on the specifications. ❈ only am018jnmpch/aa include the last four accessories. Insulation cover thermal insulation a (use for refrigerant pipe) thermal insulation b (use f...

Page 7: Indoor Unit

6 a selecting the installation location x there must be no obstacles near the air inlet and outlet. X install the indoor unit on a ceiling that can support its weight. X maintain sufficient clearance around the indoor unit. X make sure that the water dripping from the drain hose runs away correctly ...

Page 8

7 english thickness:more than 0.39inch (10mm) indoor unit a b c d front back slim duct am 7fnld7 70077/70097/70127 35.43"x7.83"23.62" (900x199x600) 35.43"×23.62" (900x600) 35.43"×23.62" (900x600) 23.62"×7.87" (600x200) 23.62"×7.87" (600x200) insulate the front and back side in proper size at the sam...

Page 9

8 selecting the installation location am007/009/012fnld777 no. Name description 1 liquid pipe connection ø6.35 (1/4”) 2 gas pipe connection ø12.70 (1/2”) 3 drain pipe connection 3/4"(odØ1.05"(26.67)) 4 drain pipe connection (option drain pump) 3/4"(odØ1.05"(26.67)) 5 power supply/communication conne...

Page 10

9 english no. Name description 1 liquid pipe connection 601866:ø6.35(1/4") ,602466:ø9.52(3/8") 2 gas pipe connection 601866:ø12.7(1/2") ,602466:ø15.88(5/8") 3 drain pipe connection 3/4"(odØ1.05"(26.67)) 4 drain pipe connection (option drain pump) 3/4"(odØ1.05"(26.67)) 5 power supply/communication co...

Page 11

10 a selecting the installation location no. Name description 1 liquid pipe connection ø9.52(3/8”) 2 gas pipe connection ø15.88 (5/8”) 3 drain pipe connection 3/4"(odØ1.05"(26.67)) 4 drain pipe connection (option drain pump) 3/4"(odØ1.05"(26.67)) 5 power supply/communication connection -- 6 power su...

Page 12

11 english am018/024fnmd777 no. Name description 1 liquid pipe connection 601866:ø6.35(1/4") ,602466:ø9.52(3/8") 2 gas pipe connection 601866:ø12.7(1/2") ,602466:ø15.88(5/8") 3 drain pipe connection 3/4"(odØ1.05"(26.67)) 4 drain pipe connection (option drain pump) 3/4"(odØ1.05"(26.67)) 5 power suppl...

Page 13

12 a selecting the installation location am030/036fnmd777 no. Name description 1 liquid pipe connection ø9.52(3/8”) 2 gas pipe connection ø15.88 (5/8”) 3 drain pipe connection 3/4"(odØ1.05"(26.67)) 4 drain pipe connection (option drain pump) 3/4"(odØ1.05"(26.67)) 5 power supply/communication connect...

Page 14

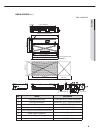

13 english 8 5 4 2 1 3 7 6 am007/009/012/015/018jnmd777 am006jnmp777 (drain pump built-in) no. Name description 1 liquid pipe connection ø6.35(1/4”) 2 gas pipe connection ø12.70 (1/2”) 3 drain pipe connection(without drain pump) 3/4"(odØ1.05"(26.67)) 4 drain pipe connection(with drain pump) 3/4"(odØ...

Page 15

14 a no. Name description 1 liquid pipe connection ø9.52(3/8”) 2 gas pipe connection ø15.88 (5/8”) 3 drain pipe connection 3/4"(odØ1.05"(26.67)) 4 drain pipe connection (option drain pump) 3/4"(odØ1.05"(26.67)) 5 power supply/communication connection -- 6 air discharge grille flange -- 7 suction fla...

Page 16

15 english no. Name description 1 liquid pipe connection ø9.52(3/8”) ( 7 018jnmp 7 : ø6.35(1/4”)) 2 gas pipe connection ø15.88(5/8”) ( 7 018jnmp 7 : ø12.70(1/2”)) 3 drain pipe connection(without drain pump) 3/4"(odØ1.05"(26.67)) 4 drain pipe connection(with drain pump) 3/4"(odØ1.05"(26.67)) 5 power ...

Page 17

16 a selecting the installation location no. Name description 1 liquid pipe connection ø1/4"(6.35) 2 gas pipe connection ø1/2"(12.70) 3 drain pipe connection 3/4"(odØ1.05"(26.67)) 4 power supply connection 5 air discharge flange 6 air filter 7 hook m8~m10 unit : inch(mm) 7.28(185) 6.22(158) 5.75(146...

Page 18

17 english unit : inch(mm) no. Name description 1 liquid pipe connection ø3/8"(9.52) 2 gas pipe connection ø5/8"(15.88) 3 drain pipe connection 3/4"(odØ1.05"(26.67)) 4 power supply connection 5 air discharge flange 6 air filter 7 hook m8~m10 7.28(185) 6.22(158) 5.83(148) 27.56(700) 23.78(604) 11x3.9...

Page 19

18 a 19.69(500) 51.18(1300) 55.12(1400) 27.56(700) 7 7.28(185) 6.30(160) 5.75(146) 27.56(700) 23.78(604) 5 6 11x3.937=43.31(11x100=1100) 49.92(1268) 51.18(1300) 53.15(1350) 30-ø0.13(3.2) 10.63(270) 11.81(300) 8.39(213) 4.92(125) 13.39(340) 1 2 3 4 2x4.53=7.06(2x1 15=230) inspection hole (air outlet ...

Page 20

19 a english indoor unit installation concrete suspension bolt( ø9.52(3/8”) or m10) hole in anchor hole in plug insert drain hose port a rubber ceiling support it is recommended to install they-joint before installing the indoor unit. 1 place the pattern sheet on the ceiling at the spot where you wa...

Page 21

20 a for hsp duct (am024/027/030/036/048jnhdch),2 pad- cushion should be removed before installing air conditioner. Caution noise will increase 3~6 db(a) when the air flow enters from the bottom side (only for slim duct type product). Caution air flow indoor unit installation.

Page 22

21 a english on delivery, the indoor unit is loaded with inert gas. All this gas must therefore be purged before connecting the assembly piping. To purge the inert gas, proceed as follows. Unscrew the pinch pipe at the end of each refrigerant pipe. Result: all inert gas escapes from the indoor unit....

Page 23

22 a connecting the refrigerant pipe 1 remove the pinch pipe on the pipes and connect the assembly pipes to each pipe, tightening the nuts, first manually and then with a torque wrench, a spanner applying the following torque. Outer diameter torque mm inch /tn mcgtgu 6.35 1/4 14~18 10.3~13.3 9.52 3/...

Page 24

23 a english cutting/flaring the pipes inclined damaged surface cracked uneven thickness 1 make sure that you prepared the required tools. (pipe cutter, reamer, flaring tool and pipe holder) 2 if you want to shorten the pipe, cut it using a pipe cutter ensuring that the cut edge remains at 90° with ...

Page 25: Leak Test

24 a performing leak test & insulation leak test with nitrogen (before opening valves) in order to detect basic refrigerant leaks, before recreating the vacuum and recirculating the r410a, it’s responsible of installer to pressurize the whole system with nitrogen (using a pressure regulator) at a pr...

Page 26

25 english 5 select the insulator of the refrigerant pipe. X insulate the gas side and liquid side pipe referring to the thickness according to the pipe size. X indoor temperature of 30°c(86°f) and humidity of 85% is the standard condition. If install in a high humidity condition,use one grade thick...

Page 27

26 a drain pipe and drain hose installation a-a’ large sealing pad metal clamp drain socket drain hose cable tie drain piping indoor unit tighten the clamp to the maximum. 1 install the drain hose as short as possible. Note x in order to discharge condensation water, the drain hose should keep tilte...

Page 28: Drainpipe Connection

27 a english drain pipe and drain hose installation 1 the drain pipe should be installed within 11.81inch(300mm) to 21.65inch(550mm) from the flexible hose and then lift down 0.79inch(20mm) or more. 2 install horizontal drainpipe with a slope of 1/100 or more and fix it by hanger space of 3.28~4.92f...

Page 29: Centralized Drainage

28 a 1 install horizontal drainpipe with a slope of 1/100 or more and fix it by hanger space of 3.28~4.92ft(1~1.5m). 2 install u-trap at the end of the drainpipe to prevent a nasty smell to reach the indoor unit. Without the drain pump 1 install main air vent at the front of the farthest indoor unit...

Page 30: Testing The Drainage

29 english water supply intake prepare a little water about 2 liters. Loosen screws and take out the side cover plate. 1 confirm that the water flows out through the drain hose. 3 when the drain pump is installed, operate the unit as cooling mode and check a drain pump pumping. 4 pour water into the...

Page 31

30 a wiring work silver solder 1 before wiring work, you must turn off all power source. 2 indoor unit power should be supplied through the breaker( elcb or mccb+elb ) separated by the outdoor power. Elcb:earth leakage circuit breaker mccb:molded case circuit breaker elb:earth leakage breaker 3 the ...

Page 32

31 english power supply mccb elb or elcb power cable earth cable communication cable max : 242v min : 198v x a x a, 30ma 0.1 sec 0.0039inch 2 (2.5mm 2 ) 0.0039inch 2 (2.5mm 2 ) 0.0012~0.0023inch 2 (0.75~1.5mm 2 ) x decide the capacity of elcb(or mccb+elb) by below formula. The capacity of elcb(or mc...

Page 33

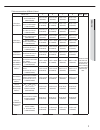

32 a wiring work(cont.) krating current unit model rating current unit model rating current unit model rating current am 7fnld7 70077 70097 70127 70187 70247 70307 70367 70487 0.32a 0.40a 0.51a 0.94a 0.98a 0.80a 1.05a 1.40a am 7fnmd7 70187 70247 70307 70367 70487 1.40a 1.50a 1.50a 1.60a 2.45a am 7jn...

Page 34

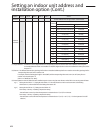

33 a english setting an indoor unit address and installation option set the indoor unit address and installation option with remote controller option. Set the each option separately since you cannot set the address setting and indoor unit installation setting option at the same time. You need to set...

Page 35

34 a option setting status 1. Setting seg2, seg3 option press low fan button( ∨) to enter seg2 value. Press high fan button( ∧) to enter seg3 value. Each time you press the button, ⋯ will be selected in rotation. 2. Setting cool mode press mode button to be changed to cool mode in the on status. 3. ...

Page 36

35 english seg16 seg18 seg21 seg23 seg17 seg20 seg22 seg24 step 4. Input option press operation button with the direction of remote control for set. For the correct option setting, you must input the option twice. Step 5. Check operation 1. Reset the indoor unit by pressing the reset button of indoo...

Page 37

36 a setting an indoor unit address and installation option (cont.) 1. Check whether power is supplied or not. - when the indoor unit is not plugged in, there should be additional power supply in the indoor unit. 2. The panel(display) should be connected to an indoor unit to receive option. 3. Befor...

Page 38

37 english 1. Check whether power is supplied or not. - when the indoor unit is not plugged in, there should be additional power supply in the indoor unit. 2. The panel(display) should be connected to an indoor unit to receive option. 3. Set the installation option according to the installation cond...

Page 39

38 a setting an indoor unit address and installation option (cont.) option no. : 02xxxx-1xxxxx-2xxxxx-3xxxxx q 02 series installation option(detailed) f4 f3 f1 f2 v2 v1 1(l) 2(n) 2 1 hot coil ac power outdoor communication wire remote controller dc 12 v * the output of hot coil terminal is ac 220 v ...

Page 40

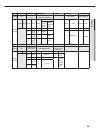

39 english option seg13 seg14 seg15 seg16 seg17 seg18 explanation page use of external control setting the output of external control / external heater on/off signal - buzzer control hours of filter usage indication and details indication details indication details indication details - indication de...

Page 41

40 a setting an indoor unit address and installation option (cont.) seg1 seg2 seg3 seg4 seg5 seg6 0 5 use of auto change over for hr only in auto mode (when setting seg3) standard heating temp. Offset (when setting seg3) standard cooling temp. Offset (when setting seg3) standard for mode change heat...

Page 42

41 english option no. : 05xxxx-1xxxxx-2xxxxx-3xxxxx option seg1 seg2 seg3 seg4 seg5 seg6 explanation page mode use of auto change over for hr only in auto mode (when setting seg3) standard heating temp. Offset (when setting seg3) standard cooling temp. Offset (when setting seg3) standard for mode ch...

Page 43

42 a (*1) height difference : the difference of the height between the corresponding indoor uint and the indoor unit installed at the lowest place. For example, when the indoor unit is installed 131.2ft(40m) higher than the indoor unit installed at the lowest place, select the option "1". (*2) dista...

Page 44: Changing A Particular Option

43 english option seg1 seg2 seg3 seg4 seg5 seg6 explanation page mode the option mode you want to change the tens’ digit of an option seg you will change the unit digit of an option seg you will change changed value indication and details indication details indication details indication details indi...

Page 45

44 to complete the installation, perform the following checks and tests to ensure that the air conditioner operates correctly. Check the following: x strength of the installation site x tightness of pipe connection to detect gas leak x electric wiring connection x heat-resistant insulation of the pi...

Page 46: Detection of Errors

45 a english after finishing the installation of the air conditioner, you should explain the following to the user. Refer to appropriate pages in the user & installation manual. 1 how to start and stop the air conditioner 2 how to select the modes and functions 3 how to adjust the temperature and fa...

Page 47

46 a troubleshooting (contiued) abnormal condition error code led display blue red error on indoor temperature sensor (short or open) e121 1. Error on eva-in sensor (short or open) 2. Error on eva-out sensor (short or open) 3. Discharge sensor error (short or open) e122 e123 e126 indoor fan error e1...

Page 48

47 a english adjusting air flow automatic air-volume "xbz.%4 main menu sub-menu 1 2 3 5 4 6 seg used 1).Press the and buttons at the same time for more than 3 seconds and then a main menu will be displayed. 2).Press the / button to select and then press button to enter a sub-menu setting screen. 3)....

Page 49

48 a adjusting air flow main menu sub menu functions seg used default range 8 1 automatic air-volume state return 1 0 0 - off (fail or disable) 1 - completion. 2 - running automatic air-volume. 2 automatic air-volume operation 1 0 0 - disable 1 - enable 9). When the air conditioning unit has stopped...

Page 50

49 english with its phase control motor,you can adjust the indoor unit fan speed depending on the installation condition. If the external static pressure is high so that the duct becomes longer or if the external static pressure is low so that the duct becomes shorter,adjust the fan speed by referri...

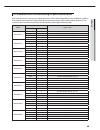

Page 51

50 a model static pressure option code inh 2 o mmaq am030fnmd 7 0.24 6 010054-1259ce-205a5a-331110 0.32 8 010054-125e02-205a5a-331110 0.40 10 010054-125e46-205a5a-331110 am036fnmd 7 0.24 6 010054-125e00-206e6e-331110 0.32 8 010054-125e44-206e6e-331110 0.40 10 010054-125e88-206e6e-331110 am048fnmd 7 ...

Page 52

51 english model am006jnmpch am018jnmpch am028jnmpch am042jnmpch static pressure option code inh2o mmaq 0 0 010054-1b5095- 201212-331110 010054-135530- 203535-331110 010054-135585- 205252-331110 010054-1355f9- 207b7b-331110 0.04 1 010054-1b50f8- 201212-331110 010054-135552- 203535-331110 010054-1355...

Page 53

52 a note x represents e.S.P(external static pressure)range of factory setting. You don’t have to adjust the fan speed separately if the external static pressure of the installation place is in . When it is out of , input the appropriate option code. X if you input the inappropriate option code,erro...

Page 54

53 a english extending the power cable 1. Prepare the following tools. Tools crimping pliers connection sleeve insulation tape contraction tube spec mh-14 20xØ0.26 inch(6.5 mm) (hxod) width 0.75 inch(19 mm) 70xØ0.31 inch(8.0 mm) (lxod) shape 2. As shown in the figure, peel off the shields from the r...

Page 55

54 a 1. Wrap it with the insulation tape twice or more and position your contraction tube in the middle of the insulation tape. Three or more layers of insulation are required. F method 1 1.57 inch (40 mm) insulation tape f method 2 insulation tape 1.38 inch (35 mm) 2. Apply heat to the contraction ...

Page 56

55 english.

Page 57

Db68-07187a-00