Summary of AM0 SERIES

Page 1

Am0**jnzdch/aa im eng_v1.5_07082015.

Page 2

Multiposition ahu am0✴✴jnzdch/aa air conditioner installation manual en imagine the possibilities thank you for purchasing this samsung product. Am0**jnzdch/aa im eng_v1.5_07082015 1.

Page 3: Contents

English contents safety precautions (carefully follow the precautions listed below because they are essential to guarantee the safety of the equipment.) warning • always disconnect the air conditioner from the power supply before servicing it or accessing its internal components. • verify that insta...

Page 4

X always remember to inspect the unit, electric connections, refrigerant tubes and protections regularly. These operations should be performed by qualified personnel only. X the unit contains moving parts, which should always be kept out of the reach of children. X do not attempt to repair, move, al...

Page 5: Safety Precautions

English safety precautions • make sure that you earth/ground the power cables. - do not connect the earth wire to the gas pipe, water pipe, lighting rod or telephone wire. If earthing is not complete, electric shock or fire may occur. • install the circuit breaker. - if the circuit breaker is not in...

Page 6: Accessories

Selecting the installation location decide the installation location, with the consideration of the following conditions, under user’s approval. • place where airflow is not disturbed. • place on flat surface where the structure can bear the weight and vibration of the indoor unit. (if the structure...

Page 7

English dimensions unit : inch no. Name description 1 liquid pipe connection ✴✴ 012/018✴✴: ø 1/4” ✴✴ 024/030/036/048/054/060/072✴✴: ø 3/8” 2 gas pipe connection 3 drain pipe connection 3/4" npt 4 air outlet - 5 air intake - note: all dimension are in inches and are approximate. All dimensions are ro...

Page 8: Indoor Unit Installation

Indoor unit installation refrigerant pipe work must be done before installing the indoor unit. Location access for servicing is an important factor in the location of any air handler. Provide a minimum of 30 inches in front of the appliance for access to the control box, heating elements, blower and...

Page 9: Indoor Unit Installation

English indoor unit installation this appliance is approved for zero (0) inches clearance to combustible material on any part of the air handler exterior casing and the inlet or outlet ducts providing no electric heater is being used. There is a one (1) inch clearance on the supply plenum and supply...

Page 10: Indoor Unit Installation

Indoor unit installation typical closet installations provisions shall be made to permit the air in the rooms and the living spaces to return to the air handler. Failure to comply may cause a reduction in the amount of return air available to the blower, causing reduced air flow resulting in imprope...

Page 11: Indoor Unit Installation

English indoor unit installation arrangement: unit is shipped from the factory arranged to be installed in an upflow or horizontal left (right to left air flow) position. Horizontal left means when the unit is laid on its side and you are facing the unit, the supply air opening is to the left and th...

Page 12: Indoor Unit Installation

Indoor unit installation horizontal application horizontal applications will normally be used in an attic or crawl space. This type of installation requires supply air plenum or duct to be connected to the supply collar and a return air plenum or duct be attached to the unit inlet collar. The supply...

Page 13: Refrigerant Piping

English refrigerant piping air handlers with dx type evaporator coils require liquid and suction piping sized in accordance with condensing unit manufacturer’s instructions. The evaporator coils have sweat copper connections. Refrigerant lines should be soldered with silver solder or high temperatur...

Page 14

Performing leak test & insulation leak test leak test with nitrogen (before opening valves) in order to detect basic refrigerant leaks, before recreating the vacuum and recirculating the r-410a, it’s responsible of installer to pressurize the whole system with nitrogen (using a pressure regulator) a...

Page 15

English performing leak test & insulation 5. Select the insulation of the refrigerant pipe. • insulate the gas side and liquid side pipe referring to the thickness according to the pipe size. • indoor temperature of 86 °f(30 °c) and humidity of 85% is the standard condition. If install in a high hum...

Page 16: Additional Refrigerant

Additional refrigerant • system refrigerant volume is based on linear feet of liquid line pipe and indoor equipment model/quantity. • refer to the outdoor unit installation manuals for information regarding refrigerant volume for system components. • see table below for additional refrigerant volume...

Page 17: Drain Pipe Installation

English drain pipe installation • make sure to keep the drain hose from getting tangled or loosened (on the connection part). • insulate all condensate pipes connected to the indoor unit to prevent condensation formation. Condensate formation on condensate pipes can lead to property damage and unsaf...

Page 18: Water Leakage Test

Water leakage test 1. Pour water into the condensate pan. 2. Make sure that draining is done properly by checking end of the drain pipe. 3. If water leakage occurs, make sure the indoor unit is level. Also verify the drain pipe is installed with a downward slope away from the indoor unit. • after co...

Page 19: Wiring Work

English wiring work power supply wiring • the unit internal wiring is complete except for the power supply and control wires. • the use of cable connectors on incoming power supply wires to relieve any strain on wiring is recommended. • follow the steps below to connect the power supply wires. • sup...

Page 20: Wiring Work

Wiring work power supply wiring with accessory electric heat kit 1. Before wiring work, you must turn off all power source. 2. Indoor unit power should be supplied through the breaker (elcb or mccb+elb ) separate from the outdoor power. Elcb : earth leakage circuit breaker mccb : molded case circuit...

Page 21: Wiring Work

English wiring work power supply wiring with accessory electric heat kit 16. Connect the green (ground) wire to the ground lug to the left of the accessory heat kit breakers and tighten the ground lug screw. Make sure to leave extra slack in the ground wire to allow service to the unit without disco...

Page 22: Wiring Work

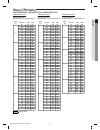

Wiring work 1 0 0 - 0 - 0.90 - 0.90 - 10.0 - 10.0 - #14 #14 - - n/a n/a 1 3 10.90 - 12.50 - 13.63 - 15.63 - 15.0 - 20.0 - #12 #12 - - n/a n/a 0 0 0 - 0 - 0.90 - 0.90 - 10.0 - 10.0 - #14 #14 - - n/a n/a 1 3 10.90 - 12.50 - 13.63 - 15.63 - 15.0 - 20.0 - #12 #12 - - n/a n/a 1 5 18.03 - 20.83 - 23.26 - ...

Page 23: Wiring Work

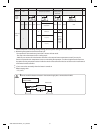

English ❈ when installing elcb(mccb + elb) indoor unit, do not connect with other indoor units attached to other outdoor units. Pba ground screw/connection to chassis wiring work communication wiring connections • communication wires connect through side of air handler and be 2 x 16 awg shielded. • ...

Page 24

Selecting compressed ring terminal silver solder norminal dimensions for cable (inch 2 ) norminal dimensions for screw (inch) b d d1 e f l d2 t standard dimension (inch) allowance (inch) standard dimension (inch) allowance (inch) standard dimension (inch) allowance (inch) min. Min. Max. Standard dim...

Page 25

English example of installation - total power cable length l = 328 ft(100 m), running current of each units 1[a] - total 10 indoor units were installed 10[a] indoor unit10 65.6 ft (20 m) 32.8 ft (10 m) 0 ft (0 m) 9[a] 1[a] 328 ft (100 m) indoor unit2 indoor unit1 elcb or mccb+ elb • apply following ...

Page 26: Wiring Work

Wiring work • select the power cable in accordance with relevant local and national regulations. • wire size must comply with local and national code. • power supply cords of parts of appliances for outdoor use shall not be lighter than polychloroprene sheathed flixible cord. (code designation h07rn...

Page 27: Wire Diagram

English wire diagram am012jnzdch/aa, am018jnzdch/aa, am024jnzdch/aa, am030jnzdch/aa, am036jnzdch/aa, am048jnzdch/aa, am060jnzdch/aa, am072jnzdch/aa, 24 v a c l1 c tbm l2 gnd re d 24 0 v a c bl k bl k re d grn g wht ladde r diagram s che m atic diag ram h e a t in g pr od uc ts no he at - 61cc0860i w...

Page 28: Wire Diagram

Wire diagram am054jnzdch/aa 24 v a c l1 c tbm l2 gnd re d 24 0 v a c bl k bl k re d grn g wht ladde r diagram s che m atic diag ram h e a t in g pr od uc ts no he at - 61cc0861a wir e colo rs blk - bl ack blu - bl ue brn - brow n grn - g re e n orn - o rang e yel - yell ow w h t - wh it e sfs r co i...

Page 29: Selecting Motor Speed

English selecting motor speed selecting the constant torque blower speed this air handler uses a constant torque high efficiency motor. This motor operates on 240 vac. The motor speed taps are 24 vac, 0.03 amps, 60 hz, 1 ph. The speed taps can be adjusted according to installation needs. Table 4 sho...

Page 30: Blower Cfm Tables

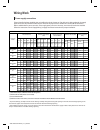

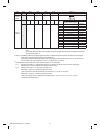

Blower cfm tables am012jnzdch/aa, am018jnzdch/aa, am024jnzdch/aa am012jnzdch/aa hp: 1/3 default motor taps: standard speed = 4, reduced speed = 3 am018jnzdch/aa hp: 1/3 default motor taps: standard speed = 4, reduced speed = 3 am024jnzdch/aa hp: 1/3 default motor taps: standard speed = 4, reduced sp...

Page 31: Blower Cfm Tables

English blower cfm tables am030jnzdch/aa, am036jnzdch/aa, am048jnzdch/aa am030jnzdch/aa hp: 1/2 default motor taps: standard speed = 4, reduced speed = 3 am036jnzdch/aa hp: 1/2 default motor taps: standard speed = 4, reduced speed = 3 am048jnzdch/aa hp: 3/4 default motor taps: standard speed = 4, re...

Page 32: Blower Cfm Tables

Blower cfm tables am054jnzdch/aa, am060jnzdch/aa, am072jnzdch/aa motor tap esp (inch) cfm rpm motor tap esp (inch) cfm rpm motor tap esp (inch) cfm rpm 0.1 1,951 707 0.1 2,027 750 0.1 2,548 864 0.2 1,942 716 0.2 2,036 757 0.2 2,508 889 0.25 1,942 717 0.25 2,027 762 0.25 2,494 905 0.3 1,942 735 0.3 2...

Page 33: External Contact Control

English external contact control the air handler has an mim-b14 external contact control interface module installed by default. The external contact interface card (small pcb to the right of the main pcb) has a jumper installed between terminals 5 and 6. As programmed from the factory, if this jumpe...

Page 34

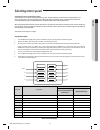

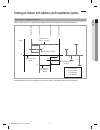

Setting an indoor unit address and installation option this unit has a wireless signal receiver on the pcb allowing address and option setting programming with a wireless controller. Set the indoor unit address and installation option with remote controller option. Set the each option separately sin...

Page 35

English setting an indoor unit address and installation option option setting status 1. Setting seg2, seg3 option press low fan button( ) to enter seg2 value. Press high fan button( ) to enter seg3 value. Each time you press the button, … will be selected in rotation. Seg2 seg3 2. Setting cool...

Page 36

Option setting status 13. Setting seg16, seg17 option press low fan button( ) to enter seg16 value. Press high fan button( ) to enter seg17 value. Each time you press the button, … will be selected in rotation. Seg16 seg17 14. Setting dry mode press mode button to be change to dry mode in the ...

Page 37

English setting an indoor unit address and installation option setting an indoor unit address (main/rmc) 1. Check whether power is supplied or not. - when the indoor unit is not plugged in, there should be additional power supply in the indoor unit. 2. Before installing the indoor unit, assign an ad...

Page 38

Setting an indoor unit installation option (suitable for the condition of each installation location) 1. Check whether power is supplied or not. - when the indoor unit is not plugged in, there should be additional power supply in the indoor unit. 2. Set the installation option according to the insta...

Page 39

English setting an indoor unit address and installation option 02 series installation option(detailed) option no. : 02xxxx-1xxxxx-2xxxxx-3xxxxx option seg1 seg2 seg3 seg4 (*1) seg5 seg6 explanation page mode use of external room temperature sensor / minimizing fan operation when thermostat is off us...

Page 40

Option seg19 seg20 seg21 seg22 seg23 seg24 explanation page heating setting compensation eev step of stopped unit during oil return/ defrost mode - remote controller display indication and details indication details indication details indication details indication details indication details heating ...

Page 41

English setting an indoor unit address and installation option 05 series installation option seg1 seg2 seg3 seg4 seg5 seg6 0 5 use of auto change over for hr only in auto mode (when setting seg3) standard heating temp. Offset (when setting seg3) standard cooling temp. Offset (when setting seg3) stan...

Page 42

Option seg13 seg14 seg15 seg16 seg17 seg18 (*3) explanation control variables when using heater remote controller display indication and details indication details set temp. For heater on/off delay time for heater on 2 0 at the same time as thermo on no delay 1 at the same time as thermo on 10 minut...

Page 43

English setting an indoor unit address and installation option seg 3, 4, 5, 6, 8, 9 additional information when the seg 3 is set as “1” and follow auto change over for hr only operation, it will operate as follows. A : set with seg4 b : set with seg5 c : set with seg6 d : set with seg8 cooling therm...

Page 44

Changing a particular option you can change each digit of set option. Option seg1 seg2 seg3 seg4 seg5 seg6 explanation page mode the option mode you want to change the tens’ digit of an option seg you will change the unit digit of an option seg you will change the changed value remote controller dis...

Page 45: Final Checks and User Tips

English final checks and user tips to complete the installation, perform the following checks and tests to ensure that the air conditioner operates correctly. Check the followings. • strength of the installation site • tightness of pipe connection to detect a gas leak • electric wiring connections •...

Page 46: Memo

Memo am0**jnzdch/aa im eng_v1.5_07082015 45.