Summary of AM009FN4DCH

Page 2: Safety Precautions

2 safety precautions carefully follow the precautions listed below because they are essential to guarantee the safety of the equipment. Warning t always disconnect the air conditioner from the power supply before servicing it or accessing its internal components. T verify that installation and testi...

Page 3

3 english x do not attempt to repair, move, alter or reinstall the unit. If performed by unauthorized personnel, these operations may cause electric shocks or fires. X do not place containers with liquids or other objects on the unit. X all the materials used for the manufacture and packaging of the...

Page 4: Safety Precautions

4 safety precautions t make sure that you earth the cables. - do not connect the earth wire to the gas pipe, water pipe, lighting rod or telephone wire. If earthing is not complete, electric shock or fire may occur. T install the circuit breaker. - if the circuit breaker is not installed, electric s...

Page 5: Accessories

5 english accessories the following accessories are supplied with the indoor unit. The type and quantity may differ depending on the specifications. Insulation cover band insulation pipe cable-tie drain hose user manual installation manual clamp bushing bracket selecting the installation location in...

Page 6

6 selecting the installation location space requirements for indoor unit 59”(1500mm) or mor e 59”(1500mm) or mor e 59”(1500mm) or mor e 59”(1500mm) or mor e t the units must be installed according to distances declared, in order to permit accessibility from each side, either to guarantee correct ope...

Page 7

7 english deciding on where to install the indoor unit drawing of the indoor unit unit : mm (inch) a b 890~910 [35~36 (celling opening)] 950 (37.4) 735 [29 (suspension position)] 890~910 [35~36 ( c elling opening)] 735 [29 (suspension position)] sub duct connection 55 (2.2) 840 (33) 370 (14.6) 346 (...

Page 8: Indoor Unit Installation

8 indoor unit installation it is recommended to install the y-joint before installing the indoor unit. 1. Place the pattern sheet on the ceiling at the spot where you want to install the indoor unit. T since the diagram is made of paper, it may shrink or stretch slightly due to temperature or humidi...

Page 9: Purging The Unit

9 english 6. Adjust the height of the indoor unit by using the gauge of dimensions. T you should adjust the gauge of dimensions and the pattern sheet to fit the cutting dimensions of ceiling. T make sure that the indoor unit is installed at a level if the indoor unit slants too much, there can be wa...

Page 10

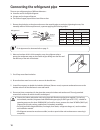

10 connecting the refrigerant pipe there are two refrigerant pipes of different diameters : f a smaller one for the liquid refrigerant f a larger one for the gas refrigerant f the inside of copper pipe must be clean & has no dust 1. Remove the pinch pipe on the pipes and connect the assembly pipes t...

Page 11: Cutting/flaring The Pipes

11 english cutting/flaring the pipes 1. Make sure that you prepared the required tools. (pipe cutter, reamer, flaring tool and pipe holder) 2. If you want to shorten the pipe, cut it using a pipe cutter ensuring that the cut edge remains at 90° with the side of the pipe. There are some examples of c...

Page 12

12 performing leak test & insulation leak test leak test with nitrogen (before opening valves) in order to detect basic refrigerant leaks, before recreating the vacuum and recirculating the r-410a, it’s responsible of installer to pressurize the whole system with nitrogen (using a pressure regulator...

Page 13

13 english 5. Select the insulation of the refrigerant pipe. F insulate the gas side and liquid side pipe referring to the thickness according to the pipe size. F indoor temperature of 30°c(86°f) and humidity of 85% is the stan dard condition. If installing in a high humidity condition, use one grad...

Page 14

14 performing leak test & insulation refrigerant pipe before eev kit and mcu or without eev kit and mcu f you can contact the gas side and liquid side pipes but the pipes should not be pressed. F when contacting the gas side and gas side pipe, use 1 grade thicker insulator. Gas pipe liquid pipe insu...

Page 15

15 english drainpipe and drain hose installation care must be taken when installing the drainpipe and drain hose for the indoor unit so that condensate water is drained correctly outside. Fix the flexible hose to the drainpipe. F push the supplied drain hose as far as possible over the drain socket....

Page 16

16 drainpipe and drain hose installation drainpipe connection 1. The drain pipe should be installed within 100mm(4”) from the flexible hose, lift up from 100mm(4”) to 550mm(22”) and lift down 20mm(3/4”) or more. 2. Install horizontal drainpipe with a slope of 1/100 or more and fix it by hanger space...

Page 17

17 english centralized drainage 1. Install main air vent at the front of the farthest indoor unit from the main drain when installed indoor units are more than 3. 2. May need to install individual air vent to prevent water flow back at the top of each indoor unit drainpipe. Hanger main drainpipe ind...

Page 18: Bushing Bracket Installation

18 bushing bracket installation if the conduit tube is used, bushing bracket must be installed as shown in the picture to fix the conduit tube. 1 2 3 push 5 4 click 1 conduit tube 2 conduit tubes.

Page 19: Wiring Work

N l n l n l n l elcb mccb+ elb v1 v2 indoor unit 1 indoor unit 2 indoor unit 3 indoor unit 4 indoor unit 5 indoor unit 6 outdoor unit wired remote controller eev kit k ceiling, wall-mounted indoor unit. 208-230v~ or k elcb : essential installation warning : power off before connecting any wires; ind...

Page 20: Wiring Work

20 wiring work selecting compressed ring terminal silver solder norminal dimensions for cable [mm 2 (inch 2 )] 1.5 (0.002) 2.5 (0.003) 4 (0.006) norminal dimensions for screw [mm (inch)] 4 (0.15”) 4 (0.15”) 4 (0.15”) 4 (0.15”) 4 (0.15”) b standard dimension [mm (inch)] 6.6 (0.25”) 8.0 (0.31”) 6.6 (0...

Page 21

21 english specification of electronic wire power supply mccb elb power cable earth cable communication cable max : 242v min : 198v xa xa, 30 mma 0.1 s 2.5 mm 2 (0.0039 inch 2 ) 2.5 mm 2 (0.0039 inch 2 ) 0.75~1.5 mm 2 (0.0012~0.0023inch 2 ) f decide the capacity of elb and mccb by below formula. The...

Page 22: Wiring Work

22 wiring work ❇ calculation t installing with 1 sort wire. 220[v] -2.2[v] -2.0[v] ····· 2.5[mm 2 ](0.003inch 2 ) ····· 208.8[v](within 198v~242v) -(2.2+2.0+1.8+1.5+1.3+1.1+0.9+0.7+0.4+0.2)=-11.2[v] it's okay 2.5[mm 2 ](0.003inch 2 ) 2.5[mm 2 ](0.003inch 2 ) t installing with 2 different sort wire. ...

Page 23

23 english setting an indoor unit address and installation option set the indoor unit address and installation option with remote controller option. Set the each option separately since you cannot set the address setting and indoor unit installation setting option at the same time.You need to set tw...

Page 24

24 setting an indoor unit address and installation option option setting status 1. Setting seg2, seg3 option press low fan button( ∨) to enter seg2 value. Press high fan button( ∧) to enter seg3 value. Each time you press the button, p p … p will be selected in rotation. Seg2 seg3 2. Setting cool mo...

Page 25

25 english option setting status 13. Setting seg16, seg17 option press low fan button( ∨) to enter seg16 value. Press high fan button( ∧) to enter seg17 value. Each time you press the button, p p … p will be selected in rotation. Seg16 seg17 14. Setting dry mode press mode button to be change to dry...

Page 26

26 setting an indoor unit address and installation option setting an indoor unit address (main/rmc) 1. Check whether power is supplied or not. - when the indoor unit is not plugged in, there should be additional power supply in the indoor unit. 2. The panel(display ) should be connected to an indoor...

Page 27

27 english setting an indoor unit installation option (suitable for the condition of each installation location) 1. Check whether power is supplied or not. - when the indoor unit is not plugged in, there should be additional power supply in the indoor unit. 2. The panel(display ) should be connected...

Page 28

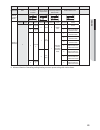

28 setting an indoor unit address and installation option 02 series installation option(detailed) option no. : 0axxxx-1xxxxx-2xxxxx-3xxxxx option seg1 seg2 seg3 seg4 seg5 seg6 explanation page mode use of robot cleaning use of external room temperature sensor use of central control fan rpm compensat...

Page 29

29 english option seg19 seg20 seg21 seg22 seg23 seg24 explanation page individual control of a remote controller heating setting compensation eev step of stopped unit during oil return/ defrost mode motion detect sensor - remote controller display indication and details indication details indication...

Page 30

30 setting an indoor unit address and installation option 05 series installation option seg1 seg2 seg3 seg4 seg5 seg6 0 5 use of auto change over for hr only in auto mode (when setting seg3) standard heating temp. Offset (when setting seg3) standard cooling temp. Offset (when setting seg3) standard ...

Page 31

31 english option seg7 seg8 seg9 seg10 seg11 seg12 explanation page (when setting seg3) standard for mode change cooling heating (when setting seg3) time required for mode change compensation option for long pipe or height diffference between indoor units remote controller display indication and det...

Page 32

32 setting an indoor unit address and installation option changing a particular option you can change each digit of set option. Option seg1 seg2 seg3 seg4 seg5 seg6 explanation page mode the option mode you want to change the tens’ digit of an option seg you will change the unit digit of an option s...

Page 33: Final Checks and User Tips

33 english final checks and user tips to complete the installation, perform the following checks and tests to ensure that the air conditioner operates correctly. Check the followings. F strength of the installation site f tightness of pipe connection to detect a gas leak f electric wiring connection...

Page 34: Troubleshooting

34 troubleshooting detection of errors f if an error occurs during the operation, an led flickers and the operation is stopped except the led. F if you re-operate the air conditioner, it operates normally at first, then detect an error again. Led display on the receiver & display unit led display ab...

Page 35

35 english abnormal conditions error code led lamp display operation defrost timer filter 1. Cond mid sensor is detached e241 × ◑ ◑ ◑ 2. Refrigerant leakage (2nd detection) e554 3. Abnomally high temperature on cond (2nd detection) e450 4. Low pressure s/w (2nd detection) e451 5. Abnomally high temp...

Page 37

Db68-03764a-1 en es fr pt this manual is made with 100% recycled paper. Cassette type series 4 way cassette air conditioner installation manual imagine the possibilities thank you for purchasing this samsung product. To receive more complete service, please register your product at www.Samsung.Com/r...