- DL manuals

- Samsung

- Air Conditioner

- AM036FXMDCH

- Installation Manual

Samsung AM036FXMDCH Installation Manual

Summary of AM036FXMDCH

Page 1

Am0@@fxmdch_im_en_03408a(1).Indd 50 2013-03-04 오후 4:28:30

Page 2

This manual is made with 100% recycled paper. Db68-03408a(1) en es fr pt am✴✴✴fxmdch series air conditioner installation manual imagine the possibilities thank you for purchasing this samsung product. To receive more complete service, please register your product at www.Samsung.Com/register am0@@fxm...

Page 3: Contents

2 contents safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 outdoor unit type . . . . . . . . . . . . . . . . . . . . ...

Page 4: Safety Precautions

3 en g lis h safety precautions carefully follow the precautions listed below because they are essential to guarantee the safety of the equipment . Warning • always disconnect the air conditioner from the power supply before servicing it or accessing its internal components . • verify that installat...

Page 5: Safety Precautions

4 safety precautions installing the unit important: when installing the unit, always remember to connect first the refrigerant tubes, then the electrical lines . Always disassemble the electric lines before the refrigerant tubes . X x upon receipt, inspect the product to verify that it has not been ...

Page 6: Outdoor Unit Type

5 en g lis h outdoor unit type shape model cooling and heating 1phase am036fxmdch✴ am048fxmdch✴ am053fxmdch✴ installation combination x x you must install the indoor unit that uses r410a only . X x if sum capacity of the combined indoor units exceeds the capacity of an outdoor unit, the capacity of ...

Page 7

6 deciding to where to install the outdoor unit decide the installation location based on the following condition and obtain the user’s approval . X x avoid a place that may disturb your neighbor . Noise may occur from the outdoor unit and the discharged air may run into the neighborhood . (be caref...

Page 8

7 en g lis h • install the indoor unit away from any interfering sources such as radio, computer, stereo equipment and also select a place where the electrical wiring work and an indoor unit installation are possible . - especially keep the unit at least 3m (9 .84ft) away from the electrical equipme...

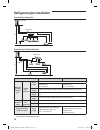

Page 9: Installation Location

8 installation location x x make a space for ventilation and service as seen in the picture . X x when multiple outdoor units are combined for installation, allow enough space for ventilation against a wall . If the ventilation space is not allowed, product malfunction may occur . X x the side with ...

Page 10

9 en g lis h when installing more than 1 outdoor unit unit: mm (inch) ❋ ❋ when 3 sides of the outdoor unit are blocked by the wall 30 0 (1 2) o r m or e 300 (12) or more 600 (24) or more 600 (24) or more 600 (24) or more ❋ ❋ when the walls are blocking front and the rear of the outdoor units 30 0 (1...

Page 11: Installation Location

10 installation location moving the outdoor unit x x select the moving route in advance . X x be sure that moving route is safe from the weight of the outdoor unit . X x do not slant the product more than 30˚ when carrying it . (do not lay the product down sideways .) x x the surface of the heat exc...

Page 12

11 en g lis h base ground work drain hole 150mm (6 inch) or more install the outdoor unit horizontally on the ground 150mm (6 inch) or more x x the outdoor unit should be supported within the range of measurement below for base ground work . Unit: mm (inch) anchor bolt position 33 0 (1 2 . 99 ) 620 ...

Page 13

12 refrigerant pipe installation refrigerant pipe work x x the length of refrigerant pipe should be as short as possible and the height difference between an indoor unit and outdoor unit should be minimized . X x the piping length between the outdoor unit and the indoor unit may not exceed the allow...

Page 14

13 en g lis h selecting refrigerant pipe temper grade and minimum thickness of the refrigerant pipe outer diameter [mm (inch)] minimum thickness [mm (inch)] temper grade Ø6 .35 (1/4) 0 .7 (0 .028) annealed Ø9 .52 (3/8) 0 .7 (0 .028) Ø12 .70 (1/2) 0 .8 (0 .031) Ø15 .88 (5/8) 1 .0 (0 .039) Ø19 .05 (3/...

Page 15

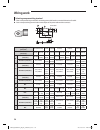

14 refrigerant pipe installation selecting y-joint x x select the first y-joint according to main pipe size of each outdoor unit capacity . X x select the other y-joints according to the total indoor unit capacity under the selected y-joint . Selecting the first y-joint other y-joints outdoor unit c...

Page 16

15 en g lis h direction of the pipe when brazing x x brazing the pipe should be done with the pipe headed downward or horizontally . X x avoid brazing with the pipe headed upward . • the test liquid used to detect leakage after pipe brazing should be the designated one . The use of the test liquid c...

Page 17

16 refrigerant pipe installation tightening flare connection area x x check that the flaring is properly made . X x align the center of the piping and sufficiently tighten the flare nut with fingers . Finally, tighten the flare nut with torque wrench until the wrench clicks . When tightening the fla...

Page 18

17 en g lis h pipe installation for an outdoor unit pipe direction the refrigerant pipe can be pulled out from front, flank, rear, and bottom side, so install it depending on the installation site condition . Caution for using knock-out hole • make sure not to damage the exterior of the outdoor unit...

Page 19

18 refrigerant pipe installation refrigerant pipe installation examples using a y-joint using a y-joint/eev kit using a header joint using a header joint/ y-joint allowable length of the refrigerant pipe and the installation examples connection by y-joint outdoor unit connection by y-joint/eev kit o...

Page 20

19 en g lis h classification y-joint connection y-joint / eev kit connection maximum allowable length of pipe outdoor unit ~ indoor units actual length the distance between the outdoor unit and the farthest indoor unit ≤ 150m (492’) ex) 8 indoor units a+b+c+d+e+f+g+p≤ 150m (492’) ex) 6 indoor units ...

Page 21

20 refrigerant pipe installation connection by header joint g outdoor unit header joint indoor unit connection by y-joint/header joint h2 h1 f c g outdoor unit indoor unit header joint y-joint classification header joint connection y-joint / header joint connection maximum allowable length of pipe o...

Page 22

21 en g lis h refrigerant pipe work refrigerant y-joint installation install the y-joint ‘horizontally’ or ‘vertically’ . X x install horizontally x x install vertically • when using a~j type of y-joint, connect the y-joint to the pipe with the provided reducer . • when using k~z type of y-joint, co...

Page 23

22 refrigerant pipe installation correct use (the insertion depth of connecting pipe) incorrect use (the insertion depth of connecting pipe) basic specification connecting pipe connecting pipe when cutting connection part connecting pipe connecting pipe • when inserting connecting pipe into the y-jo...

Page 24

23 en g lis h • when using a~j type of header joint, connect the header joint to the pipe with provided reducer . • when using k~z type of header joint, connect the header joint to the pipe by cutting the provided reducer properly . • connect the header joint in order respecting the number of the in...

Page 25

24 refrigerant pipe installation performing air tightening test x x use tools for r410a only to prevent the inflow of foreign substances and to resist the internal pressure . X x use dry nitrogen gas to do an airtight test as below . Apply pressure to the liquid side pipe, gas side pipe with nitroge...

Page 26

25 en g lis h vacuuming a pipe and an indoor unit x x use the tools for r410a only to prevent the inflow of foreign substances and resist against the internal pressure . X x use the vacuum pump with the check valve to prevent pump oil from flowing backward while the vacuum pump is stopped suddenly ....

Page 27

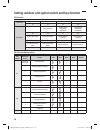

26 refrigerant pipe installation selecting additional refrigerant charging x x basic refrigerant the basic amount of additional refrigerant charged at a factory model refrigerant factory charge kg lbs am036fxmdch✴ r410a 3 .2 7 .055 am048fxmdch✴ 3 .2 7 .055 am053fxmdch✴ 3 .3 7 .275 x x charging addit...

Page 28

27 en g lis h connecting the drain hose to the outdoor unit when using the air conditioner in the heating mode, ice may accumulate . During de-icing (defrost operation), the condensed water must be drained off safely . Consequently, you must install a drain hose on the outdoor unit, following the in...

Page 29

28 refrigerant pipe installation selecting the insulation of refrigerant pipe x x insulate the gas pipe and liquid pipe by referring to the thickness of insulator for each pipe size . X x the standard condition is 30°c(86°f), with humidity less than 85% . In the conditions of high humidity, use one ...

Page 30

29 en g lis h • install the insulation not to be get wider and use adhesive on the connection part of it to prevent moisture entering . • bind the refrigerant pipe with insulation tape if it is exposed to outside sunlight . (when binding the pipe with finishing tape, be careful not to reduce the thi...

Page 31

30 refrigerant pipe installation insulating the y-join, liquid & gas side connecting pipe x x attach the insulation provided with the y-joint to the insulation purchased privately without a gap . Wrap the connected part with insulation (purchased privately) of a thickness of at least 10mm (3/8”) . X...

Page 32: Wiring Work

31 en g lis h wiring work x x wiring work should be performed in accordance with related laws such as ‘technical specification on electric installation’, ‘wiring regulations’ or ‘installation manual’ . X x copper cable should be used for wiring work and all the wires or parts should be rated product...

Page 33: Wiring Work

32 wiring work overall system configuration connection of the power cable (1 phase 2 wires) distribution board outdoor unit indoor unit communication cable 208v-230v wired remote controller earth 1 phase 2 wires 208v-230v mccb + elb elcb or mccb + elb elcb or earth 1 phase 2 wires 208v-230v connecti...

Page 34

33 en g lis h • you must install an earth leakage breaker . - elcb(earth leakage circuit breaker) - mccb(molded case circuit breaker) - elb(earth leakage fuse breaker) • manufacturers are not responsible for fire caused by not installing elcb or mccb . • install the cabinet panel near the outdoor un...

Page 35: Wiring Work

34 wiring work selecting compressed ring terminal x x select a compressed ring terminal of a connecting power cable based on a nominal dimensions for cable . X x cover a compressed ring terminal and a connector part of the power cable and then connect it . Silver solder nominal dimensions for cable ...

Page 36

35 en g lis h installing grounding wire x x grounding must be done by a qualified installer for your safety . X x use the grounding wire by referring to the specification of the electric cable of the outdoor unit . Grounding the power cable x x the standard of grounding may vary according to the rat...

Page 37: Grounding Work

36 grounding work if the power distribution circuit does not have a grounding or the grounding does not comply with specifications, a ground rod must be installed . The corresponding accessories are not supplied with the air conditioner . 1) select a grounding rod that complies with the specificatio...

Page 38

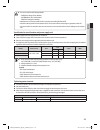

37 en g lis h setting outdoor unit option switch and key function pba shape 7-segment (display) dip s/w (k5~k16) do not connect wires to these terminal blocks terminal blocks for connection with an interface module s/w for setting number of connecting indoor units setting the number of connecting in...

Page 39

38 setting outdoor unit option switch and key function s/w function tact switch heating key operation cooling key operation reset view mode k1 k2 k3 k4 dip switch - snow prevention cooling target evaporating temperature cooling target evaporating temperature k5 k6 k7 k8 night's quiet option night's ...

Page 40

39 en g lis h x x k4 input display order (1) current frequency (2) low pressure value (3) outdoor temperature (4) discharge temperature (5) olp temperature (6) cond temperature (7) double pipe out tube temperature (8) high pressure value (9) fan rpm (10) esc(evi) eev (11) main ee...

Page 41

40 setting outdoor unit option switch and key function x x k9, k10: night’s quiet option . This reduces fam rpm to operate the outdoor unit quietly during night operation . Switch function (night’s quiet) k9 k10 on on disuse night’s quiet mode on off step - 1 off on step - 2 off off step - 3 x x k11...

Page 42

41 en g lis h x x k13, k14: changing current limit option table switch function k13 k14 3 ton 4 ton 5 ton on on default default default on off maximum current - 4(a) maximum current - 2(a) maximum current - 2(a) off on maximum current - 6(a) maximum current - 4(a) maximum current - 4(a) off off maxi...

Page 43: Pump Down

42 pump down the object of pump down x x you can reduce as much refrigerant leakage as possible during product movement or repair by collecting the refrigerant to the outdoor unit . Caution for pump down procedure x x the amount of refrigerant that can be put into an outdoor unit is limited due to t...

Page 44

43 en g lis h how to put the refrigerant into the refrigerant container before pump down operation ❋ ❋ when the amount of refrigerant charged in the system exceeds maximum receptive capacity, collect the refrigerant into the refrigerant container at first and then perform the pump down . X x prepare...

Page 45

44 checking lists after finishing installation x x before supplying power, measure the power terminal (l, n) and outdoor unit grounding using insulation-resistance tester . - the measured value should be above 30mΩ . • you must not measure the communication terminal since the communication circuit m...

Page 46

45 en g lis h inspection and check operation precautions before check operation • when the outdoor temperature is low, turn on the main power 3 hours before beginning the operation . - if you start the operation immediately after turning on the main power, it may cause serious damage to the part wit...

Page 47

46 inspection and check operation check operation 1) use key mode to run check operation . - when the check operation is not completed, up (unprepared) will appear on the led after the communication check and restrict compressor from operating . (up mode will be cleared automatically when check oper...

Page 48

47 en g lis h automatic refrigerant amount detection function (checking th amount of refrigerant) this function detects amount of refrigerant in the system through refrigerant amount detection operation start detect amount of refrigerant judge the amount of refrigerant satisfy the temperature condit...

Page 49: Trial Operation

48 trial operation x x check the power supply between the outdoor unit and the cabinet panel . - 1 phase power supply : l, n x x check the indoor unit . - check whether you have connected the power and communication cables correctly . (the communication cables between an indoor unit and outdoor unit...

Page 50: Memo

49 en g lis h memo am0@@fxmdch_im_en_03408a(1).Indd 49 2013-03-04 오후 4:28:30